Skip to first unread message

Steve Cousins

Feb 21, 2023, 11:21:28 AM2/21/23

to retro-comp

I've started to put together the various suggestions and contributions for the RCBus specification. See attached.

There is a long way to go but feedback would be appreciated.

One fundamental issue I'm having trouble with is this: If you want to design a 6502 CPU module you have a choice to make about interfacing to the backplane. Do you try to generate Z80 compatible signals so it is compatible with existing RC2014 modules, do you just support 68xx bus signals so it will only work with other modules implimeting 68xx signals, or do you provide both sets of signals to the backplane for greatest compatibility.

If you support Z80 style signals the 6502 CPU module will still not be compatible with all existing RC2014 modules. For example, the 6502 memory map requires ROM at the top of memory not the bottom, and also a space for I/O needs to be mapped into memory. That sounds like a big issue, but actually not all RC2014 modules can be used at the same time. Compatibility will always have its limitations. So perhaps this is a red herring.

In any event, the problem I'm having is how to specify what is and isn't required for compatibility. Should the RCBus-68xx specification only include 68xx bus signals or should it include the standard Z80 signals as well? In my mind, if the CPU module only supports 68xx signals then it is only compatible with the 68xx sub-set of RCBus. If it supports only Z80 signals then it is only compatible with the RCBus-Z80 sub-set. If it supports both sets then it is compatible with bith sub-sets of the RCBus spec. This suggests the RCBus-68xx spec should only include signals relevant to the 68xx. But given that there will likely still be significant compatibility issues, is the the right approach?

The alternative thinking I have is the core bus specification should include as many signals as possible even though some will not be relevant to a specific modules (rather like it is now with some RC2014 modules) or to a class of modules such as those using 68xx style signals. Using this approach only the few special signals that share pins with other signals need to be highlighted in specific sub-sets of the spec.

I'd appreciate thoughts on this issue.

Steve

There is a long way to go but feedback would be appreciated.

One fundamental issue I'm having trouble with is this: If you want to design a 6502 CPU module you have a choice to make about interfacing to the backplane. Do you try to generate Z80 compatible signals so it is compatible with existing RC2014 modules, do you just support 68xx bus signals so it will only work with other modules implimeting 68xx signals, or do you provide both sets of signals to the backplane for greatest compatibility.

If you support Z80 style signals the 6502 CPU module will still not be compatible with all existing RC2014 modules. For example, the 6502 memory map requires ROM at the top of memory not the bottom, and also a space for I/O needs to be mapped into memory. That sounds like a big issue, but actually not all RC2014 modules can be used at the same time. Compatibility will always have its limitations. So perhaps this is a red herring.

In any event, the problem I'm having is how to specify what is and isn't required for compatibility. Should the RCBus-68xx specification only include 68xx bus signals or should it include the standard Z80 signals as well? In my mind, if the CPU module only supports 68xx signals then it is only compatible with the 68xx sub-set of RCBus. If it supports only Z80 signals then it is only compatible with the RCBus-Z80 sub-set. If it supports both sets then it is compatible with bith sub-sets of the RCBus spec. This suggests the RCBus-68xx spec should only include signals relevant to the 68xx. But given that there will likely still be significant compatibility issues, is the the right approach?

The alternative thinking I have is the core bus specification should include as many signals as possible even though some will not be relevant to a specific modules (rather like it is now with some RC2014 modules) or to a class of modules such as those using 68xx style signals. Using this approach only the few special signals that share pins with other signals need to be highlighted in specific sub-sets of the spec.

I'd appreciate thoughts on this issue.

Steve

Alan Cox

Feb 21, 2023, 11:58:44 AM2/21/23

to Steve Cousins, retro-comp

On Tue, 21 Feb 2023 at 16:21, Steve Cousins <steve...@gmail.com> wrote:

> One fundamental issue I'm having trouble with is this: If you want to design a 6502 CPU module you have a choice to make about interfacing to the backplane. Do you try to generate Z80 compatible signals so it is compatible with existing RC2014 modules, do you just support 68xx bus signals so it will only work with other modules implimeting 68xx signals, or do you provide both sets of signals to the backplane for greatest compatibility.

You generate the Z80 style signals. If you didn't want to generate the

> One fundamental issue I'm having trouble with is this: If you want to design a 6502 CPU module you have a choice to make about interfacing to the backplane. Do you try to generate Z80 compatible signals so it is compatible with existing RC2014 modules, do you just support 68xx bus signals so it will only work with other modules implimeting 68xx signals, or do you provide both sets of signals to the backplane for greatest compatibility.

Z80 signals you'd use one of the other bus designs for a Motorola bus.

All the current "other" CPU cards from 1802 to Z8 take this approach.

I think of it as analogous to S100 / IEE696 in this respect, except

it's a lot simpler and doesn't require a PSU of similar size and power

consumption to a small microwave oven.

> If you support Z80 style signals the 6502 CPU module will still not be compatible with all existing RC2014 modules. For example, the 6502 memory map requires ROM at the top of memory not the bottom, and also a space for I/O needs to be mapped into memory. That sounds like a big issue, but actually not all RC2014 modules can be used at the same time. Compatibility will always have its limitations. So perhaps this is a red herring.

with ROM mapped over the full 64K so just works. The 32K/32K card has

a jumper. The flat cards almost all have a jumper. Only the old paged

ROM board and RAM combo (that nobody uses) doesn't.

For the I/O with a 256 byte map at $FExx you've got the classic 8bit

256 I/O ports so the only things that don't work are cards that use

full 16bit I/O port decoding (very very few: QUART, ZXKey, dual port

RAM interconnect, and Bill's VGA ?). It's also possible to deal with

this by putting an extra latch on the CPU card so you can set the high

byte of IO cycles. I've just never bothered because it's really not

that important.

> In any event, the problem I'm having is how to specify what is and isn't required for compatibility. Should the RCBus-68xx specification only include 68xx bus signals or should it include the standard Z80 signals as well? In my mind, if the CPU module only supports 68xx signals then it is only compatible with the 68xx sub-set of RCBus. If it supports only Z80 signals then it is only compatible with the RCBus-Z80 sub-set. If it supports both sets then it is compatible with bith sub-sets of the RCBus spec. This suggests the RCBus-68xx spec should only include signals relevant to the 68xx. But given that there will likely still be significant compatibility issues, is the the right approach?

extra lines for convenience if you want. If you are running just

Motorola bus devices and don't care about RCbus you'd use a different

bus to begin with.

I see it this way

- RCbus is a bus specification that happens to use Z80 like signals at

TTL logic levels with CMOS logic.

- The point of RCBus is to be able to use RCBus devices

So on that basis the starting point has to be compatibility. The extra

lines are a convenience for a few things, not the norm. In fact I/O

cards intended for 65xx/68xx should try not to use them unless needed

so they are still compatible with Z80, 1802, 68000 whatever.

> The alternative thinking I have is the core bus specification should include as many signals as possible even though some will not be relevant to a specific modules (rather like it is now with some RC2014 modules) or to a class of modules such as those using 68xx style signals. Using this approach only the few special signals that share pins with other signals need to be highlighted in specific sub-sets of the spec.

all the other stuff on it), the classic 40pin and bigger variants

documented as such. I'd prefer the "and this is useful if you run CPU

x" bits to be an addition not a core part of the bus. I'm not sure

they are even properly "RCbus" so much as "and here's a useful

convention on assignment of the user pins"

The base set is probably very small and that may be useful - it's what

VCC/GND/D7-D0/A7-A0/IRQ/IORQ/RD/WR/RESET (and maybe M1) ?

Alan

Jordi Autocet

Feb 21, 2023, 12:02:03 PM2/21/23

to Steve Cousins, retro-comp

Steve,

Sorry for the intrusion. I say this because I have studied it a lot. The 80 pin limit is very small. S100 didn't get away either.

Good luck with the adventure, it's really cool.

Jordi Breu

Missatge de Steve Cousins <steve...@gmail.com> del dia dt., 21 de febr. 2023 a les 17:21:

--

You received this message because you are subscribed to the Google Groups "retro-comp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to retro-comp+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/retro-comp/62e3c208-6d6d-41ac-802d-7727b9d97cf6n%40googlegroups.com.

Alan Cox

Feb 21, 2023, 12:25:38 PM2/21/23

to Jordi Autocet, Steve Cousins, retro-comp

RC-6502 is an existing thing and has been for some time. It's an "if I

did RC2014 with 6502 it would look like this" bus but it's not

compatible with RCBus so solves a different problem.

In fact Bill already has RC6502 bus cards...

did RC2014 with 6502 it would look like this" bus but it's not

compatible with RCBus so solves a different problem.

In fact Bill already has RC6502 bus cards...

