Fw: Hay Pelletizer / Biomass Machine follow-up (1)

瀏覽次數:10 次

跳到第一則未讀訊息

Snow Ranch

2011年1月29日 晚上7:41:282011/1/29

收件者:transition...@googlegroups.com

----- Original Message -----

From: Snow Ranch

Sent: Saturday, January 29, 2011 4:23 PM

Subject: Hay Pelletizer / Biomass Machine follow-up

Hey!

I was thinking a little more about that hay mower/

shredder/ pelletizer rig or a stationary operation this afternoon. Was

thinking something like this initially in regard to a cut in half propane tank

unit:

....However, you can't just direct feed the bale as

depicted above. A shredding step is required first, unless the rollers are

also shredders. So, you either have better machined rollers than a

well casing, or modify the well casings, or run a shedder phase first. One

option on a cheap shredder might be to take a wrecking yard manual transmission

and cut away both sides of the tranny casing...leaving the gears

exposed. Hopper feed into it. PTO drive. The gears of the

transmission are case-hardened steel and better engineered for stress than

any garden shredder. Hay put into a transmission will emerge shredded in

really small fragments. Junkyard cores go for about $20.

...Alternatively....do the shredding process on the

roller face.

SHREDDING

EXAMPLES

Hay shredder: http://www.youtube.com/watch?v=IdgoyVnI9HI

Heavy-Duty Shredders: http://www.youtube.com/watch?v=rabJ5gDRCoE&NR=1

Toro shredder/ mulcher: http://www.youtube.com/watch?v=-qOkW8Km3Ng

Papercrete mixer method: http://www.youtube.com/watch?v=JoLBeV6tzJ4

....Transformed tow-mixer to PTO drive: http://www.youtube.com/watch?v=1NaHP2F--WU

....Transformed tow-mixer to PTO drive: http://www.youtube.com/watch?v=1NaHP2F--WU

* For high volumes and low cost, I think the Papercrete tank with a lawnmower blade and junkyard axle make the most sense, but not towed. PTO or electric motor driven. Water added, flour, corn oil, binders, etc. Pulp then run into the pelletizer at a suitable moisture content prior to compression. Would take a little trial and error.

PELLETIZER

EXAMPLES

Pelletizer Systems International: http://www.youtube.com/watch?v=SNMQQ6ilGU8

PTO pelletizer made from axle,

screens, and rollers: http://www.youtube.com/watch?v=OEHO2Uu5-_E&feature=related

$229 -$599 die & rollers, 6mm and 4mm: http://www.makeyourownpellets.com/accessories/ss-120a-die-and-rollers

Indian pelletizer: http://www.youtube.com/watch?v=dKr-t1rBq0w

Great little 600 lb/ hr pelletizer &

info: http://www.youtube.com/watch?v=-yTZ3lftyYw&feature=related

12" Buskirgeng Pellet Mill model PM1220: http://buskirkeng.com/products-pm1200.php

* 1000 lbs/ hr...crop residue. 2 hrs per ton. [Unknown price. RFQ pending]

* 1000 lbs/ hr...crop residue. 2 hrs per ton. [Unknown price. RFQ pending]

* In light of more study, I think my earlier

idea of a butchered propane tank is not good. Though capable of higher

volumes, it'll take more shafts, longer shafts, more bearings, and more

mechanical engineering. I now favor just an expanded design that

would be just a larger version of the PTO pelletizer highlighted in red

above. The MakeYourOwnPellets people make some suitable dies and

rollers, but they're too small for any high volume throughput. Best to

machine your own at larger scale. Same general design.

These were some ideas and machining costs on the

extruder plates for the propane tank pelletizer idea:

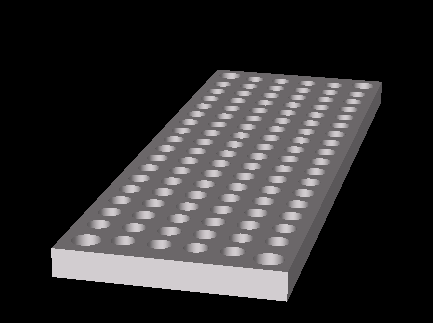

As drilled 1/2" plate. Image depicts 4 bolt

holes on the corners. There should be 2 more in the center (for resistance

to bending under all that pressure) that I forgot to draw.

1/2" single plate x 2" x 6", Al 6061 T6, +/- .005"

tolerance

$177.56/ each w/ shipping. 27 days out to machine it without rush order costs.

$177.56/ each w/ shipping. 27 days out to machine it without rush order costs.

Order of 12 = $60.80 each.

(Originally, I had considered aluminum due to rust

considerations, though they would wear out sooner.)

108 holes per plate - 6 bolt holes = 102 holes per

plate.

As O1 Oil hardened steel. $335.25/

ea

12) 142.95 ea

12) 142.95 ea

As 303 stainless steel:

1) $273.44 ea.

12) $140.95 ea

1) $273.44 ea.

12) $140.95 ea

** Cheaper to just buy the flat barstock and drillpress it yourself, or hire a kid. Figure about 1/2 hr marking and 1/2 hour drilling per plate. About 1hr/ plate total. Minimum of around 12 plates needed on a 6' long propane tank unit.

Depending on the material selection and loading

pressures...1/4" plate could be used at about 1/2 the cost:

Al 6061 T6, 1/4" single plate, $146.30 ea

12) $31.02/ea.

12) $31.02/ea.

--------

回覆所有人

回覆作者

轉寄

0 則新訊息