NEED ADVISE CORROSION IN INHIBITOR TANK REGD

Neilash Kumar

Good Morning, please find the attached tank drawing

fabricated by us for our client & it is corroded fully ,

Can you please clarify,

1. Why the tank are corroded So fast?

2. Can you please advise us the method to stop /reduce the rate of corrosion by applying a top coat & what

type of coating to be applied?

please advise me . Material is 316L tank.

Regards

P.Neilashkumar

george....@gr.bureauveritas.com

It looks like iron contamination.

Actions to implement:

- Removal of rust by stainless steel compatible brushes/disks.

- Pickling

- Avoid contact with carbon steel tools, jigs etc

best regards

Dr. Georgios Dilintas

Authorized Nuclear Inspector

Authorized Inspector Supervisor

I&F REGIONAL TECHNICAL MANAGER

BUREAU VERITAS PIRAEUS - GREECE

Tel: +30 210 40 63 113 /4 /5

Fax: +30 210 40 63 118

Cell: +30 69 44 64 62 04

P.Neilashkumar[attachment "20150909_102338.jpg" deleted by George H Dilintas/GRC/VERITAS] [attachment "20150909_102358.jpg" deleted by George H Dilintas/GRC/VERITAS]

This message contains confidential information.

To know more, please click on the following link: http://disclaimer.bureauveritas.com

Kannayeram Gnanapandithan

Do acid pickling after wet sand blasting

--

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/OF5C1CA9F0.D638C881-ONC2257ECF.0026A74C-C2257ECF.0026D431%40LocalDomain.

For more options, visit https://groups.google.com/d/optout.

Neilashkumar

P.NEILASHKUMAR

It looks like iron contamination.

Actions to implement:

- Removal of rust by stainless steel compatible brushes/disks.

- Pickling

- Avoid contact with carbon steel tools, jigs etc

best regards

Dr. Georgios Dilintas

Authorized Nuclear Inspector

Authorized Inspector Supervisor

I&F REGIONAL TECHNICAL MANAGER

BUREAU VERITAS PIRAEUS - GREECE

Tel: +30 210 40 63 113 /4 /5

Fax: +30 210 40 63 118

Cell: +30 69 44 64 62 04

<graycol.gif>Neilash Kumar ---29/09/2015 09:56:39--- Dear Sir, Good Morning, please find the attached tank drawing

From: Neilash Kumar <neilas...@yahoo.com>

To: George H Dilintas/GRC/VERITAS@VERITAS, Welding Groups <material...@googlegroups.com>

Date: 29/09/2015 09:56

Subject: NEED ADVISE CORROSION IN INHIBITOR TANK REGD

Dear Sir,

Good Morning, please find the attached tank drawing

fabricated by us for our client & it is corroded fully ,

Can you please clarify,

1. Why the tank are corroded So fast?

2. Can you please advise us the method to stop /reduce the rate of corrosion by applying a top coat & what

type of coating to be applied?

please advise me . Material is 316L tank.

Regards

P.Neilashkumar[attachment "20150909_102338.jpg" deleted by George H Dilintas/GRC/VERITAS] [attachment "20150909_102358.jpg" deleted by George H Dilintas/GRC/VERITAS]

This message contains confidential information. To know more, please click on the following link: http://disclaimer.bureauveritas.com

--

elias jarjoura

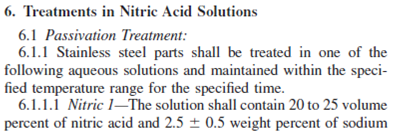

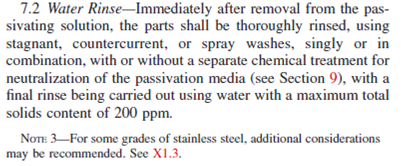

Nitric Acid Passivation of Stainless Steels | |

| —Chromium-Nickel Grades (300 Series) —Grades with 17% Chromium or more (except 440 Series) | 20% by vol. nitric acid at 120/140°F (49/60°C) for 30 minutes |

| —Straight Chromium Grades (12-14% Chromium) —High Carbon-High Chromium Grads (440 Series) —Precipitation Hardening Stainless | 20% by vol. nitric acid + 3 oz. per gallon (22 g/liter) sodium dichromate at 120/140°F (49/60°C) for 30 minutes or 50% by vol. nitric acid at 120/140F (49/60°C) for 30 min. |

Passivation is a post-fabrication method of maximizing the inherent corrosion resistance of the stainless alloy .

