RE: [RDG-Hack] Re: 3D printing and Laser Cutting of Medical Shields

Alex Gibson

Copying TVRRUG members on this discussion of 3D printing medical shields locally…

As Emil mentions, the crucial thing is that it’s possible to make parts that will actually be usable in a clinical setting IE sterile or able to be made so, in quantity, and FAST – we expect mass production to ramp up soon, so this is an operation that will have a short life then be disbanded, but there will be a short term gap to fill which could be life saving.

With any community effort there is potential for many cooks so I’ve kept my powder dry so far but this initiative from University of Reading School of Pharmacy is well placed with contacts in government and at RBH.

A great starting point would be to confirm how many of us have printers able to print the attached part, repeatedly with *reasonable* reliability, and are willing to loan them to be operated by others in a suitable location.

Here are the instructions:

https://www.prusaprinters.org/prints/25857-prusa-protective-face-shield-rc2

I’ve set up a Google sheet to collate info about who has what printers with what properties available – please add info here!

https://docs.google.com/spreadsheets/d/13LWV3yWP8m0KFVF7P5dm83Uhp2HIuyTj2e2a41xC2_0/edit?usp=sharing

You could separately email me your contact details, stored for this purpose ONLY – to me al...@alexgibson.net

This is not a commitment to do ANYTHING right now – just to check what printers are potentially available…

Please suggest to me any edits that should be made to the form itself. I have left off contact details for data protection reasons and location as I think a usable printer is worth collecting anywhere locally – please let me know if you are OUTSIDE Berkshire, Oxfordshire, Hampshire, Buckinghamshire?

There may be other ways to contribute including maintenance, training of operators, remote or onsite support – right now just focusing on the printers we can cluster in the very near future.

If you also happen to have a laser cutter – please email me the specs and I can collate this too!

Kind regards,

Alex Gibson

@alexgibson3d

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

From: reading-...@googlegroups.com [mailto:reading-...@googlegroups.com] On Behalf Of Emil Jonasson

Sent: 21 March 2020 20:25

To: rLab / Reading's Hackspace

Subject: [RDG-Hack] Re: 3D printing and Laser Cutting of Medical Shields

Hi Al,

If you can find this out, please let us know. I would happily get involved in organising this for the Reading area - I may only have one 3D printer but I'm working from home so could run it all day if it helps!

Alex,

We could also get the TVRRUG group involved - with most of us being home (and with out printers) we could churn out hundreds of the things if we figure out a good procedure for keeping them hygenic...

Best,

Emil

Den lördag 21 mars 2020 kl. 13:46:34 UTC skrev Alexander Edwards:

Dear rLab

There is in fact an now URGENT APPEAL from local hospitals for FACE SHEILDS. (and other PPE)

"

Face protection is an urgent problem.

We are desperate for Single use face visors (or any sort of face visors).

"

I am in process of finding out if they can make use of carefully produced ones rapid fabricated by local teams - with the Prusa design in mind. There are other similar designs out there.

I am happy to help to refine the specification from the medical manufacturing perspective. It would be great to understand who locally is best placed to laser-cut (or otherwise rapidly produce the clear shield) and also 3D print the headband. We must have a number of local 3D print farms.

We can do this on an individual scale - for example the University has at least 2 laser cutters, plus 4-5 3D printers. We have staff who can help some with pharmaceutical manufacturing expertise. We have clinical trial suite set up for clean work, and also a food manufacture plant that could be adapted for aseptic assembly. But it would be far better to use local manufacturing sites as it will be easier to quality-control production conditions.

There will be support for the hospital/NHS with respect to procurement processes, distribution, etc.

Let me know if anyone can help, or knows who can help.

Thanks,

Al Edwards (University of Reading School of Pharmacy)

On Thursday, 19 March 2020 22:54:32 UTC, Emil Jonasson wrote:

Came across this on Josef Prusa's site. Given that the Covid19 pandemic is starting to hit the UK hard (and London especially) maybe we can help by making Medical Shields even if hacking together a Ventilator is a bit much at the moment?

They have released the designs online, and only 3D-printers and laser cutters are needed.

Best,

Emil

--

You received this message because you are subscribed to the Google Groups "rLab / Reading's Hackspace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to reading-hacksp...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/reading-hackspace/14b969ed-2d5c-45fb-a6e7-1e8366e345b9%40googlegroups.com.

