How to machine inner angles

65 views

Skip to first unread message

Mustapha Redouane

Jan 31, 2021, 1:00:36 AM1/31/21

to Pocket NC

Hello,

Completely new to CNC and Pocket-NC, I have a couple of questions:

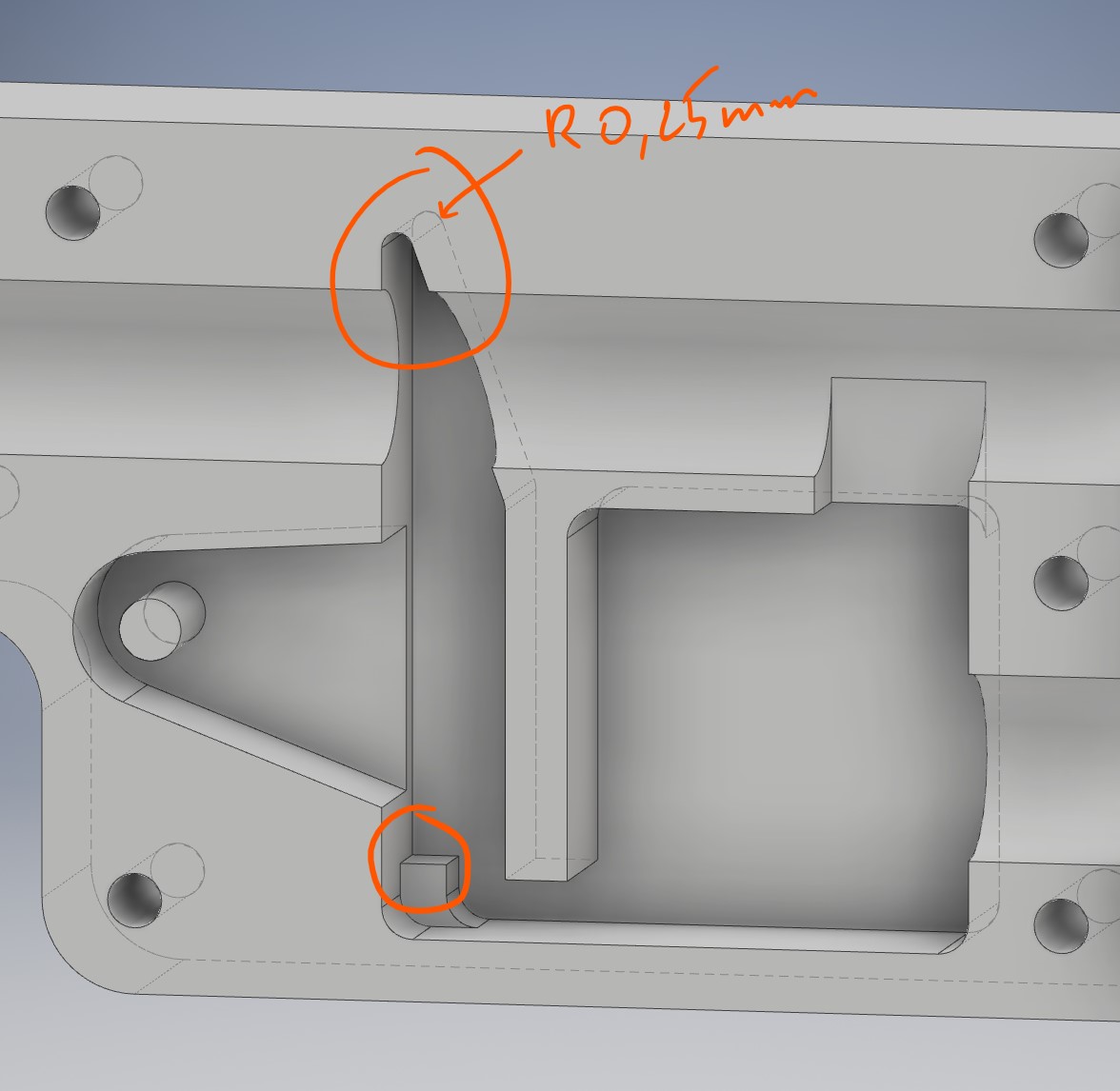

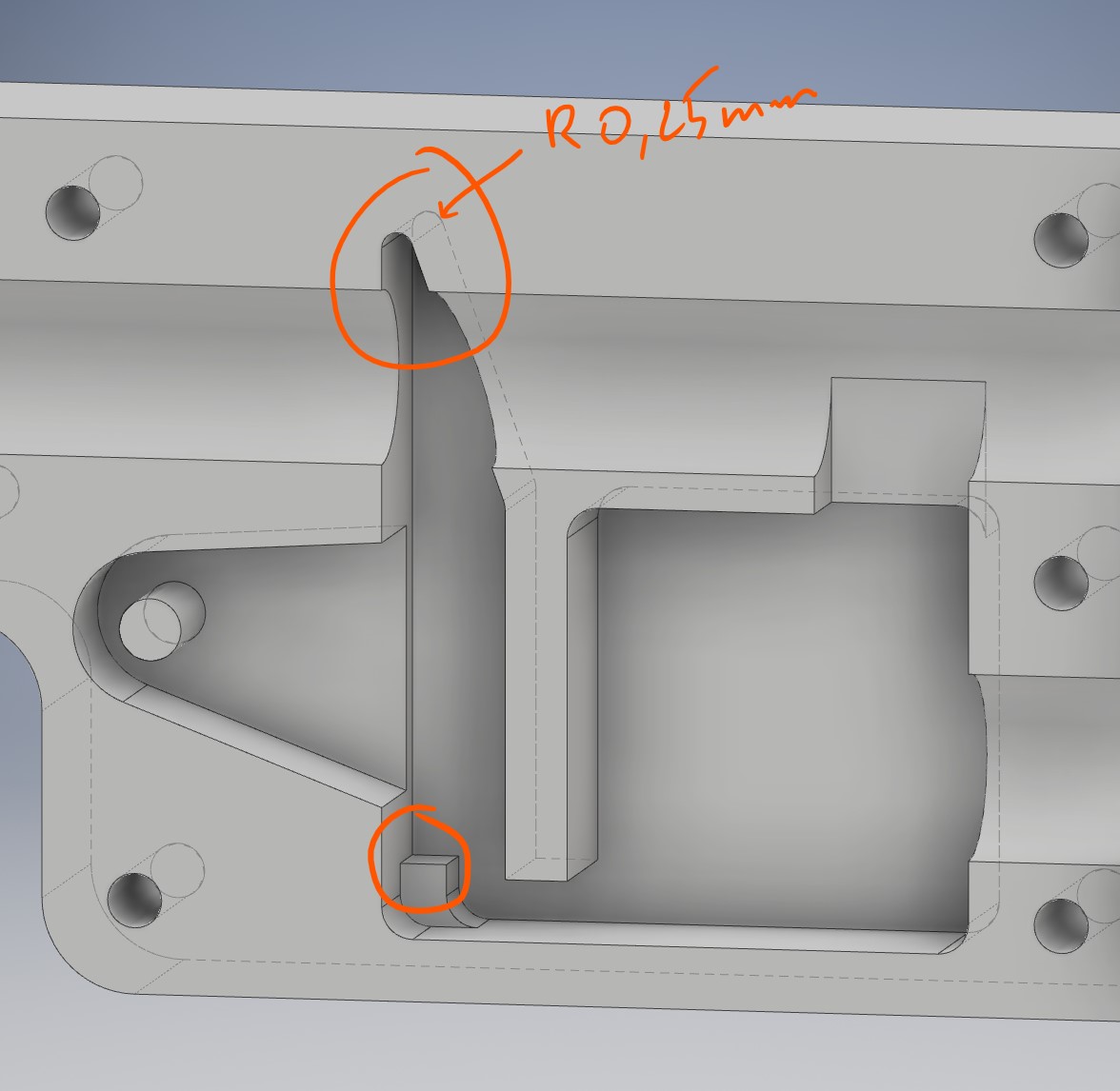

How to machine angles in internal features as shown in the attached image? thank you.

gre...@gmail.com

Jan 31, 2021, 7:33:46 AM1/31/21

to Pocket NC

If you milled that cavity you would end up with radii on the inner corners equal to the cutters radius. You can go to very small cutters to minimise it but not get rid of it. In mould making sharp corners like that would be created using EDM, a shaped electrode is plunged into the material and sparks erode it.

You can also design for manufacture to avoid sharp internal corners or if you simply need the corner gone for clearance, drill at that location first.

As a further tip, it is better to make your minimum internal radius in the model slightly larger than your minimum cutter radius, this reduces the load on the cutter when it goes into the corner, otherwise you end up with 100% engagement all of a sudden. When machining you often use a larger cutter for roughing and will then do "rest machining" to clean up the corners with a smaller cutter.

Cheers,

Graham

On Sunday, 31 January 2021 at 06:00:36 UTC

Mustapha Redouane

Feb 2, 2021, 10:54:32 AM2/2/21

to Pocket NC

Thank you very much, I think it is possible to avoid inner corners in my design indeed.

Best regards,

Rédouane

Reply all

Reply to author

Forward

0 new messages