Fw: Hay Pelletizer / Biomass Machine follow-up (3)

7 views

Skip to first unread message

Snow Ranch

Jan 29, 2011, 8:45:08 PM1/29/11

to transition...@googlegroups.com

-------

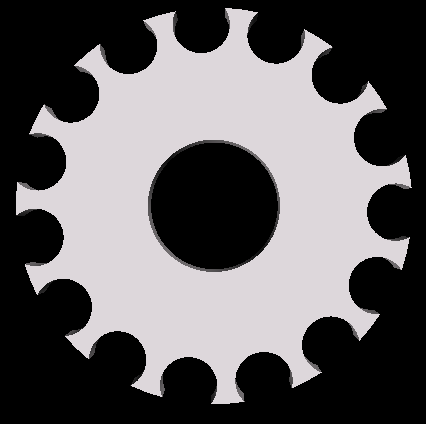

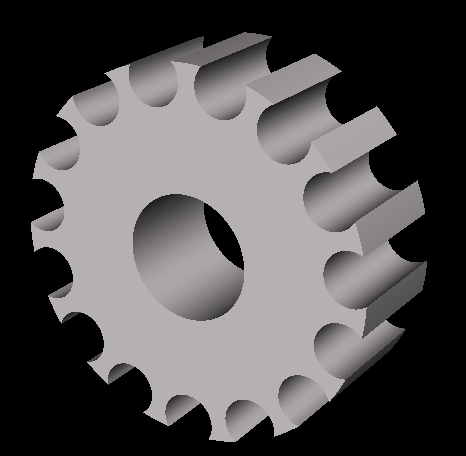

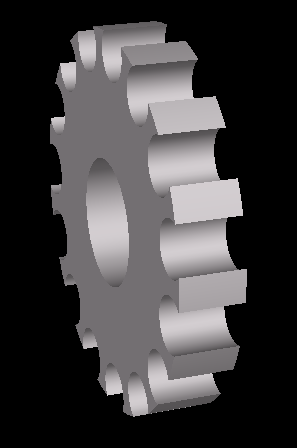

Okay, now to my rollers. These are 3"

diameter rollers x 1/2" thick. Making them 1" thick adds way more

expense. They can be made from just a 1/2" x 3" x 3" plate turned on a

lathe and drilled....or from 3" bar rounds cut, ground, and then drilled.

Inner hole drilled to a diameter matching the OD of the selected bearings. Press

fit. Most rollers have square (broached) machining done, but that's more

costly and difficult as do-it-yourself. Here, the radial holes are

set up to allow a really sharp shreeding edge that will just axe away on the hay

or wood chips, but the opening of the mouth is left wide enough to prevent

clogging. The circular nature of things will add some vortex flow of

material to enhance shredding efficiency. Though only 1/2" rollers, you

stack them on the shaft (like dualie wheels on trucks) into a single rolling

array. That allows also for variance in roller RPM with length and

varying resistance encountered

when shredding and compressing. The outward

round face does the compression into the extrusion holes and must be at least a

bit larger than the diameter of the holes.

Rollers (1" thick), T303

Stainless

$235.44 ea

10) $99.34 each

$235.44 ea

10) $99.34 each

[5 needed]

(1/2" thick), 303 Stainless

Steel

1) $144.73

10) $46.84 ea

1) $144.73

10) $46.84 ea

[10 needed]

Do-It-Yourself Roller Material Options for

Machining:

3 inch Dia. 304 Stainless Steel Round Bar x 1 foot. $150.18

Tool Steel D-2 Flat Ground. 1/2 x 3 x 18"....$307.75

1/2" x 3" x 18" tool steel A2 flat ground, air hardened. $214.43

Tool Steel O-1 Flat Ground, 1/2 x 3 x 18"....$160.36

3 inch Dia. 1018 Cold Finish Steel Round x 1' $48.06

1/2 X 3 Cold Finished C1018 Flat Bar, 2'....$33.66

For shafts:

1/2 inch Alloy 4140 Steel Round - Cold Drawn Annealed, 4' bar...$12

For Bearings:

Bearings ...drill hole to match bearing OD desired; Lathe shaft to desired bearing ID. At least 3/4" shaft OD.

http://www.nationalprecision.com/nu-nx-bearings/

"NX" prelubricated bearings

http://www.nationalprecision.com/cgi-bin/start.cgi/product_selector/nu/doSelector.html?inchBore=0%3A%3A1&metricBore=&selectortype=nx...Price unknown. Need and RFQ.

The Make Your Own Pellets dies appear to have about

120 holes compared to my design's 416. They

claim about 384 lbs/ hr @ 540 tractor PTO RPM. My design will

probably produce in the range of 1,328 lbs/ hr at the same PTO rpm and should

require about 3.5 times the PTO horsepower, too. About 88 HP

needed. Either take up the RPM and burn more fuel....or probably

better to just get a little, junkyard Toytota 4 banger motor...used, running,

EFI. Something like a 3SFE. Add some HHO for additional fuel

economy.

In comparison, the propane tank unit and a single

row extruder would have 1,224 holes. If running a good set of

rollers like mine (not 5" well casings), it could shred and compress maybe 3,917

lbs/ hr....per roller....and one could gear in about 3 per propane tank.....so,

about 11,751 lbs/ hr pellet production....or maybe about 5.8 tons per hour

capable on a 3 roller rig. That's a capacity to convert maybe 106

three-wire bales/ hr....or about 1 3/4 bales/ minute shredded and transformed to

pellets. You'd need at least a 255 HP engine driving it

now, but that's just a junkyard V-8 or truck's diesel engine on HHO. The

greater the machine can shed and produce, the less time you have to run the

engine per Ton....and less fuel required per Ton. Over a bale/

minute feed-in now starts to justify the cost of overhead and hired labor doing

feeds. And, if you're going to bother building one with self-labor

rather than just off-the-shelf purchases....you might as well go big!

:-) Gives you greater profit margin as a commercial

operation. Most these smaller units would cost more than building a

big one, and you get less production....higher costs per ton produced, etc.

Anyhow, think about that some. Might open up

the pelletized feed and wood pellet fuel market for you. Expands the hay

market options. On a little labor and time spent in a month's work....and

costs about the same as buying another used tractor implement like a

baler...there's a whole new business angle right there for ya. :-)

Stan

Reply all

Reply to author

Forward

0 new messages