Inconel 6625 Gr1 - PQR tensile requirements

Balakrishnan Srinivasan

TDK YOKESH

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/11e0e284-5a85-471d-a7d7-4dd57af59d0an%40googlegroups.com.

PGoswami

Hi

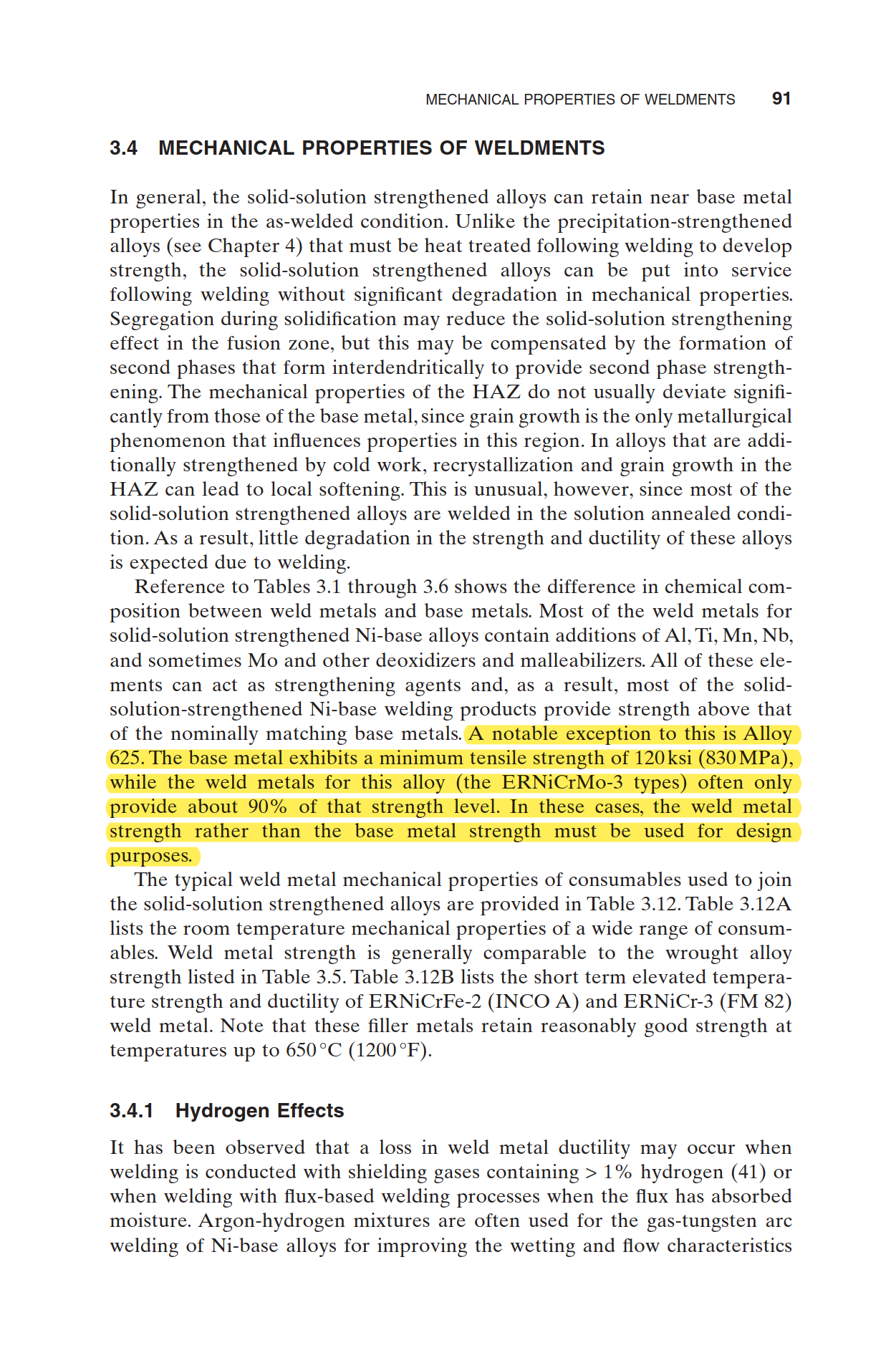

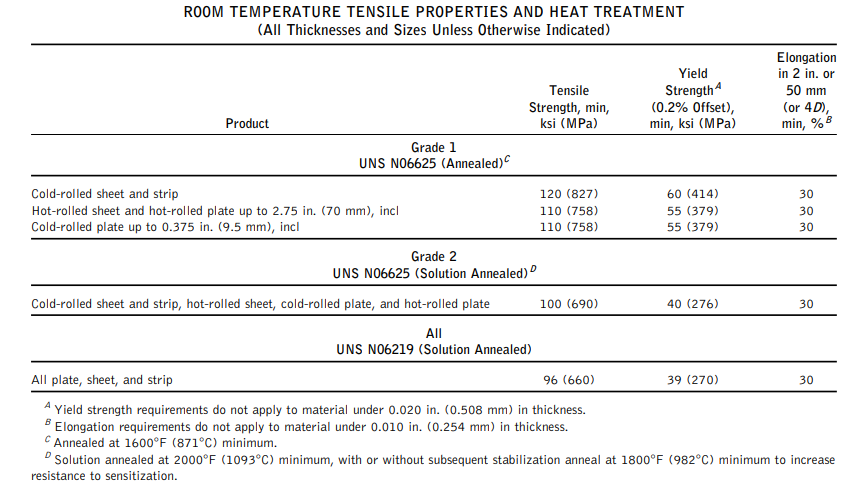

Some basic information on this alloy is provided here. If the alloy is of Grade 1 type, meeting the nominal UTS with ER-NiCr-Mo3 filler and matching SMAW electrodes may be difficult. This would NOT be an issue if the alloy is changed to Type 2,(Solution Annealed ) variety. Pleas find the relevant information as attached.

At the first place, I would like to know, what’s the rationale behind choosing Type-1 alloy(Annealed) , strength/weight reduction?

Response would be appreciated.

Thanks.

P.Goswami.P.Eng, IWE.

Independent & Consulting Welding & Metallurgical Specialist

Cell/Whasapp- 1-905-979-3232

India( Mobile) Till 10th April- 91-8981917949

From: material...@googlegroups.com <material...@googlegroups.com> On Behalf Of TDK YOKESH

Sent: March 8, 2022 6:11 PM

To: material...@googlegroups.com

Subject: Re: [MW:32958] Inconel 6625 Gr1 - PQR tensile requirements

Hi Balakriahnan,

I do have the same concern with Gr. 1 of UNS 6625 when welded with ERNiCrMo3 Kindly do reconfirm of grade again (Gr. 1 or Gr. 2) . Did you check if the filler manufacturer can retest the tensile properties and provide the as welded values? 785Mpa which is 95% of 827Mpa will suffice thd requirment. We do all weld tensile test for every batch we receive.

I hope the expert in this forum can guidw us to sort this out.

On Tue, Mar 8, 2022, 9:15 AM Balakrishnan Srinivasan <sbka...@gmail.com> wrote:

Dear Experts,

Greetings for the day!!

