27233 Cranford Avenue Dearborn Heights, MI 48127 July 23, 1967

Mr. Carroll Shelby Shelby American, Inc. 6501 W.. Imperial Highway Los Angeles, California 90009

Dear Mr. Shelby:

I am a Mechanical Engineer and I nm employed by the Ford Motor Co. (Design Analysis Group, Heavy Truck). Last January I became the proud owner of a G.T..500 Shelby Mustang. It's difficult not to be proud after receiving so many compliments on my good looking ("tough, "bad", "cool", "mean", etc.) automobile from people of all age groups. I believe there may be an accident if people keep tailgating and gazing at my G.T. while my vehicle and their vehicle are both in motion.

I’m pleased with the acceleration, handling characteristics and general solid feel of the car. Stability at highway speed during crosswind gusts is very good. Traction in low gear is excellent (with no ______________________________). The wide wheel _________________must __________________.

Of course, all is not perfect. I have some complaints which I believe deserve immediate attention.

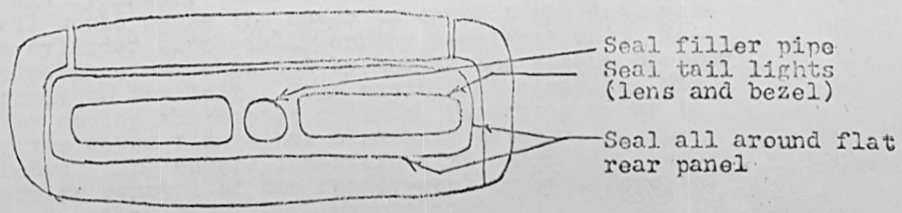

Safety Hazard. Exhaust fumes enter the car via the tail light openings between the flat tail light panel and original Mustang (concave) rear panel. This occurs primarily when the pressure inside the car due to a window being open. Low pressure due to the spoiler brings the exhaust fumes into the car. I solved the problem by a complete sealing job (after removing the rear bumper).

Poor Quality Control.

Fiberglass hood doesn’t fit properly.

Fiberglass cracks. Cracks have developed in the hood, trunk and to a limited extent, the air scoops. The adhesive which bonds the fiberglass to the steel under panel (hood and trunk) should allow for the difference in expansion rate between the steel and fiberglass components The spoiler itself should be reinforced so the will not develop paint cracks if someone leans against it.

Chrome plate is of poor quality on the hood lock pins. This is a small item but one which was noticed by myself and several other people. The pin and ring assembly have both rusted (despite the application of wax a light coat of oil). The dealer has since replaced he rusted items but I foresee more trouble next winter.

The chrome plate is poor on the "Mag Star" steel rims (Kelsey Hayes). The plate seems to have a copious supply of pin holes which allow salt, etc. to contact the steel base. Rust rings formed over night last winter on all four rims. A grease coat stopped the rust but proved unsightly.

Chrome plate extremely poor on exhaust extensions. I’ve tried to maintain plate by sealing with acrylic lacquer. This is a losing battle!

Right and left front fender and trunk lid "Shelby G.T. 500" aluminum embossed emblems not affixed securely to the chromed base. The right and left fender emblems peeled half way off before I used some rubber base adhesive to fasten them down. The trunk lid “Shelby” strip was missing when the car arrived.