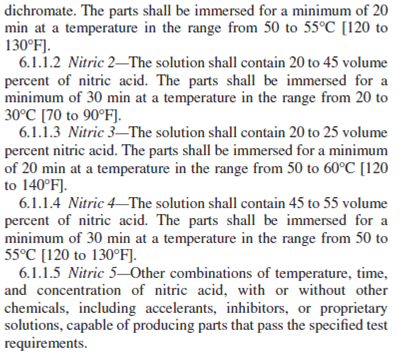

he table below gives details of paint systems suitable for coating stainless steels and, in accordance with ISO 12944 and ISO 9223, classifies them in terms of the severity of the envisaged service environment.

| Exterior Environment | Coating System | ||

|---|---|---|---|

| Category | Corrosion Risk | Location | . |

| C3 | Medium | Rural and urban areas with low sulphur dioxide, acid, alkali and salt pollution | Two pack epoxy or polyurethane primer suitable for stainless steel at 30-50 micron dry, FOLLOWED BY High solids polyurethane finish at 100 micron dry |

| C4 | High | Urban and industrial areas with moderate sulphur dioxide and/or coastal areas with low salinity | Two pack epoxy or polyurethane primer suitable for stainless steel at 30-50 micron dry, FOLLOWED BY High build epoxy MIO* at 100 mm dry, FOLLOWED BY Re-coatable polyurethane finish at 60 micron dry |

| C5I | Very High | Industrial areas with high humidity and aggressive atmospheres | Two pack epoxy or polyurethane primer suitable for stainless steel at 30-50 micron dry, FOLLOWED BY High build epoxy MIO* at 200 micron dry (one or two coats), FOLLOWED BY Re-coatable polyurethane finish at 60 micron dry |

| C5M | Very High | Coastal and offshore areas with high salinity | Two pack epoxy or polyurethane primer suitable for stainless steel at 30-50 micron dry, FOLLOWED BY High build epoxy MIO* at 200 micron dry (one or two coats), FOLLOWED BY Re-coatable polyurethane finish at 60 micron dry |

MIO = Micaeous Iron Oxide

Cleanliness is extremely important in the successful application of paint coatings to stainless steels surfaces. Paint coatings should be applied in clean, dust-free conditions to clean, dry stainless steel surfaces.

If the correct precautions are taken, the complete coating systems suggested in the table can be applied in 'on-site'.

Best Regards

Elias

Subject: [MW:23584] Re: NEED ADVISE CORROSION IN INHIBITOR TANK REGD

To: neilas...@yahoo.com

CC: material...@googlegroups.com

From: george....@gr.bureauveritas.com

Date: Tue, 29 Sep 2015 10:04:06 +0300

george....@gr.bureauveritas.com

| From: elias jarjoura Sent: Τρίτη, 29 Σεπτεμβρίου 2015 - 11:06 To: material...@googlegroups.com; Neilash Kumar Reply To: material...@googlegroups.com Subject: RE: [MW:23590] Re: NEED ADVISE CORROSION IN INHIBITOR TANK REGD |

Shamal Daw

Sent from my iPhone

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/OF7C1DCF44.3C7C7EB8-ONC1257ECF.002E46BE-1443515128316%40LocalDomain.

Mattia Degli Esposti

Neilashkumar

P.NEILASHKUMAR

george....@gr.bureauveritas.com

| From: Neilashkumar Sent: Τρίτη, 29 Σεπτεμβρίου 2015 - 19:14 To: George H Dilintas Cc: Welding Groups Subject: Re: NEED ADVISE CORROSION IN INHIBITOR TANK REGD |

pgoswami

Hi Neileshkumar,

What're the surrounding operating or environmental conditions around the tank. Are there any acid fumes involved. Looks like this tank was not insulated at all??? Is that true.

Appreciate more information on the operating conditions.

Pradip Goswami, P.Eng,IWE

Welding

& Metallurgical Engineering Specialist

Hamilton, Ontario,

Canada

pgos...@quickclic.net

pradip....@gmail.com

ca.linkedin.com/pub/pradip-goswami/5/985/299

Jim Price

Sent from my iPad

--

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/OF57240EB1.3777AADA-ONC1257ECF.005C9F78-1443545501800%40LocalDomain.

<graycol.gif>

Shamal Daw

Sent from my iPhone

--

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/OF57240EB1.3777AADA-ONC1257ECF.005C9F78-1443545501800%40LocalDomain.

For more options, visit https://groups.google.com/d/optout.

<graycol.gif>

Shabbir Ahmad

| Sent: Tuesday, 29 September 2015 8:02 PM To: Neilashkumar Reply To: material...@googlegroups.com Cc: Welding Groups Subject: [MW:23611] Re: NEED ADVISE CORROSION IN INHIBITOR TANK REGD |

Neilashkumar

P.NEILASHKUMAR

<Tank Corrosion.pdf>

Alan Denney

In my view it comes down to understanding the environment in which the material is to be exposed, (marine and high temperature relative to CPT) and the limitations of 316 stainless steel. There is a lot of information on the web if you do a search. The material selection is hence wrong for the external environment, or the tank should have been painted – yes you do paint stainless steel!

