Nozzles with special Rotation Modes

ma...@makr.zone

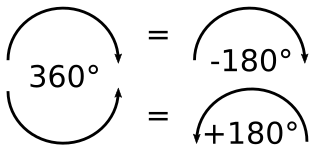

- Support machines that have nozzles with restricted angular articulation, i.e. that cannot articulate the full 360°. Machines with a bit more than 180° (add the allowance for bottom vision alignment adjustments) are now supported. Even for machines with >= 360° articulation, but still limited range (e.g. tubing that is not free-running), the mode will reduce the angular movements to a minimum.

- Optimize the performance of shared rotation (C) axes machines: Parts are picked at angular offsets that make them pre-rotated for placement, i.e. all the nozzles are subsequently pre-rotated for alignment and placement at their shared 0° position. No large rotations are therefore needed for alignment and placement (only the small and fast adjustments from bottom vision alignment offsets). The more precise pre-rotate bottom vision is therefore available without performance penalty.

- If none of the above applies, there is still an optimization available that simply picks the part at whatever rotation the nozzle currently has. Alignment and placement are then rotated relative to that. This might speed up operation if multiple nozzles pick from the same feeder, or from feeders that are close together, i.e. where the move time between picks is not enough to rotate nozzles fast enough (e.g. in LED panel assembly).

ma...@makr.zone

Hi all,

Thanks to Jason, the deployment issue was resolved. The nozzle

Rotation Mode feature is now in the testing version.

Again, please read the "Instructions for use" in the Pull Request:

!! HELP WANTED NEEDED

WITH TESTING !! 👍 💯

_Mark

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/vmqSQh9bWfE/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f2b30793-4e5b-4e68-8397-c119ef4d5bb9n%40googlegroups.com.

Mike Menci

M. Mencinger

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/fa02e459-6e33-47c0-bb09-6ea7be91f434n%40googlegroups.com.

--

Shai

M. Mencinger

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/54cdb83d-4e65-4364-829c-1bd4f84bc857n%40googlegroups.com.

ma...@makr.zone

Hi Mike,

you should follow my instructions carefully, step by step. You

missed steps 6 and 7, here:

https://groups.google.com/g/openpnp/c/taXWhONJ6zY/m/LzV6rwKyAAAJ

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAGg7SLR8OJafawKRZg9nhunZ53o0%3DL-jTiSr96GzwJtkLPcAsw%40mail.gmail.com.

