funBart

| lonesock (Jonathan) | Sep 9 |

| PenskeGuy | Sep 9 |

On Tuesday, September 9, 2014 1:07:31 AM UTC-7, Andrea Pirazzini wrote:

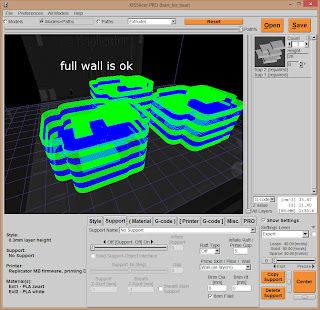

Hi JonathanLittle Bug with Wall and Skirt enabled. The path are crossing. But i think that if i use the wall why i have to use the skirt to purge the nozzle right?

| lonesock (Jonathan) | Sep 9 |

| lonesock (Jonathan) | Sep 9 |

- The Wall goes up until all extruders in use have been primed at least once

- sort of an extended Prime Skirt so that all extruders get primed

- this will probably be taller than a single layer Skirt, but shorter than the Full Wall

- The Wall goes up until there is only 1 extruder left

- so it can be used as a prime / wipe for changing extruders

- This will be taller than the previous mode, but often not the full height of the model

- User Specified height

- model dependent, so harder to fit in the UI

- would need a default value for when the Prime mode is set to this, but the model's prime height hasn't been set.

- I don't really like this one, IFF the other 2-4 modes would do everything required.

| me (funBart change) | Sep 9 (19 hours ago) |

| plexuss | 01:20 (18 hours ago) |

Plexus/brett

| me (funBart change) | 01:44 (17 hours ago) |

On Wednesday, 10 September 2014 01:20:53 UTC+2, plexuss wrote:

Hi there. so, just curious, do you want to start using kisslicertalk.com or just keep adding to this incredibly long thread? I think a forum would do Kisslicer better justice and lead to more users when they see there is a well organized community resource available to them. It's there, set up and ready to go! Also of course I can re-organize it to better suit our collective needs. Or, if you decide you don't want to use it let me know so I can take it down.

Plexus/brett

| Michael Skupien | 02:19 (17 hours ago) |

In addition, im not sure if this is possible by playing with the <nextx>/y commands, but it would be extremely nice if the print head could inteligently move fully (all extruders outside the prime skirt) away and back at the same level as the skirt to brush off any ooze from the nozzles. Currently, durring an extruder change, i cool the unused extruder below oozing temp, but there is still a small (2mm long) sting on the cooled extruder that could be brushed off. As well as a similar ammount on the extuder that just started, but this is knocked off durring priming.

I have been forced to run with cooler temps so that the extruders cool faster and only ooze a couple mm, but it is starting to cause layer adhesion issues.

Thanks for all your efforts on such an awesome software, keep it up,

Michael

| Jesper Lindeberg | 09:46 (9 hours ago) |

lonesock (Jonathan)

- Seam can happen in the middle of a straight line now (I may make this optional: "anywhere" or "prefer corners")

- Even when the slice plane is exactly on a surface, the perimeter is not blocky

- BUG: Sometimes there are some artifacts *outside the part* when the slice plane is right on a surface.

- I am starting to really dislike this bug!

- definitely check all paths before printing with this version

- regarding the Prime Skirt / Wall

- I like the idea of a possible brim on the Prime Wall...unfortunately that means I need to add another option

- I will add the second mode (go as high as the last extruder change)

- any success stories with it yet?

- regarding the forum

- I am fine with another location, but there were some really good posts / pictures, etc. on the old forum.

- I can probably get a backup of the old database. I know nothing about this...is porting to a new forum even possible?

- Will it be possible to populate whichever forum we choose with the "best of" threads from here?

- regarding sleep

- I need some

lonesock (Jonathan)

- Fixed the problem with blocky paths when the slicing plane is right on a model surface.

- Changed some code to be much more robust with good meshes, and hopefully w/ some bad ones too. (bit slower though)

- The "Inflate Raft" control sets the Prime Skirt / Wall gap too. (so can't use the prime with a raft yet)

- Fixed the bug Andrea found where an object which didn't use the same extruders as other objects on the same Z plane would have the Prime wall paths out of order (that was a fun one to find!!)

- Added the Prime "Short Wall" mode, where the Prime Wall will go to the layer of the last extruder change plus 1.

Andrea Pirazzini

Ok perfect now is working! Thanks!

lonesock (Jonathan)

lonesock (Jonathan)

funBart

Especially about <seconds>!

Desperately searching for Bugs! Can't find one! AAAAAARG!

Bart

funBart

lonesock (Jonathan)

funBart

Davide Ardizzoia

By the way, Bart, how did you fine out the new tokens ?

Brgds

Davide Ardizzoia

Bart

--

You received this message because you are subscribed to the Google Groups "Kisslicer Refugee Camp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to kisslicer-refugee...@googlegroups.com.

To post to this group, send email to kisslicer-r...@googlegroups.com.