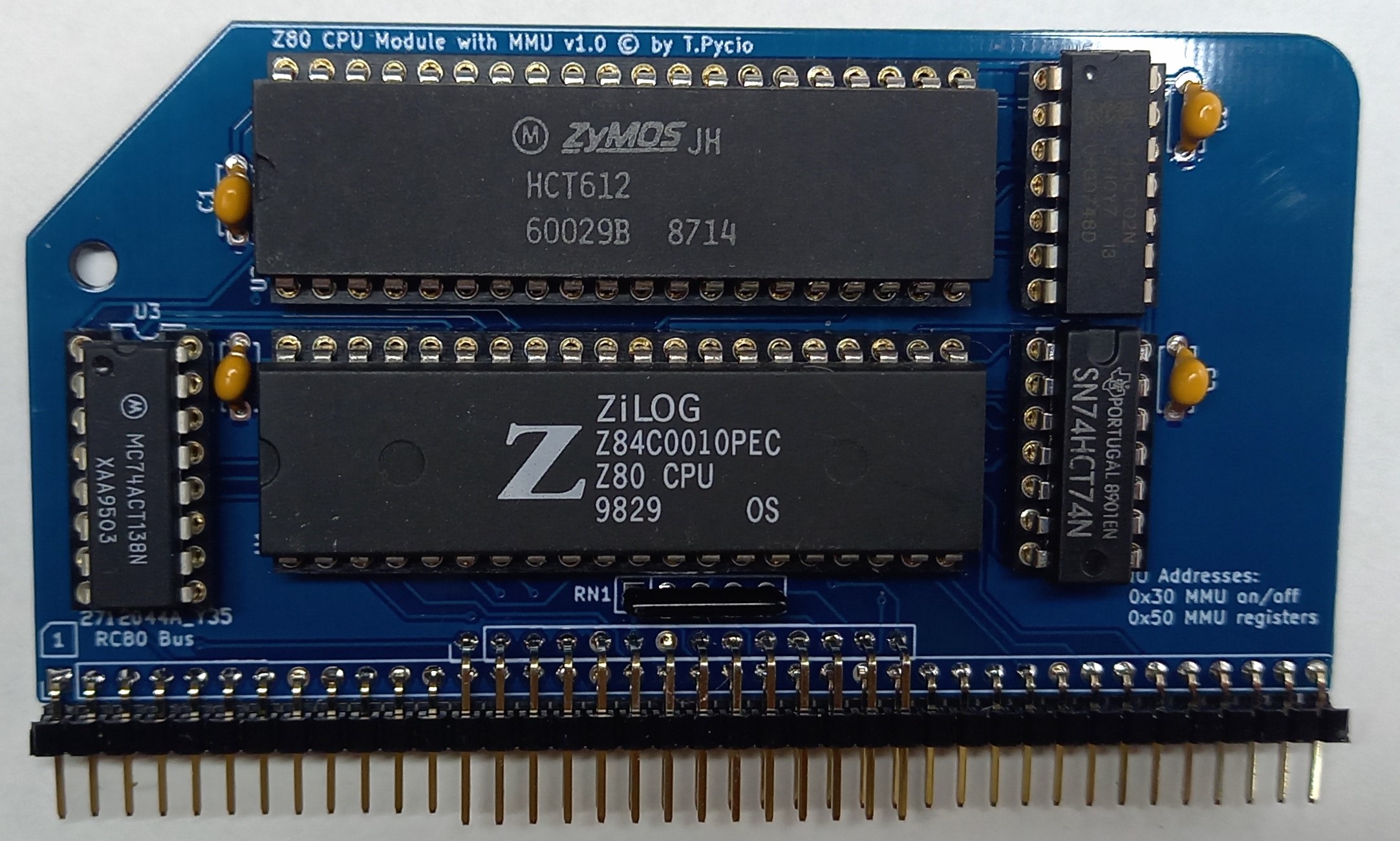

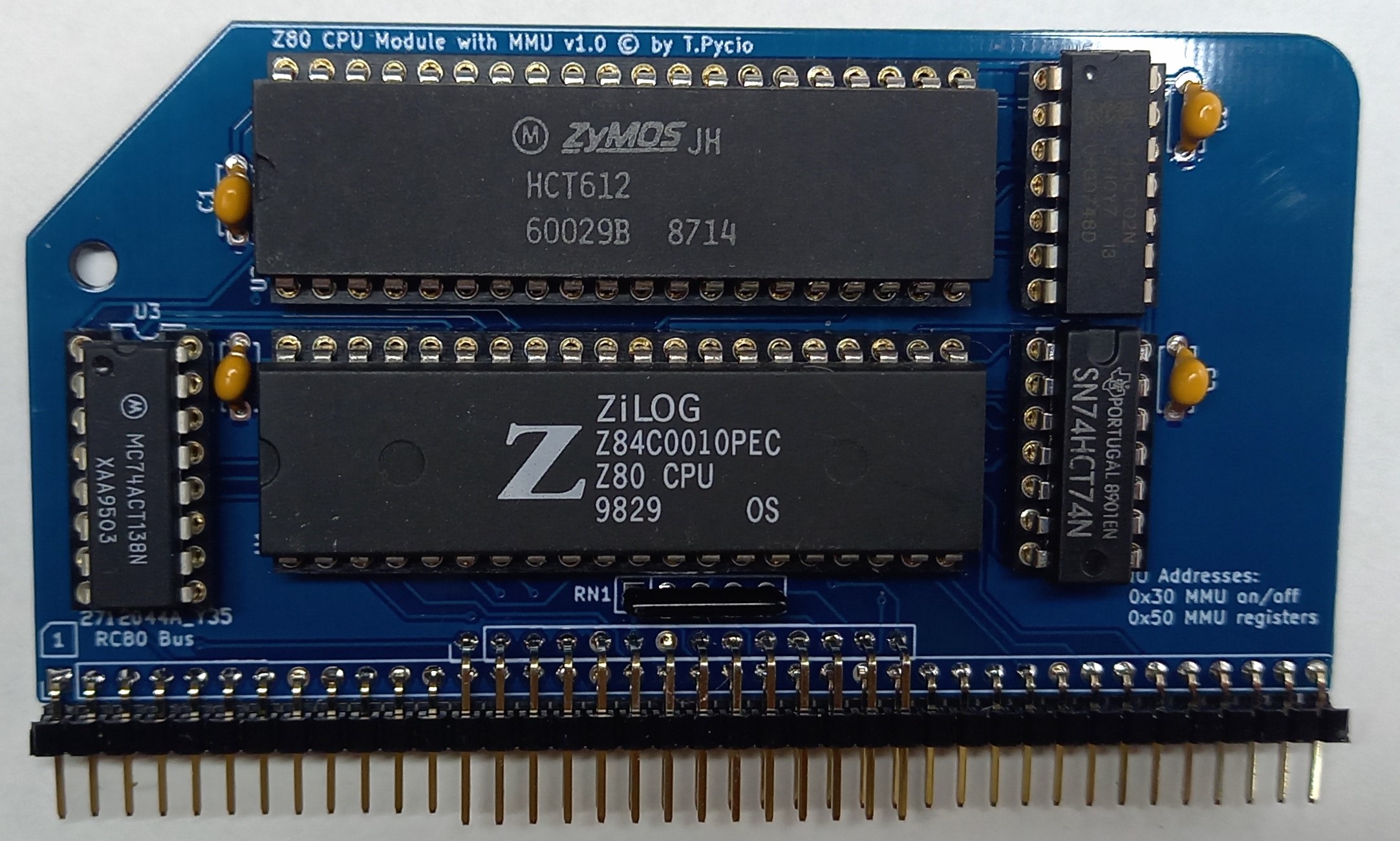

Tadeusz Pycio

Feb 21, 2023, 12:43:51 PM2/21/23

to retro-comp

I think compatibility of all modules for different architectures is impossible without introducing another layer as Jordi mentioned. Signals, e.g. in 6502 have to be adapted to universal I/O chips, memory anyway, so making them compatible with Z80 standard is a good direction for RCBus. Architecture-specific I/O circuits should work with that architecture on RCBus, with others not necessarily. For example, I don't know if anyone has managed to get a Z80 SIO to work with the 6809. As Alan mentioned, the basic kit is small.

I mentioned earlier that I have a Z80 training kit and there is one MEM_EN signal that is worth putting in RCBus space. Obviously it won't be compatible with existing memory module solutions, but as a prospective solution because it does the trick of injecting code onto the bus. A similar solution has been used in the Z80-MBC2, V20-MBC from J4F. This could be useful, but I assume it will require dedicated modules.

I mentioned earlier that I have a Z80 training kit and there is one MEM_EN signal that is worth putting in RCBus space. Obviously it won't be compatible with existing memory module solutions, but as a prospective solution because it does the trick of injecting code onto the bus. A similar solution has been used in the Z80-MBC2, V20-MBC from J4F. This could be useful, but I assume it will require dedicated modules.

Alan Cox

Feb 21, 2023, 12:57:29 PM2/21/23

to Tadeusz Pycio, retro-comp

I don't believe anyone has ever gotten the classic Zilog peripheral

chips to work with anything but a Z80 or Z180 (and maybe Z280 in 8bit

mode ?). They have magic knowledge of the internal behaviour of the

processor. The later stuff you can (but the later stuff like the Z8530

is instead a pig to nail onto a Z80)

The only cards that don't work with the other processors that I know

of are some of the ACIA boards (because of the way their motorola bus

interfaces are glued to the Z80 bus), the Zilog peripherals and the

cards using 16bit I/O.

The 16bit I/O is doable if wanted, and I think Phillip got his 8085

generating the signals correctly for the 68B50 to work ?

The other oddments are electrical issues - unbuffered CF with NMOS

devices (affects NMOS Z80 as well) and cards that are naughty with

voltage levels (not shifting 3v3 because they know the CPU is a Z80 so

TTL level high/low)

Alan

chips to work with anything but a Z80 or Z180 (and maybe Z280 in 8bit

mode ?). They have magic knowledge of the internal behaviour of the

processor. The later stuff you can (but the later stuff like the Z8530

is instead a pig to nail onto a Z80)

The only cards that don't work with the other processors that I know

of are some of the ACIA boards (because of the way their motorola bus

interfaces are glued to the Z80 bus), the Zilog peripherals and the

cards using 16bit I/O.

The 16bit I/O is doable if wanted, and I think Phillip got his 8085

generating the signals correctly for the 68B50 to work ?

The other oddments are electrical issues - unbuffered CF with NMOS

devices (affects NMOS Z80 as well) and cards that are naughty with

voltage levels (not shifting 3v3 because they know the CPU is a Z80 so

TTL level high/low)

Alan

Mark T

Feb 21, 2023, 3:18:59 PM2/21/23

to retro-comp

I was thinking PAGE could be renamed RAMEN, as this is its function with the pageable ROM and 64K ram modules. This can also be used in systems without Pageable ROM to provide code injection with RAM disabled.

I was a little confused on first reading of Steve’s document when I saw RCBus-Zx80, until I realised this was for both Z80 and Z180 rather than the old Science of Cambridge machine. Would Z*80 cause more or less confusion?

I think supply voltage should be defined as 5v, but if someone feels the need to build a 3.3v system they should make that very clear in their documents. Regulating down to 3.3v is very easy local on modules for supply to sdcards etc.

Signal levels on the bus should meet TTL input levels for compatibility with nmos on some older devices, with 5v tolerant inputs. I think cmos input loading should be recommended, not proscribed. Output levels should be recommended as 5v HCT outputs, again not mandated.

Mark T

Feb 21, 2023, 3:27:04 PM2/21/23

to retro-comp

Sorry, that should be 5v tolerant inputs and outputs, for cases where a 3.3v device is driving ttl compliant outputs onto the bus.

Ed Porter

Feb 21, 2023, 5:46:39 PM2/21/23

to retro...@googlegroups.com

On 21/02/2023 18:56, Alan Cox wrote:

> I don't believe anyone has ever gotten the classic Zilog peripheral

> chips to work with anything but a Z80 or Z180 (and maybe Z280 in 8bit

> mode ?). They have magic knowledge of the internal behaviour of the

> processor. The later stuff you can (but the later stuff like the Z8530

> is instead a pig to nail onto a Z80)

Pages 198-205 of "THE Z8000 MICROPROCESSOR A Design Handbook" by Bradly

> I don't believe anyone has ever gotten the classic Zilog peripheral

> chips to work with anything but a Z80 or Z180 (and maybe Z280 in 8bit

> mode ?). They have magic knowledge of the internal behaviour of the

> processor. The later stuff you can (but the later stuff like the Z8530

> is instead a pig to nail onto a Z80)

K Fawcett shows some TTL glue to attach Z80 peripherals to the Z8000

bus, including an I/O port to generate the ED4D RETI sequence at the end

of an interrupt service routine. It does look like more trouble than

it's worth.

https://archive.org/details/bitsavers_zilogz8000andbook1982_15357800/page/n207/mode/2up

-ed

Tadeusz Pycio

Feb 24, 2023, 2:42:34 PM2/24/23

to retro-comp

I would like to clarify the meaning of pin 60 - PAGE (although a better name would be RAM_EN). The High state enables RAM (all or part of it), the Low state disables its activity. This will allow existing modules using the PAGE signal to continue to operate (to disable ROM and enable RAM instead), and newly created modules will be able to temporarily disable all RAM in order to inject code onto the data bus by modules running on the Z80-MBC2 concept.

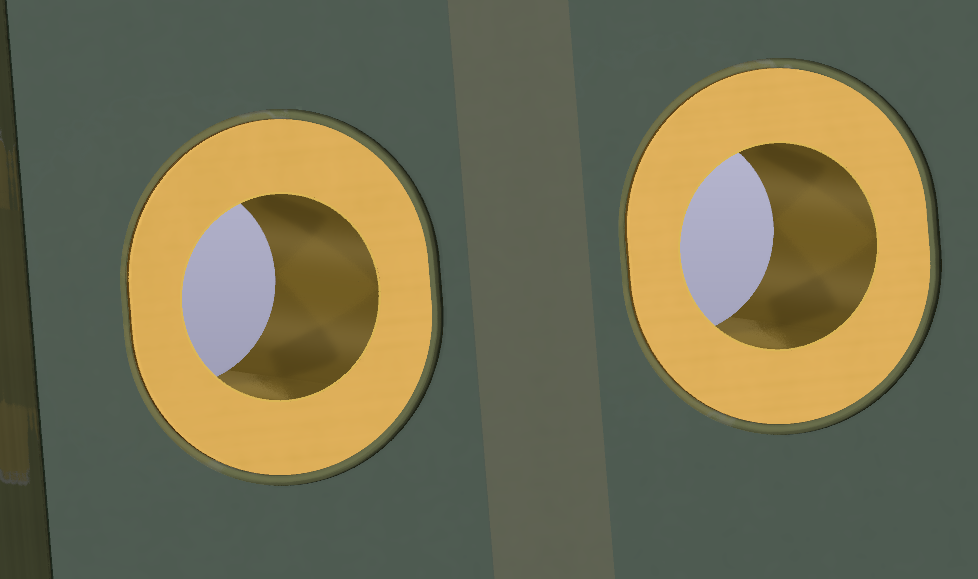

We still do not have assigned pins for the DMA service request signals. My suggestion was to use pins 78 (DREQ1) and 79 (DREQ2), but if others see the need to add DACK/EOP in addition to these signals it is worth considering another location (pins 45-48 ?).