ma...@makr.zone

Hi Shai,

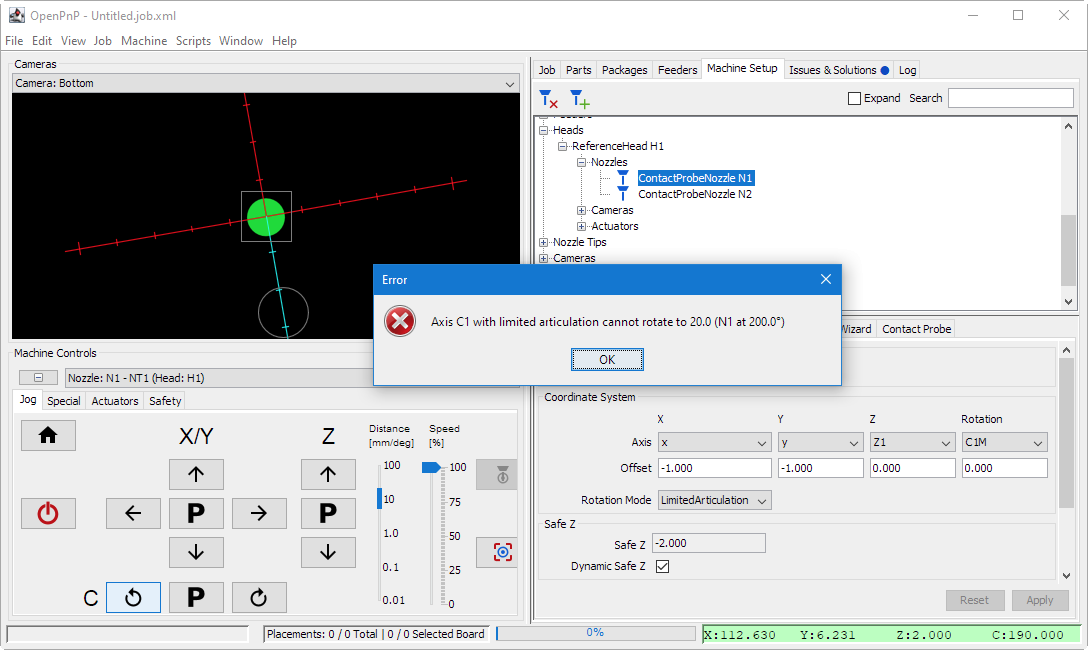

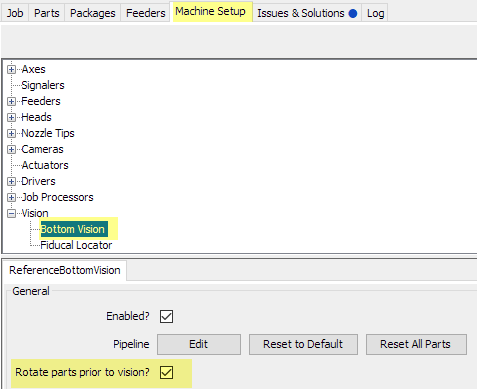

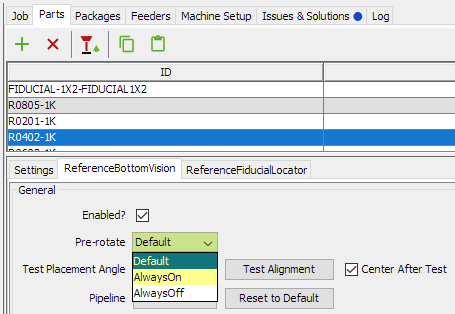

Re 1.

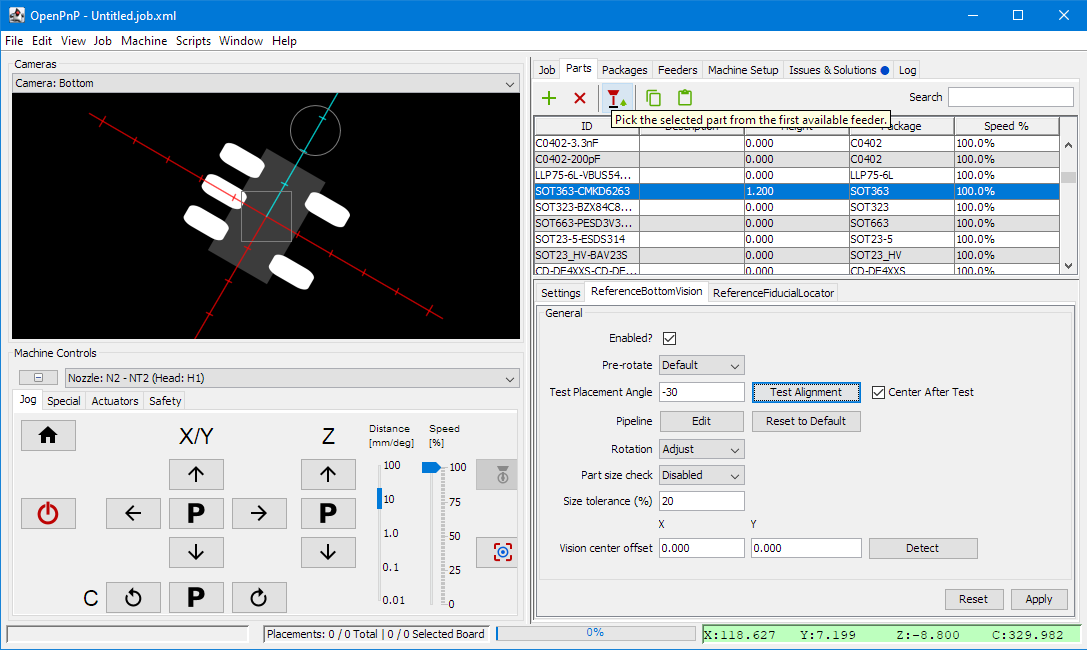

And on each part, make sure it is Default or AlwaysOn:

Re 2. and 3. :

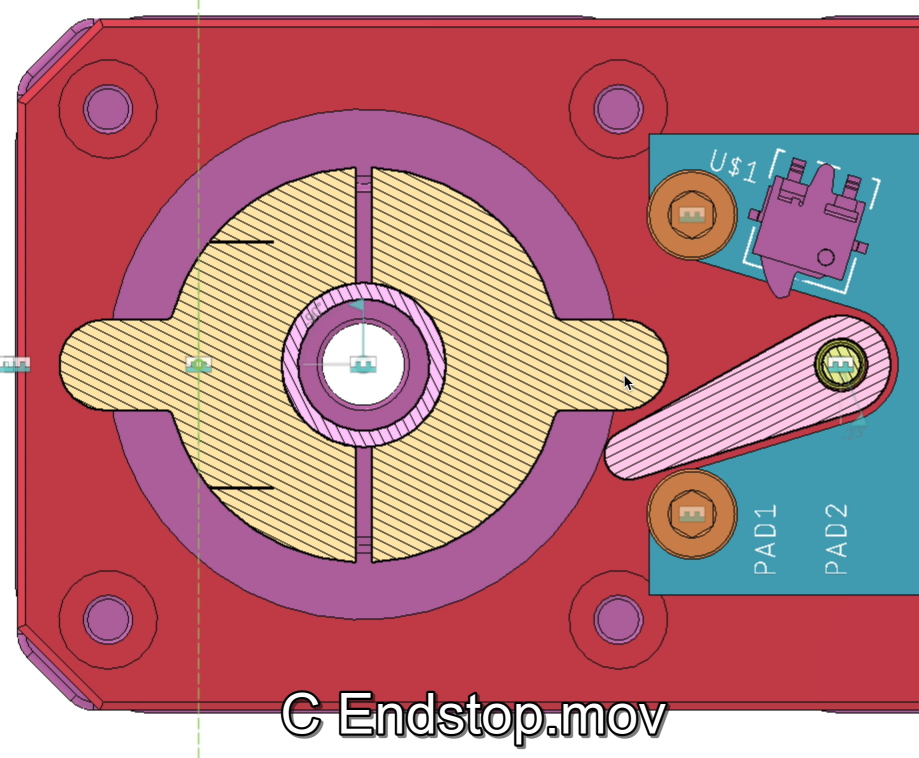

You told me and we discussed earlier, that the machine can only articulate 200°, you even made a movie of the mechanical limits:

That's why I made (priorized) the whole PR. Now you say you have

low = 0° , high = 360° ??? I don't get it. I really hope this is a

misunderstanding!

The errors will of course only appear when your articulation (axis range) is < 360°.

Re 4.

Tests: Real-world job placement tests for many feeder angles and

many placement angles. Both with and without alignment (bottom

vision). But that only makes sense, when you have <360°

articulation on the nozzle.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/54cdb83d-4e65-4364-829c-1bd4f84bc857n%40googlegroups.com.

M. Mencinger

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/6d898749-3c87-446e-6aaa-ab17a5822eab%40makr.zone.

Shai

ma...@makr.zone

> Yes I missed steps 6 and 7- But I do not understand how to do it!!

If a step is unclear, it is always best to ask back, immediately 😉 It also helps me to formulate things more clearly, in the future. As you can imagine, quietly skipping two steps will almost never result in a working machine 🤨

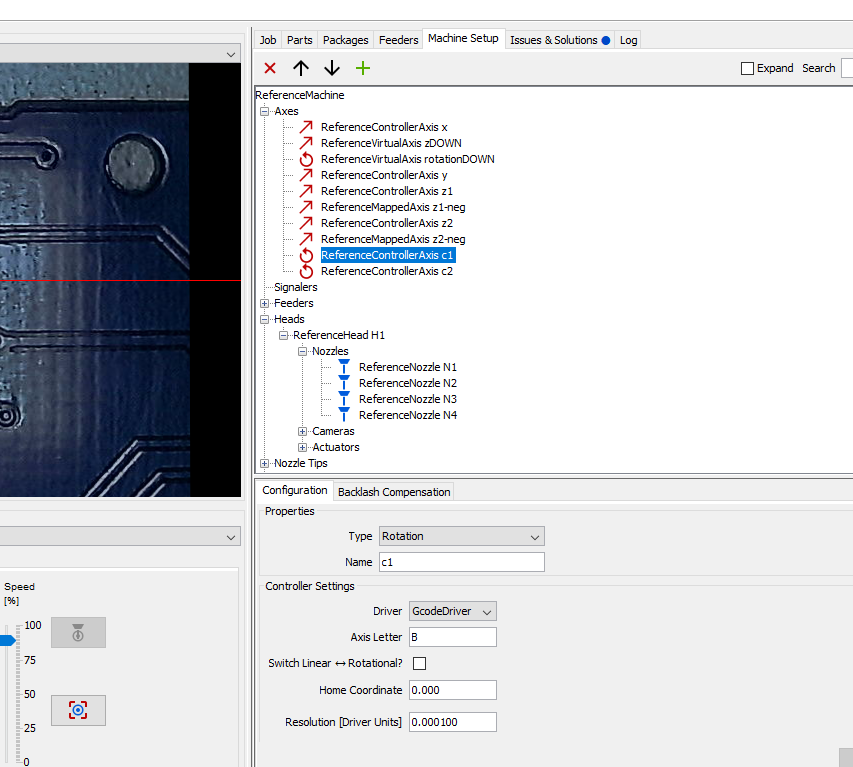

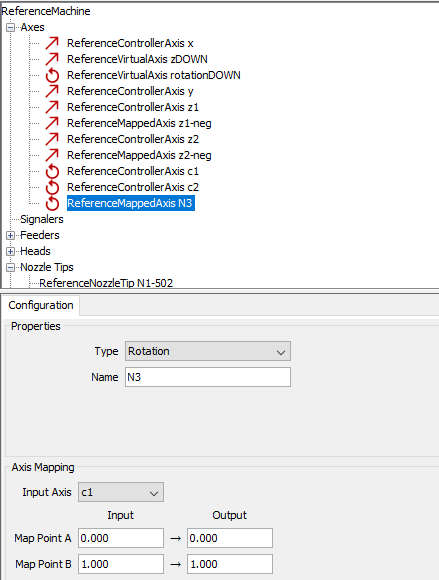

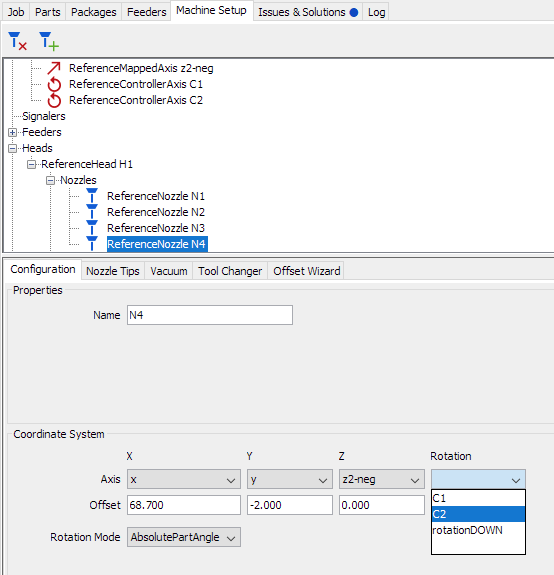

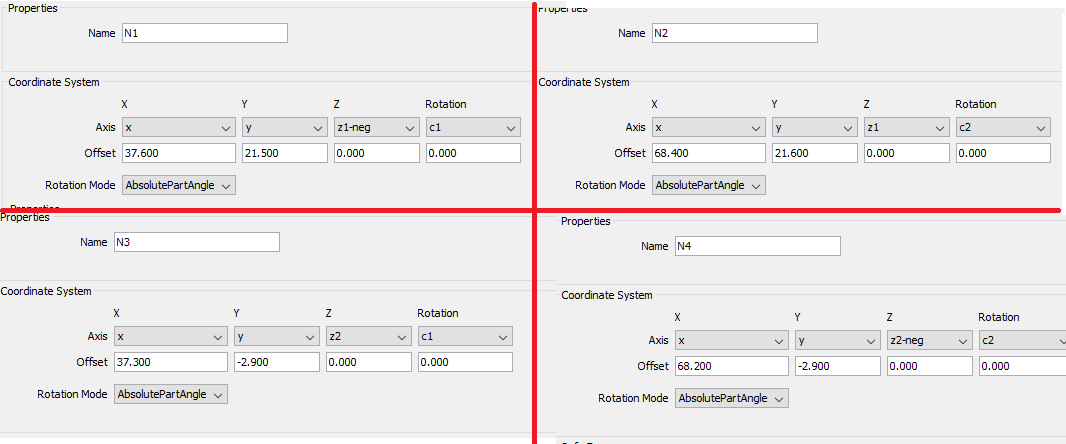

> 6. Assign axis C1 to nozzle N3 (shared with N1)

> 7. Assign axis C2 to nozzle N4 (shared with N2)

What I mean is this:

https://github.com/openpnp/openpnp/wiki/Mapping-Axes

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAGg7SLQa%2BC%3DDA4VsM_n5V3w9JQSuydBFxzs9ca2_P3KTP6X8Bw%40mail.gmail.com.

ma...@makr.zone

Ah ok. Yes, I'm not on discord (I don't like it).

But I did tell you this in PM:

> On Aug 31, 2021, at 9:31 AM, ma...@makr.zone

wrote:

> ...

> I will bump-up the angle limiting/pre-rotated pick on my

TODO list.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ffc5b223-3ac9-40f3-8423-40c1b5b0fe6fn%40googlegroups.com.

M. Mencinger

> 6. Assign axis C1 to nozzle N3 (shared with N1)

> 7. Assign axis C2 to nozzle N4 (shared with N2)

But now - I do not have Up-Down motion on A axis = C3 & C4, and no rotation on any of C1-C4 ?

Machine + trace enclosed

Please review and advise me.

Thanks

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/c9fea81b-63d8-57df-7ee1-496f5c12c031%40makr.zone.

ma...@makr.zone

What?

Please re-read all the steps and make sure they are all done right (axes and assigned letters).

https://groups.google.com/g/openpnp/c/taXWhONJ6zY/m/LzV6rwKyAAAJ

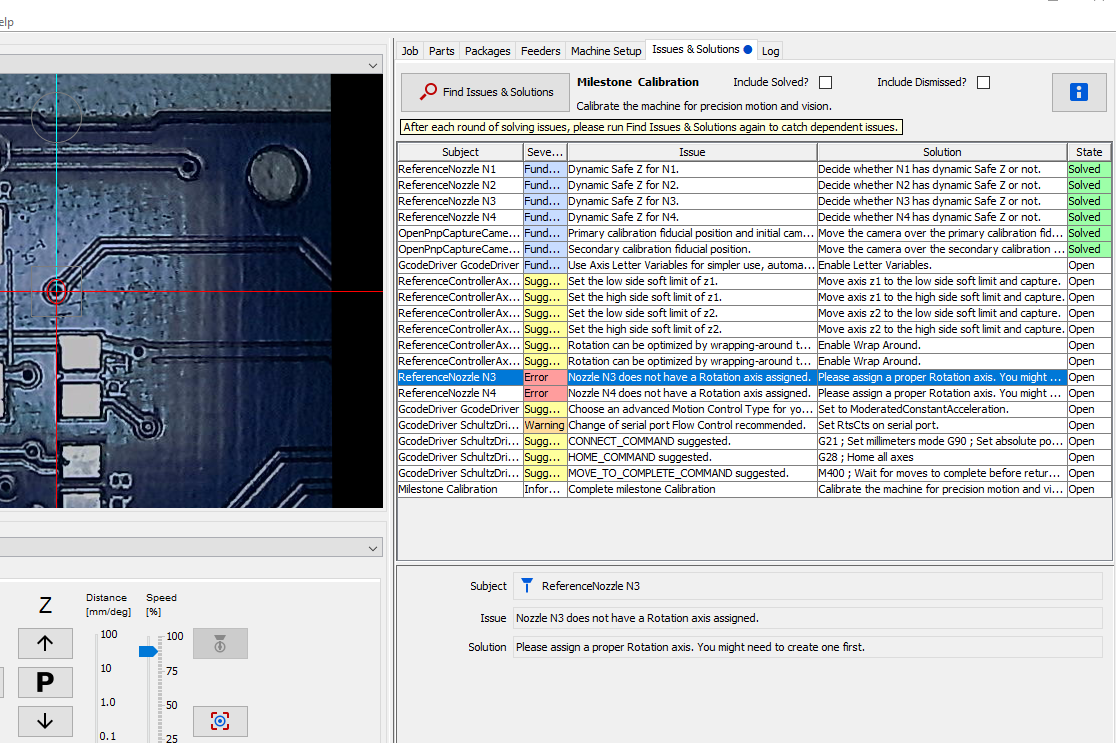

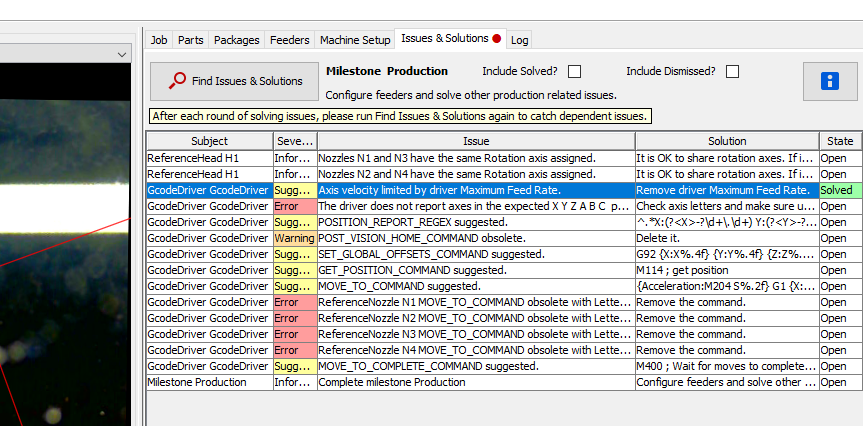

After you have done that: Press Find Issues & Solutions and

do as it tells you (where it makes sense).

You need to delete the N1, N2, N3, N4 MOVE_TO_COMMAND

(these are obsolete). Otherwise they will override the new good

command.

Also accept the newly suggested commands.

Press Find Issues & Solutions again, until

everything is resolved.

Unfortunately, I need to go now and will be away for a day 😕

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAGg7SLTYkM4WU6_pgRG8WSDyN1JE-EM-FSa01kKK3BQog1Sf5Q%40mail.gmail.com.

M. Mencinger

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/12a8fb17-8e6a-8777-8e9b-0dde40cbda5f%40makr.zone.

