Dissimilar thickness weldment

111 views

Skip to first unread message

meisam shokri arfaei

Feb 9, 2015, 6:00:43 AM2/9/15

to material...@googlegroups.com

Dear Experts

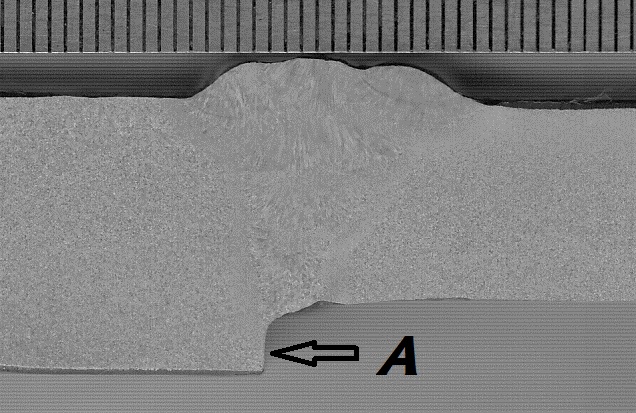

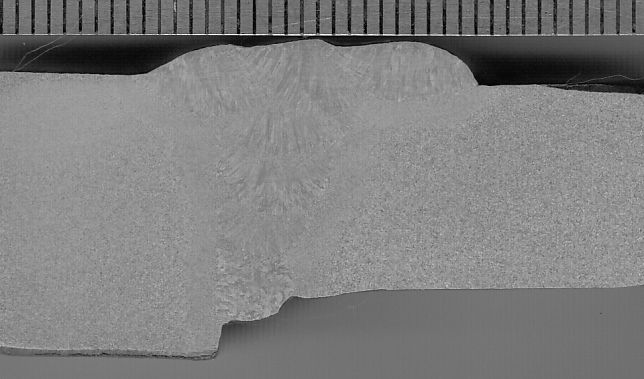

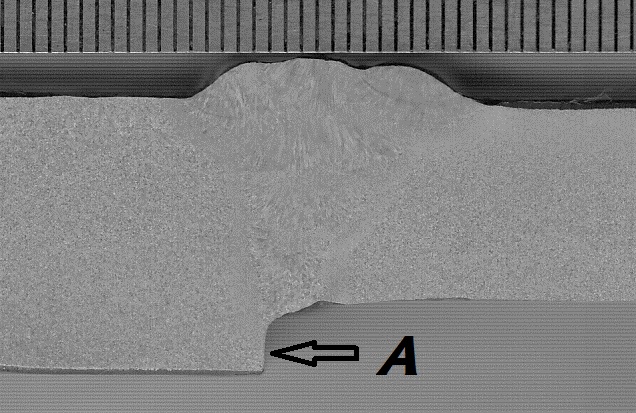

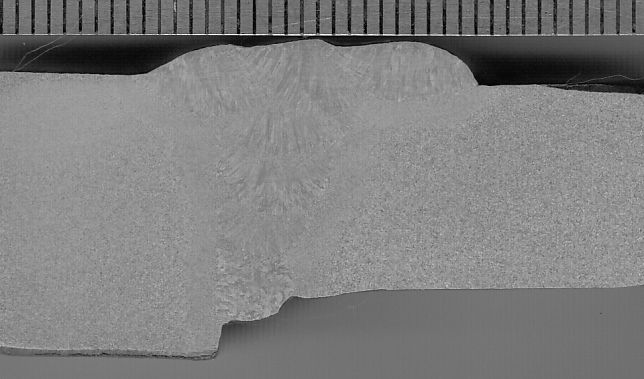

In the attached images which are macrographs of a sample that welded 8" pipe to 8" pipe (about 12mm thick to 16mm thick). The offset done by the surface allignment so the effect of dissimilar thickness is in root of the weld.

The questions are according to AWS D1.1 (consider it as a statically loaded):

1 - Is this joint design is permitted or not?

2 - What is your idea about the surface which is marked with "A" letter? It could be LOF or any other type of flaw?

Regards

--

In the attached images which are macrographs of a sample that welded 8" pipe to 8" pipe (about 12mm thick to 16mm thick). The offset done by the surface allignment so the effect of dissimilar thickness is in root of the weld.

The questions are according to AWS D1.1 (consider it as a statically loaded):

1 - Is this joint design is permitted or not?

2 - What is your idea about the surface which is marked with "A" letter? It could be LOF or any other type of flaw?

M. Shokri Arfaei

ISA-ISTS - Metallurgy Lab. Manager

ASNT NDT Level III

International Welding Engineer

Tel.: +98 21 66282127

Fax: +98 21 66282779

Mob.:+98 912 1394023

Sergio Antonio Muñoz Pinzón

Feb 9, 2015, 7:18:32 AM2/9/15

to material...@googlegroups.com

That is a poor join desing, please see fig. 2.6 for good transition thickness designs

Sergio Muñoz

IWE-IIW

http://Weld-ING.blogspot.com

Sergio Muñoz

IWE-IIW

http://Weld-ING.blogspot.com

Sergio Antonio Muñoz Pinzón

Feb 9, 2015, 8:25:47 PM2/9/15

to material...@googlegroups.com

Hello, that is a poor joint design, for tubular please se fig 2.4, and numeral 2.41. It is necesary to do a chamfer the thickness part.

Sergio Muñoz

IWE-IIW

http://weld-ING.tk

Sergio Muñoz

IWE-IIW

http://weld-ING.tk

Rems Okonkwo

Feb 10, 2015, 10:22:08 PM2/10/15

to material...@googlegroups.com

I have a different opinion on this issue. My question to Mr. Shokri will be to confirm where is this macro from, if it is from WPQR qualification, to confirm where the PQR will be applicable to. The show macro is a typical macrographic report of a 6GR welding procedure qualification for welding of TYK joints in tubular connection for examples in Jackets, Bridges Boat landing etc. this type of qualification is preceeded by a tubular mock-up

Rems Okonkwo

IWE Nigeria

--

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/c049d0f8-1ae0-4309-bcd1-8f4f0b3266f8%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Meisam

Feb 11, 2015, 4:38:07 AM2/11/15

to material...@googlegroups.com

Mr. Okonkwo

Those pictures are from 6 & 12 O'clock of a 6GR WPQR. However this is not responsibility of laboratory to discover the application of WPQR.

So a new question added to my last questions is: Do the applications of the WPQR's affect the interpretation of discontinuities? If yes, please give me your reference.

Regards

Those pictures are from 6 & 12 O'clock of a 6GR WPQR. However this is not responsibility of laboratory to discover the application of WPQR.

So a new question added to my last questions is: Do the applications of the WPQR's affect the interpretation of discontinuities? If yes, please give me your reference.

Regards

From: Rems Okonkwo

Sent: 2/11/2015 6:52

To: material...@googlegroups.com

Subject: Re: [MW:22841] Dissimilar thickness weldment

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAEpWm6tkvmN0Fkqr9hfxRuX1Oa-KFZ%2BAYjboixsqgqH%3D5WC76Q%40mail.gmail.com.

Rems Okonkwo

Feb 11, 2015, 6:01:04 AM2/11/15

to material...@googlegroups.com

Mr Shokri,

You have just confirmed that this is macro from a 6GR PQR and looking at the macro, I cannot see any problem. The point you marked as A is a code requirement for 6GR qualification. In 6GR qualification, there is no transition. It is a requirement that there shall be a minimum of 5mm difference in thickness of the pipe of the same OD. Ref AWS D1.1 para 4.13 and figure 4.28 for detail insight on this.

Like I said before, this type of qualification is not meant for girth weld in tubulars but for TYK connection.

Regards,

Rems Okonkwo

IWE Nigeria

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/54db16f7.ca43e00a.1fae.0776%40mx.google.com.

Sergio Antonio Muñoz Pinzón

Feb 11, 2015, 3:15:02 PM2/11/15

to material...@googlegroups.com

Agree with Mr Okonkwo, if this macro was taken from a 6GR coupon made for WPS qualification, chamfering does not apply.

Sergio Muñoz

IWE

Http://weld-ing.blogspot.com

Sergio Muñoz

IWE

Http://weld-ing.blogspot.com

meisam shokri arfaei

Feb 15, 2015, 4:38:56 AM2/15/15

to material...@googlegroups.com

I'm also agree with Mr. Okonkwo and Mr. Sergio about the joint detail (6GR for T, K, Y qualification), but in AWS D1.1-2010>4.13.4.1>3>b we could see a requirement for macro etch sections as follow:

(b) Thorough fusion between adjacent layers of weld metal and between weld metal and base metal.

What is your interpretation about "through fusion between weld metal and base metal"? We cann't see any fusion in "A" surface.

However I know, it is very hard or impractical to weld "A" surface specially in greater thickness differences, but the standard has no special comment about the issue.

I hope the standard add a comment that clearly introduce the minimum required depth for sides to be welded and the fusion (e.i. equal to the thinner part or etc.) in both sides.

Regards

--

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/ba58088e-4a4e-45fb-9430-5ed03445e4a1%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Reply all

Reply to author

Forward

0 new messages