Automatic Machine Calibration using Issues & Solutions

ma...@makr.zone

Jonathan Oxer

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f1713243-6e84-457a-add1-58da80fd5258n%40googlegroups.com.

Shai

ma...@makr.zone

> Is the idea to then use this to integrate auto focus camera or is that wishful thinking? ;)

No, the camera is a normal fixed focus ELP. The "Auto-Focus" is

done by the nozzle Z, it brings the nozzle tip point into focus

perfectly, then setting the camera Z (which will make sure it is

used for all bottom vision in the future).

_Mark

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/dBg7txMB0R0/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/fcae0ddd-5a01-499e-8c79-81c03224fc96n%40googlegroups.com.

ma...@makr.zone

Or did I misunderstand you?

Nozzle driven Auto-Focusing is already used to learn part heights, if that is what you mean:

https://github.com/openpnp/openpnp/wiki/Up-looking-Camera-Auto-Focus

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/940666ae-2f9f-d986-53ce-dee2b006165a%40makr.zone.

Shai

ma...@makr.zone

> My thinking was auto focus for different heights for the

downward looking cam.

Well, within reasonable Z distances this is not needed. As you

see (in the video) the secondary fiducial is quite blurred, but

not a problem to recognize, if you are using my Circular Symmetry

stage:

https://youtu.be/md68n_J7uto?t=81

This also works for other "probabilistic" stages, like Template Match. Using these, I see all simple feeder (sprocket hole) and nozzle tip changer vision applications covered. Precision applications like visual homing and sophisticated feeders with OCR/QR codes etc. should really always use PCB surface level Z.

The important thing for simple "on top of surface" feeders etc., is to get the Units per Pixel right, dependent on feeder pick Z (for instance). And that's coming soon! 😎

Btw. the underlying 3D Units per Pixel work was done by Tony

Luken, so this will mostly be his merit!

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/957b1695-a02f-4146-9fea-f02dfebad5d3n%40googlegroups.com.

fxframes

ma...@makr.zone

😃

ma...@makr.zone

Forgot the link to the Pull Request with extensive description

(sorry about that):

https://github.com/openpnp/openpnp/pull/1248

See also:

https://makr.zone/openpnp-automatic-machine-calibration-with-issues-solutions/676/

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f5367164-078c-437d-b15a-fb28f5736fcfn%40googlegroups.com.

james.edwa...@gmail.com

Mark, this looks fantastic. It must have been a huge amount of work! I am looking forward to implememting it. I have a question: Does it require auto-focus camers? Mine are fixed focus.

Best, Jim

From: ope...@googlegroups.com <ope...@googlegroups.com> On Behalf Of ma...@makr.zone

Sent: Saturday, August 14, 2021 5:18 PM

To: ope...@googlegroups.com

Subject: Re: [OpenPnP] Re: Automatic Machine Calibration using Issues & Solutions

Forgot the link to the Pull Request with extensive description (sorry about that):

https://github.com/openpnp/openpnp/pull/1248

See also:

https://makr.zone/openpnp-automatic-machine-calibration-with-issues-solutions/676/

_Mark

Am 15.08.2021 um 00:01 schrieb ma...@makr.zone:

Hi,

I've made the Pull Requests and merged/deployed it as a testing version.

For those who haven't seen the video yet:

Important: this is not yet officially accepted into OpenPnP, it is still to be discussed with Jason (@vonnieda) and others and may need changes.

So if you try this out, be sure to save a backup of your machine.xml from before the upgrade and be ready to go back!

Download here:

This will need some broad machine spectrum testing, who's helping?

😃

Thanks!

_Mark

On Friday, August 13, 2021 at 1:19:03 AM UTC+2 ma...@makr.zone wrote:

Hi all

I've uploaded a video of the Automatic Machine Calibration using Issues & Solutions that I'm working on:

This is mostly done and tested on my machine, but I still have to parcel out the Pull Request(s), so it will take some time before this pops up in the OpenPnP (testing) version.

What do you think? ;-)

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f5367164-078c-437d-b15a-fb28f5736fcfn%40googlegroups.com.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/1945ea9a-421d-550b-d19e-67d6ea7a63ea%40makr.zone.

ma...@makr.zone

Jim,

thanks for the praise.

> Does it require auto-focus camers? Mine are fixed focus.

No special camera needed, the "auto-focus" is not done by

adjusting the lens, but by moving the subject i.e. the

nozzle tip in Z.

It determines the focal plane i.e. the Z coordinate, where the

bottom camera sees the subject most sharp (highest contrasts

observed). It then sets this as the Z coordinate of the camera

position.

Later, when parts need to be aligned, or nozzle tips calibrated,

those will be brought to exactly that Z height.

Btw. there is already an automatic part height detection in

OpenPnP for some time now. Read more about this here:

https://github.com/openpnp/openpnp/wiki/Up-looking-Camera-Auto-Focus

_Mark

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/dBg7txMB0R0/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/085801d791d3%2400b3cf70%24021b6e50%24%40gmail.com.

