B3 Pico, 1.75mm, PLA, Jamming

199 views

Skip to first unread message

Steve White

Nov 12, 2015, 9:08:26 AM11/12/15

to B3 Innovations - Pico Support

Hi, all -

I've recently built my own 12V MEGA/RAMPS 1.4 based CoreXY printer, and I put a Pico on it. It's my first foray into bowden extruder land, and it took me a while to sort out that insanity, and I had some z-axis stability issues. Once I got those sorted out, though, everything looks great. I printed some beautiful test cubes while I was dialing in my dimensions. Then I move on to printing a shroud for a PLA cooling fan and the filament jams about 20mm in. I clear the jam, start over. Jams up about 15mm in. I clear the jam and wrap for the night. Come back the next morning, fire up the printer, start again; jams up about 25mm in. I try a couple of test prints; it jams up every time, 10-25mm into the print. Can't finish anything taller.

I have a small fan cooling the fins of the B3.

Any suggestions?

B3

Nov 13, 2015, 6:03:01 PM11/13/15

to B3 Innovations - Pico Support

Steve,

Thank you for coming to us with help. Let's see if we can get some more info from you first:

What filament are you printing with? (PLA/ABS, Brand, Color?)

What temperatures have you tried printing at?

Are you using a temporary fan shroud or deflector(even paper, aluminum foil or cardboard will work)? Can you send us a picture of your hot-end and fan setup?

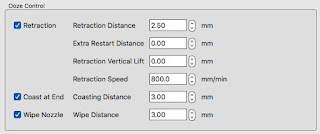

What are your retraction settings at? (Speed and length of retraction)

Do you have a pair of calipers around to measure the filament diameter in a couple different places across the windings of your spool?

Thanks and please do get back to us!

Mike

The B3 Team

Steve White

Nov 20, 2015, 12:22:32 PM11/20/15

to B3 Innovations - Pico Support

Hi, Mike - Sorry, I didn't get a notification that you'd responded!

Here's my setup:

The fan on the left is the print cooling fan, the fan in back is the hot end cooling fan. I tried the unrestricted fan 'air guide' B3 recommends, and had significant issues. This one works better - the cooling fins stay cool to the touch.

I'm printing PLA and PETG; the problem is universal. Filament currently on the printer is Inland PLA, while I also have Hatchbox PLA and PETG, Inland PLA and PETG, Madesolid PET+, and eSun PLA and PETG. I always measure my filament with calipers; all of these spools are consistent throughout a couple of meters. All of these spools work perfectly well on my Replicator Dual.

I'm printing PLA at 205 right now. I've tried speeds ranging from 50mm/s to 250mm/s, and temperatures ranging from 205-240 (PLA) and 215-250(PETG).

If I turn off retraction, I don't have jams, but I don't get useful prints, either (too much stringing and oozing - I think I hate bowden extruders). I've experimented with all kinds of settings, but here is what I was using on my last go-round, where I had a jam (every print I've made that was longer than a few minutes had a jam):

I'm using Simplify3D, though I've tried with Repetier-Host as well with similar results. I still get jams with every print.

Any thoughts?

Thanks!

Steve White

Nov 20, 2015, 12:39:58 PM11/20/15

to B3 Innovations - Pico Support

I forgot to mention color. I have all different colors, but what I'm printing right now is gray. in PETG I've tried MadeSolid green and Hatchbox Blue and eSun Solid White; in PLA I've tried Inland gray and red, and Hatchbox yellow. And here's pictures of my test print:

In case you can't read the captions, the left print is with the current retraction settings, the right one with the default retraction settings.

B3

Nov 22, 2015, 9:09:56 PM11/22/15

to B3 Innovations - Pico Support

Steve,

Thank you for all the info. It helps a lot to get a full picture of what's going on as often, small details are missed.

One thing I have noticed is how slow your retraction speed is: 800mm/min (13mm/sec). We typically do not go any slower than 3,000 mm/min (50mm/sec)

I'm guessing that the slow retraction allows for the filament to cool and solidify in the cool zone because of the slow retraction. If you do indeed have a Bowden setup, 2.5mm distance of retraction is good, however, if you have direct drive, 2.5mm is too much and would recommend 0.5mm retraction distance.

