Zeroing the tool

Eric

Tokyo Pav

Pocket NC

Eric

Pocket NC

Eric

So it looks like my tool length might be off just a little?

Randy Kopf

Pocket NC

Hi Eric,

From the looks of it, I would say your tool is cutting deeper than it

should. I will talk with Michael and see if we cannot pump out a better

tutorial on setting tools with the old spindle. I am sure that you will

have to measure each tool and set up an offset in the offset table but

maybe we can come up with a better way measuring. With our new spindle, we

have users measuring off a 125 block. That seems to provide good results.

When I am working with tighter numbers surfaces that need to blend, I use

the method of making a test cut on two sides of a block. You might find

that this helps a good deal.

-Matt

Eric

Eric

I'm about .08 off. I had my tool sticking out of the spindle 1" (that's from the base of the collet to the tip of the tool)

I had my tool length offset at -2.6 (3.6-1)

Does anyone have any idea what I'm doing wrong here?

Randy Kopf

Eric

T1 means "tool 1" right? I did the check too in the tutorial to make sure my offset took and it did.

So I wonder what's going on here... Could I have a bad prox switch? Could my software be out of calibration in some way? (I triple checked that I had the tool length correct in Fusion.)

I'm a little leary of using a block of wood as my calibration guide.. Seems like not a 100% accurate way to calibrate everything... I'd rather an electronic touch off or a physical block I could use to set the tools...

Here's the file I used to mill:

Randy Kopf

Eric:

So yes if you input that 2.6" number in Pocket NC tool length column for tool 1 that is correct.

Notice the additional line N85 that I highlighted. That is the code that applies tool length compensation and the H1 address tells the control to use the value from the tool comp table you had input for tool 1.

I agree using a block of wood to calibrate your machine does not make sense. I also suspect your specific Pocket NC needs to use a constant that is more like 3.638" as the starting point to subtract your tool length offset from. You should ask Pocket NC if they recorded a different constant for your machine. It's the only thing that makes sense.

Randy

Eric

Gary Swank

Eric

So right now this seems like good workaround but I think it needs to be fixed so that my Tool Length Offset is actually correct.

So Randy has been helping me with this a bit too. With his help I found the PocketNC.ini that has the home offsets in it. I think the next step is going to be changing those so that I don't have to have a wacky tool length offset number....

I'm going to wait until I can get my hands on some really accurate measuring tools so I can make sure I get it exactly right. Wood blocks are only so accurate :)

Randy Kopf

Gary Swank

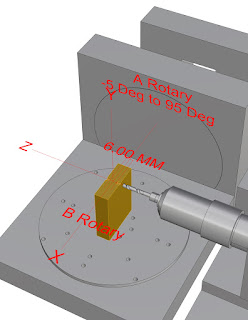

See Image

Please Check code BEFORE running to be sure mill does not crash! Finger on emergency stop!

G00 B0.000

G01 Z20.000 F300

G01 Z3.000 F50

G01 Z20.000 F300

G00 B180.000

G01 Z3.000 F50

G01 Z30.000 F300

See Image

%

G00 B0.000

G01 Z20.000 F300

G01 Z0.000 F50

G01 Z20.000 F300

G00 B180.000

G01 Z0.000 F50

G01 Z30.000 F300

Gary

Randy Kopf

Gary the concept you proposed is excellent.

I attempted to do this in Fusion and found a couple of constraints that inhibits this from working as exactly as proposed.

Please afford me a little time to work this out further. But here is what I ran in to:

1) The ability to place the stock on perfect C/L is not always possible on the Pocket NC with supplied tooling.

2) The Pocket NC requires rotation to occur always about intersection of AB Center-lines. And this also dictates math output.

3) The stock size proposed in the test can't be setup and satisfy the 2 prior notes I made. I can't rotate it so satisfy the cuts being balanced off center without rotating the stock 90 degrees in vise. And if I do the set screws can't grip it. So I need to alter the model size to accommodate Pocket NC's limits on model placement.

I will circle back with everyone here.

:-)

Randy Kopf

http://desktopartisan.blogspot.com/

Thanks Gary: