P-No. of UNS 06626

251 views

Skip to first unread message

ilham fauzi

Feb 28, 2024, 5:13:00 AMFeb 28

to Materials & Welding

Dear Experts,

What is P-No. of UNS 06626, my client say its P No.45 but that materials simillar with UNS 06625 which is its P-No.43. Please for the advice

What is P-No. of UNS 06626, my client say its P No.45 but that materials simillar with UNS 06625 which is its P-No.43. Please for the advice

Thanks

Mostafa DAIF

Feb 28, 2024, 5:57:15 AMFeb 28

to material...@googlegroups.com

Dear all,

The P number is P42 according to ASME Boiler & Pressure Vessel Code Section IX;

Best Regards,

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/c105a43f-72c7-44b6-96e1-0e11095552a3n%40googlegroups.com.

|

| |

TAQA MOROCCO is a member of the Abu Dhabi National Energy Company Group of companies. The information contained in this communication is confidential, may be attorney-client privileged, and is intended only for the use of the addressee. It is the property of Abu Dhabi National Energy Company PJSC (TAQA) or one of its affiliates. Unauthorized use, disclosure or copying of this communication or any part thereof is strictly prohibited and may be unlawful. If you have received this communication in error, please notify me immediately by return email and destroy this communication and all copies thereof, including attachments. | ||

cyndiso yapi

Feb 28, 2024, 5:57:20 AMFeb 28

to material...@googlegroups.com

Its P-No 43 check ASME IX Table QW422 it's listed there

--

Chiranjeevi A

Feb 28, 2024, 5:57:31 AMFeb 28

to material...@googlegroups.com

Dear Fauzi,

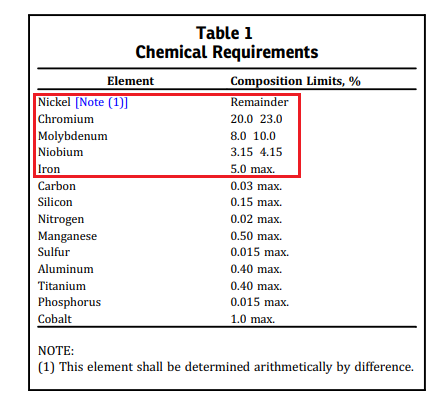

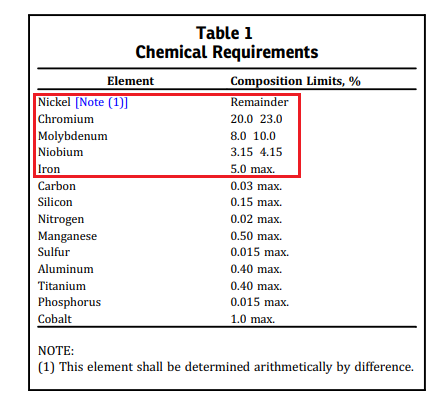

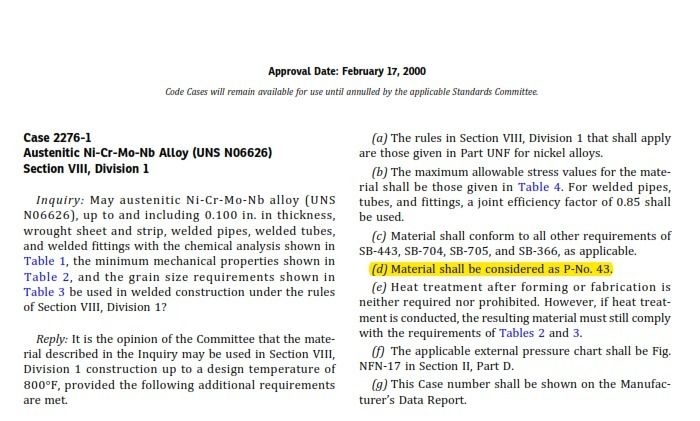

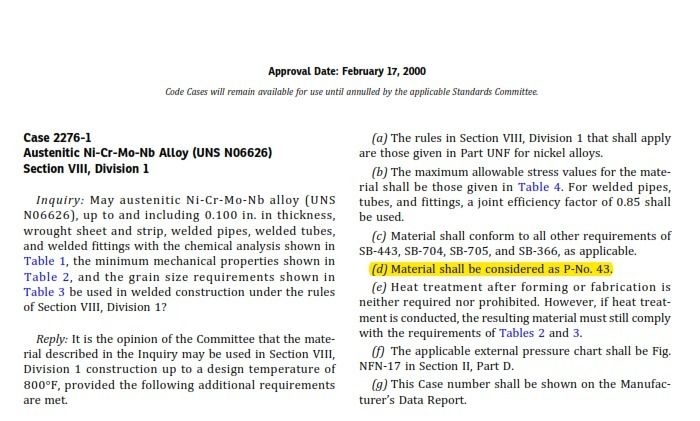

Please refer to the Limiting chemical composition in MTC & concerning ASME Code Case 2276