We still do not have assigned pins for the DMA service request signals. My suggestion was to use pins 78 (DREQ1) and 79 (DREQ2), but if others see the need to add DACK/EOP in addition to these signals it is worth considering another location (pins 45-48 ?).

Steve Cousins

Feb 24, 2023, 2:57:41 PM2/24/23

to retro-comp

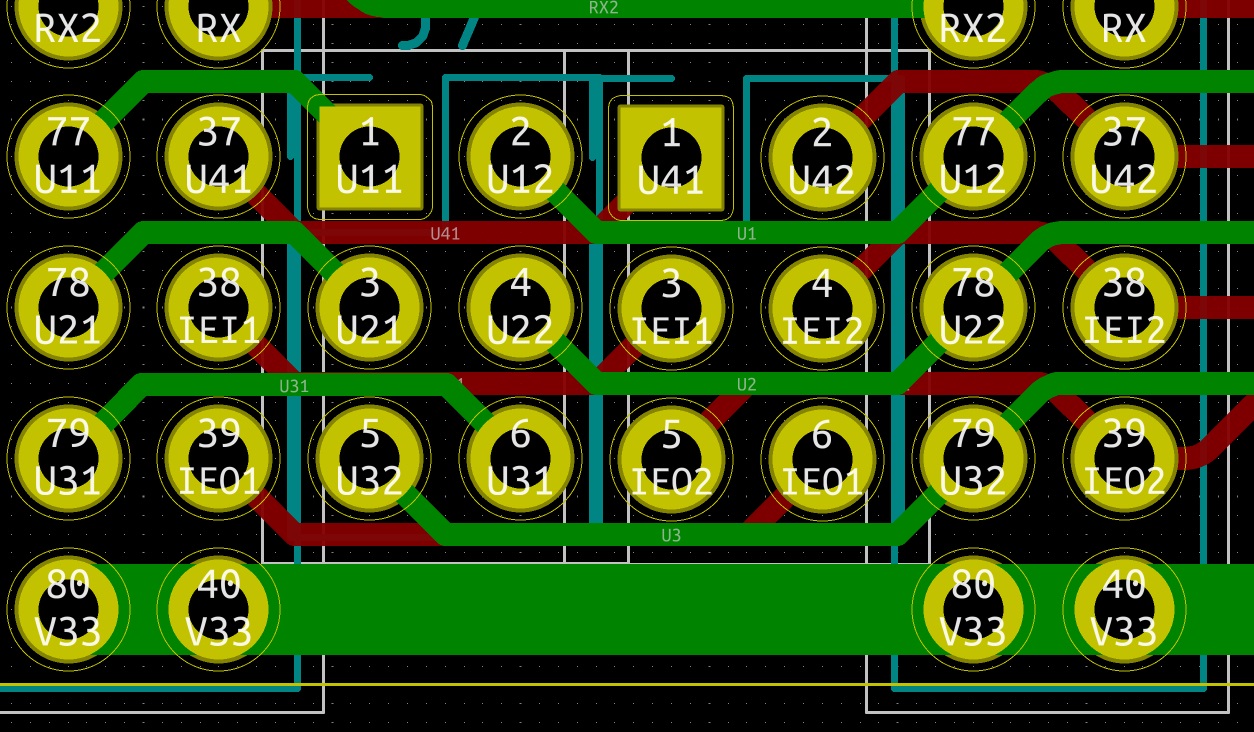

I've updated the RCBus Specification to reflect the views above. This is mainly seen in the table of pin assignments where most of the traditional RC2014 pins are clearly shown as common to all processor types.

I've also padded it out a bit more with pin descriptions and connector details.

If there is anything you feel is wrong, not well presented, or missing please point it out. There are unanswered questions in the "Unresolved issues and notes" section.

Steve

Alan Cox

Feb 24, 2023, 5:00:59 PM2/24/23

to Steve Cousins, retro-comp

You have an appended where I think you mean appendix.

On the high address lines wiring them to 0v or 5v is bad if a wrong

card combination is used. It's also a problem because cards may not

even have those pins present. Perhaps

Current RC2014 systems use either 16bit or 20bit addressing and do not

support using a memory card that has more address lines than the

processor card. If a memory card is intended to be usable with

processor cards that have less address pins it should have pull up or

pull down resistors on the upper address lines.

ie

- it's optional

- nobody does it right now

- use resistors so it doesn't go boom if an error is made

On the high address lines wiring them to 0v or 5v is bad if a wrong

card combination is used. It's also a problem because cards may not

even have those pins present. Perhaps

Current RC2014 systems use either 16bit or 20bit addressing and do not

support using a memory card that has more address lines than the

processor card. If a memory card is intended to be usable with

processor cards that have less address pins it should have pull up or

pull down resistors on the upper address lines.

ie

- it's optional

- nobody does it right now

- use resistors so it doesn't go boom if an error is made

Steve Cousins

Feb 27, 2023, 5:28:24 PM2/27/23

to retro-comp

I've made further progress on the RCBus specification. Most of what I think is necessary is now in place although use with more processor types need to be added - anyone???

It would be helpful if more members of the community could share their thoughts on the RCBus specification. It will only succeed if it is acceptable to most people here.

I'm sure there are lots of improvements that need to be made so feedback your thoughts please.

Steve

Mark T

Feb 27, 2023, 8:15:34 PM2/27/23

to retro-comp

I think I would prefer BAI/BAO at the same end of the bus as IEI and IEO. Partly because then Z80 is allocated existing user pins and leave n41 to n48 for functions not used by z80 processors, and maybe not for any of the 8 bit micros. I think that also works better with the option of IEI/IEO and BAI/BAO to be via link wires between modules and only having those at one end of the modules rather than opposite ends. Its likely that a module using BAI/BAO would also need IEI/IEO.

I have considered using RCBus for INS8060 or INS8073 to reuse modules with these two processors. I think these have a close enough match to z80 interface to not need their own bus variant. I expect SIn and Sout to rx and tx. Sense A to Int. Sense B and flags to user pins. Possibly using refresh for NADS, though I think this could be limited to the processor module. BAI/BAO would be reused for NENIN and NENOUT.

Alan Cox

Feb 27, 2023, 8:31:51 PM2/27/23

to Mark T, retro-comp

> I have considered using RCBus for INS8060 or INS8073 to reuse modules with these two processors. I think these have a close enough match to z80 interface to not need their own bus variant. I expect SIn and Sout to rx and tx. Sense A to Int. Sense B and flags to user pins. Possibly using refresh for NADS, though I think this could be limited to the processor module. BAI/BAO would be reused for NENIN and NENOUT.

That was my conclusion some time ago - I've just never found a source

of INS807x parts at a sane price to bother turning the PCB design into

a board. Passing NENIN/NENOUT would make sense. I just had those as

flying leads so you could run multi-processor if you could afford to

spend $150 a shot on possibly dodgy remarked parts.

Alan

Brad Hines

Feb 27, 2023, 11:38:00 PM2/27/23

to Steve Cousins, retro-comp

Hi All,

I've been enjoying the RCBus discussion. Something just occurred to me last night that I thought I should mention, which is that I'm worried about the name "RCBus". I'll leave it to all of you to decide what to do with it or about it.

The issue is the possibility of brand confusion between RC2014 and RCBus. As someone who has just recently discovered RC2014 and Z50Bus and all of the above, I can say that it took me a couple of days to sift through everything that was out there and figure out what the situation was.

One of the questions that one has to resolve as you peel all this back is "which came first, which is derived from which", and so on.

I think if I had been coming into it and had seen both RCBus and RC2014, I would have been a bit confused. To a newbie, the assumption would be that they are related, probably branches off the same tree. And to a degree they are, but at the same time, our new RCBus is intended to be a fresh start, with different parentage. And it definitely would have been confusing figuring out which is more recent.

To some degree, maybe we want the similarity of names for what that communicates. But that's where one can run into trouble with trademarks. Having dealt with this in my businesses a bit over the years, I suspect that we will have an issue with RCBus infringing on the RC2014 trademark.

Why? The reason is that the way the trademark office looks at these things (at least in the U.S. - I am admittedly slightly out on a limb with extrapolating this to the UK) is, "What are the chances that a consumer will confuse the protected brand with the competing brand?" If a realistic chance for confusion is present, the new mark is infringing.

If the owner of the RC2014 trademark seeks to enjoin us from calling our bus RCBus, I would give high odds that he would succeed.

So that was the thought I thought I'd share. Feels like it might be good to pick a different name.

Brad

--

You received this message because you are subscribed to the Google Groups "retro-comp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to retro-comp+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/retro-comp/66b4c474-b868-4027-baac-cc046531900dn%40googlegroups.com.

Brad Hines

Brade...@gmail.com

Brade...@gmail.com

Tadeusz Pycio

Feb 28, 2023, 4:59:36 AM2/28/23

to retro-comp

Hi Brad,

I think you have misread our intentions, RCBus is meant to unite not divide. If someone confuses RC2014 with RCBus it will not be a mistake, any RC2014 module will work on RCBus. This is not an attempt to build a new standard (a very tempting proposition) or to build a new brand. We want to standardise the naming and standardise the missing signals on the bus. If we don't do this, everyone will call it according to their own vision, use the free pins in the way most convenient for themselves. This state of affairs will create more confusion for new users. One final point, Spencer did not object to using a different name.

If the idea of RCBus were to be about something new, the bus would certainly change. I've only designed 15 modules, so I already know the disadvantages of this arrangement of signals on the bus. I have old-fashioned PCB design principles, I believe that power lines should be a minimum of 18 mils wide and I do not tolerate vias for these lines, and placing them on the bus in the middle leads to circus tricks to keep these principles for a double-sided PCB. This would certainly be the first thing I would change. Here no one wants to change it to be consistent with existing solutions.

I think you have misread our intentions, RCBus is meant to unite not divide. If someone confuses RC2014 with RCBus it will not be a mistake, any RC2014 module will work on RCBus. This is not an attempt to build a new standard (a very tempting proposition) or to build a new brand. We want to standardise the naming and standardise the missing signals on the bus. If we don't do this, everyone will call it according to their own vision, use the free pins in the way most convenient for themselves. This state of affairs will create more confusion for new users. One final point, Spencer did not object to using a different name.

If the idea of RCBus were to be about something new, the bus would certainly change. I've only designed 15 modules, so I already know the disadvantages of this arrangement of signals on the bus. I have old-fashioned PCB design principles, I believe that power lines should be a minimum of 18 mils wide and I do not tolerate vias for these lines, and placing them on the bus in the middle leads to circus tricks to keep these principles for a double-sided PCB. This would certainly be the first thing I would change. Here no one wants to change it to be consistent with existing solutions.

@All

I have a suggestion that further ideas should already be concretised - name/meaning/no. pin.

We should have already released the first version of the RCBus specification, Steve has done a lot of work and we are still moving on general outlines of what should be in there. Maybe try to finish the bus for Z*80, 6800 and 6502 and then focus on developing for other architectures. For example, I don't know what signals we want to have for 68000 support, not counting byte select signals. Is that all this processor needs to run on the RCBus?