Alex Gibson

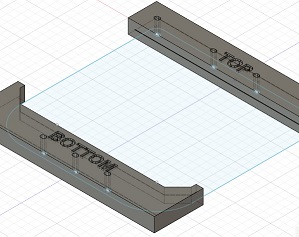

All – I have attached an updated version of the Prusa headband STL from David Price – this is NOT a change to the design in any significant way. It fixes an issue where the original part does not sit flush to the build bed on all slicers on import. THIS is the one to use for testing your machine…

I am going right now to pick up a stock of A4 ring binder front and rear plastic sheets – a good source of the right sort of plastic. I’ve got acetate sheets already in stock, and another rLab member has some A3 ring binder covers either in stock or incoming.

Al

- Yes, thanks for updating! Completely agree that Face shields are the way to go.

- I still think that if the university has a canteen area this would be ideal – many printers on many long benches, with space between them and cleanable surfaces will be good.

- The power requirements are not outrageous - in terms of power density most modern offices could do the same.

- I am asking a friend about one possible local space, will update when I’ve had the conversation.

Emil-

- Thanks still for adding it! – in my opinion the TVRR machines are capable, and as we have potentially many of them, they are a known quantity. If we are limited for space they would not be as productive as some other machines as to achieve a useful output they’d need to be run more slowly, but they are (or can be made to be) very reliable (I can fix them until they are and have many spares!!). Unless you’ve eliminated it from yours they do have a small amount of wood in their construction – but we could quickly make alternate parts to eliminate it.

- I don’t know that we really need a PM software tool right now, but thanks for the offer!!! Our needs are fairly simple, and right now a space to operate is a clear stumbling block.

I’m in touch with Andy Harris (copied) who is already printing Prusa shields on his Mark 3, he even has a laser cutter at home, but needs the sheets, which I have and will pass on to him…

Enzo – I saw the Decathlon face mask conversion – I have one reserved and will collect today or tomorrow morning. Looks great. Not sure I’d want to treat it as ‘disposable’ so cleaning options…?

Alex Gibson

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

From: reading-...@googlegroups.com [mailto:reading-...@googlegroups.com] On Behalf Of Emil Jonasson

Sent: 22 March 2020 10:27

To: rLab / Reading's Hackspace

Subject: [RDG-Hack] Re: 3D printing and Laser Cutting of Medical Shields

Hi Al and Alex,

So it seems that my printer is a bit rubbish compared to others in the spreadsheet, but I'l still really like to help.

It seems to me that there are several different conversations which need to be had at once If we are going to make this happen we will need to organise ourselves a bit more. Would you all mind if I created a project on a productivity/project management site such as ClickUp? That way we can define different areas for people to work on, people can volunteer to sirt specific things out, there is a chat/forum functionality etc. It's also free for unlimited users (they just lock some Premium fetures behind a paywall, but it's great anyway).

Best,

Emil

Den söndag 22 mars 2020 kl. 07:40:05 UTC skrev Alexander Edwards:

An update: It's both clear that WHO guidance reccomends using disposable FACE SHIELD i.e. clear plastic visor as secondary protection over goggles and mask/respirator. It's also clear that local NHS has not got enough of these so many staff are working without them.

Unlike masks/respirators/ventilators that require more sophisticated engineering to get right (but are still very worthy targets), making these FACE SHIELDS can be done immediately and locally, probably at significant scale.

A major help would be to find a suitable clean and clear space for production and assembly. I am trying to find this within the University but it's not straightforward.

Several people agree that a single clinically supervised assembly location for sterililsation and distribution is vital. Anyone who can think of other locations, do so. It needs to be clean, with power supply for print farm, plenty of handwashing facilities, space to set up assembly work flow. Not obvious to me what this would be!

As soon as this location can be confirmed, we must form a core team and make sure there is a standardised production and assembly. At that point, 3D printers, plastic film, filament etc will be needed in unknown quantities. Bag sealers with supply of large bags might be ideal for packaging after sterilisation.

Distribution then needs sorting out because we can't just drop off random FACE SHIELDS at random hospitals or GP practices.

What we've seen with COVID-19 testing is that there are VERY MANY offers of help, but only a few people get the offer taken up, usually the closest or the people with equipment/reagents that happens to match the system. So, in advance, my apologies to anyone offering to help who ends up feeling their offer wasn't heard!

Also, we really hope central supplies will reach everyone very soon, so this could be something set up and then shut down very quickly, if we are lucky it will just fill a temporary gap in supply chain.

Al

On Thursday, 19 March 2020 22:54:32 UTC, Emil Jonasson wrote:

Came across this on Josef Prusa's site. Given that the Covid19 pandemic is starting to hit the UK hard (and London especially) maybe we can help by making Medical Shields even if hacking together a Ventilator is a bit much at the moment?

They have released the designs online, and only 3D-printers and laser cutters are needed.