It should be P-No. 43

--

Chiranjeevi A

Feb 28, 2024, 8:29:11 AMFeb 28

to material...@googlegroups.com

Dear all,

Please refer to the table below for the required chemical composition of UNS 06626 under case 2276, as per the ASME BPV code cases. The P-No. for material UNS 06626 is P-43.

Please refer to the table below for the required chemical composition of UNS 06626 under case 2276, as per the ASME BPV code cases. The P-No. for material UNS 06626 is P-43.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CABktmDfFasCLFOTjL_7%2Bogw_AjzR2T_aTCeoV_oOr%3DZTNiH7kw%40mail.gmail.com.

ilham fauzi

Feb 29, 2024, 12:35:04 AMFeb 29

to material...@googlegroups.com

Dear All Experts,

Thanks all for the advice and information. I checked ASME code case 2276-1, which states that UNS 06626 can be classified as category P-No.43.

Thanks a bunch.

Thanks a bunch.

Thanks all for the advice and information. I checked ASME code case 2276-1, which states that UNS 06626 can be classified as category P-No.43.

Best Regards,

M Ilham Fauzi Pane

Welding Engineer

M Ilham Fauzi Pane

Welding Engineer

You received this message because you are subscribed to a topic in the Google Groups "Materials & Welding" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/materials-welding/SpmpHXyXbjw/unsubscribe.

To unsubscribe from this group and all its topics, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAN4%2Bm0zYAakAwiLyp2J3AqpDMTSFAhCZXPSKUY5ZFFYy2gTh8Q%40mail.gmail.com.

Vinay

Mar 25, 2024, 5:18:18 AMMar 25

to material...@googlegroups.com

PL confirm , it is UNS N06626 . Its Ni-Cr moly steel.. P-45 is correct.

P-43 is for Inconel 625 i.e UNS 06625 .

--

saleem manhappulath

Oct 23, 2024, 5:59:16 AMOct 23

to material...@googlegroups.com

Dear Team

KINDLY SUGGEST PREHEAT TEMP. MIN. AND MAX. FOR INC625

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CA%2BQ29Oh4_KzW-XOuphs89C0sJ5YSoCX%3DEUdLaNiiuK3%2BxhoB-A%40mail.gmail.com.

sridhar cn

Oct 24, 2024, 12:33:56 AMOct 24

to material...@googlegroups.com

Mr. Saleem,

Incl 625,minimum preheat temp. should be 50 deg. C and should not cross 200 deg. C. Interpass temp. should not

exceed 250 deg. C to avoid effects on material integrity and mechanical properties.

Generally, Preheat is not required for incl 625. This range will help to reduce the thermal shocks in thicker sections,

control the cooling rates, provide good weldability, and to prevent cracking during cooling. Heat-input to be controlled

to avoid grain growth and reduced toughness.

C Sridhar.

-----------------------------------------------------------------------------------------------

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAKH3OmsPa3KPgtthzTknbk_JUjcbfY0GvBGsA%3Dk3J9JgivYJQg%40mail.gmail.com.

sridhar cn

Oct 24, 2024, 10:35:37 AMOct 24

to material...@googlegroups.com

P. no for UNS 06626 (inconel 625 LCF) is P45 and UNS 06625 (inconel 625) is P43.

Though both are Ni-Cr-Mo based, 06626 has more controlled microstructure for increased fatigue resistance

at cyclic temperature conditions and is used for bellows and aerospace joints used at elevated temperatures.

UNS n06625 is used for its high strength and corrosion resistance applications.

Sridhar.

On Wed, 23 Oct 2024 at 15:29, saleem manhappulath <salee...@gmail.com> wrote:

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAKH3OmsPa3KPgtthzTknbk_JUjcbfY0GvBGsA%3Dk3J9JgivYJQg%40mail.gmail.com.

Reply all

Reply to author

Forward

0 new messages