Visit this group at http://groups.google.com/group/kisslicer-refugee-camp.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/853b3037-00e3-4fab-b9db-cd33a526b3be%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

lonesock (Jonathan)

funBart

funBart

lonesock (Jonathan)

Isaac Thompson

frozen...@yahoo.com

Say on a standing figure when printing the legs, correct example would be left leg/ right leg/ layer change/ left leg/ right leg, etc. But KS often does left leg/ right leg/ layer change/ right leg/ left leg, printing the next layer starting with the last section of the previous layer.

Andrea Pirazzini

Il giorno domenica 14 settembre 2014 17:40:19 UTC+2, funBart ha scritto:

Bart

--

You received this message because you are subscribed to the Google Groups "Kisslicer Refugee Camp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to kisslicer-refugee...@googlegroups.com.

To post to this group, send email to kisslicer-r...@googlegroups.com.

Visit this group at http://groups.google.com/group/kisslicer-refugee-camp.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/56cd746c-85e9-4be0-9703-bd4b23e1dbe0%40googlegroups.com.

EdK

It makes sense to stay on the one island and do it first for the next layer, when only considering speed.

But for the best quality, it is better, as you say, to do everything is precisely the same order each layer.

Perhaps this could be a Style choice, or change depending on the Fast/Precise setting (at a given percentage that could be selected?). It would be OK if it only stayed on the same island when Fast/Precise was set to 0%, or less than 25%, for example.

Ed Koffeman

On 9/14/2014 10:18 AM, frozen.rabbit via Kisslicer Refugee Camp wrote:

I'm still seeing what i consider a minor bug, on a layer change, KS will print on the same island/section that was last on the previous layer causing too much heat build up on that section, instead of jumping to another section/island which gives enough time for the last island to cool before the next layer.

Say on a standing figure when printing the legs, correct example would be left leg/ right leg/ layer change/ left leg/ right leg, etc. But KS often does left leg/ right leg/ layer change/ right leg/ left leg, printing the next layer starting with the last section of the previous layer.

--

You received this message because you are subscribed to the Google Groups "Kisslicer Refugee Camp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to kisslicer-refugee...@googlegroups.com.

To post to this group, send email to kisslicer-r...@googlegroups.com.

Visit this group at http://groups.google.com/group/kisslicer-refugee-camp.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/f372ad45-1a84-49b2-bcec-4e096fb97e98%40googlegroups.com.

Joris [van Tubergen]

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/5415C8EC.5060109%40kinetric.com.

Franz Scherz

garr...@gmail.com

Michael Skupien

Davide Ardizzoia

Especially with very large prints (ie.: 600x300mm), the prime skirt/wall add AGES....

Best Regards

Davide Ardizzoia

Bart

--

You received this message because you are subscribed to the Google Groups "Kisslicer Refugee Camp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to kisslicer-refugee...@googlegroups.com.

To post to this group, send email to kisslicer-r...@googlegroups.com.

Visit this group at http://groups.google.com/group/kisslicer-refugee-camp.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/72598d65-f20c-400e-9a4c-739be76ae09c%40googlegroups.com.

lonesock (Jonathan)

Bart

That should be straight-forward to do...and maybe the extra gap could be implemented as additional pillar radius. Does it really add that much time? I know it adds quite a bit of plastic, but I thought I had it running at solid speeds....I will need to check that.Jonathan

--

You received this message because you are subscribed to the Google Groups "Kisslicer Refugee Camp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to kisslicer-refugee-camp+unsub...@googlegroups.com.

To post to this group, send email to kisslicer-refugee-camp@googlegroups.com.

Visit this group at http://groups.google.com/group/kisslicer-refugee-camp.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/8cb812ef-91ed-41d4-b911-995873ccd342%40googlegroups.com.

lonesock (Jonathan)

Bart

--

You received this message because you are subscribed to the Google Groups "Kisslicer Refugee Camp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to kisslicer-refugee-camp+unsub...@googlegroups.com.

To post to this group, send email to kisslicer-refugee-camp@googlegroups.com.

Visit this group at http://groups.google.com/group/kisslicer-refugee-camp.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/90bfa503-0606-4897-9d00-e3434dda0984%40googlegroups.com.

lonesock (Jonathan)

Bart

There are 2 walls for any layer with 2 extruders active, 3 for 3, 1 for 1, etc. And they are done inside to out, that way if the outer loop's material droops (with no loop beneath it), it will catch on the outside of an existing wall, instead of dragging onto the part.Jonathan

--

You received this message because you are subscribed to the Google Groups "Kisslicer Refugee Camp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to kisslicer-refugee...@googlegroups.com.

To post to this group, send email to kisslicer-r...@googlegroups.com.

Visit this group at http://groups.google.com/group/kisslicer-refugee-camp.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/386247af-28b3-4378-894d-e5eae729207a%40googlegroups.com.

PenskeGuy

Why is the wall idea even being considered to replace the Pillar? The Pillar uses enough material as it is. That's why I'd like to adjust its size. The wall will use a ton of material. I would only use it on problem parts.

Question: The tooltip says "good for cooling small parts". How? Blocking the airflow doesn't seem like it would cool better. Further, I understood that the wall idea was to keep ABS parts warm to limit warping.

Color me confused.

@Bart

How did you get the holdoff from the part? When I try a slice, the wall is right up against the part—far too close for my liking; especially after looking at the third image in your 3:06 PM post, above. Yikes!