M. Mencinger

M. Mencinger

Mike Menci

ma...@makr.zone

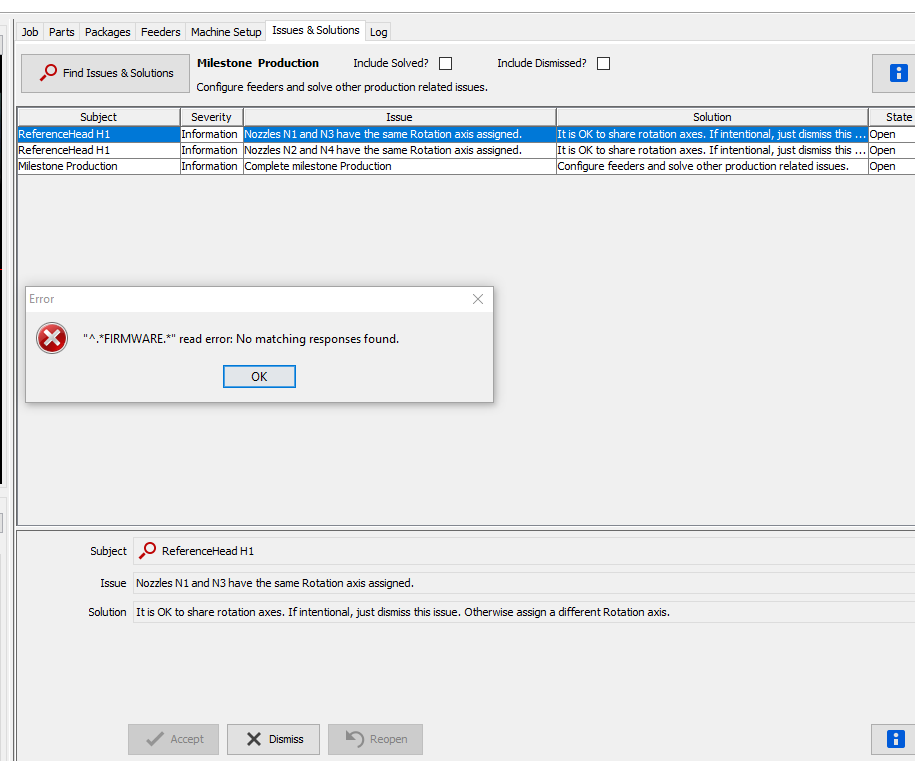

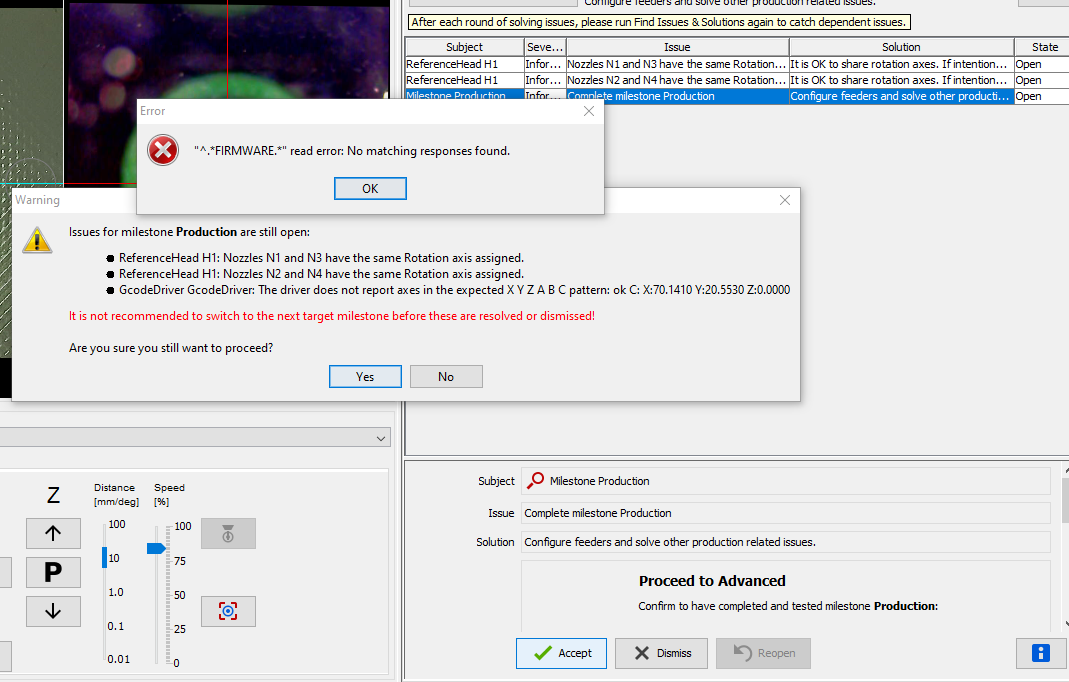

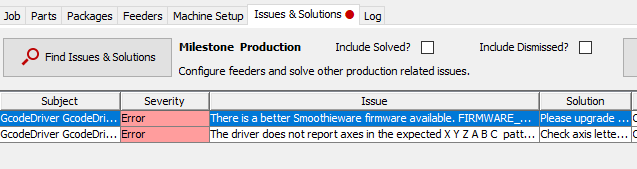

> 1) I do get in this testing version I&S following:

> And Firmware error:

> With respect to above I think this testing version

works and can be released.

I don't understand what you mean?

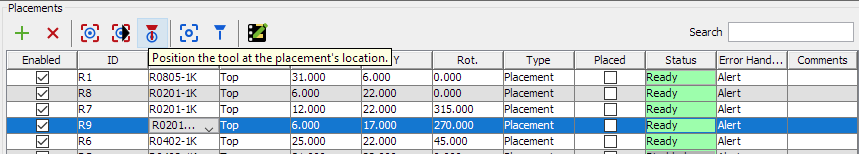

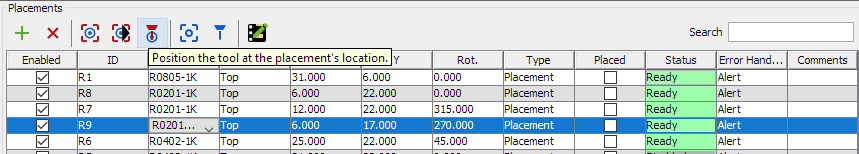

> 2) The second subject is placing of Parts to PCB location

is not working for me.

> When I use Jog I can locate all Fiducial & Job

Parts with DownCamera - location is OK.

> When I run the Job -parts are NOT placed to location

on PCB but apx. 20-40 mm off which is strange!!

What happens when you position the nozzle to the part location?

Have you used Issues & Solutions to calibrate everything, especially the precise nozzle offsets?

https://youtu.be/md68n_J7uto?t=461

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/af6b74a5-3709-4007-b066-77e16ecb86a2n%40googlegroups.com.

Mike Menci

Mike Menci

ma...@makr.zone

Re 1):

Read the message in the Issues & Solutions Error, and use the

blue  button to jump to the Wiki. It should explain everything.

button to jump to the Wiki. It should explain everything.

In short: you need to upgrade your Smoothieboard firmware to the special one I made to fix some bugs and add some feature that OpenPnP needs:

https://github.com/openpnp/openpnp/wiki/Motion-Controller-Firmwares#smoothieware

I think you already use my version for the mid-axis homing, but

you probably need a newer one.

Re 2):

Just one idea what it could be:

Check the PCB Z.

It should have a negative coordinate.

Again, test with the Positioning button.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/83585aec-ea9a-4e51-878a-ef015563ffe4n%40googlegroups.com.

Mike Menci

Mike Menci

Mike Menci

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/eb9c1525-3932-4018-a64e-f7652f22d897n%40googlegroups.com.

ma...@makr.zone

No, only in testing Version.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/9A9523E6-AE8A-409E-8C66-DB293FA95F90%40gmail.com.

Shai

mark maker

See here, and especially read the highlighted note:

Working with Limited Articulation

This section describes working with a nozzle that has a limited articulation, i.e. less than 360°, and the LimitedArticulation rotation mode set.

...

P button on the jog

controls will now move to the 90° step angle nearest to the

mid-position of a limited articulation nozzle (Note: this angle can vary, when a part is on the

nozzle, i.e. when a RotationMode offset is applied).

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ff92bec8-83e9-42e4-b1f7-2b782412015dn%40googlegroups.com.