Best,

Emil

--

You received this message because you are subscribed to the Google Groups "rLab / Reading's Hackspace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to reading-hacksp...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/reading-hackspace/ba77cf53-af29-44c8-ba9c-ec211bca069d%40googlegroups.com.

Malcolm Napier

--

---

You received this message because you are subscribed to the Google Groups "TVRepRapUG" group.

To unsubscribe from this group and stop receiving emails from it, send an email to tvreprapug+...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/00a301d60038%249d064250%24d712c6f0%24%40alexgibson.net.

daprigoo

As far as I can tell you need three elements;

- The "fixed" version of Alex's face shield

- The "bottom_reinforcement.stl" from Prusa's original fileset

Combined these took 2h30m on my Prusa Mk3 with .3 layers, 3

perimeters and PLA. PET-G should take the same amount of time, I

would probably speed things up after the first couple of layers to

shorten the run.

You also need the stencil to cut the holes (normal A4 punches are not spaced correctly);

- https://www.prusaprinters.org/prints/26154-stencils-for-protective-face-shield-work-in-progre

this is designed for drilling 0.5mm acetate while presentation

acetates could simply be punched. Unfortunately the holes don't

match any paper punches I have so it will need to be a case of

stacking a few then drilling.

david

--

---

You received this message because you are subscribed to the Google Groups "TVRepRapUG" group.

To unsubscribe from this group and stop receiving emails from it, send an email to tvreprapug+...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/00a301d60038%249d064250%24d712c6f0%24%40alexgibson.net.

ETJonasson

To unsubscribe from this group and stop receiving emails from it, send an email to reading-...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/reading-hackspace/ba77cf53-af29-44c8-ba9c-ec211bca069d%40googlegroups.com.

--

---

You received this message because you are subscribed to the Google Groups "TVRepRapUG" group.

To unsubscribe from this group and stop receiving emails from it, send an email to tvrep...@googlegroups.com.

Alex Gibson

Good news is it appears we have a suitable venue at Green Park…!

Please add to the Google sheet any machines you’d be willing for us to operate there?

Cheers,

Alex Gibson

+44 7813 810 765 @alexgibson3d 37 Royal Avenue, Reading RG31 4UR

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

To unsubscribe from this group and stop receiving emails from it, send an email to tvreprapug+...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/50caccb5-8321-43dc-9a3e-6cfcec01cb6b%40googlegroups.com.

Alex Gibson

Very awesome Andy – and I love the colour J

Al is heading into Rymans to buy up their stock of comb binder covers…

Cheers,

Alex Gibson

+44 7813 810 765 @alexgibson3d 37 Royal Avenue, Reading RG31 4UR

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

From: Andy [mailto:an...@thirtover.com]

Sent: 22 March 2020 14:58

To: daprigoo; tvrep...@googlegroups.com; Alex Gibson; reading-...@googlegroups.com

Subject: Re: [TVRepRapUG] RE: [RDG-Hack] Re: 3D printing and Laser Cutting of Medical Shields

Hi there.

I have successfully made two full versions of the Prusa RC2 face shield with PET visor sheets.

I have three more frames left and awaiting more visor sheet.

I have these printers:

Prusa i3 Mk3

Prusa Mini

ADMG Zedmaker Mini -- which will probably go to Alex Gibson for management.

I believe the first two printers could could output 6 per day.

Regards

Andy

mikethebee

Alex Gibson

Hi Mike

Funny you should say that – I have one of these, and have been in touch with the Reading branch of Decathlon, they are shut but I have a mobile number to procure if needed.

I have zero bandwidth as today I’m putting my entire print farm on a Reading Bus to Green Park…!!!

Would you be able to properly read up on how this modification is made, what ‘vitamins’ are needed, and maybe test print a piece please????

Alex Gibson

+44 7813 810 765 @alexgibson3d 37 Royal Avenue, Reading RG31 4UR

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

--

---

You received this message because you are subscribed to the Google Groups "TVRepRapUG" group.

To unsubscribe from this group and stop receiving emails from it, send an email to tvreprapug+...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/92127e77-127a-4874-905b-529c71cc4ad2%40googlegroups.com.

Richard Ibbotson

Hi Mike

Funny you should say that – I have one of these, and have been in touch with the Reading branch of Decathlon, they are shut but I have a mobile number to procure if needed.

I have zero bandwidth as today I’m putting my entire print farm on a Reading Bus to Green Park…!!!

Would you be able to properly read up on how this modification is made, what ‘vitamins’ are needed, and maybe test print a piece please????