Zdenko Stanec

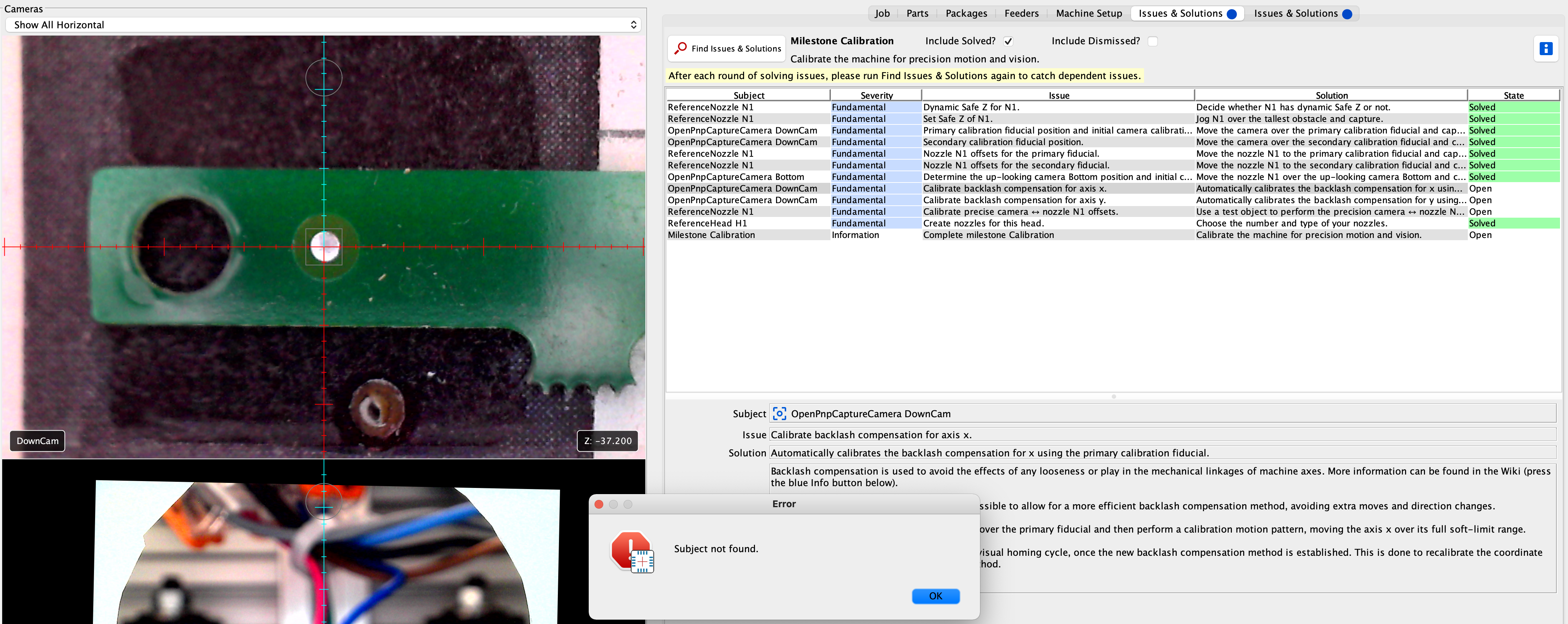

jdlv

Hi Mark,

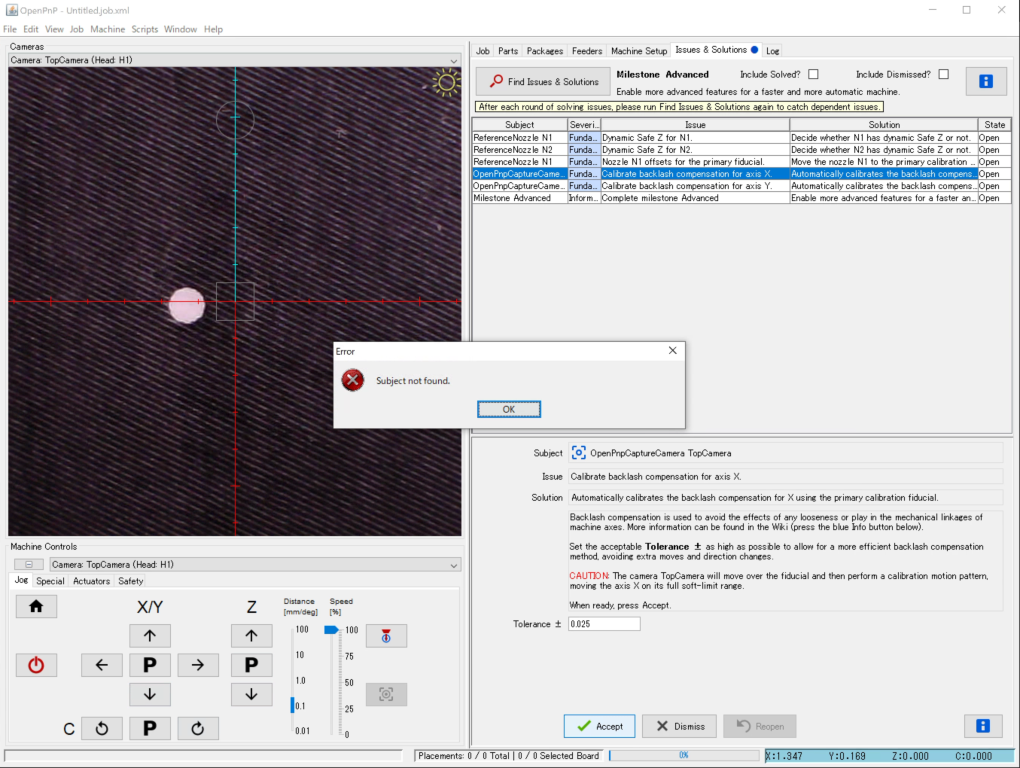

backlash compensation issue and solution stops with an error, see attached screenshot.

Nozzle offset calibration doesn't move the nozzle down so the confetti never moves. Do I have to set the nozzle at confetti Z before?

Have a nice day

joël

--

jdlv

Just in case, the backlash autosetup log.

Thanks

joël

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/961ec7ac-9bb0-9713-345c-c679eb9d19fe%40makr.zone.

tony...@att.net

ma...@makr.zone

Hi jdlv,

Thanks for testing! 😄

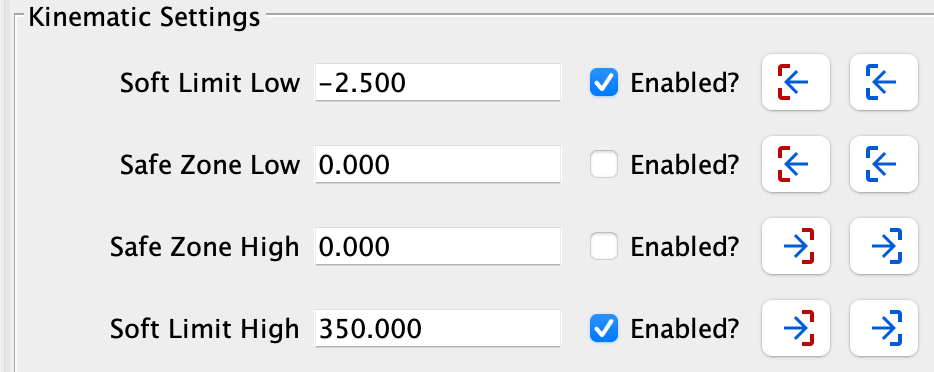

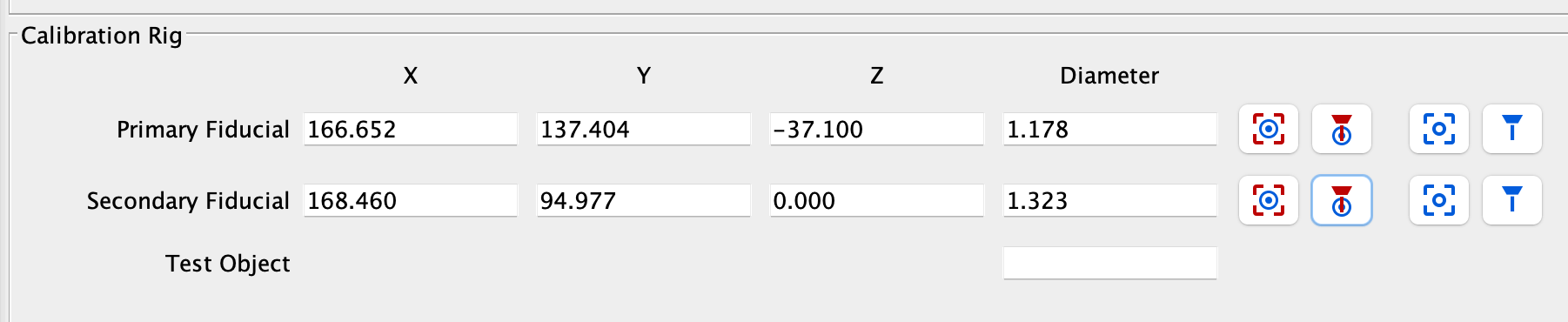

There are two issues:

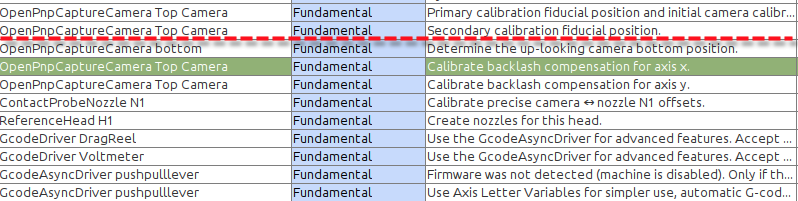

- The first was already pointed out by Tony. I guess your

fiducial is too close to the soft limit, you need a ~120mm+ X, Y

distance from soft limits, even better is a machine central

location. I must improve that Wiki section:

https://github.com/openpnp/openpnp/wiki/Vision-Solutions#calibration-primary-fiducial - The second is a dependency bug (thanks for reporting it): All

these following steps (under the red dashed line) should not

appear, before you set the fiducial Z is also set by moving

the Nozzle to the two fiducials. These two steps correctly

only appear when you press "Find Issues & Solutions" again,

after having solved the first two, i.e. after having set the

pair of fiducial X and Y. But the others (that now erroneously

appear) should only pop up even later, after you have

set the fiducials' Z as well, and after you pressed "Find Issues

& Solutions" yet again. Each of these solutions builds on

top of the others. You may have a look at the video and will

understand why this information is needed.

I will fix these bugs as soon as possible, until then please

press "Find Issues & Solutions" after each solved solution.

Again thanks everybody for testing! 👍👍

_Mark

I suspect you need to move your calibration fiducials farther away from the edge of your machine so that there is room to maneuver around the fiducial. Make sure you place them such that you can jog the camera and see the fiducial in all four corners of the image without running into any soft limits/limit switches.

On Tuesday, August 17, 2021 at 1:32:50 PM UTC-5 jdlv...@gmail.com wrote:

Just in case, the backlash autosetup log.