Matej Rozman

It would be okay though if you could make wall with birm so it would at least have some stick area to the plate, but Id still choose pillar over wall any time.

Again, supporting Penske`s wish to make prime pillar adjustable in size /diameter and user placeable. I have this on my wish list since the first time printing with pre1.5.

Best regards,

Matej

Dne četrtek, 18. september 2014 06:53:41 UTC+2 je oseba PenskeGuy napisala:

lakyrc

hopefully this is the place where you are collecting the problems with 1.5 beta. Here's one I found and maybe not known yet:

- Using 1.5 Beta Pro, 'Default Extruder Mapping' is not taken into account when generating the G-Code. Example:

- All four parameters are set to Ext 2 (T1)

- The generated G-Code still starts with:

G54

M108 T0

where it should generate

G54

M108 T1

Thanks.

Tom Tumilty

On Wednesday, 10 September 2014 13:40:20 UTC-4, funBart wrote:

The last part of the ''m not deadmy" discussion copied to be continued, as the thread got way to long.Please post only Beta related issues here, and open a new topic for other (new) issues. Browse and search first if there already posts about your question.There are as well some links mentioned in the welcome message above.Bart

lonesock (Jonathan) Mark as complete

PenskeGuy

On Tuesday, September 9, 2014 1:07:31 AM UTC-7, Andrea Pirazzini wrote:Hi JonathanLittle Bug with Wall and Skirt enabled. The path are crossing. But i think that if i use the wall why i have to use the skirt to purge the nozzle right?This post has been editedMark as complete

lonesock (Jonathan) Mark as complete

lonesock (Jonathan)

- The Wall goes up until all extruders in use have been primed at least once

- sort of an extended Prime Skirt so that all extruders get primed

- this will probably be taller than a single layer Skirt, but shorter than the Full Wall

- The Wall goes up until there is only 1 extruder left

- so it can be used as a prime / wipe for changing extruders

- This will be taller than the previous mode, but often not the full height of the model

- User Specified height

- model dependent, so harder to fit in the UI

- would need a default value for when the Prime mode is set to this, but the model's prime height hasn't been set.

- I don't really like this one, IFF the other 2-4 modes would do everything required.

So, do these seem useful to anyone? They are relatively easy to put in place (well, not the 3rd mode), and if they are at all helpful, I would like them in. *However*, if they are hard to explain well and cause more confusion than help I may not want them in.Opinions?thanks,JonathanMark as complete

me (funBart change) Mark as complete

plexuss

Plexus/brettMark as complete

me (funBart change)

On Wednesday, 10 September 2014 01:20:53 UTC+2, plexuss wrote:Hi there. so, just curious, do you want to start using kisslicertalk.com or just keep adding to this incredibly long thread? I think a forum would do Kisslicer better justice and lead to more users when they see there is a well organized community resource available to them. It's there, set up and ready to go! Also of course I can re-organize it to better suit our collective needs. Or, if you decide you don't want to use it let me know so I can take it down.

Plexus/brettMark as complete

Michael Skupien In addition, im not sure if this is possible by playing with the <nextx>/y commands, but it would be extremely nice if the print head could inteligently move fully (all extruders outside the prime skirt) away and back at the same level as the skirt to brush off any ooze from the nozzles. Currently, durring an extruder change, i cool the unused extruder below oozing temp, but there is still a small (2mm long) sting on the cooled extruder that could be brushed off. As well as a similar ammount on the extuder that just started, but this is knocked off durring priming.

I have been forced to run with cooler temps so that the extruders cool faster and only ooze a couple mm, but it is starting to cause layer adhesion issues.

Thanks for all your efforts on such an awesome software, keep it up,

Michael

Mark as complete

Jesper Lindeberg

lonesock (Jonathan)

lonesock (Jonathan)

Davide Ardizzoia

BUT

IMHO having the wall sitting on the outer edge of the raft is not extremely useful. IMHO I would think of a minimal distance between object and wall.

Best Regards

Davide Ardizzoia

lonesock (Jonathan)

Boris Camelo

frozen...@yahoo.com

Dreide

PenskeGuy

The Prime Pillar will return.

Great!

The reason for the Wall instead of the Pillar was for sequential prints. When printing sequentially, having a single pillar obviously wouldn't help much, so I went to the Wall to have a 1-prime-per-extruder-per-layer-per-model. Once that functionality was in, I was hoping this would be the 1-size-fits all solution, letting me get rid of the Pillar and any associated options. Since it seems to *not* be a solution for all the world's problems, I will add an option for the pillar again. [8^)

Could mini-pillars be generated in that case? A lot of parts, each having their own surrounding wall, would be a lot of material.

Regarding using the wall for part cooling vs keeping warm, it's kind of both. "Cooling" is too strong a word, but it does allow time where the head is not touching a small plastic island, letting it gel a bit, much like the prime pillar would. However, the wall as a whole should help the part's overall temperature stay a bit higher. IMO the ideal temperature for the entire printed part would be somewhere just under melting, so the wall seems like a win here. Of course, the placement of any fans will affect all this.

Ah, so its Contact Cooling that is what is cited. Got it. Might add that and Part Temperature Stabilization to the tooltip.

See, this is why I ask for feedback...I know full well my decisions are reasonably rational, but based entirely on my (limited) experiences. You guys are like a world-class think tank, focused directly on 3D printing problems and solutions, with the experience to back up your suggestions! [8^)

And pains in the @$$, too. :)

Davide Ardizzoia

The pull on large parts is quite strong: having more control on basement (ie: large and thick but spaced first raft layer) would be great.

Best Regards

Davide Ardizzoia

giovanni.v

funBart

The other technique would be to add the shadow of the wall to the raft computation. This has the downside of potentially having a disjointed raft, which may not even be a downside. I am leaning toward method #2 unless it proves very difficult to program.

PenskeGuy

When switching between Skirt, Pillar, Short Wall, Wall, sometimes the Wall won't come back. Other times it does, but once it goes AWOL, it's gone forever and a re-slice is necessary. Spurious. It's a great feature to not trigger a re-slice between choices unless you adjust the Inflate.

When slicing with Raft on and Pillar selected, the Raft is generated beneath the Pillar. Switching to Skirt, Short Wall or Wall and back to Pillar, the Raft under the Pillar disappears. This leaves the Pillar floating 2 layers up.

On the UI drop down, I'd suggest switching the order of Skirt and Pillar. Skirt, Short Wall and Wall are all the same path, just different heights. Pillar is a different path.

Further, why are these betas, supposedly of 1.5, numbered 1.4.6.x?

Ewald Ikemann

Am Samstag, 20. September 2014 22:09:31 UTC+2 schrieb PenskeGuy:

... Further, why are these betas, supposedly of 1.5, numbered 1.4.6.x?

This is usually made this way.

In this case "1.5" is the announcement of the new version number after the beta phase is closed.

For this is still beta and there is still work on it, the version numbers are 1.4.m.n to keep track of the development.

You can get further information here (Wiki) and here (Wiki).

Eddy

PenskeGuy

lonesock (Jonathan)

PenskeGuy

This even caught me when a user was asking a question, saying that they were using 1.5b. I DL all of the releases, as I happen to find them in these threads (not going to the Downloads page), and try them out. When the reference was to 1.5b, I went looking through the threads for a release that I missed; thinking that the 1.4.6.xx stream had been graduated to 1.5x status, is now on the way to RC and I missed its posting here. No prob. Got it now.

DDME-Marc

Hi Jonathan,

I have noticed with the release 1.4.6.9 that we are now getting blank lines when saving to gcode, not seen with releases just prior. Fortunately blank lines do not appear to cause any grief with our particular printer.

And since you are always striving for perfection I noticed a

typo in the G code section which you may want to fix.

Cheers,

Marc

lonesock (Jonathan)

- Added some code to try to make the printer not start the next layer on the same island it just finished (more of a sweep now)

- Fixed the case where the short-wall didn't go high enough (when there was only a single extruder per layer, it didn't trigger the short-wall test).

- Fixed the blank lines in the G-code when comments are suppressed (needed to leave in newlines for when the comment came after a valid command, only in the G-code includes).

PenskeGuy

Arjen

Op woensdag 24 september 2014 00:36:56 UTC+2 schreef lonesock (Jonathan):

funBart

lonesock (Jonathan)

funBart

lonesock (Jonathan)

PenskeGuy

Arjen

EDIT: attached pics, you see the problem? look at the layer heights

lonesock (Jonathan)

Bart

@Bart: I am a total idiot.

I could do the solid speed for all brim paths, or do fast outer ones, then slow down to perimeter speed close to the perimeter, just like the mirror of the regular loops. Or do all brim paths at the average of brim and solid speeds. I just want it to stick well. I guess I would default to just using the solid speed, and users can do a first layer speed limit if they desire slower. Thoughts?

To unsubscribe from this group and stop receiving emails from it, send an email to kisslicer-refugee...@googlegroups.com.

To post to this group, send email to kisslicer-r...@googlegroups.com.

Visit this group at http://groups.google.com/group/kisslicer-refugee-camp.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/87a5ba83-41a1-4326-8c45-08857dd79e6b%40googlegroups.com.

Arjen

Op donderdag 25 september 2014 17:19:03 UTC+2 schreef lonesock (Jonathan):

@Arjen: I know which cases cause that, I think. I will be working on explicitly adding raft support for under the Prime paths. For shapes with vertical walls it will often work as-is, but there are many cases where it won't.