If you don't mind and when you have time, can you try increasing the speed of your retraction and let us know how it goes. If that does not work, we will brainstorm another solution.

Thanks,

Mike

The B3 Team

Steve White

Nov 23, 2015, 10:13:57 AM11/23/15

to B3 Innovations - Pico Support

Hi, Mike -

Thanks for your response. I've had my retraction speed as high as 2500 (never went to 3k!); the S3D default is 1800. Slowing it down was a troubleshooting step that made no difference except the sound it makes retracting. Do you think the difference between 2500 and 3000 is significant enough to make a difference?

B3

Nov 23, 2015, 9:52:25 PM11/23/15

to B3 Innovations - Pico Support

Steve,

I doubt the 500mm/min will make the difference. My next question is to find out if you have tried the filament filter with oil on it? Specifically for the PLA materials. Pico should have no issues with the other materials, but PLA can be tricky to learn at first. The oil reduces the learning curve.

Let us know if you have tried that yet and if not, how it goes.

Thanks

Mike

The B3 team

Steve White

Nov 24, 2015, 8:53:23 AM11/24/15

to B3 Innovations - Pico Support

So I cut a 1" piece of PTFE and connected my bowden extruder directly to the inlet on the Pico and zip-tied the extruder to the carriage, so it's almost a direct extruder now. I reduced my retraction settings to something more appropriate for a direct extruder (.5mm retraction). Now I can print in PETG, no jams. (PLA as well, of course). (also reduced acceleration and jerk so that it doesn't shake the extruder off the carriage). I'm thinking I'm going to convert it to a direct extruder - which should solve all these problems.

Something I observed that might drive this that isn't related to the Pico directly is that somehow, retractions sometimes stack up. Like, I had it set to 2.5mm retraction, but every once in a while I'd see the filament retract ten or fifteen mm. No explanation yet.

Thanks for your time!

calle...@gmail.com

Jun 4, 2016, 12:26:14 AM6/4/16

to B3 Innovations - Pico Support

Steve, this is a little late but I have some information regarding the excessive retractions.

Try the M83 gcode in your slicer to set Relative positioning on the extruder axis.

I'm currently running a Smoothieboard and was having the same problem as you when I was setting it up.

Best I can figure is a rounding error or a wrap-around from something like 32768 steps causing a big filament rewind and an instant jam.

Also make sure that the M83 gcode is actually getting passed to the controller, Pronterface currently seems to drop initial gcode for (at least) pre-homing, Z axis auto-calibration, and M83.

If you slice M83-enabled gcode without passing M83 to the RAMPS controller, it will extrude a pile of plastic spaghetti.

Try the M83 gcode in your slicer to set Relative positioning on the extruder axis.

I'm currently running a Smoothieboard and was having the same problem as you when I was setting it up.

Best I can figure is a rounding error or a wrap-around from something like 32768 steps causing a big filament rewind and an instant jam.

Also make sure that the M83 gcode is actually getting passed to the controller, Pronterface currently seems to drop initial gcode for (at least) pre-homing, Z axis auto-calibration, and M83.

If you slice M83-enabled gcode without passing M83 to the RAMPS controller, it will extrude a pile of plastic spaghetti.

Jesse West

Dec 3, 2016, 2:34:21 PM12/3/16

to B3 Innovations - Pico Support

I had problems with jamming like you with my Pico. A fan blowing on it was not enough so I added a deflector and still not enough. It was not until I made a duct to channel airflow directly over the fins that the jamming ceased completely. Ever since then I've not had any jams. Pico has been rock solid.

sat...@gmail.com

Mar 14, 2017, 2:55:59 PM3/14/17

to B3 Innovations - Pico Support

so you had to make a fan shroud similar to what e3d does with their hotend

that might explain the new pico hybrid they have coming out

that might explain the new pico hybrid they have coming out

always wondered about this hotend but could never bring myself to try it out.

Reply all

Reply to author

Forward

0 new messages