Thanks

joël

Hi Mark,

backlash compensation issue and solution stops with an error, see attached screenshot.

Nozzle offset calibration doesn't move the nozzle down so the confetti never moves. Do I have to set the nozzle at confetti Z before?

Have a nice day

joël

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/c27d417d-e3cc-48f9-b455-e09f1a1a9bebn%40googlegroups.com.

ma...@makr.zone

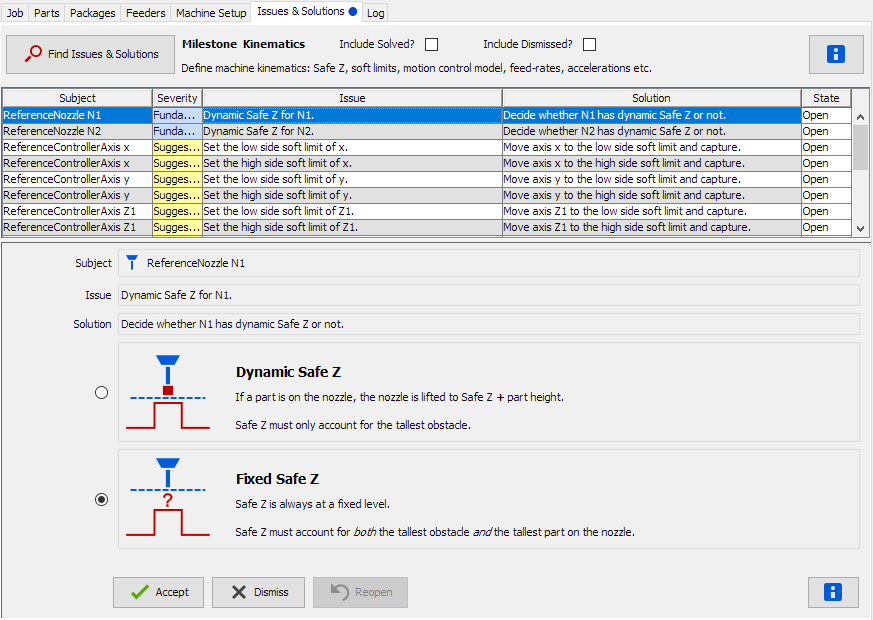

I might add, that some of this may be due to you probably not

following the Milestones. You're probably already at Milestone

"Advanced" with your already setup machine. Therefore, the

Milestones all appear "heaped up".

A user with a fresh machine will instead move up Milestone by

Milestone and these "premature" solutions will not appear. Still

I'll try and insert a dependency check, because I guess this is a

realistic situation.

If you want, you can switch back to earlier Milestones to check

this out:

https://github.com/openpnp/openpnp/wiki/Issues-and-Solutions#milestones--tracking-progress

See the Outline here:

https://github.com/openpnp/openpnp/wiki/Issues-and-Solutions#the-milestones

Btw. Wiki feedback is equally welcome.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/8c6f424f-fa28-31cc-f36c-3c88ae92b33f%40makr.zone.

jdlv

the test rig is in the middle of the working area, more than 400m

away from the X limits. The log shows this just before the error,

the last 2 moves:

2021-08-17 20:25:47.923 AbstractHeadMountable DEBUG: Top Camera.moveTo((433.867017, 191.759117, 0.000000, 0.000000 mm), 0.25)

2021-08-17 20:25:47.924 AbstractHeadMountable DEBUG: Top Camera.moveTo((-5.142914, 191.759117, 0.000000, 0.000000 mm), 1.0)

at X = 433.867017 the camera is where the fiducial is, -5.142914 is far away and more than the 120mm required.

Pressing "Find Issues & Solutions" after each solved solution helps a lot! Camera - nozzle offset is now calibrated.

Thank you for your great work!

joël

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/40689ef8-1924-ae81-5d42-e1e9d268352d%40makr.zone.

ma...@makr.zone

Hi joël

> the test rig is in the middle of the working area, more than 400m away from the X limits.

Finally found it.

Background: As part of the calibration it will move right to/from

the soft limits (maximum possible move). It needs to convert raw

axis coordinates (soft limits) to camera coordinates. And that's

where the bug lay dormant.

You seem to have head offsets on the camera that are non-zero,

which is unusual but perfectly legal. This flushed out the

bug, my code was not accounting for the head offsets.

--> Fixed the bug. It will be in the upcoming version.

Unfortunately there is no workaround, unless you want to set the camera head offsets to all zero.

May I ask, why yours is non-zero?

Again, many thanks for helping with this!

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/8535fb70-3554-9bb9-fa15-afac11c01a48%40gmail.com.

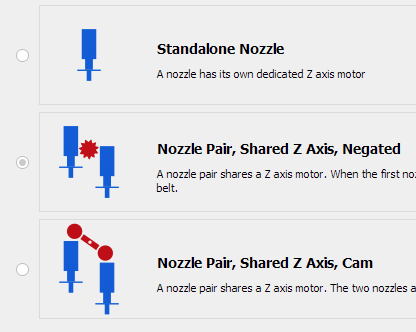

ma...@makr.zone

Good catch!

This was initially only offered when you are in the Welcome

Milestone.

But then I made it fully revisitable, i.e. you can change the

solution any time later. But of course, then it needs to discover

the machine configuration, on the very first incarnation.

I've now implemented that. This now also sets the solution as

initially solved on machines that are already beyond the Welcome

Milestone.

It discovers your machine.xml as follows. Note, how it is marked

"Solved" and you have to enable Include Solved to see it:

You could now at any time press Reopen it and then change the number and configuration of your nozzles, without losing any existing settings (except names). For instance if one day you add two more nozzles 😂

Thanks!

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/201e995b-be01-4cb1-9eb5-f679e8d418dbn%40googlegroups.com.

jdlv

Hi Mark,

no problem to wait for the next version. My machine has closed

loop servo and linear scale so the backlash should be very low.

The camera head offset became non zero when I changed the camera for a color one. Didn't have the courage to re-calibrate everything or so, camera offsets was a handy workaround...

I did calibrate the camera - nozzle offsets and then the

uplooking camera position. Everything went fine but now there is a

placement offset when doing a real placement job. Something like

100µm and 50µm on X and Y axis.

Cannot say if the error offset comes from the nozzle - camera or

the uplooking camera calibration or something else I missed. I

tweaked the up camera offsets to compensate.

Would it be possible to use a real part instead of the confetti,

a part that can be seen and aligned by the 2 cameras?

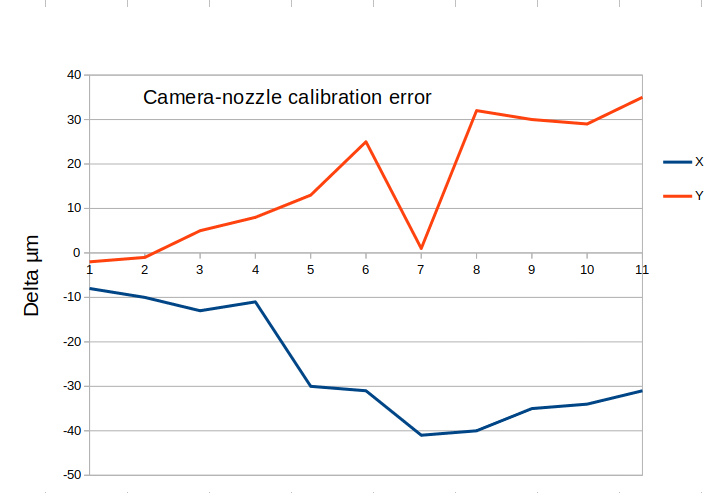

I did a few tests to evaluate the camera - nozzle offset

calibration accuracy;

Successive calibration offsets are subtracted from the first

calibration offsets at machine power up, difference is plotted in

µm. Sorry the sampling frequency is not constant at all and maybe

the Y value at measurement 7 is wrong, previous values entered

instead of new ones (wrong line). Nevertheless it seems to show a

drift over time, maybe the camera self heating?

If the seventh Y value is really a mistake the delta of 2 consecutive value is rather low, my machine has 10µm resolution linear scale. I did not use a confetti but a printed fiducial, a black circle with a 1mm white circle at the center. Don't know if a small circle is better or not.

I will do this again to know if the drift comes from the camera

warm-up or not.

That's a great tool, thank you Mark!

joël

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f3e2e1d8-77b3-aaae-98ea-38468f404c52%40makr.zone.

ma...@makr.zone

Hmmm... difficult. I'm no Java Swing expert, just trying my best.

AFAIK, only JLabel can render HTML text and there is no way to

make this selectable.

So I made a hack: you can press the right mouse button and it is

copied to the clipboard.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/9b53c9c8-f1dc-4088-a600-24156c10bf47n%40googlegroups.com.

ozzy_sv

ozzy_sv

ma...@makr.zone

Hi joël

The question is whether it will go on growing. As long as it is

<= 50 µm, I don't see a problem.

It could also come from the nozzle mechanics, there are hot steppers heating the whole head assembly.

If I'm not too tired to get this right:

Aluminium has a CTE of ~24E-6/°C, so with say a 20° to 80° = 60°

heat-up you get 0.00144 parts expansion. With say 70mm offset you

get ~100µm. It may be less heat-up in the aluminium (gradient) but

it may also bend the nozzles out with some leverage because the

front is hotter than the rear.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/2a5d2691-3831-7fe9-a4b8-eb95d16e8f8a%40gmail.com.

ma...@makr.zone

Done.

It can now be up to 40% of the camera smaller dimension, before

only 25%.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/7c6ca572-4e13-47d2-ab0f-02430b58a28fn%40googlegroups.com.

ma...@makr.zone

jdlv

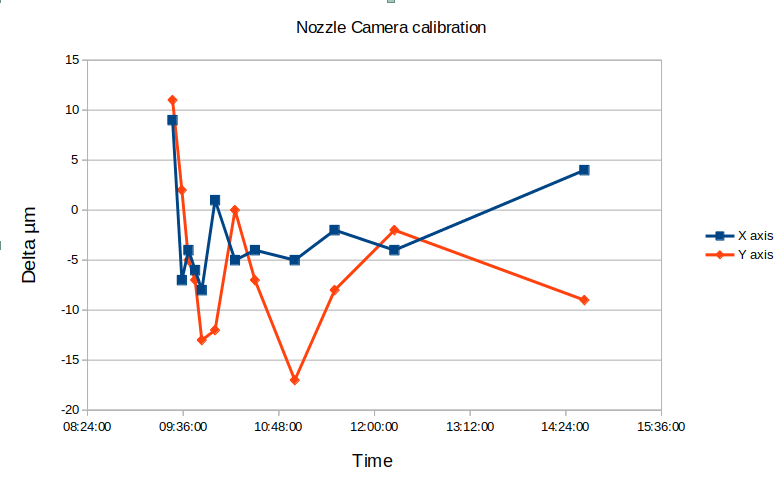

I did the same tests and today the drift is gone, very good and consistent results:

As the previous plot, successive calibration offsets are

subtracted from the first calibration offsets at machine power up,

difference is plotted in µm.

No more drifts, strange... Maybe a mechanical issue somewhere...

Did the same for up looking camera position. If I have understand

correctly the calibration Z height is determined by auto focus.

Looks like the results depends a lot on initial nozzle Z value

something like 1 mm lower. So the initial height value was reset

to the same value of -26mm before each calibration tests:

| delta X | delta Y | Z autofocus |

Rotation |

| -2 | -3 | -27 | 0.147 |

| 4 | -15 | -27 | 0.159 |

| 5 | -18 | -27 | 0.152 |

| 9 |

-6 | -26.9 | 0.176 |

| 8 | -9 | -26.95 | 0.142 |

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/55846be4-0947-7125-0123-d98dcfe06c89%40makr.zone.

ma...@makr.zone

Auto focus has much less resolution than anything else and

accuracy is (luckily) also much less important, as the focal depth

of the camera is not that shallow and the pick/place Z are not

that important, having a spring on the nozzle.

The autofocus has a resolution of 0.05mm, it will not even try

something more precise. Given that, your results are very good.

There is something that I want to improve one day: today it seeks

for the focus up and down, so backlash will be present. In the

future it should only seek moving down, because all

movements that matter are down anyway.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/059579b1-4835-b1c4-cc3e-b808e24570e3%40gmail.com.

ma...@makr.zone

Zdenko Stanec

ma...@makr.zone

> I tested this new "Testing" release, I did not find any big issues and everything was clear and simple to me.

Cool!

> The only minor issue I found is after N3 and N4 (camera to nozzle offset), C3 and C4 stay on -30deg

The final C rotation of the nozzle is not reset after doing the

calibrations, so this could well be.

I will rotate them back to zero, to allay any concerns that this

might be a "result" of the calibration.

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/70892780-d58c-44b1-9982-6e29c3dfe7fdn%40googlegroups.com.

ma...@makr.zone

Hi,

Please help with testing, everybody! 👍👍👍

Another small update in the testing version, and merged the latest contributions by @doppelgrau:

https://github.com/openpnp/openpnp/pull/1262

It just bothered me to let the user manually fiddle with that fiducial diameter. This stuff is supposed to be automatic! 😅

So there is now Auto-Adjust! It might not work every

time, so there is still the manual option.

More info and links:

https://makr.zone/openpnp-automatic-machine-calibration-with-issues-solutions/676/

Please help with testing, everybody! 👍👍👍

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/b497055a-effb-7323-799d-56ce1d607ac6%40makr.zone.

Robert Harrison

tony...@att.net

Zdenko Stanec

ma...@makr.zone

Thanks Zdenko, for you ongoing testing! Much appreciated! 😃💯

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/c977e62a-8c20-4df2-be1e-284358aefbf8n%40googlegroups.com.

tonyl...@gmail.com

- It would be nice to have an "undo reopen button" for things that have already been solved - I accidentally clicked reopen on something I really didn't want to revisit but my only options at that point were to accept or dismiss.

- The calibration fiducials don't have to be white on a black background - I used black on a white background and they worked just fine. Both calibration fiducials don't have to be present on the machine at the same time. I "stack" mine vertically to save space. The operator just has to have the information to know which one to place on the machine at each step.

- When I first tried the backlash calibration it would hit a soft limit exception because I had my calibration fiducials too close to the axis limits. However, I don't have any place on my machine where I could meet the 250mm requirement described in the Wiki without moving a bunch of feeders. While it's probably a good goal it doesn't seem absolutely necessary to get a decent calibration. So I slightly modified your code in displacedAxisLocation (see highlighted section below) to limit at the soft limits rather than just blindly ignore them. It seemed to work ok after that.

- The nozzle offset process is cool but one improvement to speed it up (not that it takes too long) would be to just lift the test object a couple of millimeters instead of all the way to safe Z before rotating and replacing it.

- Initial bottom camera setup seems a bit incomplete - I expected its default Z to be set to the same coordinate as its head offset Z coordinate (set by auto-focus) but it wasn't. Am I misunderstanding something?

ma...@makr.zone

Hi Tony,

Thanks for the thorough examination.

Re 1: Yes, this also accidentally happened to me. But I

haven't found an easy way around it without cluttering the GUI and

making it overly complex (you've probably seen the discussion

feed-back, it really needs to be simple).

Any good ideas? The best idea so far was to add a confirmation message box, asking "Reopening <name of solution> will possibly invalidate dependent calibrations. Are you sure?"

Btw. I spent a lot of effort to make calibration steps as

independent as possible. Examples: X, Y re-calibration will

carefully preserve Z. And vice versa, setting the rough nozzle

head offsets and Z by manually jogging the nozzle over the

fiducial, will preserve calibrated X, Y if those are within

tolerance (within the fiducial radius). Setting new (default)

nozzle head offsets will be propagated to dependent settings, such

as the bottom camera position or an actuator (e.g. Push-Pull) that

was on the same offsets as that nozzle.

So redoing a calibration even out of order is not that bad

anymore.

Re 2: True. Up until now I wanted it be as simple as

possible i.e. handle Visual Homing the same way, where the

standard pipeline expects a bright on dark fiducial. However, now

the Visual Homing solution does replace the FIDUCIAL_HOME

pipeline too, installing one with

DetectCircularSymmetry, so this can go away.

I will change the description.

Re 3. Good remedy. I trust a user would be reasonable

enough to see that a very close limit would really degrade the

results. Do you think the limiting should be limited😉?

Re 4. Well, there are some machines that have pneumatic

nozzles (only up or down). They have a Virtual Z axis and actuate

the pneumatics via Safe Z threshold. Those would be unnecessarily

excluded:

https://github.com/openpnp/openpnp/wiki/Axis-Interlock-Actuator#pneumatic-nozzles

Note: I'm not saying that all the other solutions of the

calibration support such a machine, I just want to avoid

exclusion, where it is unnecessary.

Re 5. You're right. But there's a reason.

My ongoing work on the next round aims to deploy 3D

calibration to most of the various feeder classes, nozzle

tip changer, PCB fiducials (if someone has their PCB not at

default Z, despite all recommendations to the contrary). In order

to do that, I had to examine all direct and indirect (!) uses of

Units per Pixel in the whole of OpenPnP. After working through all

that, I concluded that bottom camera 3D calibration has no use

case. The subject can either be brought into the focus plane

(nozzle Z), or the focus plane is unknown (Auto-Focus).

Therefore, I have now already moved setting the "working plane Z"

fully to the (virtual) axis Z of the camera and removed stuff from

CameraView that allows setting it independently. As it has no Z

axis, this implicitly excludes the bottom camera from having a 3D

"working plane Z".

If we ever find a real-world use case for 3D calibration in the

bottom camera, we will have to find a way of "registering" the

currently viewed subject movable (nozzle) with the bottom

camera and then use the subject movable Z axis

(but sometimes minus part height?) as the working plane. But it

does not make sense, I see no such application. Do you?

So I excluded 3D calibration completely for the bottom camera.

Yes, we could do it, it would even be easier with the

movable Z subject, and my programming is all prepared for it. But

No, I don't think we should. It just makes things more

complex with no gain.

I hope you see that too, acknowledging you must already have spent considerable time and effort implementing it 😕

What do you think?

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/3b1ee34b-4664-4bec-a24b-c436bcffc40cn%40googlegroups.com.

ma...@makr.zone

Afterthought, just to be clear: if you need to preform 3D

calibration anyways, to determine camera tilt and the "true

center", there is nothing standing in its way. I would just not

expose it to the user.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0f0ba43c-0a0c-87bc-af44-2b5952d8fc77%40makr.zone.

tonyl...@gmail.com

ma...@makr.zone

Hi Tony,

> The second is not defined anywhere so I'm defaulting it to the Z coordinate half-way between the first and zero with an option for the operator to change it if its not in good enough focus - does that sound reasonable to you?

By "zero" you mean Safe Z, right?

When I was still planning it, I thought I would choose these:

Za = Camera location Z (which is what the auto-focus calibrated)

Zb1 = Camera location Z + the Max. Part Height, as set on the Nozzle. This is also what the Auto-Focus uses as its search-range, when the part height is unknown and must be auto-learned. See the Wiki.

Zb2 = Camera location Z + the diff between primary fiducial Z and secondary fiducial Z, under the assumption that this gives us the useful Z range for this particular machine (maximum practical part heights, etc.) that are equally sensible for the bottom camera.

Zb3 = Safe Z minus 0.01mm (to make it outside the Safe Z zone)

And then:

Zb = min(Zb1, Zb2, Zb3)

But that's probably overkill.

Perhaps Zb1 is sufficient and if need be, it can be

easily changed by the user, on the GUI. Using a LengthProperty,

you can easily expose the Max. Part Height field directly

on the solution. See the backlash calibration acceptableTolerance

for an example.

_Mark

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/dBg7txMB0R0/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/a52f512b-d953-4ae0-91e9-5c6a971e64ebn%40googlegroups.com.

bert shivaan

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/67d86bef-dcb9-b176-e206-ba7916ae94e7%40makr.zone.

ma...@makr.zone

Yes, absolutely. Many brains are so much better than just one or two. 😉

The problem: you would have to have different known height test parts (spacer + fiducial on the underside) on the nozzle, to be able to calibrate 3D.

So this would be a non-trivial addition. I guess we have to keep

this in mind for later.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CA%2BKNHNy%2BdQXqn6WTcMvhqmX4Lq8aRM7Zp4HJSO4iXNSfLGDBdg%40mail.gmail.com.

Robert Harrison

Robert Harrison

Robert Harrison

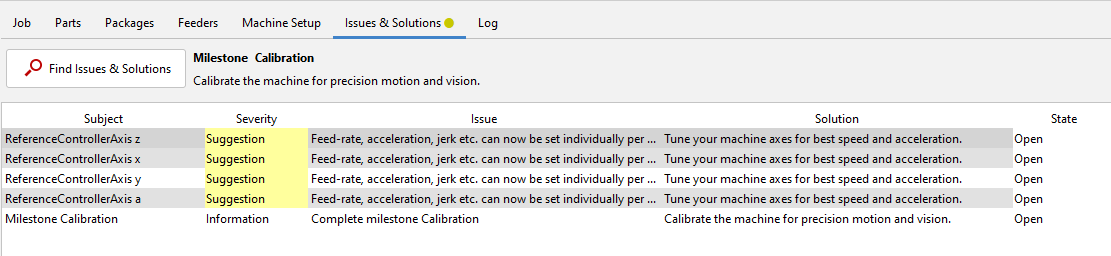

ma...@makr.zone

Hi Robert,

these I&S suggestions show up when you haven't changed the feed-rate, acceleration and jerk from the defaults set (or migrated) by OpenPnP.

Most machines can be optimized to use a different setting for

feed-rate, acceleration and jerk for each axis individually.

On a typical portal style machine, the X axis can be faster, as

the head is much lighter than the whole portal moving in Y. The

accelerations (jerk) are very important for the overall machine

speed.

Even more important, the rotation axis can often be dramatically

made faster in number terms, as these are degrees, not

mm. It is on most machines much easier to rotate a nozzle by 180°

than it is to move an Y axis by 180mm. So you can and should tune

your settings up!

However, you always need to consult your controller's settings.

These limits are often in addition to what OpenPnP sets.

OpenPnP settings must always be lower than or equal your

controller's settings.

As to TinyG's settings, I hope Tony can answer you. You might

search this group for other messages by Tony, he has repeatedly

posted his config, as far as I remember.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/83093f51-2432-428c-b903-ea911dfb95fan%40googlegroups.com.

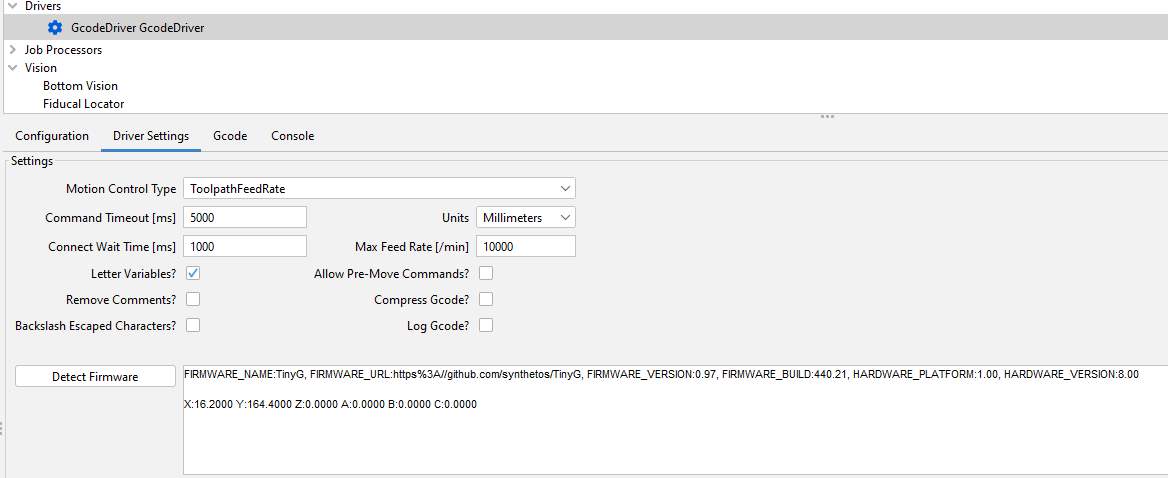

Robert Harrison

ma...@makr.zone

Hi Robert,

You still need to set accelerations too, even if TinyG itself

does not use or support such a thing. OpenPnP will instead predict

the motion ramp and then reduce jerk, if the set

acceleration limit is reached. So the jerk limit will effctively

be set dynamically, depending on how far a move is, i.e. how long

the jerk can increase the acceleration.

Note, you can look at what OpenPnP does, here (you'll need some Advanced configuration, offered by Issues & Solutions):

https://github.com/openpnp/openpnp/wiki/Motion-Planner#motion-planner-diagnostics

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0fab82cc-e8b2-46b2-98f8-a089b4893912n%40googlegroups.com.

ma...@makr.zone

tonyl...@gmail.com

fxframes

Robert Harrison

ma...@makr.zone

Robert,

Does Issues & Solutions not say anything?

I guess you still have a feed-rate limit on the driver. But again, I&S should tell you so.

A bit of background:

https://github.com/openpnp/openpnp/wiki/GcodeAsyncDriver#control-of-speed-factors

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/c72c52f2-e8c3-4c6f-821e-1af90da32999n%40googlegroups.com.

Robert Harrison

Fixed it my Max Feed Rate was set to 1000 here and I've now set it to 10,000 and all is good.

Robert Harrison

ma...@makr.zone

Yes, but let I&S take care of it. Just go to the "Advanced" Milestone.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/55b04963-d2a9-4a55-987d-8391b5f8190bn%40googlegroups.com.

Saito Ryosuke

I am trying your test release which was delivered on the 5th.

Version : 2021-09-05_18-21-56.6f36853

From the milestone, I tried to calibrate the X axis.

To start the calibration, I did the following steps to prepare.

1. set up the test fiducial (FiducialHome.pdf) at the focus height

2. Jogged the downward-facing camera on the head to the center of the fiducial at 1.

3. select "Calibrate backlash compensation for axis X." in the "Issues & Solutions" tab.

4. click "Accept

The X axis of the head moves 1.347, the Y axis moves 0.169, and the error message "Subject not found.

Here is a video of this scene.

https://www.youtube.com/watch?v=ybGVW8KmTTI

It seems that sometimes the same procedure can start the calibration correctly.

Immediately after proceeding to "Random Move Accuracy Test Step 1"

An error message "Subject not found." pops up and the calibration stops.

Here is a video of this scene.

https://youtu.be/JydbBlKm1eo?t=418

The OpenPnP log taken at the same time as this video was taken is shared below.

http://gofile.me/3PODq/5gxPS4Dek

I want to solve this issue. I would like some tips on what I need to check first.

Thanks.

Ryosuke

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/9a89eca6-62c1-a870-7b22-44430ddfa04e%40makr.zone.

ma...@makr.zone

Hi Saito

The only thing that comes to mind is camera settling. You seem to

have fixed time settling (no settling log entries) and an

extremely short settle time of ~40ms:

2021-09-07 15:53:26.819 Scripting TRACE:

Scripting.on Camera.BeforeCapture

2021-09-07 15:53:26.863 Scripting TRACE: Scripting.on

Camera.AfterCapture

2021-09-07 15:53:26.864 Scripting TRACE: Scripting.on

Camera.AfterSettle

Please investigate, if a (much) longer camera settling time

helps. The fact that it seems to fail in "Random Move Accuracy

Test" hints at some camera vibration/lag issue, related to harsh,

fast moves.

For more info, also about configuring adaptive settling, that

waits longer when the machine vibrates, but is still fast when

not, see here:

https://github.com/openpnp/openpnp/wiki/Camera-Settling

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAH6K8ZXHKEdbSkNq9ssodTc%2BsNaiGcq4KNCWrNHhK3fEWD%3D0gQ%40mail.gmail.com.

Saito Ryosuke

I was able to successfully calibrate the X axis while checking the camera settings.

## Downward facing camera settings

The downward facing camera was set to "FixedTime" "267mSec".

I chose "Euclidean" from the Settle Method and successfully completed the X-axis calibration.

It is difficult to judge whether this setting is appropriate or not because I don't know enough about each parameter, but anyway, the X axis has been solved.

## Calibrating the X-axis

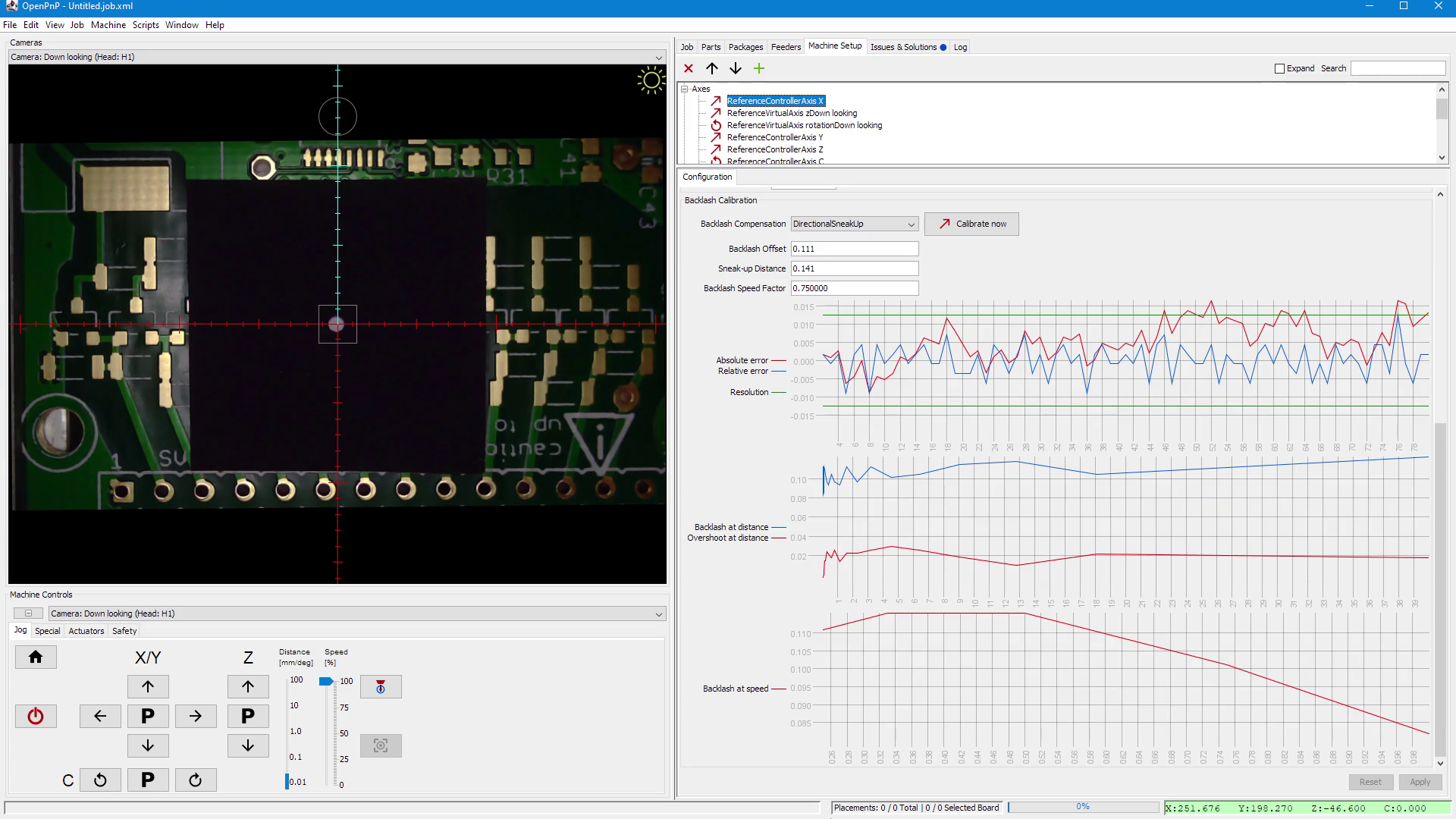

The calibration of the X-axis was successful and I saw the graph.

