Simulation Not the same as Actual on Tracing

123 views

Skip to first unread message

Ngoc Nguyen

May 8, 2021, 3:20:05 AM5/8/21

to Pocket NC

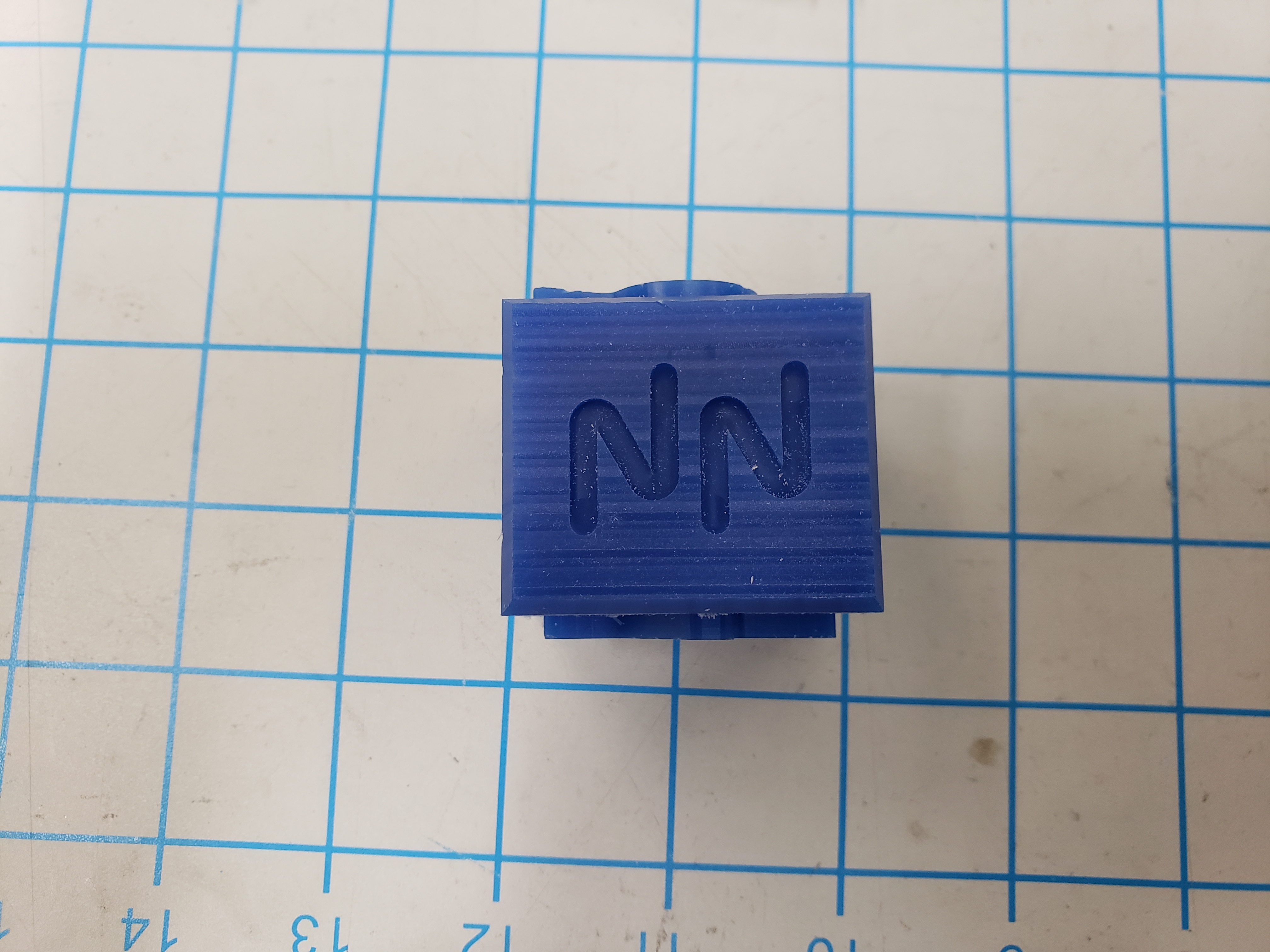

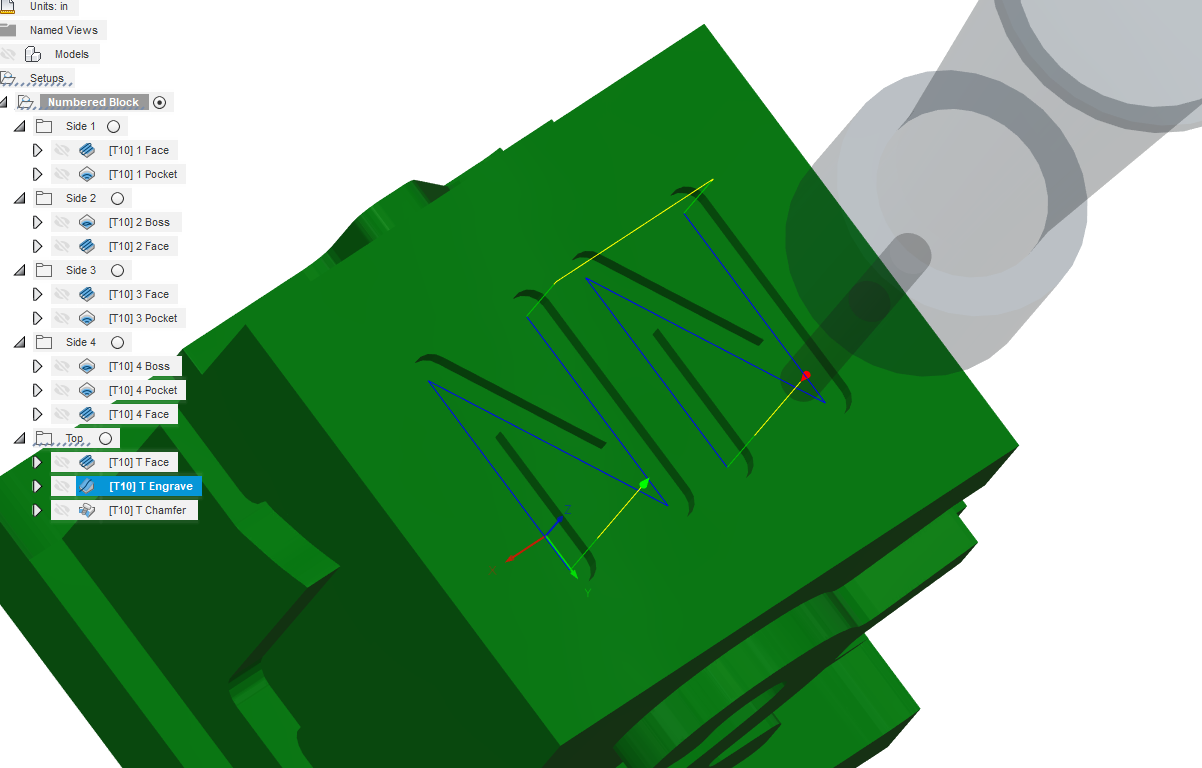

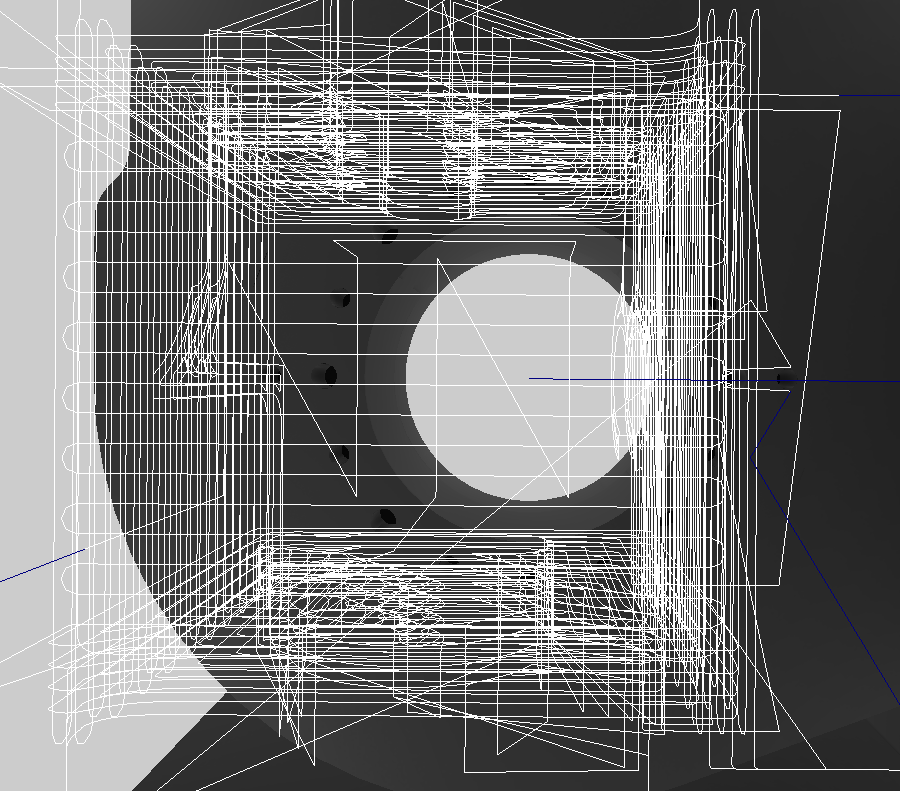

Hi there. I'm a new user and I took the Pocket NC course and followed the course to create the Numbered Block. Interestingly everything went well except the trace. As shown below, you can see that the "NN" trace doesn't fully extend (weirdly shifted/skewed) compared to the Fusion 360 simulation as well as the Pocket NC Online Simulator. I'm using a Pocket NC V2-10. Any help or advice would be greatly appreciated. Thank you in advance.

qrot...@pocketnc.com

May 10, 2021, 10:21:33 AM5/10/21

to Pocket NC

Hello,

Would you mind posting a top view picture of the final part? Your Fusion 360 file (.f3z) would also be helpful if you don't mind sharing that as well.