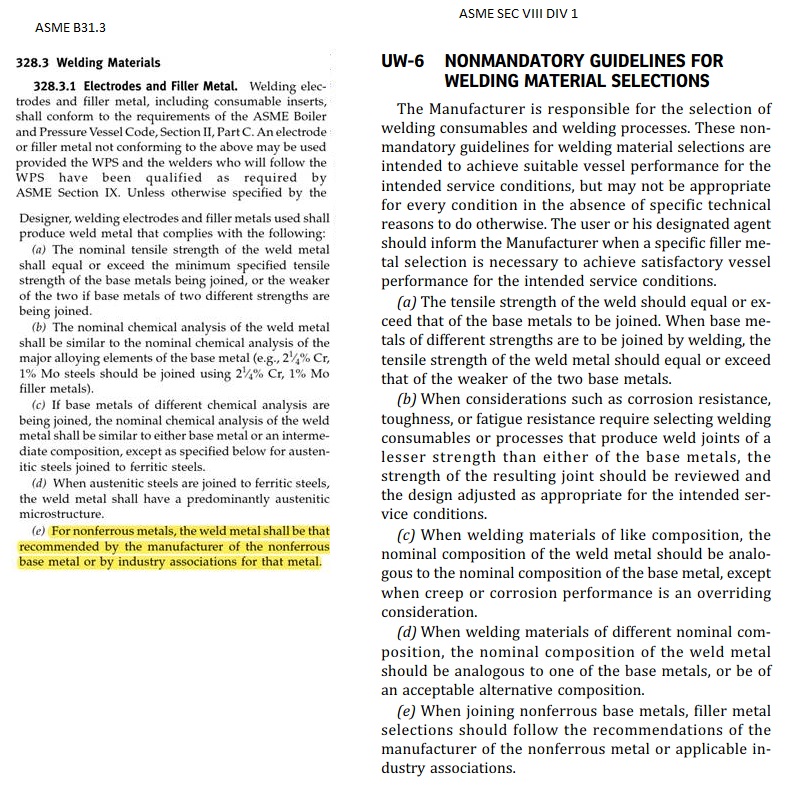

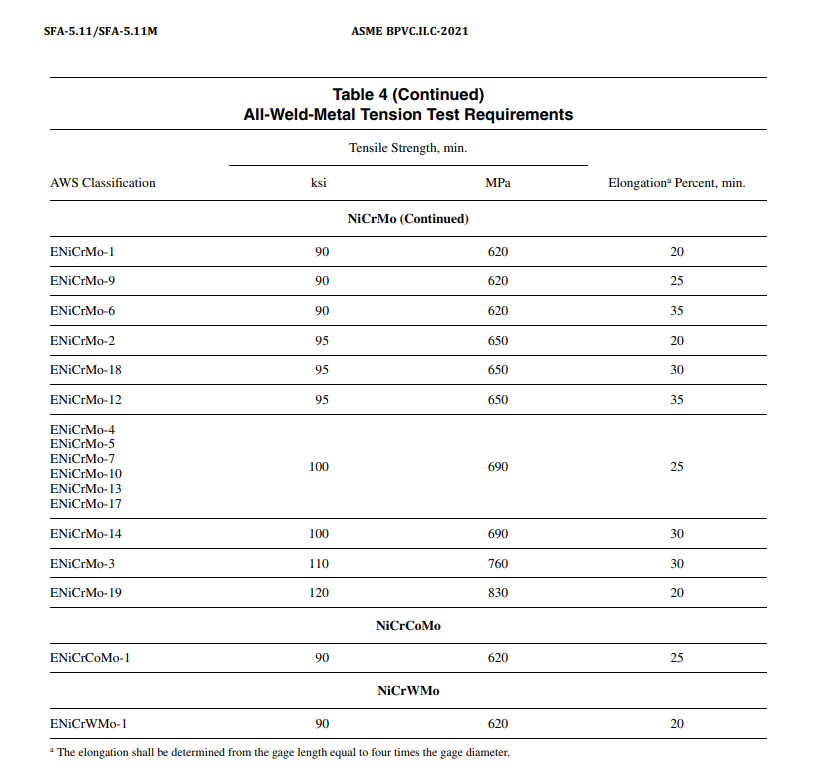

I want to quality PQR for Base material UNS N06625 GR1 which has tensile property 827Mpa, ERNiCrMo-3 Fillerwire was selected based on API582 & ASME sec II C recommendations. The filler wire tensile value is 760Mpa.

In PQR tensile test result lies in between 760-827 Mpa. The obtained tensile value is not greater than the base metal. It can't fulfill the requirement of QW-153 (ASME SEC IX).

As stated above clause QW153.1.c, " the applicable section".

Are there any provisions to qualify with lower strength than base metal?.

Reference WPSs were approved based on the tensile value being greater than filler metal tensile value (UTS) 760 Mpa MIN (sec II C), But there we could not get explanations from the originators.

Please also refer, ASME-B 31.3 clause 328.3.1 (welding materials) & ASME sec VIII div1 QW-06 (non-mandatory guidelines for welding material selection.

Thank you

Balakrishnan S

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/11e0e284-5a85-471d-a7d7-4dd57af59d0an%40googlegroups.com.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAKT-TupWJh4L258XN-f3bMO6YJYFVqvn6wWbjt7rPPqLCDkMgw%40mail.gmail.com.

Balakrishnan Srinivasan

SN

Dear experts,

james gerald

Thanks & Regards

J.Gerald Jayakumar

Sourav Bohrays

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CALi4c7OH_hUGjCE6_po8SYPADwcxOepy0W9-EgAKFhxX%2BXMQyg%40mail.gmail.com.

james gerald

Selection of suitable Alloy based on SMTS of consumable ENiCrMo3 is one option

Thanks & Regards

J.Gerald Jayakumar

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CACd6DTwXDWDpJ4OPCG89H2wgHKe_rqTaf655GJHExHxaiEZ1zQ%40mail.gmail.com.

manish kulkarni