<image001.png>

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/002201d60289%2441cc9530%24c565bf90%24%40alexgibson.net.

mikethebee

On Wednesday, 25 March 2020 09:40:15 UTC, Alex Gibson wrote:

Hi Mike

Funny you should say that – I have one of these, and have been in touch with the Reading branch of Decathlon, they are shut but I have a mobile number to procure if needed.

I have zero bandwidth as today I’m putting my entire print farm on a Reading Bus to Green Park…!!!

Would you be able to properly read up on how this modification is made, what ‘vitamins’ are needed, and maybe test print a piece please????

Alex Gibson

+44 7813 810 765 @alexgibson3d 37 Royal Avenue, Reading RG31 4UR

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

From: tvrep...@googlegroups.com [mailto:tvreprapug@googlegroups.com] On Behalf Of mikethebee

Sent: 25 March 2020 09:14

To: TVRepRapUG

Subject: [TVRepRapUG] Re: [RDG-Hack] Re: 3D printing and Laser Cutting of Medical Shields

This looks a lot more complicated but I was passed this link as potentially of interest

--

---

You received this message because you are subscribed to the Google Groups "TVRepRapUG" group.

To unsubscribe from this group and stop receiving emails from it, send an email to tvreprapug+unsubscribe@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/92127e77-127a-4874-905b-529c71cc4ad2%40googlegroups.com.

mikethebee

Ian Bowden

At Richmond Makerlabs we printed two of the valve adaptors for the Decathalon mask, in response to a request from a local hospital anesthetist.

The items seem to fit fine, as we were sent a photo of the prototype. Our bit is the thing printed in blue on top of the mask.

No idea whether it will go forward or not. We wouldn't be able to print guaranteed sterile gear anyway.

Looking into this idea further it seems to fall between stools and imo does not represent a suitable project for a crowdsourcing. The non-respiration versions of a face mask such as you are already producing are a good choice.

--

---

You received this message because you are subscribed to the Google Groups "TVRepRapUG" group.

To unsubscribe from this group and stop receiving emails from it, send an email to tvreprapug+...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/3c927015-1675-4b1c-b122-fc298aa845a0%40googlegroups.com.

Alex Gibson

Hi Ian!

Looks great – could you point me to the correct STL please? I would be keen to at least print an example, as we may get media interest in what we are doing with the face shields, and I think it’s important to put it in context that there are other projects, and a worldwide stepping up of makers to fill the gaps in health system planning!

And God forbid it might be needed locally…!

Cheers,

Alex Gibson

+44 7813 810 765 @alexgibson3d 37 Royal Avenue, Reading RG31 4UR

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

This email has been checked for viruses by AVG antivirus software. |

--

---

You received this message because you are subscribed to the Google Groups "TVRepRapUG" group.

To unsubscribe from this group and stop receiving emails from it, send an email to tvreprapug+...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/d9827c70-958b-beef-97c4-1eacf115a1d8%40gmail.com.

richard....@btinternet.com

Get this wrong and it is your responsibility if people suffer CO2 toxicity. The dead space in this design and the introduction of filters makes it very high risk as PPE.

Please never test this alone.

Ashfaq Juna

--

---

You received this message because you are subscribed to the Google Groups "TVRepRapUG" group.

To unsubscribe from this group and stop receiving emails from it, send an email to tvreprapug+...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/f34ac180-14cc-473e-a231-45c98b0729e9%40googlegroups.com.

Alex Gibson

HI Ashfaq,

Try this for size? It’s including raft to be on the safe side – let me know if it all prints OK, and we could try without!

We’ve right now got no mechanism to accept individual prints but there are other projects doing so, and we are working on it as a fully controlled process!

Cheers

Alex Gibson

+44 7813 810 765 @alexgibson3d 37 Royal Avenue, Reading RG31 4UR

admg consulting

edumaker limited

· Project management

· Operations & Process improvement

· 3D Printing

From: tvrep...@googlegroups.com [mailto:tvrep...@googlegroups.com] On Behalf Of Ashfaq Juna

Sent: 01 April 2020 06:54

To: tvrep...@googlegroups.com

Subject: Re: [TVRepRapUG] Re: [RDG-Hack] Re: 3D printing and Laser Cutting of Medical Shields

Hello all

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/CAG0h4%3DKbdM%3DBR83i%2B3tOn%2BnCmk6N4%2BBZL-UCAdjrrZEpXLQ1fw%40mail.gmail.com.

Ian Bowden

Hi Alex,

The link to the design is here: https://www.isinnova.it/easy-covid19-eng/?fb-edit=1

The request was " I need to 3D print a couple of small items to convert a snorkel face mask into a CPAP device for treating patients with severe COVID19."

It's clear that the application is not PPE, it's a breathing

device. The idea is that in times of shortage, the snorkel mask

may be available in quantity.