I have a suggestion that further ideas should already be concretised - name/meaning/no. pin.

We should have already released the first version of the RCBus specification, Steve has done a lot of work and we are still moving on general outlines of what should be in there. Maybe try to finish the bus for Z*80, 6800 and 6502 and then focus on developing for other architectures. For example, I don't know what signals we want to have for 68000 support, not counting byte select signals. Is that all this processor needs to run on the RCBus?

TonyD

Feb 28, 2023, 5:01:56 AM2/28/23

to retro-comp

Hi All

I've been following this discussion with great interest.

A couple of discussion points I would like to add is that of:

- Board dimensions

- External Connector positions

best regards

Tony

I've been following this discussion with great interest.

A couple of discussion points I would like to add is that of:

- Board dimensions

- External Connector positions

Thank you all for such a good and open discussion.

Tony

Karl Albert Brokstad

Feb 28, 2023, 5:15:59 AM2/28/23

to retro-comp

Good discussion. At last, we may agree on a standard.

My suggestion is that the name RCbus covers the general standard, and provision for different sub-standards like 40 and 80 pins connectors, giving RC40bus and RC80bus respectively. This a naming convention I have used on my designs.

Karl

Steve Cousins

Feb 28, 2023, 5:39:02 AM2/28/23

to retro-comp

I think the RCBus specification should suggest board dimensions and connector positions but not try to limit designers to them.

There are two common RC2014 module sizes in Spencer's range: standard and low profile. I think both of these should be suggested in the spec.

The low profile modules are the full 40 pins long, whilst the standard modules are 39 pins long. I'd like to start making my standard modules 40 pins long. Spencer's module template for standard size modules also places the bus connector slightly off centre which seems odd. I would like to suggest anyone making modules 40 pins long should centre the bus connector, as Spencer has done with his low profile modules.

In addition I'd like to add a larger module size to allow more highly integrated designs and to allow nicely spaced components and useful screenprint. I very much like Spencer's single function modules as it has a valid educational aspect to it and, well, it is just nice. However, once you are over that part of the learning curve it is desirable to have the option of fewer modules. Less soldering, greater reliability. Some people building kits have never done any soldering before so it is important to me to be able to space components out etc. to make the assembly process less intimidating for inexperienced makers. I don't really like the look of modules greater than about 3 inches (75mm) tall but I think I would still like to suggest a module size nearer 4 inches (100mm) tall.

Steve

There are two common RC2014 module sizes in Spencer's range: standard and low profile. I think both of these should be suggested in the spec.

The low profile modules are the full 40 pins long, whilst the standard modules are 39 pins long. I'd like to start making my standard modules 40 pins long. Spencer's module template for standard size modules also places the bus connector slightly off centre which seems odd. I would like to suggest anyone making modules 40 pins long should centre the bus connector, as Spencer has done with his low profile modules.

In addition I'd like to add a larger module size to allow more highly integrated designs and to allow nicely spaced components and useful screenprint. I very much like Spencer's single function modules as it has a valid educational aspect to it and, well, it is just nice. However, once you are over that part of the learning curve it is desirable to have the option of fewer modules. Less soldering, greater reliability. Some people building kits have never done any soldering before so it is important to me to be able to space components out etc. to make the assembly process less intimidating for inexperienced makers. I don't really like the look of modules greater than about 3 inches (75mm) tall but I think I would still like to suggest a module size nearer 4 inches (100mm) tall.

Steve

Alan Cox

Feb 28, 2023, 6:22:32 AM2/28/23

to Brad Hines, Steve Cousins, retro-comp

> To some degree, maybe we want the similarity of names for what that communicates. But that's where one can run into trouble with trademarks. Having dealt with this in my businesses a bit over the years, I suspect that we will have an issue with RCBus infringing on the RC2014 trademark.

To quote Spencer from the RC2014 list

"RCBus or RC80 Bus sound good to me. It takes the essence of what the

bus is without limiting it by what the RC2014 natively supports."

So we should be good on that front. It's not really about lawyers

anyway it was a polite request. Either way Spencer's quote I think

probably counts for estoppel ;)

Alan

Brad Hines

Feb 28, 2023, 4:37:19 PM2/28/23

to Tadeusz Pycio, retro-comp

Hi Tadeusz,

To be clear, my point wasn't about intent, it was about legal jeopardy. I think the goals you suggest are good ones.

I do still think confusion is a concern. The use case is a newbie trying to decide on the backplane for his or her system. Does the term inform which kind of backplane is recommended for a new system, or does it muddy the water?

In my case, when I got started with RCxx, I had to decide what kind of backplane modules to buy. RC2014, RC40, RC80, Z50Bus? There was a bit of alphabet soup, and no clear indication of which was the latest. Once RCBus is complete and available, then a newbie would likely want to buy a RCBus backplane. It would be a sadness for someone to buy a RC2014 backplane and then realize that the slick new card that they want is only available for the newer bus. If our new bus were called "RC2023", for example, then it would clearly inform the user. But that would likley run afoul of trademarks even more than RCBus.

As far as legal, it may be okay given what you said. I'm not sure who Spencer is - if he's the owner of the RC2014 trademark and has blessed the use of the term RCBus, then I'm sure it's fine. If not, we could end up in a situation where we are forced to change the name in a year or two or three.

It may be that RCBus is the best term. To me the ideal term would capture the heritage but also let you know which came first. Something like "RCNext"? I'll be happy with whatever is chosen; it doesn't really affect me, just thinking about new folks entering the domain.

Brad

--

You received this message because you are subscribed to the Google Groups "retro-comp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to retro-comp+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/retro-comp/29a9dea7-9b2c-4de4-9554-062133ebacf7n%40googlegroups.com.

Brad Hines

Brade...@gmail.com

Brade...@gmail.com

Brad Hines

Feb 28, 2023, 4:45:13 PM2/28/23

to Alan Cox, Steve Cousins, retro-comp

Just saw this.

I guess Spencer must be the trademark holder. Yes, I agree that that puts us in the clear.

Brad Hines

Brade...@gmail.com

Brade...@gmail.com

Tadeusz Pycio

Feb 28, 2023, 5:23:41 PM2/28/23

to retro-comp

Hi Brad,

You are quite right about the choice of backplane, but that is the only risk of error that can be made. I think the name RCBus will make it unnecessary to do an analysis of what RC2014, RC80, RC40 are, because for this environment they will become a homogeneous name. Of course, the modules that will be created on the new specification will not be able to make the most of their capabilities on the RC2014 backplane, but it will be possible to run them, without interrupt priority cascade, additional interrupt lines or be handled by DMA. The vast majority of kits can cope without these enhancements. I think we'll also be waiting a long time on the new standard for practical implementation of DMA usage - I only started needing interrupt priority cascade when I wanted to use RTM-Z80, and additional interrupt lines when building CP/Net, so these are not common used applications.

brade...@gmail.com

Feb 28, 2023, 6:21:14 PM2/28/23

to Tadeusz Pycio, retro-comp

Those sound like well-reasoned arguments to me. Thanks for the dialog.

--

You received this message because you are subscribed to the Google Groups "retro-comp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to retro-comp+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/retro-comp/c169c764-d9c5-4cf6-9fa0-49d41a6c19bdn%40googlegroups.com.

Wayne Warthen

Feb 28, 2023, 10:19:11 PM2/28/23

to Steve Cousins, retro-comp

On Tue, Feb 28, 2023 at 2:39 AM Steve Cousins <steve...@gmail.com> wrote:

The low profile modules are the full 40 pins long, whilst the standard modules are 39 pins long. I'd like to start making my standard modules 40 pins long. Spencer's module template for standard size modules also places the bus connector slightly off centre which seems odd. I would like to suggest anyone making modules 40 pins long should centre the bus connector, as Spencer has done with his low profile modules.

I don't have a lot of input on the RCBus specifications, but I strongly agree with a couple things Steve suggests here.

Yes, please deprecate 39 pin connectors. Far too easy to misplug them. Yes, please center the bus connector. It simply makes no sense for it to be offset. Since Spencer has already made those adjustments in his latest form factor, it does not seem like a problem to standardize that way.

Thanks,

Wayne

Mark T

Feb 28, 2023, 11:48:18 PM2/28/23

to retro-comp

Maybe keep the pin1 end of the module the same profile relative to pin 1, but extend the pin40 end of the module to centre the module on the 40/80 pin connector. I think this would avoid a random staggered apearance to the system, at least at one end of the bus.

I think Jlcpcb allows 102mm with before the price starts to increase, unless they changed that recently. Last I checked you could used 102.4mm as they round to nearest mm for pricing. This does have the disadvantage of locking in to a single supplier, unless any other manufacturers have started to support this.

Sergey Kiselev

Mar 1, 2023, 12:09:35 AM3/1/23

to retro-comp

Not sure if it is documented anywhere or was mentioned before. I'd recommend having connectors that normally go to external devices on the right side of the board, connectors that go to the internal devices (e.g. floppy) on the top, and indicators (and perhaps buttons/switches or configuration jumpers) on the left, more narrow side.

Tadeusz Pycio

Mar 1, 2023, 2:44:57 AM3/1/23

to retro-comp

A frequently raised issue is the difficulty of removing modules from the slots. It might be worth thinking about suitable holes in the PCB and trying to design ejectors to make this task easier. It would have to be a simple design that allows such a component to be made on a 3d printer. I don't know if there are any ready-made solutions widely available.

TonyD

Mar 1, 2023, 5:10:59 AM3/1/23

to retro-comp

On Wednesday, 1 March 2023 at 07:44:57 UTC Tadeusz Pycio wrote:

A frequently raised issue is the difficulty of removing modules from the slots. It might be worth thinking about suitable holes in the PCB and trying to design ejectors to make this task easier. It would have to be a simple design that allows such a component to be made on a 3d printer. I don't know if there are any ready-made solutions widely available.

Yes, I agree 40-pin connector cards can be difficult to pull out a backplane.

I've used these types of PCB card ejectors / pulls of other board designs.

https://uk.rs-online.com/web/p/pcb-card-inserters-extractors-ejectors/5073687

https://www.toby.co.uk/pcb-hardware/card-guides-and-pulls/

https://www.essentracomponents.com/en-gb/s/card-ejector

I'm sure there will be 3D printed equivalents

Tony

I've used these types of PCB card ejectors / pulls of other board designs.

https://uk.rs-online.com/web/p/pcb-card-inserters-extractors-ejectors/5073687

https://www.toby.co.uk/pcb-hardware/card-guides-and-pulls/

https://www.essentracomponents.com/en-gb/s/card-ejector

I'm sure there will be 3D printed equivalents

Tony

Tadeusz Pycio

Mar 1, 2023, 8:37:54 AM3/1/23

to retro-comp

I don't know if this is a good idea with the ejector though. The PCBs are small, the edges are often used so there is no room for such facilities. The only idea I have is a rectangular PCB with holes on the top corners and handles in the form of a whistle.

Mark T

Mar 1, 2023, 11:25:13 AM3/1/23

to retro-comp

Maybe someone could design something to fit around 40 or 80 pin female headers on the backplane with levers to push up on the edge of the pcb at each end. No modification to the modules needed, but possibly mounting holes on the backplane if its not a firm fit on the headers. Would a 3d printed part be strong enough?

PauldB

Mar 1, 2023, 5:15:31 PM3/1/23

to retro-comp

Here's a (very) low-tech method for lifting modules from an RC2014 / RCBus40 / RCBus80 backplane which doesn't require any

modification to current hardware. A KISS solution that works well, most of the time *

The 'tool' is a toothbrush handle with the brush end cut off. Note that the plastic on this handle is of a softer type that doesn't scratch the backplane.