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CACd6DTwXDWDpJ4OPCG89H2wgHKe_rqTaf655GJHExHxaiEZ1zQ%40mail.gmail.com.

PGoswami

Hi Balakriahnan,

If the reduction in Tensile strength is not acceptable by your client, you may think about the option of switching to ERNiMo-19 type of welding consumable. Here’re some salient information, which you be worth considering. You’ve to keep the process conditions also in mind.

Thanks.

P.Goswami.P.Eng, IWE.

Independent & Consulting Welding & Metallurgical Specialist

Aramco Designated Project Welding Engineer(DPWR)

Cell/Whasapp- 1-905-979-3232

India( Mobile) Till 10th April- 91-8981917949

![]()

From: material...@googlegroups.com <material...@googlegroups.com> On Behalf Of Balakrishnan Srinivasan

Sent: March 9, 2022 2:04 PM

To: material...@googlegroups.com

Subject: Re: [MW:32961] Inconel 6625 Gr1 - PQR tensile requirements

Dear Mr.P.Goswami.P.Eng, IWE.

We received the material of UNS N06625 Gr 1 (827 Mpa) only. As per the Welding consumable TC, the UTS is 772 Mpa which is higher than the requirement of ASME II C. The suitable consumable is ERNiCrMo-3 / ENiCrMo-3 as per API 582, ASME II C recommendations. But UTS of weldment lies less than 827Mpa. Some textbooks ( Welding Metallurgy and weldability of Nickel base alloys - John C Lippold) also explain that it can't be achieved. My query is any provisions in the applicable codes to allow lower base metal strength.

Thanks,

Balakrishnan S

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CACd6DTwXDWDpJ4OPCG89H2wgHKe_rqTaf655GJHExHxaiEZ1zQ%40mail.gmail.com.

SN

Jenish Mistry

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CALi4c7Nec6BfBKdCqZUGTE8EniXLawpYC1jULU%2BwC73rGa4bDg%40mail.gmail.com.