Thanks!

Q Rothing

Applications Engineer, Pocket NC

Ngoc Nguyen

May 12, 2021, 7:06:39 AM5/12/21

to Pocket NC

qrot...@pocketnc.com

May 12, 2021, 10:53:54 AM5/12/21

to Pocket NC

Thank you for those items. After taking a closer look at your Fusion file, I was not able to find anything that was out of place or incorrect. I will need to do a little more digging on this issue.

In the meantime, would you mind trying the same process, but with a different set of initials? I am curious if it machine specific or letter specific.

Thanks!

Q

qrot...@pocketnc.com

May 12, 2021, 12:03:56 PM5/12/21

to Pocket NC

Hi Ngoc,

We took a closer look at your gcode and we are pretty sure the issue is just with the positional tolerance the machine can hold when moving at a certain feed rate. Basically, the machine has G64 active upon startup which means that it is going to maintain the best speed possible, not matter how far from the commanded point it ends up. There are a few ways to resolve this:

1) Slow the feed rate down on that operation. This allows the machine to maintain the best possible speed (stay as close to commanded speed as possible) while getting closer to the actual commanded point.

2) Turn on Exact Path mode (G61). This makes the machine follow the exact path of the commanded toolpath. This could be done with the Manual NC feature in Fusion 360, or manually after generating the gcode.

3) Use Path Blending (G64 P_ Q_). This allows the user to find some middle ground between following the exact path and solely maintaining the best feed rate.

More info on Exact Path mode and Path Blending can be found here - http://www.machinekit.io/docs/gcode/gcode/#sec:G61-G61_1 and http://www.machinekit.io/docs/common/User_Concepts/#sec:trajectory-control

Let us know if you have any questions on this!

- Q

Reply all

Reply to author

Forward

0 new messages