Ian.

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/013601d607a9%240649b6d0%2412dd2470%24%40alexgibson.net.

Ashfaq Juna

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/017101d607f9%24028bb610%2407a32230%24%40alexgibson.net.

Norro

To unsubscribe from this group and stop receiving emails from it, send an email to tvrep...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/92127e77-127a-4874-905b-529c71cc4ad2%40googlegroups.com.

--

---

You received this message because you are subscribed to the Google Groups "TVRepRapUG" group.

To unsubscribe from this group and stop receiving emails from it, send an email to tvrep...@googlegroups.com.

Alex Gibson

Forwarded it to your direct email… got it? If not will wetransfer it

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/CAG0h4%3DJjsEXzMDY99Qs7fbzJaph1SxbYAUBOKRP9fv8PbgsfRg%40mail.gmail.com.

Ashfaq Juna

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/002001d60824%24d1ef3cd0%2475cdb670%24%40alexgibson.net.

Ashfaq Juna

Alex Gibson

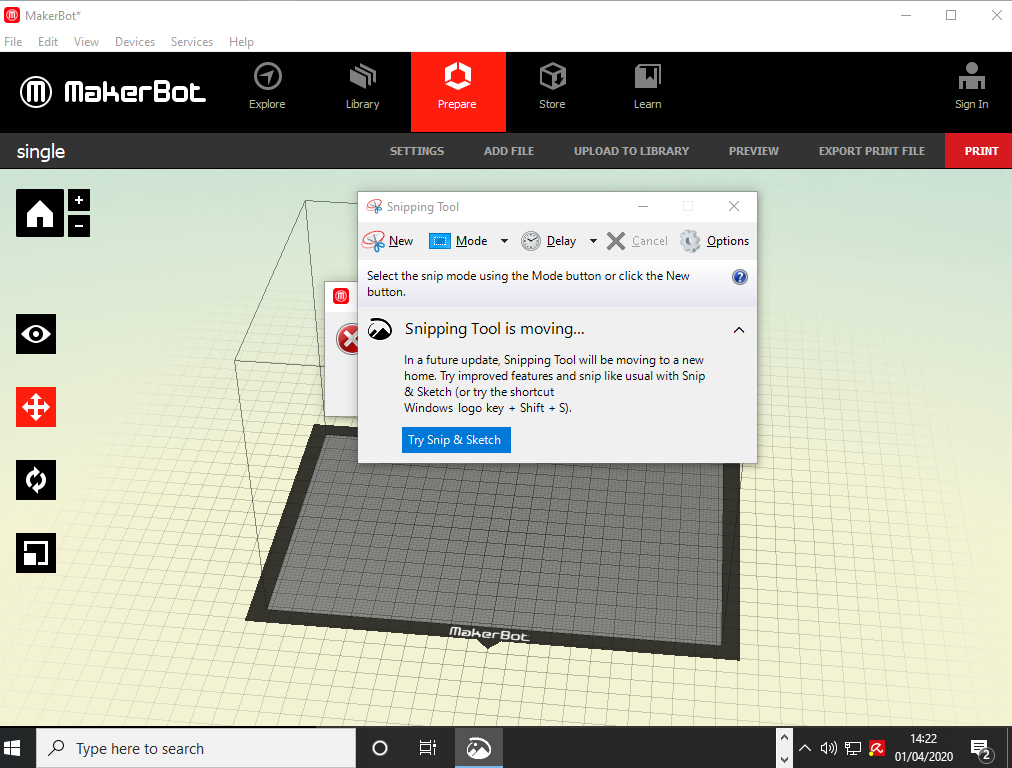

Ah!

I forwarded the .X3G file – if you pop it on the SD card it should ‘just work’ in your CTC. But it won’t open in MakerBot Desktop.

Attached are the .stl files which will open in MakerBot Desktop…

Cheers,

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/CAG0h4%3DJHE3VxmyOkmBVTAX62JcZRR-0GwLX_9-S%2BQYs0mvG3ig%40mail.gmail.com.

Alex Gibson

Hi Ashfaq,

As long as the printer remains calibrated it should be no risk, that’s exactly as intended J Just check the first layer has the right amount of ‘smoosh’ on the build bed and it should be good!

Cheers,

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/CAG0h4%3DKkY3GhdzZzNx84PmxAnz5F6jASysSKccaLV%3DtY1MfLiQ%40mail.gmail.com.

Ashfaq Juna

To view this discussion on the web, visit https://groups.google.com/d/msgid/tvreprapug/003e01d6082a%241cb63480%2456229d80%24%40alexgibson.net.