I've made a number of these over time and they work quite well as a lever (among other uses; I usually trim the end of the handle to a flat blade with a knife for poking around electrical things 8) )

* It can be a bit tricky to use if the module to be removed is mounted in the socket on the side of the backplane that has an LED, switch, etc. right next to it.

Paul

modification to current hardware. A KISS solution that works well, most of the time *

The 'tool' is a toothbrush handle with the brush end cut off. Note that the plastic on this handle is of a softer type that doesn't scratch the backplane.

I've made a number of these over time and they work quite well as a lever (among other uses; I usually trim the end of the handle to a flat blade with a knife for poking around electrical things 8) )

* It can be a bit tricky to use if the module to be removed is mounted in the socket on the side of the backplane that has an LED, switch, etc. right next to it.

Paul

Bill Shen

Mar 1, 2023, 5:20:19 PM3/1/23

to retro-comp

I found an angled forceps very effective in prying a board loose.

For board I need to remove frequently, I would place it at the end of the backplane where I can get index and middle fingers of both hands under the 90-degree connector and push board out against my thumbs. It is quick and easy.

Bill

For board I need to remove frequently, I would place it at the end of the backplane where I can get index and middle fingers of both hands under the 90-degree connector and push board out against my thumbs. It is quick and easy.

Bill

Gary S

Mar 1, 2023, 6:07:48 PM3/1/23

to retro-comp

The toothbrush handle is actually allow the way to an idea I am have been thinking of.

In the S100 arena as many others it the lifters being on the removable board, which also entails a frame to work against.

This a bit in reverse, a good motherboard design could have "optional" designed in to act againt the base of the boards inserted. Yes this is actually a development along the idea of the toothbrush handle.

In the S100 arena as many others it the lifters being on the removable board, which also entails a frame to work against.

This a bit in reverse, a good motherboard design could have "optional" designed in to act againt the base of the boards inserted. Yes this is actually a development along the idea of the toothbrush handle.

Sorry Steve, maybe we can throw this back onto you to design a suitable compatible motherboard ?? (hehe).

Tadeusz Pycio

Mar 2, 2023, 4:32:20 AM3/2/23

to retro-comp

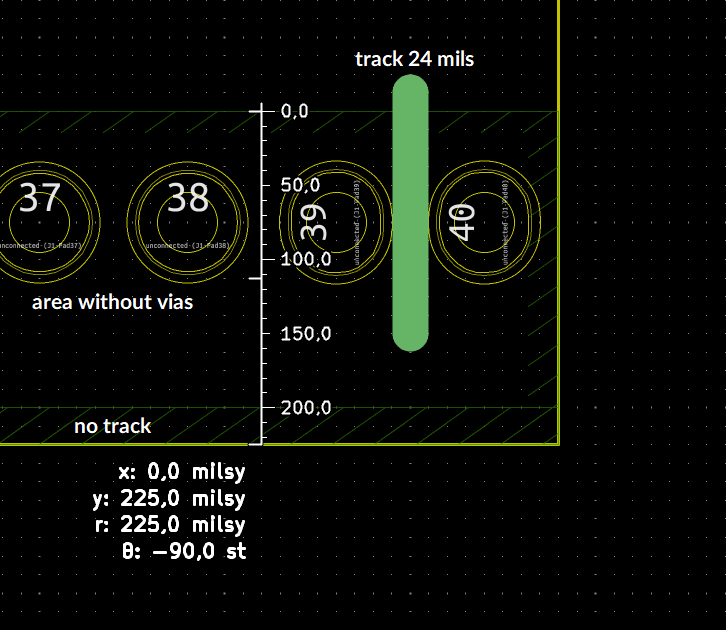

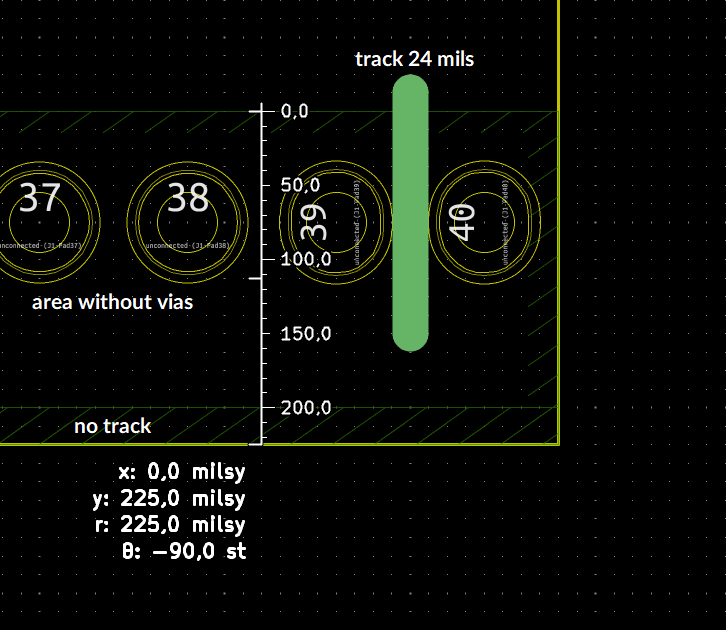

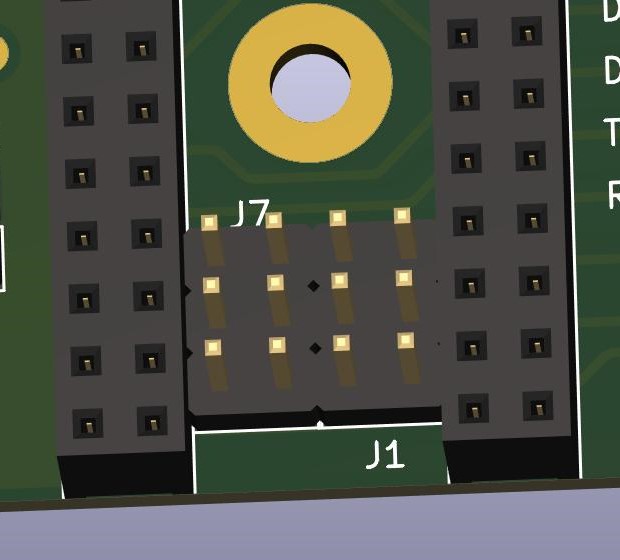

Proposal for dimensioning the standard PCB size of the RCBus module. I have raised the connector so that the plastic part rests on the PCB and increased the size of the whole PCB propionally for the 40 pin connector. In the slot such a module will be 2.54mm taller and 1.6mm longer. The position of the hole has been retained. I don't know if we shouldn't also decrease the bevel to 0.5", not much, but it increases the PCB area. For 40-pin connectors, it would be necessary to use angled asymmetrical connectors in order to maintain an equal distance between modules in the backplane.

Steve Cousins

Mar 2, 2023, 5:35:00 AM3/2/23

to retro-comp

Hi Tadeusz,

I was thinking the same things. The extra space between the bus header and the edge of the PCB could be used to run 5V and GND to the ends of the PCB. This would allow the creation of a power ring around the outer edge of the module, thus reducing the power routing issues we have at the moment. There should also be room to run a track of two in the new space to help with routing.

I think your dimension to the mounting hole (1450.000 mils) might be wrong. Looks like it should be 1400.000 to me.

I'm very keen to move to 4000 mils wide and like the idea of reducing the size of the bevel. I think the rounded corner could be reduced as well, possible to 50 mils. The PCB would still retain the familiar look. Altering the look slightly might help distinguish RCBus modules from RC2014 modules - if that is considered desirable.

I would still like to suggest a larger module size as an option, perhaps as large as 4000x4000 mils.

I doubt this will be a popular idea, but I've also been looking at the cost implications of slightly longer modules, say 4400 mils. For prototyping the cost issue is significant but for production quantities I think the benefits might justify the small extra cost. Going longer would further help with routing power around the bus header. It could also provide an overhang beyond the bus header which would make levering the modules out much easier. One of the things I like about the Z50Bus is the modules are wider than the bus headers. It really helps with extracting modules from the backplane. My thinking is while the PCB may be longer it might not make the overall space required for a module any longer as connectors could be within the outline of the PCB rather than stick out. This would allow prototypes to stay withing the proposed 4000 mils size. Also, the module would still be narrower than the official RC2014 backplanes. Mixing the two sizes would look horrible which might be the biggest reason to avoid the idea.

Steve

Steve Cousins

Mar 2, 2023, 5:41:31 AM3/2/23

to retro-comp

Regarding Mark's suggestion for placing BAI/BAO at the same end as IEI/IEO. There are two reasons I'd rather not do this:

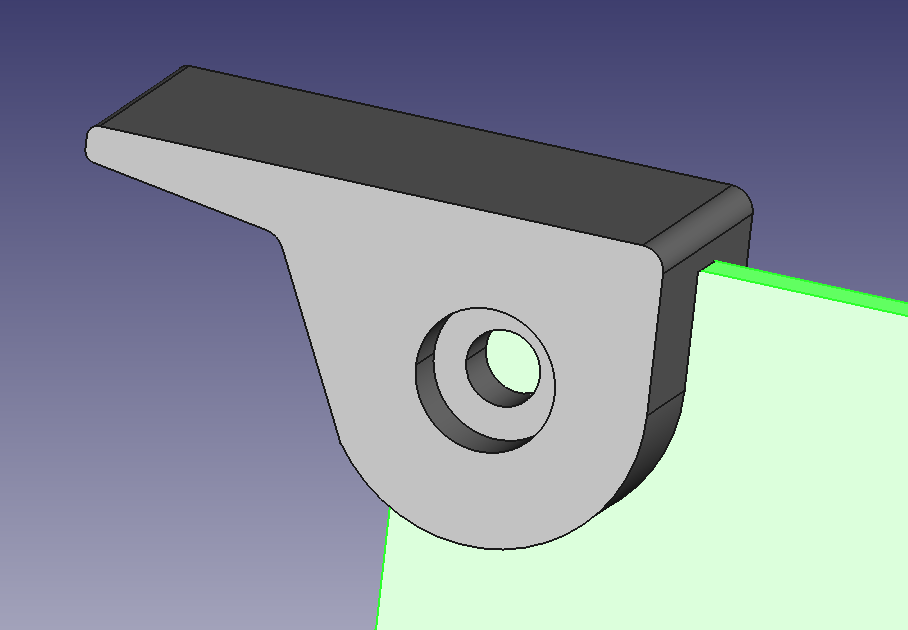

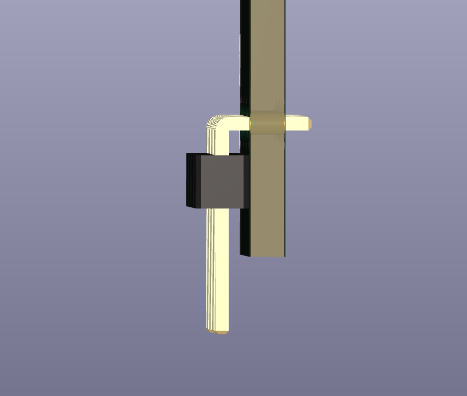

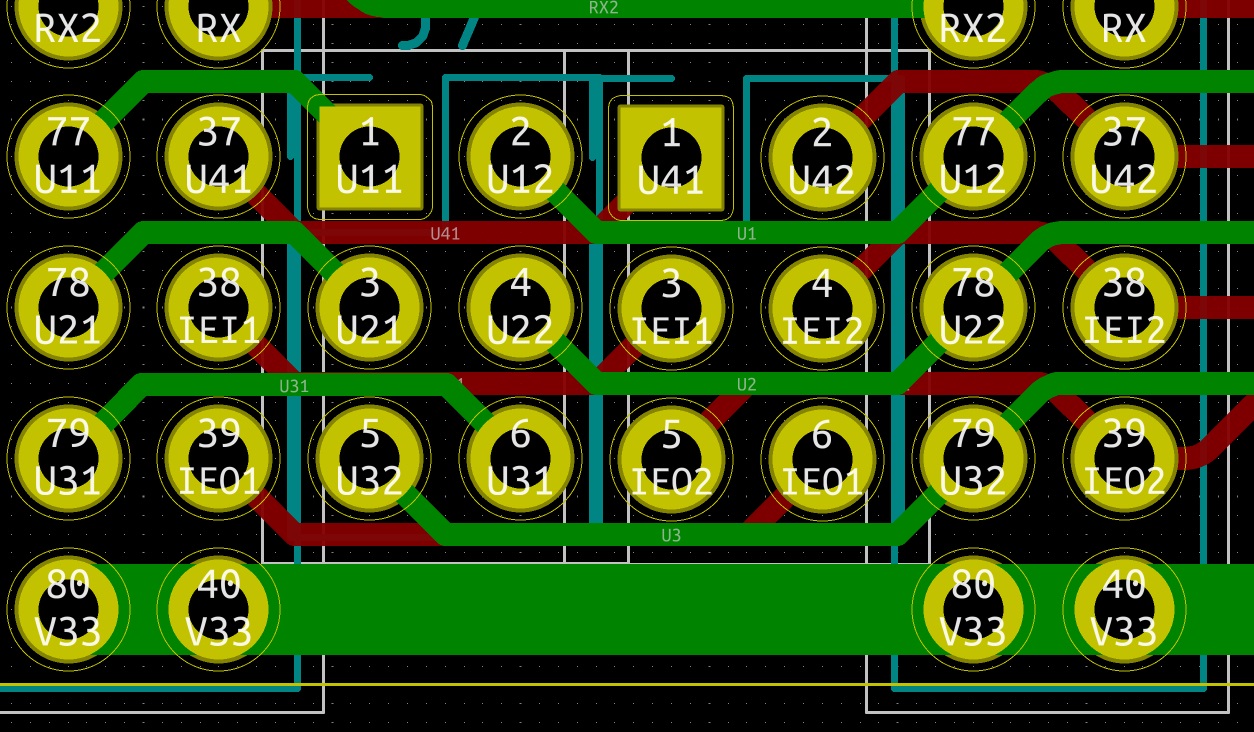

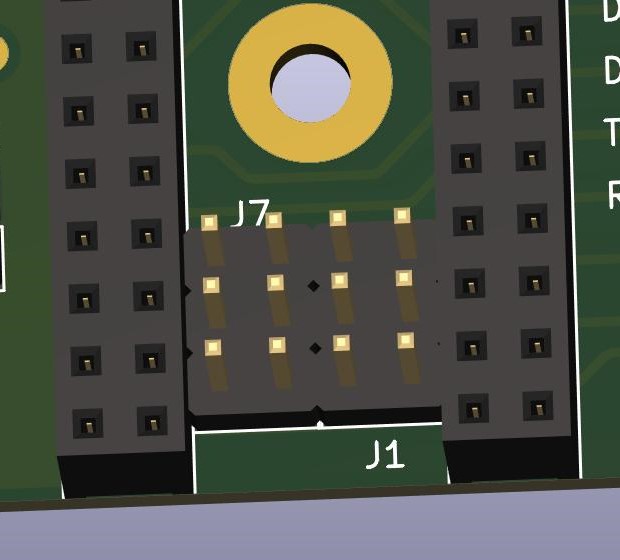

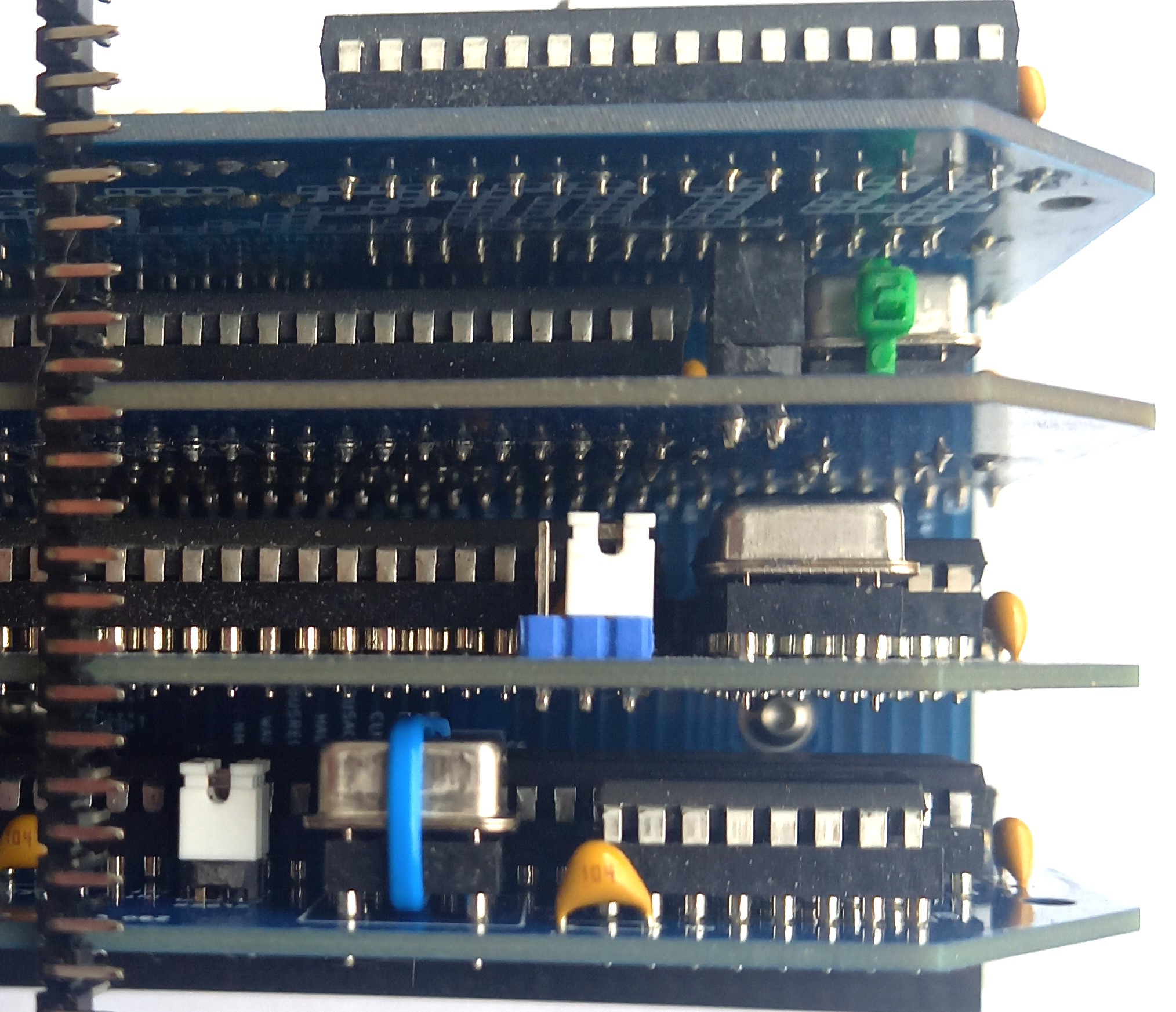

1/ I assume the backplane will have jumpers to make the BAI and BAO pins either direct connections (for non-Z80 uses) or daisy-chained (for advanced Z80 systems). Similarly for IEI/IEO. Trying to put these together at one end will cause space issues. Attached is a rendered image of my latest thinking for an RCBus backplane.

2/ I'd rather use the newly available pins at the other end so as to minimise compatibility issues with the established USER pins. Although, USER5 to 8 have not been used by many designs.

On Tuesday, 28 February 2023 at 01:15:34 UTC Mark T wrote:

I think I would prefer BAI/BAO at the same end of the bus as IEI and IEO. Partly because then Z80 is allocated existing user pins and leave n41 to n48 for functions not used by z80 processors, and maybe not for any of the 8 bit micros. I think that also works better with the option of IEI/IEO and BAI/BAO to be via link wires between modules and only having those at one end of the modules rather than opposite ends. Its likely that a module using BAI/BAO would also need IEI/IEO.

I have considered using RCBus for INS8060 or INS8073 to reuse modules with these two processors. I think these have a close enough match to z80 interface to not need their own bus variant. I expect SIn and Sout to rx and tx. Sense A to Int. Sense B and flags to user pins. Possibly using refresh for NADS, though I think this could be limited to the processor module. BAI/BAO would be reused for NENIN and NENOUT.

Tadeusz Pycio

Mar 2, 2023, 9:17:24 AM3/2/23

to retro-comp

Yes, indeed the hole should be at 1400 mils. I've attached a corrected drawing, with the replacements Steve was talking about. I'm wondering if extending the PCB further on the connector side would eliminate the wobble of the modules, but doing so will make the modules even harder to pull out.

Mark T

Mar 2, 2023, 10:44:07 AM3/2/23

to retro-comp

I prefer the style of 40 pin connecter shown in Tadeusz last post, as this then has the same height as the dual roaw connector, both of these have a more defined mating face with the backplane connectors.

I find extending the board edge behind the connector makes it easier to fit the connectors in a consistent angle on the modules, but probably not a good idea to extend the board past the plastic of the connector. I’m not sure it would make the module harder to remove, but it might make it harder to fit if extra care is not taken when the connector is soldered to the module. The female headers are slightly wider than the plastic carrier of the pin headers.

One issue of changing the board edge is compatibility with standard modules if someone does design a card eject system based on the board edge. One possible solution is to only extend the board edge in the range of pins 8 to 32 or similar, this leaves edges at the same height for card ejectors but provides some extra support fitting the pin headers.

I think we should avoid too many changes to the outline shape, I think only the right edge should be changed to allow 40 pin connectors.

I consider the hole in the board to be optional but some people might consider that useful for additional support.

Tadeusz Pycio

Mar 2, 2023, 11:30:22 AM3/2/23

to retro-comp

Here are the more specific non-mandatory rules I will follow. The space under the connector will allow for a 24 mils track width after custom pads modification. Nice. :)

Mark T

Mar 2, 2023, 11:55:28 AM3/2/23

to retro-comp

I think you need to allow a little more for alignment between solder mask and tracks to avoid any slight mis-registration allowing bare copper on the edge of a track, which could allow solder shorts if the assembler doesn’t take enough care during soldering.

Tadeusz Pycio

Mar 2, 2023, 12:21:34 PM3/2/23

to retro-comp

I have not given the pads fillings, so perhaps the drawing is misleading. There is actually quite a bit of gap there without violating the DRC rules.

Steve Cousins

Mar 2, 2023, 5:40:06 PM3/2/23

to retro-comp

Attached is an updated version of the RCBus specification, including the latest contributions from Alan.

I've really only pasted in the contributions and have done nothing to remove duplicate information or improve consistency.

Further contributions and feedback welcome.

Steve Cousins

Mar 3, 2023, 5:31:57 AM3/3/23

to retro-comp

The RCBus specification will include suggested or recommended module sizes and shapes. I assume this will take the form of dimensioned drawings. In order to pin this down could we vote on the following:

Question 1: Should we include a module size suggestion of 4"/4000mil/101.6mm long? (that allows space for the full 40/80 pin headers)

Question 2: Should we include a module size suggestion of 3.9"/3900mil/99mm long? (for those who want consistency with RC2014 39-pin long modules and for a wider choice of low cost PCB manufacturers)

Question 3: Should we include a module size suggestion similiar to the RC2014 Classic 2 low profile modules? (4"/4000mil/101.6mm long by 1"/1000mil/25.4mm high)

Question 4: Should we include a larger module size, perhaps 4"/4000mil/101.6mm square? (particular well suited to prototyping but also allows greater functionality or nicer component spacing and labelling)

Question 5: Should we recommend the PCB extends below the header mounting holes by 0.15"/150mil/3.81mm as proposed by Tadeusz yesterday?