Alan Denney

AKD Materials Consulting Ltd

--

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/81B20544-18A9-45D3-81A3-EDB56129B98A%40yahoo.com.

For more options, visit https://groups.google.com/d/optout.

Jim Price

I definitely agree with the below statement.

From corrosion testing we have performed on 316L and 2101 duplex the HAZ on these welds are very prone to pitting and crevice corrosion due to austenite and ferrite balance.

Heat input is critical.

The elevated temperatures are definitely a factor in the corrosion equation.

With the environment carbon pickup is definitely a factor.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/000001d0fb75%243f7b6060%24be722120%24%40denney1.freeserve.co.uk.

george....@gr.bureauveritas.com

true because of sensitization

but the image of the vessel indicates iron contamination

best regards

Dr. Georgios Dilintas

Authorized Nuclear Inspector

Authorized Inspector Supervisor

I&F REGIONAL TECHNICAL MANAGER

BUREAU VERITAS PIRAEUS - GREECE

Tel: +30 210 40 63 113 /4 /5

Fax: +30 210 40 63 118

Cell: +30 69 44 64 62 04

Neilashkumar

P.NEILASHKUMAR

--

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/OF08805F06.076C09E4-ONC2257ED0.0052193B-C2257ED0.00522E6B%40LocalDomain.

Alan Denney

Alan Denney

AKD Materials Consulting Ltd

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/814BB6E9-0EF6-4E65-A727-56F0BDA575AE%40yahoo.com.

For more options, visit https://groups.google.com/d/optout.

Lu, Feng

Try coating with thermal sprayed aluminum.

Feng Lu

--

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to

materials-weld...@googlegroups.com.

To post to this group, send email to

material...@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/0B2230C4544741E7BC1C50621C281EEA%40homepg.

pgoswami

To: material...@googlegroups.com

Subject: RE: [MW:23640] RE: 23626] Re: NEED ADVISE CORROSION IN INHIBITOR TANK REGD

pgoswami

From: material...@googlegroups.com [mailto:material...@googlegroups.com] On Behalf Of pgoswami

Sent: Friday, October 02, 2015 11:45 PM

To: material...@googlegroups.com

Subject: RE: [MW:23642] RE: 23626] Re: NEED ADVISE CORROSION IN INHIBITOR TANK REGD

Lassaad Mokrani

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/FB8ADC9BDEEC4E87830EDA2AD77946A6%40homepg.

For more options, visit https://groups.google.com/d/optout.

--

Sent from Gmail Mobile

Alan Denney

You only apply insulation if you need to insulate for process reasons.

The risk of corrosion under insulation is very real and you should not confuse insulation with protecting against corrosion. If it saturates (which it can easily do so) it is both the medium causing the corrosion and mask the corrosion from view.

Pickling and passivating will deal with the current surface corrosion on 316 stainless steel and leave it looking rust free, but the pits will still be there.

In an exposed marine environment, which has already caused a significant amount of corrosion the rust staining will re-appear.

You can pickle and passivate to clean up and then apply paint coatings to prevent this happening, but they need good surface preparation and proper application, and you should get advice from the coatings companies.

The application of coatings to 316 stainless steel is a recognised way of minimising corrosion in warm marine environments.

The idea of flame-sprayed aluminium (suggested by one correspondent) is interesting but applying it in-situ seems to be to be an even more difficult challenge than the idea of applying a decent paint coating.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAOzUbK75O_Y%3DdiAjhy5pgSZ%3DzLOtpmtEHVLAFAtbco6YRHdRaw%40mail.gmail.com.

For more options, visit https://groups.google.com/d/optout.

Neilashkumar

P.NEILASHKUMAR

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/000001d0fe80%24a65260f0%24f2f722d0%24%40denney1.freeserve.co.uk.

pgoswami

Hi Neilashkumar,

Aramco has some of the most comprehensive standards on Corrosion Protection".Two relevant standards are cited below. The following paragraph from SAES-L-133 may provide you some guidelines as heads up.

SAES-H-004, 11 October 2006,Protective Coating Selection & Application, Requirements for Offshore Structures and Facilities

SAES-L-133, 10 August 2009 Corrosion Protection Requirements for Pipelines, Piping and Process Equipment

7.2.5 Completely coat the outer metal surface of all 300-series stainless steels that may cycle into the temperature range from 104 deg F (40 deg C) up to the maximum service temperature of the available coating systems in order to protect them from pitting and stress corrosion cracking. Use thermal spray aluminum, organic coatings with zero leachable chlorides that are approved for immersion service, or foil wraps as detailed in the NACE RP0198 - 2004, Section 4, Table 1 and EFC 55. Contact the coatings RSA in CSD/ME&CCD for a list of approved coating products. Use low leachable chloride insulation in accordance with ASTM C795. Use insulation materials and weatherproofing to prevent water ingress and that do not allow the absorption of water.