@Bart: I am a total idiot. My mind was stuck on the prime paths, but you said "Brim", not "Prime". [8^/ I could do the solid speed for all brim paths, or do fast outer ones, then slow down to perimeter speed close to the perimeter, just like the mirror of the regular loops. Or do all brim paths at the average of brim and solid speeds. I just want it to stick well. I guess I would default to just using the solid speed, and users can do a first layer speed limit if they desire slower. Thoughts?Jonathan

Tom Tumilty

On Wednesday, 10 September 2014 13:40:20 UTC-4, funBart wrote:

The last part of the ''m not dead" discussion copied to be continued, as the thread got way to long.Please post only Beta related issues here, and open a new topic for other (new) issues. Browse and search first if there already posts about your question.There are as well some links mentioned in the welcome message above.Bart

lonesock (Jonathan) Mark as complete

PenskeGuy

On Tuesday, September 9, 2014 1:07:31 AM UTC-7, Andrea Pirazzini wrote:Hi JonathanLittle Bug with Wall and Skirt enabled. The path are crossing. But i think that if i use the wall why i have to use the skirt to purge the nozzle right?This post has been editedMark as complete

lonesock (Jonathan) Mark as complete

lonesock (Jonathan)

- The Wall goes up until all extruders in use have been primed at least once

- sort of an extended Prime Skirt so that all extruders get primed

- this will probably be taller than a single layer Skirt, but shorter than the Full Wall

- The Wall goes up until there is only 1 extruder left

- so it can be used as a prime / wipe for changing extruders

- This will be taller than the previous mode, but often not the full height of the model

- User Specified height

- model dependent, so harder to fit in the UI

- would need a default value for when the Prime mode is set to this, but the model's prime height hasn't been set.

- I don't really like this one, IFF the other 2-4 modes would do everything required.

So, do these seem useful to anyone? They are relatively easy to put in place (well, not the 3rd mode), and if they are at all helpful, I would like them in. *However*, if they are hard to explain well and cause more confusion than help I may not want them in.Opinions?thanks,JonathanMark as complete

me (funBart change) Mark as complete

plexuss

Plexus/brettMark as complete

me (funBart change)

On Wednesday, 10 September 2014 01:20:53 UTC+2, plexuss wrote:Hi there. so, just curious, do you want to start using kisslicertalk.com or just keep adding to this incredibly long thread? I think a forum would do Kisslicer better justice and lead to more users when they see there is a well organized community resource available to them. It's there, set up and ready to go! Also of course I can re-organize it to better suit our collective needs. Or, if you decide you don't want to use it let me know so I can take it down.

Plexus/brettMark as complete

Michael Skupien In addition, im not sure if this is possible by playing with the <nextx>/y commands, but it would be extremely nice if the print head could inteligently move fully (all extruders outside the prime skirt) away and back at the same level as the skirt to brush off any ooze from the nozzles. Currently, durring an extruder change, i cool the unused extruder below oozing temp, but there is still a small (2mm long) sting on the cooled extruder that could be brushed off. As well as a similar ammount on the extuder that just started, but this is knocked off durring priming.

I have been forced to run with cooler temps so that the extruders cool faster and only ooze a couple mm, but it is starting to cause layer adhesion issues.

Thanks for all your efforts on such an awesome software, keep it up,

Michael

Mark as complete

Jesper Lindeberg

PenskeGuy

Please endeavor to delete all but the minimal amount of quoted previous messages when replying; if any are included at all. Your post is less than a one-liner, yet contained 15 or more previous posts in their entirety. I lost count.

Thank you for your understanding.