Question 6: Should we recommend the same size 45 degree bevel and the same curve radius as Spencer's RC2014 modules, or should we recommend different sizes or shapes to differentiate new RCBus modules from RC2014 modules?

Question 7: Should we recommend header pins be centred along the length of the board, rather than be offset like Spencer's RC2014 standard size modules?

Question 8: Anything else we need to decide on this issue?

Question 1: Should we include a module size suggestion of 4"/4000mil/101.6mm long? (that allows space for the full 40/80 pin headers)

Question 2: Should we include a module size suggestion of 3.9"/3900mil/99mm long? (for those who want consistency with RC2014 39-pin long modules and for a wider choice of low cost PCB manufacturers)

Question 3: Should we include a module size suggestion similiar to the RC2014 Classic 2 low profile modules? (4"/4000mil/101.6mm long by 1"/1000mil/25.4mm high)

Question 4: Should we include a larger module size, perhaps 4"/4000mil/101.6mm square? (particular well suited to prototyping but also allows greater functionality or nicer component spacing and labelling)

Question 5: Should we recommend the PCB extends below the header mounting holes by 0.15"/150mil/3.81mm as proposed by Tadeusz yesterday?

Question 6: Should we recommend the same size 45 degree bevel and the same curve radius as Spencer's RC2014 modules, or should we recommend different sizes or shapes to differentiate new RCBus modules from RC2014 modules?

Question 7: Should we recommend header pins be centred along the length of the board, rather than be offset like Spencer's RC2014 standard size modules?

Question 8: Anything else we need to decide on this issue?

Steve Cousins

Mar 3, 2023, 5:58:08 AM3/3/23

to retro-comp

My votes on the above questions:

1 Yes

2 No, just include link to rc2014.co.uk somewhere in the spec

3 Yes

4 Yes

5 Yes

6 No, I think slightly different dimensions

7 Yes

8 Not at the moment

Karl Albert Brokstad

Mar 3, 2023, 6:00:26 AM3/3/23

to Steve Cousins, retro-comp

I totally agree with you Steve!

Karl

--

You received this message because you are subscribed to the Google Groups "retro-comp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to retro-comp+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/retro-comp/0e907810-ec1d-4ecb-9f03-2b0e6caa1a35n%40googlegroups.com.

Tadeusz Pycio

Mar 3, 2023, 7:29:15 AM3/3/23

to retro-comp

I have the same opinion as Steve, so I have nothing to add.

Steve Cousins

Mar 3, 2023, 8:59:55 AM3/3/23

to retro-comp

I agree, so here are a few questions that need answering to pin down the RCBus backplane and signals.

Question 11: Should the backplane include a dedicated 3V3 pin?

The alternative is to generate 3V3 on any module that needs it. Having a pin on the bus for this will not mean the supply is always present, so will that mean a module needing 3V3 will require a suitable power module to be present, or does it mean those modules needing 3V3 will have a regulator on them anyway plus a jumper to determine if its 3V3 supply is connected to the bus?

I've faced the same issue with my designs that have a voltage supervisor. I initially included the supervisor on processor modules but later introduced power supply modules that include a supervisor. So now some combination of boards mean I have two supervisors!

Question 12: Should BAI and BBAO be on pins 42 and 43?

Mark T suggested it would be better to put them near IEI and IEO (pins 38 and 39, previously known as USER 6 and 7). Mark's reasons were to keep the new pins free for other processors and proximity to the back of the PCB is more convenient for link wires etc. As the likely implementation will involve jumpers on the backplane to select daisy chain or direct connections there might be a space issue near IEI and IEO. Also, USER 6 and 7 are more likely to be used by existing designs than the new pins.

Question 13: Should we call the fixed function pins "common pins/signals"?

These are the pins that have a single clearly defined function, so mainly the standard RC2014 bus signals.

Other options are "Base pins/signals" or "Fixed function pins/signals" or "Core pins/signals" or "Standard pins/signals" or ???.

Question 14: Should we call the multi-function (ie. processor specific or use case dependent) pins/signals "Extended"?

These are the pins currently named n## and include the RC2014 USER pins. I 've found that they need a simple name when trying to document them.

Other options are "Multi-function" or ???

Question 15: Should the multi-function pins be identified by labels of the form n## (eg. n41)?

Question 11: Should the backplane include a dedicated 3V3 pin?

The alternative is to generate 3V3 on any module that needs it. Having a pin on the bus for this will not mean the supply is always present, so will that mean a module needing 3V3 will require a suitable power module to be present, or does it mean those modules needing 3V3 will have a regulator on them anyway plus a jumper to determine if its 3V3 supply is connected to the bus?

I've faced the same issue with my designs that have a voltage supervisor. I initially included the supervisor on processor modules but later introduced power supply modules that include a supervisor. So now some combination of boards mean I have two supervisors!

Question 12: Should BAI and BBAO be on pins 42 and 43?

Mark T suggested it would be better to put them near IEI and IEO (pins 38 and 39, previously known as USER 6 and 7). Mark's reasons were to keep the new pins free for other processors and proximity to the back of the PCB is more convenient for link wires etc. As the likely implementation will involve jumpers on the backplane to select daisy chain or direct connections there might be a space issue near IEI and IEO. Also, USER 6 and 7 are more likely to be used by existing designs than the new pins.

Question 13: Should we call the fixed function pins "common pins/signals"?

These are the pins that have a single clearly defined function, so mainly the standard RC2014 bus signals.

Other options are "Base pins/signals" or "Fixed function pins/signals" or "Core pins/signals" or "Standard pins/signals" or ???.

Question 14: Should we call the multi-function (ie. processor specific or use case dependent) pins/signals "Extended"?

These are the pins currently named n## and include the RC2014 USER pins. I 've found that they need a simple name when trying to document them.

Other options are "Multi-function" or ???

Question 15: Should the multi-function pins be identified by labels of the form n## (eg. n41)?

If not what should they be labelled?

Question 16: Should we have a logo of some sort for RCBus?

The alternative is just to use "RCBus".

Question 17: Should we recommend a minimum spacing between sockets of 0.6"/600mil/15.24mm?

This is the spacing I use for SC112, SC113, SC116 and on my motherboard designs.

The RC2014 backplanes are 0.65"/650mil/16.51mm.

Question 18: Should we suggest a wide spacing of 0.8"/800mil/20.32mm as an alternative?

This give more wiggle room but it is not enough for really large components. The alternative is to simply say there will be odd cases where you need to fit the module in the last slot or have it cover a second (unusable) slot.

Question 19: Should the labels for the bus signals include a symbol/character to indicate active low?

Question 20: Is there anything fundamentally wrong with the attached render of a backplane?

Question 21: Anything else we need to decide on this issue?

Question 16: Should we have a logo of some sort for RCBus?

The alternative is just to use "RCBus".

Question 17: Should we recommend a minimum spacing between sockets of 0.6"/600mil/15.24mm?

This is the spacing I use for SC112, SC113, SC116 and on my motherboard designs.

The RC2014 backplanes are 0.65"/650mil/16.51mm.

Question 18: Should we suggest a wide spacing of 0.8"/800mil/20.32mm as an alternative?

This give more wiggle room but it is not enough for really large components. The alternative is to simply say there will be odd cases where you need to fit the module in the last slot or have it cover a second (unusable) slot.

Question 19: Should the labels for the bus signals include a symbol/character to indicate active low?

Question 20: Is there anything fundamentally wrong with the attached render of a backplane?

Question 21: Anything else we need to decide on this issue?

dhen...@gmail.com

Mar 3, 2023, 9:53:44 AM3/3/23

to retro-comp

I've been following the RCBus discussion with interest. I think it's a good idea and haven't felt the need to disagree with anything so far.

To answer the questions:

1. yes

2. no

3. yes

4. yes

5. yes

6. no

7. no

8. no

...

11. yes

12. no opinion

13. yes

14. yes

15. yes

16. yes, with the text as a fallback

17. yes

18. no

19. yes

20. no

21. no

Mark T

Mar 3, 2023, 11:09:14 AM3/3/23

to retro-comp

1 yes

2 no, link to rc2014.co.uk on drawing for 1, with outline of spencers module shown as overlay.

3 yes, X dimension on drawing for 1, with table of recommended X.

4 yes, same as 3

5 maybe, but no extension past plastic support of dual row header

6 yes

7 pin 1 to left edge should match spencers modules, centred on wider module.

8 don’t think so

Tadeusz Pycio

Mar 3, 2023, 11:25:42 AM3/3/23

to retro-comp

Ad.11 No. Current backplanes are not prepared for this, the number of modules requiring this voltage in complete kits is small, additional voltages should be provided by the module which requires them (an implicit example is RS232 with MAX232 which generates +10V and -10V), the only safe place to provide sufficiently wide tracks is 40-80.

Ad.12 Yes. The proposed circuit allows the cascade to be connected using jumpers, no wire connections are needed to implement it.

Ad.13 Yes.

Ad.14 I think extended is a good term

Ad.15 Maybe the solution would be to call them by the names of the RCZ*80 bus with a # or * sign?

Ad.16 I have a dilemma here, there should be a recognisable designation, clearly indicating the supported standard, but there may be people who see this as an attempt to build a new brand. I will certainly leave the 1980s style lettering/logo in my backplane, will I use it in the modules? I do not know.

Ad.17 Yes. A minimum spacing of 0.6" is sufficient.

Ad.18 No. I think that wide modules can occupy two slots, something like in 19" racks - 2U

Ad.19 Yes. This is a clear signal indication

Ad.20 No. I have no objections

Ad.21 I have no idea

Ad.12 Yes. The proposed circuit allows the cascade to be connected using jumpers, no wire connections are needed to implement it.

Ad.13 Yes.

Ad.14 I think extended is a good term

Ad.15 Maybe the solution would be to call them by the names of the RCZ*80 bus with a # or * sign?

Ad.16 I have a dilemma here, there should be a recognisable designation, clearly indicating the supported standard, but there may be people who see this as an attempt to build a new brand. I will certainly leave the 1980s style lettering/logo in my backplane, will I use it in the modules? I do not know.

Ad.17 Yes. A minimum spacing of 0.6" is sufficient.

Ad.18 No. I think that wide modules can occupy two slots, something like in 19" racks - 2U

Ad.19 Yes. This is a clear signal indication

Ad.20 No. I have no objections

Ad.21 I have no idea

Karl Albert Brokstad

Mar 3, 2023, 11:47:40 AM3/3/23

to retro-comp

My thoughts on the RCbus specification

1. We should make a decision as soon as possible and issue a version 1 specification as suggested in this discussion. More exotic and special signals can be agreed on later in an updated specification.

2. The initial specification should not contain recommendations on the size and shape of the modules except the size of the connector. The recommended size and shape can be amended later. As long as the pin layout is specified, the modules will work in compatible backplanes, although they may not fit in certain configurations or builds.

3. How to vote for a specification? I think one way is just to collect the names of those who agree, those who disagree will probably make their own standard anyway.