From: material...@googlegroups.com [mailto:material...@googlegroups.com]

Sent: Sunday, October 04, 2015 2:40 PM

To: material...@googlegroups.com

Subject: Re: [MW:23659] RE: 23626] Re: NEED ADVISE CORROSION IN INHIBITOR TANK REGD

Neilashkumar

P.NEILASHKUMAR

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/48177E9226F54509A70A3665458286C1%40homepg.

Jim Price

First you probably would need to check the depth of pitting to ensure integrity concerning stress flows and repair as required especially at toe of welds or violation of allowed depth.

From what I see passivation would be minimal help, pickling would be my choice.

As far as painting is concerned you would need to clean and either passivate or pickle prior to painting.

Natural formation of oxide layer requires oxygenated condition painting would not allow for this natural process.

Copy of emails for reference I have received:

Jim,

Stainless steel self-passivates in air but the Cr/Fe surface is less than the chemically passivated stainless steel and corrosion resistance is better on chemically passivated stainless steel.

Dear Jim,

The nitric and citric acid treatments below are extracts from ASTM A967, I would recommend you buy it and/or other standards if you are carrying out passivation treatments on a regular basis? While natural passivation of a virgin stainless steel surface will occur immediately it can take a day or more for the passive layer to thicken and develop an optimum thickness, assuming the surface is well aerated. That is why acid passivation treatments have been designed to accelerate the process.

From BSSA

Nitric Acid Treatments

Citric Acid Treatments

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/4AAB17B3-7EDB-4279-A748-47B7EAF64508%40yahoo.com.

Alan Denney

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/4AAB17B3-7EDB-4279-A748-47B7EAF64508%40yahoo.com.

For more options, visit https://groups.google.com/d/optout.

Alan Denney

Alan Denney

AKD Materials Consulting Ltd

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/71617a49adb54c2da99ab4a2af484828%40POLARMAIL.PolarTank.local.

For more options, visit https://groups.google.com/d/optout.

pgoswami

-

Remove the corrosion pits by grinding/power brushing( too difficult and very arduous task in an offshore platform). Try to get as good a surface finish as possible free from any corrosion nicks.

-

Pickle and passivate with the appropriate product(Table in Page 10 would be of guidance).

-

Following pickling and passivation think about application of one full coat of Belzona products as per the link provided below.

To: material...@googlegroups.com

Subject: RE: [MW:23696] RE: 23626] Re: NEED ADVISE CORROSION IN INHIBITOR TANK REGD

Emilio Cerato

Kannayeram Gnanapandithan

--

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/BLU173-W3689E2A3AE06CB0D90201CA4320%40phx.gbl.

pgoswami

Hi Emilo,

This alloy is often used for high temperature furnace and other environments. You have the options of using welding products of matching or similar chemistry, such as Rolled Alloy RA-330-4 (please see the attachment) or more alloyed welding products such as Inconel 82(E-NiCr-3) or Inconel 617(see attachment).

Also please see the generic guidelines for the welding product manufacturers.

Use the following resources to your discretion.

This alloy is a fully austenitic alloy an have tendency to crack while welding in thick sections. Controlled heat input , typically 1.5Kj/mm max to be on the safe side would be advisable.

Do you have the design conditions with you?? That’s more important to know before making the final selection.

Thanks.

Pradip Goswami, P.Eng,IWE

Welding & Metallurgical Engineering Specialist

Hamilton, Ontario, Canada

ca.linkedin.com/pub/pradip-goswami/5/985/299

Welding: RA330 is readily welded using RA330-04 weld fillers of matching composition. RA330-04 DC lime type electrodes are available from stock in popular sizes. RA330-04 bare welding wire is available as straight lengths for GTA welding or spooled for GMA welding. For best results do not preheat, keep interpass temperature low and use reinforced bead contours. Detailed coverage of heat resistant alloy welding techniques is given in Bulletin 201.

INCOLOY alloy 330 is weldable by conventional processes. Shielded-metal-arc welding should be done with INCO- WELD A welding electrode; gas-shielded-arc welding with INCONEL filler metal 82. Acceptable welds have been made in relatively heavy sections with these welding products.

For additional strength and corrosion resistance up to 2100°F (1150°C), INCONEL filler metal 617 and INCONEL welding electrode 117 may be used.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

Ing. Emilio Cerato

Pradip,

Thank you very muchos, very useful your help!!

Emilio