I noticed that the "Absolute" value of "Error at step" was accumulating errors in a linear pattern.

I understand that the error shown in this graph is corrected by calibration. Is this understanding correct?

Because, at the moment, I cannot find any way to correct the value of Absolute.

.png?part=0.3&view=1)

//------------

## Calibrating the Y axis

In the process of calibrating the Y axis, I ran into a problem that I don't know the way out of.

"Accuracy Test Step 85-100", when the fiducial moves in the negative direction of the Y-axis.

In "Accuracy Test Step 85-100", when the fiducial was moving in the negative direction on the Y-axis, the green line surrounding the fiducial mark was decreasing as it moved away from the starting point.

The green line around the fiducial mark decreases as it moves away from the starting point, and I am unable to solve the problem of the calibration failing at around 100.

I suspect the settings in "Machine Setup" - "Vision" - "Fiducial Locator".

I tried loosening the range of "Mask Circle" (from 300 to 500), which I had defined additionally,

.png?part=0.4&view=1)

If there are any other points I should check, I'd love to hear from you.

The current machine.xml and the log file when the Y axis failed to calibrate

http://gofile.me/3PODq/v8KWd4QRv

By the way, I still haven't solved the problem of the axis "running away" at the start of calibration. Do you have any experience with this situation?

The fiducial mark was definitely in the center of the crosshairs when I started the calibration....

.png?part=0.5&view=1)

Thanks.

Ryosuke

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/4e2ecbfb-3640-af41-9fce-8124ebec27a1%40makr.zone.

ma...@makr.zone

Hi Saito,

Thanks for testing!

> It is difficult to judge whether this setting is appropriate or not because I don't know enough about each parameter

I guess you've already looked at the WIki? To improve it, please

say where it is not understandable, then perhaps I can improve the

instructions:

https://github.com/openpnp/openpnp/wiki/Camera-Settling#advanced-settle-methods-and-diagnostics

> I noticed that the "Absolute" value of "Error at step" was accumulating errors in a linear pattern.

That red absolute error looks like I made a mistake in one of the

last revisions. I will have a look tomorrow.

Your backlash values look very nice, but the end result is

strange. The orange dots (in the first graph) are the random move

test, that is done at the end with the new calibrated settings.

These show errors of ~0.2mm, which is too much. I don't understand

at all.

Can you please send a log?

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/dBg7txMB0R0/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAH6K8ZWtZzfYLy%2Bdg1hxSuEq8ThGi03Nx9uaEoXOtb_35%2B3Y4Q%40mail.gmail.com.

Saito Ryosuke

Thank you for your support!

## Understanding of camera parameters.

>I guess you've already looked at the WIki?

Yes, I often come back to this document and read it over.

It seems that the units of the parameter you specify for "Center Mask" are not clear.

I give a value such as "1.000" as the setting value, but am I correct in understanding that this is "mm (1/1000meter)"?

Is this a function equivalent to "MaskCircle" - "diameter" in the pipeline?

## Another topic about cameras

Changing the camera settings will (of course) invalidate the calibration values.

I didn't notice for a while that the calibrated axes were invalidated.

It should be made clear to the user on the screen where the camera parameters are modified that changing the parameters will invalidate the calibration that has been performed up to that point.

I think it needs to be communicated to the user that changing the camera parameters will invalidate the previously performed calibration.

## not good value of "random" in calibration result.

>Can you please send a log?

I'll share two of the logs.

01 is a case where the log shows that there was an error and it appears to have been aborted.

02 is a case where the calibration appears to have completed successfully.

However, the random value is still not good.

In this thread I will probably continue to share the logs.

Instead of individual files, I will share a dedicated directory.

http://gofile.me/3PODq/2qILJRrOi

I've also saved the videos as files. Please give me a shout if a Youtube link would be more convenient.

Thanks.

Ryosuke

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/07eeee6a-337c-e8fa-2dc3-d37830d9fb63%40makr.zone.

ma...@makr.zone

> It seems that the units of the parameter you specify for "Center Mask" are not clear.

Fair point, I tried to improve the description:

Use the Center Mask to remove unwanted image peripherals that might spoil Contrast Enhance (like a diffuser or shade partially in view). If set to 0.0, no mask is applied. Values larger than 0.0 are relative to the camera dimension, i.e. 1.0 means from edge to edge. You can set values larger than 1.0, the circle will then be partially cropped.

https://github.com/openpnp/openpnp/wiki/Camera-Settling#advanced-tuning

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAH6K8ZU10BFT0Vhd3Vj6H66kW3LUPEmk2x9dNDZE8frhO6U1QA%40mail.gmail.com.

Saito Ryosuke

The behavior of the "Center Mask" was completely unexpected.

Now I feel like I've conquered the settings of this screen ;-)

>What settings exactly do you mean?

But sure enough. If there are no factors such as the focal length of the camera or the distance between the object and the camera, which change the length corresponding to one pixel distance, the calibration is valid.

I understand that if gain or contrast changes, it is still valid, and the same is true for shutter speed, etc.

What made me think this way was that the (finally) successful calibration of the X axis (the graph) was lost for some reason, and the "no data" message appeared.

The reason why I thought this way is because I experienced an incident where the (finally) successful calibration of the X axis (the graph) somehow disappeared and became "no data". (Reference Machine - Axes - ReferenceControllerAxis X screen)

I still can't figure out what causes the "no data" message. Oh, it's gone again...

I always believe that I am responsible for undesirable results. I must be doing something wrong.

After a successful calibration, the last operation I performed was to change the "Settle Threshold" in TopCamera.

This led me to believe that the calibration would be invalidated if the camera settings were changed.

However, it turns out that this understanding is not always correct.

//----

I found out the procedure to lose the calibration result of the X axis.

Maybe this test version still doesn't save the calibration results?

Then I can focus on the results of the calibration.

1. run "Calibrate now" on the Reference Machine - Axes - ReferenceControllerAxis X screen.

2. wait until the calibration is complete.

3. view the calibration result graph

4. Click on the power icon of OpenPnP to shut down.

5. Close the OpenPnP application.

6. start the OpenPnP application.

7. click the power icon of OpenPnP again.

8. Perform the homing operation with the "Home" icon.

9. Check the calibration results on the Reference Machine - Axes - ReferenceControllerAxis X screen.

10. "no data" is displayed.

thanks

Ryosuke

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ab07209d-86fc-c732-0ae7-2d7611270290%40makr.zone.

ma...@makr.zone

> I still can't figure out what causes the "no data" message.

The calibration graphs are only a nice feed-back for the user, it

is only available momentarily until you exit OpenPnP. That's

normal. We would have to implement persisting that graphical data,

but that's not quite so easy.