Karl

--

You received this message because you are subscribed to the Google Groups "retro-comp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to retro-comp+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/retro-comp/bb6977e0-47f7-47b2-9a5c-a4fcc24dff08n%40googlegroups.com.

fixit9660

Mar 3, 2023, 12:51:17 PM3/3/23

to retro-comp

As an ageing newbie to this group, my only valid input concerns

Tadeusz Pycio's comment about "extending the PCB further on the connector side would

eliminate the wobble of the modules, but doing so will make the modules even

harder to pull out."

Has the use of card guides been considered to mitigate this? As I say, I'm new here and not aware of established practices in regards hardware specifications. Apologies for this.

Greg Holdren

Mar 3, 2023, 12:59:00 PM3/3/23

to retro-comp

Q6: Not a fan of the curve and 45 degree bevel at all along with the bullet hole. Hinders part placement. Too much like RC2014. I'm going to come out with a FPGA board it will grow vertically some what.

Greg

Mark T

Mar 3, 2023, 1:08:24 PM3/3/23

to retro-comp

11 no

12 no

13 I think to discuss signals collectively would be Standard, Enhanced and Extended. With Extended qualified by processor group. Also with Enhanced and Extended not being inclusive of the subset.

14 as in 13

15 I think usefull to have a common method of describing the physical connection, not sure about n41 etc as n prefix is common for active low. Is pin41 or p41 not easy to use?

16 do you intend to copyright or control how the logo can be used?

17 yes

18 no, 17 is just a recommendation

19 yes, pick something that works well on silkscreen, I think lower case n rather than /, with upper case for the rest of the label.

Wayne Warthen

Mar 3, 2023, 1:38:34 PM3/3/23

to retro-comp

1. yes

2. no

3. yes

4. yes

5. yes

6. no

7. yes

8. no

...

11. yes

12. no opinion

13. weak yes

14. weak yes

15. yes

16. yes

17. yes

18. weak yes

19. yes

20. no

21. no

Thanks,

Wayne

Tadeusz Pycio

Mar 3, 2023, 2:20:07 PM3/3/23

to retro-comp

Placing the BAI/BAO cascade on pins 77 and 78 does not seem to be a good idea. If you don't want to use vias, then put the two 2x3 pin headers side by side. Maintaining 0.6" spacing between the slots will be impossible. I consider the return to wiring the module to the backplane to be too much of a step backwards. The drawing also included the 3.3V line - the only sensible place for the backplane.

Alan Cox

Mar 3, 2023, 2:52:32 PM3/3/23

to Steve Cousins, retro-comp

Question 11: Should the backplane include a dedicated 3V3 pin?

Would be nice but where is a good question.

Question 15: Should the multi-function pins be identified by labels of the form n## (eg. n41)?If not what should they be labelled?

Convention seems to be to give them a base name and where needed refer to them with a / list of their forms - at least that's what half the microcontrollers seem to do.

Question 16: Should we have a logo of some sort for RCBus?

The alternative is just to use "RCBus".

Does it matter - if someone makes one then fine if not then fine 8)

Question 17: Should we recommend a minimum spacing between sockets of 0.6"/600mil/15.24mm?

This is the spacing I use for SC112, SC113, SC116 and on my motherboard designs.

The RC2014 backplanes are 0.65"/650mil/16.51mm.

I prefer 16.51. 15.24 is too tight with socketed can oscillators.

Question 18: Should we suggest a wide spacing of 0.8"/800mil/20.32mm as an alternative?

This give more wiggle room but it is not enough for really large components. The alternative is to simply say there will be odd cases where you need to fit the module in the last slot or have it cover a second (unusable) slot.

Does it matter. Specify the minimum spacing and "wider spacings may be used and may be more convenient"

Question 19: Should the labels for the bus signals include a symbol/character to indicate active low?

Yes

Amd catching up on the earlier ones

Question 1: Should we include a module size suggestion of 4"/4000mil/101.6mm long? (that allows space for the full 40/80 pin headers)

Yes but note the RC2014 size and why

Question 2: Should we include a module size suggestion of 3.9"/3900mil/99mm long? (for those who want consistency with RC2014 39-pin long modules and for a wider choice of low cost PCB manufacturers)

2 & 3

Link to or appendix the RC2014 ones as commonly used profiles.

I mean - for interoperability it doesn't matter if your card is the shape of a dinosaur providing it has the connector and flat in the right place.

Question 4: Should we include a larger module size, perhaps 4"/4000mil/101.6mm square? (particular well suited to prototyping but also allows greater functionality or nicer component spacing and labelling)

Given there is no standard established shape what is wrong with modules may be taller or longer than the suggested profiles but this may cause problems with cases.

Question 5: Should we recommend the PCB extends below the header mounting holes by 0.15"/150mil/3.81mm as proposed by Tadeusz yesterday?

Question 6: Should we recommend the same size 45 degree bevel and the same curve radius as Spencer's RC2014 modules, or should we recommend different sizes or shapes to differentiate new RCBus modules from RC2014 modules?

Don't care but having something is helpful

Question 7: Should we recommend header pins be centred along the length of the board, rather than be offset like Spencer's RC2014 standard size modules?

Don't see that it matters either way

Alan

Alan Cox

Mar 3, 2023, 2:55:13 PM3/3/23

to Karl Albert Brokstad, retro-comp

On Fri, 3 Mar 2023 at 16:47, 'Karl Albert Brokstad' via retro-comp

<retro...@googlegroups.com> wrote:

>

> My thoughts on the RCbus specification

>

> 1. We should make a decision as soon as possible and issue a version 1 specification as suggested in this discussion. More exotic and special signals can be agreed on later in an updated specification.

I would agree - stuff like 3v3, and bus arbitration are currently

<retro...@googlegroups.com> wrote:

>

> My thoughts on the RCbus specification

>

> 1. We should make a decision as soon as possible and issue a version 1 specification as suggested in this discussion. More exotic and special signals can be agreed on later in an updated specification.

theoretical topics. When we've got some actually built and working

then might be a better time to actually write it down 8)

Tadeusz Pycio

Mar 3, 2023, 3:27:20 PM3/3/23

to retro-comp

I would agree - stuff like 3v3, and bus arbitration are currently

theoretical topics. When we've got some actually built and working

then might be a better time to actually write it down 8)

I also think 3.3V is nice, but the Paralax Propeller and WiFi modules did just fine without it. The BAI/BAO cascade is also a bit of a leap into the future, especially as we still don't have established request signals to invoke even one rather than several DMA chips. However, if we want to use such a cascade, we need to provide for it on the backplane, otherwise we will have unnecessary wire connections.

Mark T

Mar 3, 2023, 4:48:50 PM3/3/23

to retro-comp

I think not impossible, just a little bit awkward. Difficult to change links without removing modules. The headers for the links could be put on the bottom side of the backplane but then soldering the backplane connectors and header pins for the links is a little tricky.

I was considering a similar arrangement as links on the middle pair of connectors can allow a daisy chain using any pair of user pins, but doesn’t work with the proposed standard for IEI/IEO on n38 and N39.

I think n40 and n80 as a daisy chain would also work for BAI/BAO. Then only extended width cards could use BAI/BAO, but that doesn’t seem to me to be a disadvantage.

Sergey Kiselev

Mar 3, 2023, 5:37:12 PM3/3/23

to Mark T, retro-comp

Q1: Weak yes... I'd rather keep module to 100 mm x 100 mm (or even 100 mm x 80 mm... is anyone still using Eagle?)

Q2: Yes, add a reference to Spencer's specs

Q3: No, I never cared for low profile modules... Always looked like a waste of backplane space ;)

Q4: Yes, although, as specified before, 100 mm x 80 mm or 100 mm x 100 mm would be my preference.

Q5: Weak no

Q6: Weak no. 45 bevel is cute, but it eats up PCB space, and doesn't add to functionality. If decided on a rectangular shape, perhaps a couple of M3 holes on each one of the corners would be nice (so standoffs can be used to build a more rigid construction, say 5 mm (or 5.08 mm if we want to be imperial system compliant) from the top and left/right edges.

Q7: No. Instead, pin 1 center should be placed 1.27 mm (50 mil for fellow US people) to the right from the left edge of the board. In this case, the connector will be "centered" for 101.6 mm / 4 in board.

Q8: Still thinking :)

---

Q11: Weak yes, I like the proposal of using pins 40/80 for it

Q12: Weak no. Without looking much at the layout, I'd put them near IEI and IEO pins.

Q13: Yes

Q14: Yes, call them CPU-dependent? Extended can mean many things

Q15: Weak yes... I don't have a better suggestion

Q16: Yes. Do we have graphic designers? :)

Q17: Weak no for 0.6". It seems to tight in some cases - socketed oscillators, vertical connectors, D-sub, Mini-DIN, RJ45 modular connectors

Q18: Yes for 0.8" alternative... Maybe someone would design a backplane with both 0.6" and 0.8", e.g., 3 slots with 0.6" spacing and two with 0.8" spacing? 0.6" is really narrow for almost any kind of vertical connectors

Q19: Yes, definitely.

Q20: Kind of... I'd use top side for the ground fill and the bottom for the signals (or the opposite way)... No real need for that wide traces, especially given that we operate with CMOS logic. At the same time, having a ground plane will reduce EMI

Q21: All this discussion makes me think why wouldn't we do ECB instead :) Good quality, although a tad pricey, DIN 41612 connectors. Better pinout than RC2014... And if you fancy not buffering your bus - just don't do that :). Andrew Lynch (N8VEM), one of the people that IMHO restarted the Z80 interest among hobbyists 15 or so years ago, is now working on 100 mm x 100 mm version of ECB. A bit more modular than the original approach. Still buffered bus. Still ECB pinout / DIN 41612 connectors.

Thanks,

Sergey

Sergey

--

You received this message because you are subscribed to the Google Groups "retro-comp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to retro-comp+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/retro-comp/49d9ce0d-ccc3-462f-8c41-28ff916ecd9fn%40googlegroups.com.

Dylan Hall

Mar 4, 2023, 2:05:58 AM3/4/23

to retro-comp

On Sat, 4 Mar 2023 at 11:37, Sergey Kiselev <skis...@gmail.com> wrote:

Q18: Yes for 0.8" alternative... Maybe someone would design a backplane with both 0.6" and 0.8", e.g., 3 slots with 0.6" spacing and two with 0.8" spacing? 0.6" is really narrow for almost any kind of vertical connectors

I have a backplane that mixes 600 and 900 mil slot widths. I use the 900 mil slots for "fat" modules (memory with ZIF sockets, Raspberry Pi Zero daughterboard, Flock with ribbon cable). It looks like 800 mil would have been sufficient in hindsight.

Dylan

Steve Cousins

Mar 4, 2023, 7:36:42 AM3/4/23

to retro-comp

I've attempted to evaluate the answers to the questions by tabulating them with values of 2 (definite YES) to -2 (definite NO). Result attached.

I'll now study the comments in more detail and try to come up with a best fit proposal for all the issues. Obviously not everyone will get their first choice.

There seems to be a general feeling that we should move forward quickly even though that means leaving some uses/processors/signals unspecified.

One important point I think we need to remind ourselves of is the original reason we started this at this time: Spencer raised the issue of what an RC2014 is. Our solution, of which he seemed happy, is to call non-RC2014 products by the name RCBus. Our specification for the RCBus should not exclude existing products from using the name and meeting the specification, wherever possible. Use of the terms "Suggested" and "Recommended" essentially cover this, but I think we should recommend public designs and commercial products that use the name RCBus should clearly point out where they do not meet the recommendations in the specification.

Steve

On Friday, 3 March 2023 at 10:31:57 UTC Steve Cousins wrote:

Tadeusz Pycio

Mar 4, 2023, 8:12:59 AM3/4/23

to retro-comp

The table shows that there are three places to agree (sum of responses -2 to 2). The addition of the 3.3V lines, the location of the BAI/BAO cascade and the spacing of the slots.