funBart

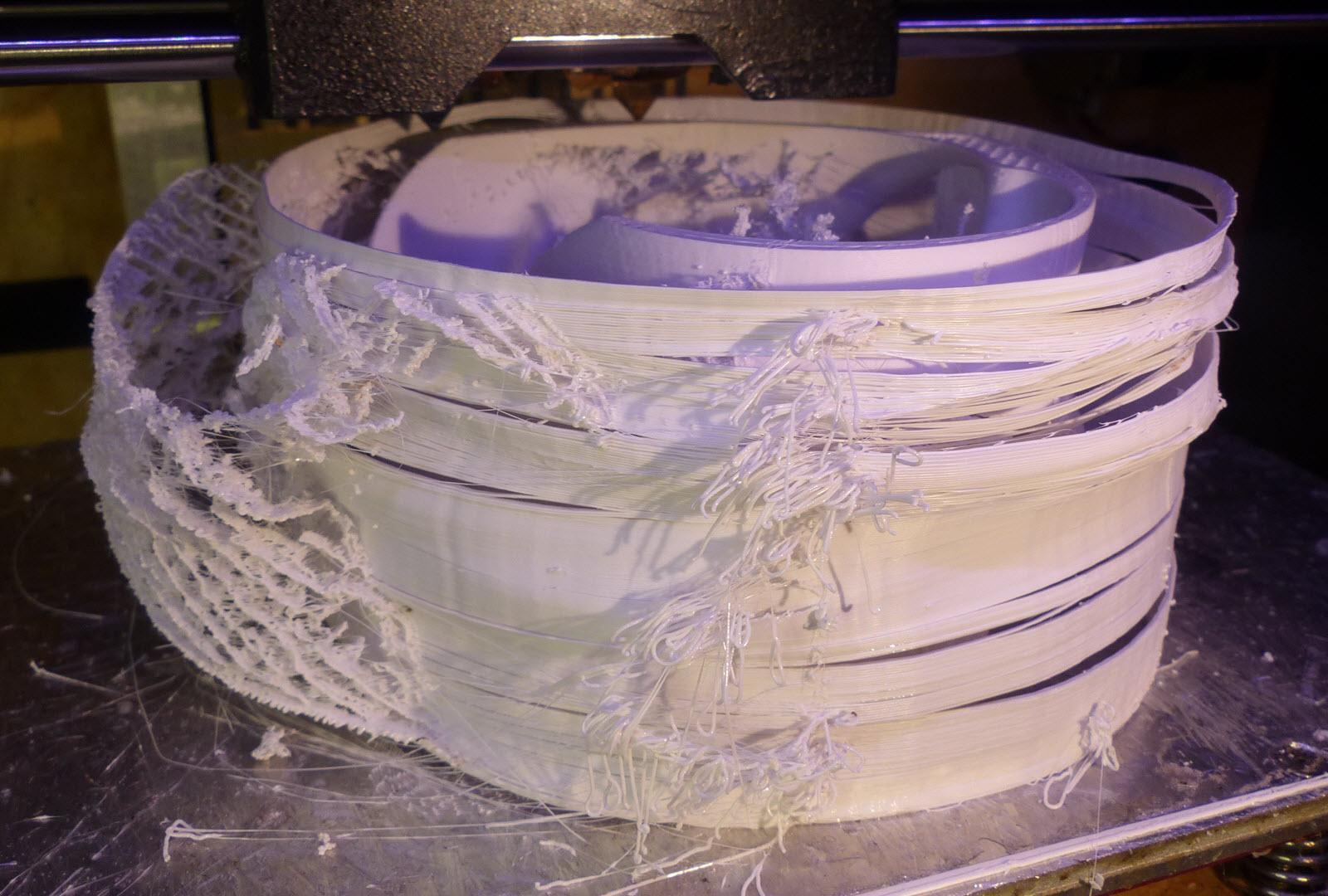

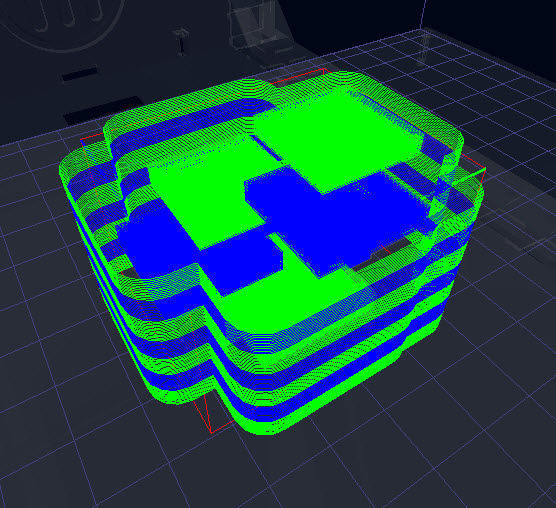

Jonathan, one more thing about the wall.see attached pictures. when dual extruding it seems like the wall layer materials are constantly switching from position. this creates a very unstable wall. especially when using PLA in combination with PVA or something like that that doesnt attach that wel to each other.

funBart BTW: I don't get why the extruders don't have their own wall (like it was with the prime pillar). Now they switch each layer: not nice for a combo of PLA and ABS, barely attaching to each other.

I didn't use one wall per extruder because it takes a lot of extra material to keep a full N walls in the case where one extruder only gets used infrequently (e.g. only at the top of a print). I can use the same behavior as the prime pillar used to, if that is deemed worthwhile. Or, Yet Another Option... [8^/

lonesock (Jonathan)

Tom Tumilty

--

You received this message because you are subscribed to a topic in the Google Groups "Kisslicer Refugee Camp" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/kisslicer-refugee-camp/UBI5gPxyc0o/unsubscribe.

To unsubscribe from this group and all its topics, send an email to kisslicer-refugee...@googlegroups.com.

To post to this group, send email to kisslicer-r...@googlegroups.com.

Visit this group at http://groups.google.com/group/kisslicer-refugee-camp.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/44c5eafe-0beb-4168-ba67-1601128bb2ff%40googlegroups.com.

Arjen

Op vrijdag 26 september 2014 13:42:55 UTC+2 schreef funBart:

PenskeGuy

Regarding the Wall, Short Wall, Pillar, in the case of single material + Support, I can see where not having the Support extruder contributing to the Wall or the Pillar would be beneficial. For the majority, I care about accuracy only on the part. Support is done at a faster speed, accuracy really doesn't matter and it can be Stacked. Having the ability to exclude that extruder from these external elements would save time and materials.

Where I noticed this was on a part that had a long stalk up the center and didn't go to full X/Y dimension until a long ways above the bed. I had Short Wall selected, but a full 2-material Wall was generated instead. This is because the Last Extruder Change was all the way up at the point where the overall dimensions were realized and Support was no longer needed. This is just a waste of material and the time to deposit it. To get around that, Skirt can be chosen; but then you don't have the warming function of the Wall if you want it.

