WPS from AWS to BS Standards

592 views

Skip to first unread message

Hani Al Masry

Oct 15, 2020, 9:17:19 AM10/15/20

to material...@googlegroups.com

Dear Experts

Our client is asking to convert our WPS from AWS to BS Standards

can you please advise

which BS standards we need to use

what the mean steps to be changed according to this BS

Requirement of back stip for pipe welding

Regards,

H.A

Vinoth Rajendran

Oct 15, 2020, 11:29:44 PM10/15/20

to material...@googlegroups.com

Please go through EN ISO 15609, EN ISO 15614-1, EN ISO 9606

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAKOkEzfjuGE1OGLGRz%2B7gY0syR5F8ifC9jRFWdyzzR3n7bZDXA%40mail.gmail.com.

Hani Al Masry

Oct 16, 2020, 11:50:23 PM10/16/20

to material...@googlegroups.com

how about

· BS EN ISO 15614-1 Specification and qualification of welding procedures for metallic materials — Welding procedure test — Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

what is the major changes i need to made to the current WPS to convert it from AWS to

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CA%2Ba0BHbLE%2BRtObsF4XaaMcen325c4QbBTeGs4DK5VDC%2ByeQV%2Bg%40mail.gmail.com.

Hani Al Masry

Oct 20, 2020, 10:43:14 AM10/20/20

to material...@googlegroups.com

Dear

Vinoth / Experts

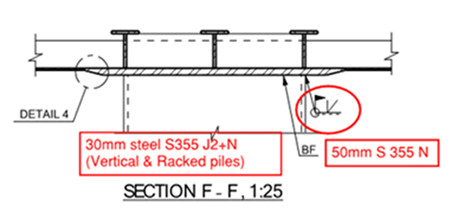

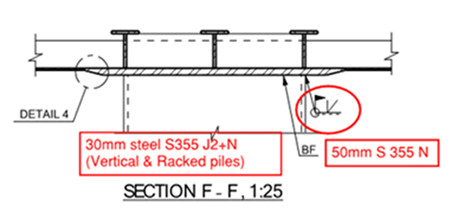

i had prepared preliminary WPS as per ISO 15614-1 so please check all parameters and inputs are ok or not

additionally , check if this cover welding positions up to 6G and steel grade S355 and thickness up to 32mm

Appreciate your fast action and assistance

Regards,

H.A

Mayur Hiremath

Oct 20, 2020, 11:19:00 AM10/20/20

to material...@googlegroups.com

Hello,

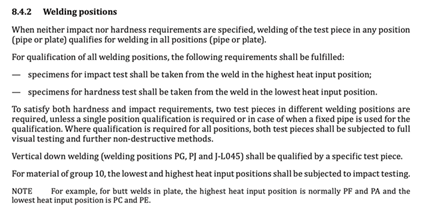

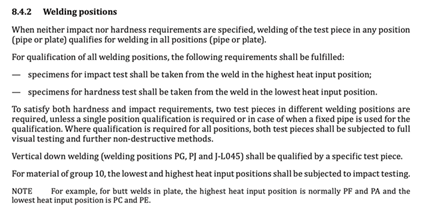

PG will not cover 6G, Refer attached Welding positions.

Also need to change the Current , voltage according to Consumable Manufacturer Data sheet as per the thickness of electrodes. Then heat input <=3KJ/mm.

When preparing pWPS parameters need to consider as per data sheet of consumable.

Regards,

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAKOkEzeQ36kA5njY74o4nv-c8QPGy7mmKGc4XywouR3mbmCFEg%40mail.gmail.com.

Hani Al Masry

Oct 20, 2020, 11:38:22 PM10/20/20

to material...@googlegroups.com

Welding position here is as per ISO 15614-1 Not AWS D1.1 as i said before and clearly mentioned in WPS and subject title

as per ISO 15164-1

This means only PG and H-LO45 need to be separately qualified , and if qualified for any position all other position will be qualified except PG and HI-LO45

My case here in over head welding (5G See below Sketch ) so PG will cover all position expect HI-LO45

For Current and voltage this values are taken already from actual WPS/PQR but according to AWS D1.1 as i told you i need only to convert it to BS EN

this Preliminary WPS as you know actual values will be recorded and written during running of final PQR

Trade name and brand is not mandatory variable here too

Hope it is clear now

Regards,

H.A

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAGQ515wG_%3DMQkEYDQDTVYdM8pW161EpHdbJ_p2MZzqUcDY8jBA%40mail.gmail.com.

Vinayak Naik

Oct 21, 2020, 10:13:12 AM10/21/20

to material...@googlegroups.com

Can any one tell me how to read this?

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CA%2Ba0BHbLE%2BRtObsF4XaaMcen325c4QbBTeGs4DK5VDC%2ByeQV%2Bg%40mail.gmail.com.

Mayur Hiremath

Oct 21, 2020, 10:36:41 AM10/21/20

to material...@googlegroups.com

Kindly send your AWS WPS with PQR, let look into details and get back to you.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAKOkEzf_kjM4EoG-WJiB%3DGJQP26NH_-bwBDkhQ5M3_%3DT3SjmPQ%40mail.gmail.com.

Reply all

Reply to author

Forward

0 new messages