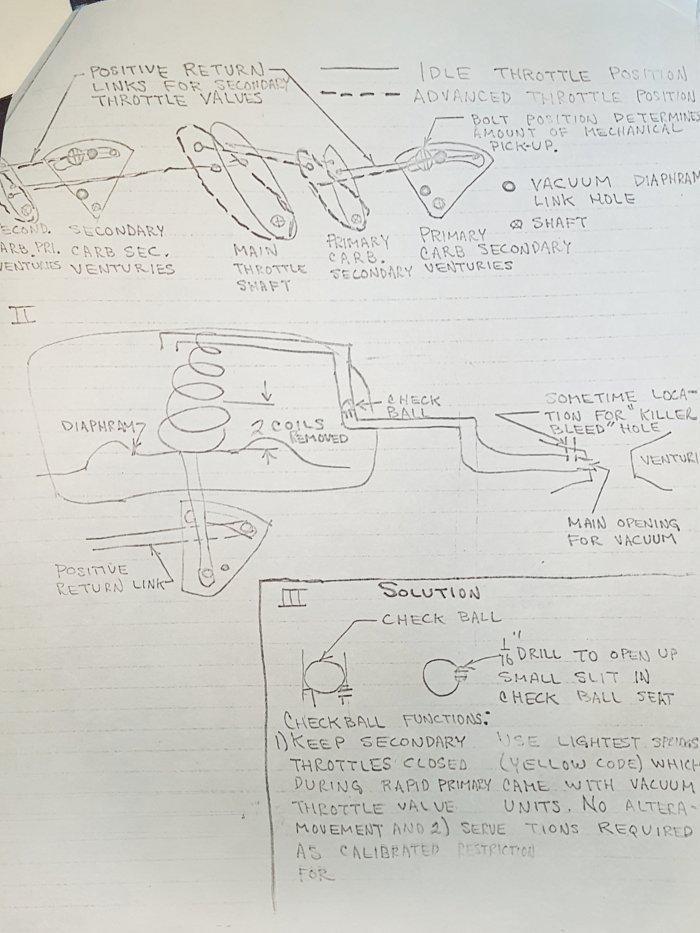

Design. The die-cast aluminum rocker arm covers are unnecessarily massive. The left cover barely clears the dual master brake cylinder. When I first obtained the car the engine roll would cause the cover to contact the dual master brake cylinder (especially during deceleration). Necessary clearance was obtained by moving the vacuum booster over slightly to the left. Some additional clearance was obtained by moving the master cylinder reservoir cover to the left (the cover flange has clearance between the reservoir body). The covers interfere with spark plug removal and require removal of the fender-cowl brace before the covers can be removed.

Aluminum would have been much more suitable for the grill screen. Last winter all of the black paint flaked off the steel mesh. I had to repaint the entire grill screen. The original paint job was obviously of inferior quality.

Miscellaneous. The Goodyear tires may be good for high speed driving but they seem to have the resistance to weathering (cracks in the casing) that tires of a decade or two past had. After only six months use, one tire has extensive side wall cracks.

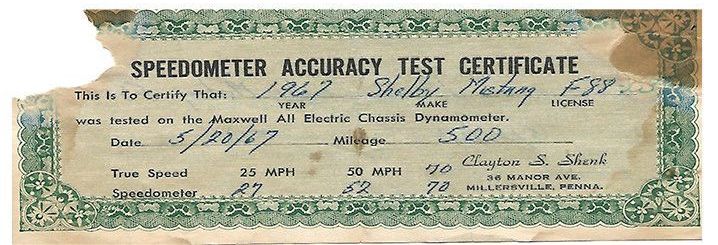

The speedometer and odometer readings were approximately 10 percent low when the car was first received. It was necessary to remove the 18 tooth (natural color) drive gear and install a 16 tooth (orange color) drive gear. Low odometer readings are tough on gas mileage figures and low speed readings are great for receiving speeding tickets (especially with a G.T. 500).

Other annoying problems occurred which could be attributed to the hasty and rather careless assembly of the Mustang fastback. These problems belong more to Ford than to Shelby American and, I realize, are common to the industry.

I hope you will forward this letter so that some of the more imminent problems can be taken care of. Shelby American has produced a vehicle possessing a strong image and wide appeal this year. It would be a shame to tarnish the "350" and "500" through small, easily corrected problems.

Good luck and good health to you and yours.

Sincerely,

CC. Mr. R. Geddes, Mgr. Special Vehicles Lawrence J. Fetter P.E.

|