frozen...@yahoo.com

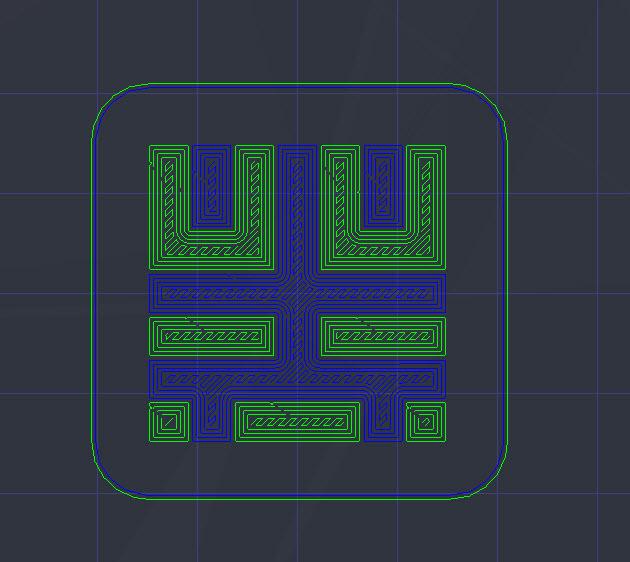

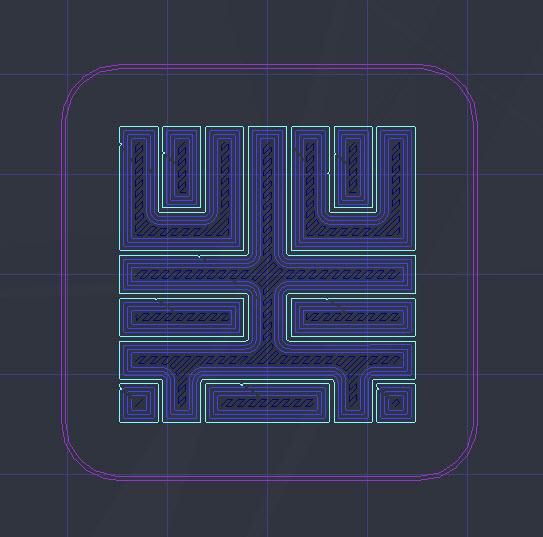

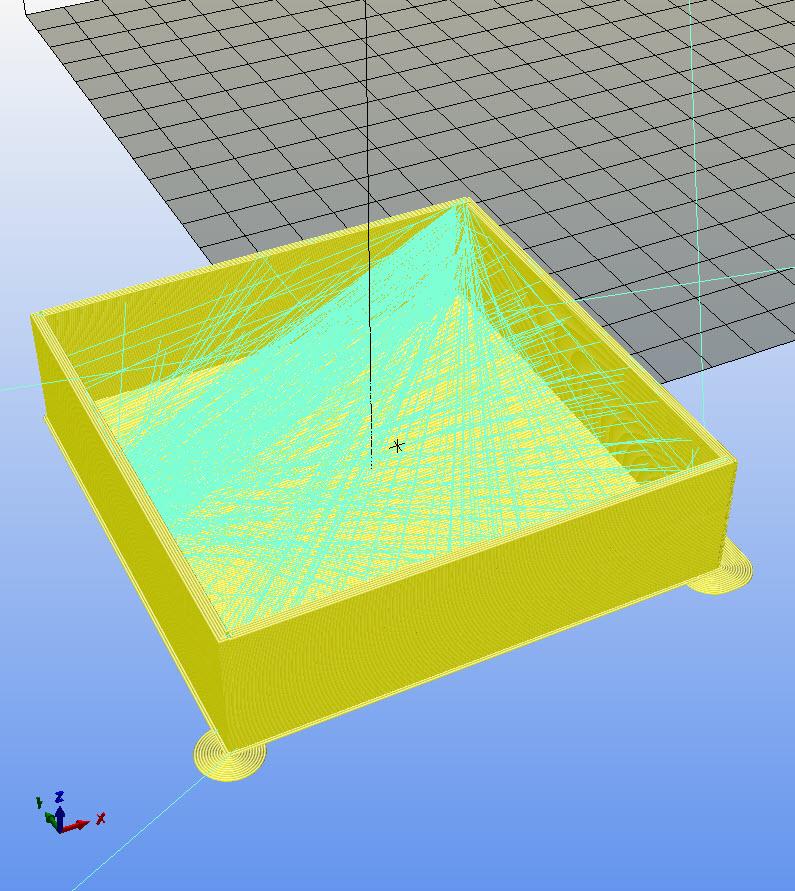

This is a box lid. 3rd image is output from KS 1.2.0.1.

PenskeGuy

Jitter == 360, I get starts distributed all over, as expected.

Bart

Is this with 1.4.6.10? Not seeing anything unexpected. Jitter == 0, I get a seam wherever the angle dial points. Move the dial close to a corner, that's where the seam goes. Jitter == 360, I get starts all over, as expected.

On Saturday, September 27, 2014 4:07:04 PM UTC-7, frozen...@yahoo.com wrote:I'm getting repeating non-random start points for loops. Printing with translucent materials, I'm getting a heavy visible seam. Would be less visible if random, or moved to a corner, but the start points are in the center of the loops. This is with Jitter set to 360.

This is a box lid. 3rd image is output from KS 1.2.0.1.

--

You received this message because you are subscribed to the Google Groups "Kisslicer Refugee Camp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to kisslicer-refugee-camp+unsub...@googlegroups.com.

To post to this group, send email to kisslicer-refugee-camp@googlegroups.com.

Visit this group at http://groups.google.com/group/kisslicer-refugee-camp.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/e11b4071-0646-4b48-9e84-abfc74a2a9c3%40googlegroups.com.

frozen...@yahoo.com

Franz Scherz

cakeller98

for Mac version search:from:lonesock filename:Macfor Windowsfrom:lonesock filename:Win64orfrom:lonesock filename:Win32for Linuxfrom:lonesock filename:Linux32orfrom:lonesock filename:Linux64

from:lonesock filename:KISSlicer

On Tuesday, September 23, 2014 1:01:45 PM UTC-7, PenskeGuy wrote:

Hear that; regarding what's important ! :) Thanks for the confirm. Just ends up being potentially confusing to new users when they go to the Downloads page and it's labelled "1.5 Beta 1" but the filename is referencing 1.4: "KISSlicer_Win32_1_4_5_10.zip". The possibilities are that there is an error in the page code or the new file hasn't been uploaded.

This even caught me when a user was asking a question, saying that they were using 1.5b. I DL all of the releases, as I happen to find them in these threads (not going to the Downloads page), and try them out. When the reference was to 1.5b, I went looking through the threads for a release that I missed; thinking that the 1.4.6.xx stream had been graduated to 1.5x status, is now on the way to RC and I missed its posting here. No prob. Got it now.

On Tuesday, September 23, 2014 9:37:19 AM UTC-7, lonesock (Jonathan) wrote:Regarding the versioning, I am using a Code::Blocks plugin for auto-versioning, and it didn't quite behave as I expected (very likely my own fault). So instead of spending time on that, I chose to use the "asymptotically approaching 1.5 numerically" scheme, and spend time on KISSlicer development instead. [8^)

Bart

I always got frustrated looking through the posts for the betas... then I realized if you search your gmail (assumign you have gmail, and are subscribed to all posts) you can search your gmail forfrom:lonesock has:attachmentand you'll find all the posts he put out. I may be subscribed to Jonathan tho... point is - it's a clean way to search. (though there may be another clean way as well, but this works well for me)

On Tuesday, September 23, 2014 1:01:45 PM UTC-7, PenskeGuy wrote:Hear that; regarding what's important ! :) Thanks for the confirm. Just ends up being potentially confusing to new users when they go to the Downloads page and it's labelled "1.5 Beta 1" but the filename is referencing 1.4: "KISSlicer_Win32_1_4_5_10.zip". The possibilities are that there is an error in the page code or the new file hasn't been uploaded.

This even caught me when a user was asking a question, saying that they were using 1.5b. I DL all of the releases, as I happen to find them in these threads (not going to the Downloads page), and try them out. When the reference was to 1.5b, I went looking through the threads for a release that I missed; thinking that the 1.4.6.xx stream had been graduated to 1.5x status, is now on the way to RC and I missed its posting here. No prob. Got it now.

On Tuesday, September 23, 2014 9:37:19 AM UTC-7, lonesock (Jonathan) wrote:Regarding the versioning, I am using a Code::Blocks plugin for auto-versioning, and it didn't quite behave as I expected (very likely my own fault). So instead of spending time on that, I chose to use the "asymptotically approaching 1.5 numerically" scheme, and spend time on KISSlicer development instead. [8^)

--

You received this message because you are subscribed to the Google Groups "Kisslicer Refugee Camp" group.

To unsubscribe from this group and stop receiving emails from it, send an email to kisslicer-refugee...@googlegroups.com.

To post to this group, send email to kisslicer-r...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/kisslicer-refugee-camp/80f05f53-ad66-451b-893d-9953d855fa1e%40googlegroups.com.

Chris Keller

funBart

https://groups.google.com/forum/#!msg/kisslicer-refugee-camp/-mW8RzwpXAg/npxL020WjTAJ

PenskeGuy

lonesock (Jonathan)

Davide Ardizzoia

Bugs are never stupid, rather the opposite, if it takes time to chase them :-)

Best Regards

Davide Ardizzoia

DDME-Marc

Tarjei Knapstad

Aggresive

lonesock (Jonathan)

- Fixed blank lines in G-code when removing comments

- Fixed typo ("adter => "after")

- Brim is now at solid speed

- Prime paths are a tiny bit thicker (25% wider than extrusion width)

- Trying to place a raft under Wall, if necessary (mostly works)

- Added version and OS to the window title

Davide Ardizzoia

Thank you!

Best regards

Davide Ardizzoia

lonesock (Jonathan)

frozen...@yahoo.com

Nothing off or tweaked from my normal slice settings, 0.1mm layer, 0.35 extrusion width, 360 jitter, Oversample 0.05, Crowning -1.

Just looks to me that loops are not randomizing start points. In the wall_test.stl, start points are also not very jittered for the perimeters either when looked at layer by layer, in Repetier.

Results are from latest beta 1.14, same with last beta, but is a clean slice with 1.2.0.1. Test these .stl's, I can send gcode and ini's later if you don't get the same results.

Edit: Did an ini file check by creating a new KS folder with no ini files, only changed jitter to 360 in sample style settings and I get the same center heavy start points. Start points are not exactly in center but more like jitter is only set to 30 or 45.