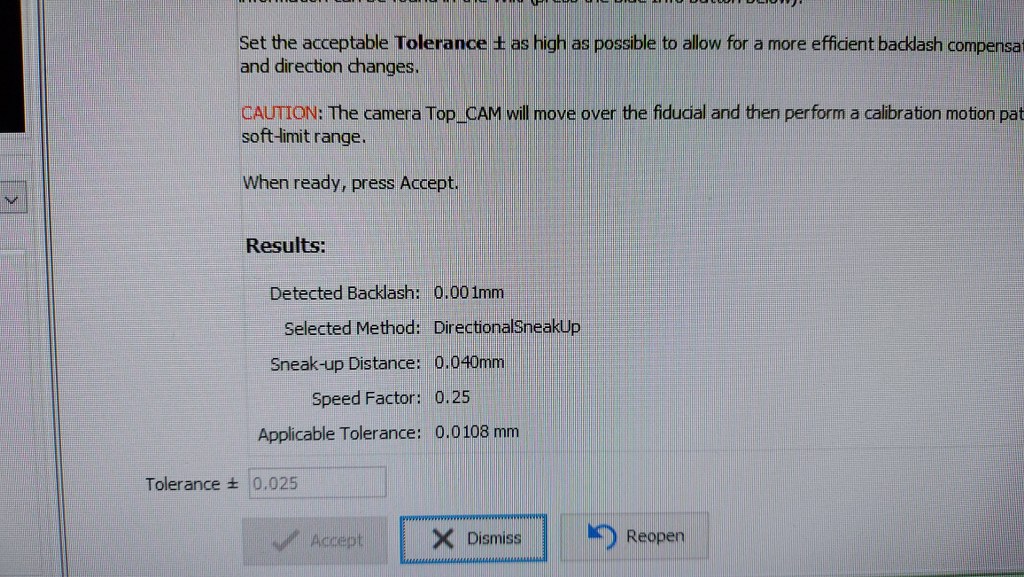

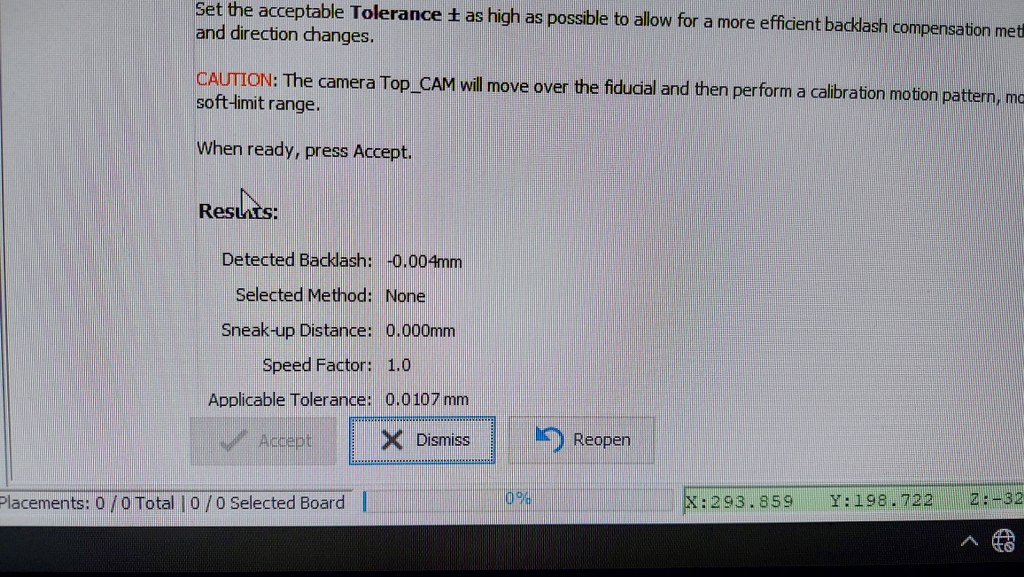

What is important is that the result of the calibration,

i.e. the backlash method, offset, speed, and

sneak-up distance are persisted and that is the

case.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAH6K8ZWqcAU82%3D%2B1XOVj-D%3Dv%2B53-hLKRx2C39KXuTDTo41pYgQ%40mail.gmail.com.

fxframes

fxframes

Just adding that soft limits are enabled for y and also the y min switch is being normally used during homing.

fxframes

ma...@makr.zone

Have you checked the log? Is OpenPnP actually commanding it to go beyond the soft limits?

If not: The soft limit must be set for the worst case

motion. The Liteplacer is extremely shaky i.e. when you go at full

blast to the soft limit, the switch might be triggered by the

portal, head or belts swinging around.

On my Liteplacer I had to set soft limits several mm away from

the switches. You can test this using the ![]() and

and ![]() buttons back and forth rapidly and at full machine

speed.

buttons back and forth rapidly and at full machine

speed.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0718d0e3-4db7-4790-9304-d059deaee9can%40googlegroups.com.

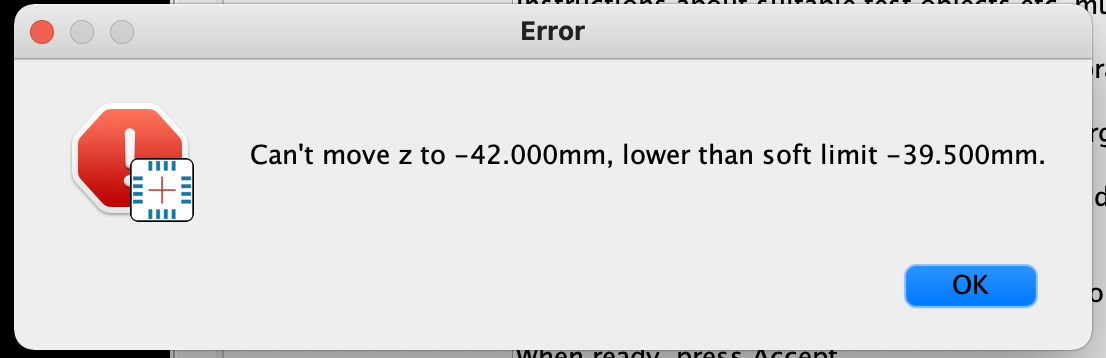

fxframes

fxframes

ma...@makr.zone

Hi fxframes,

Strange. During development I did exactly that a gazillion times and it never did that.

Some ideas:

- Please check the Safe Zone on your Z axis, i.e. make sure you

did the Safe Z solutions right.

- Check if there is a Z head offset on the nozzle. That would

probably point to a bug.

Please send the log of that session. Note, OpenPnP keeps the last

100 logs around, so you should be able to find it.

See the $HOMEDIR/.openpnp2/log/

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/91fdbceb-c909-4358-8d43-9417486ea108n%40googlegroups.com.

fxframes

ma...@makr.zone

Hi fxframes,

Be mindful of the selected tool in the Machine Controls.

Issues & Solutions will automatically select the right tool

for a task when you select a solution that needs positioning

that tool. This might be unexpected! So when it selects the

camera, for instance, and you then want to jog Z, nothing

(visibly) happens. You need to switch back to the nozzle if you

want the nozzle.

I'm aware of pros and cons of this behavior. Personally,

I found it useful, but I'm open for

discussion. I could also make it conditional on the Auto

tool select switch:

https://github.com/openpnp/openpnp/wiki/Setup-and-Calibration:-Machine-Setup#the-machine-setup-tree

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f0ffa1a8-6c6e-48f1-8aea-e710124f861en%40googlegroups.com.

fxframes

ma...@makr.zone

> One another note, wouldn't you expect a little interaction between the backlash setting and the XY calibration?

By "XY calibration" you mean Units per Pixel, right?

In the Camera calibration, that comes before the

backlash calibration, I tried to exclude any influence of

backlash, by forcing the machine to execute huge deliberate

"backlash compensation" moves. All locations are always approached

slowly, and going into the same direction +X/+Y.

If you look closely in the video, you see these slow diagonal

approaches it in the overlaid machine view:

https://youtu.be/md68n_J7uto?t=34

> And vice-versa, if the pix/in setting is a bit off,

wouldn't that influence the backlash results?

Yes, Units per Pixel must be set, before backlash

calibration. In fact, Issues & Solutions takes great care to

propose these steps in the right order. The order is one of the

most complex problems for (typically new) users to get right,

sometimes it would even involve iterative re-visits to

get good precision. I&S aims to remedy that.

Having said that, as long as Units per Pixel are not off by more

than say ±5% (which is a lot), it would not actually matter,

because the distances involved are tiny and backlash is usually

quite inconsistent anyway, at last for "mechanically challenged"

machines like mine.

But in general you are right that things interfere back and

forth, and there are some complex dependency tracking updating

mechanisms built-in, so that chicken-and-egg loops can be broken.

One example is the calibration of the precise nozzle-to-head

offsets. Changing the offsets it also (by implication) changes the

bottom camera position, because it was earlier calibrated using

the old imprecise nozzle-to-head offsets that was

taken from manually jogging the nozzle tip over the fiducial.

Therefore, after the precise nozzle-to-head offsets calibration,

OpenPnP will automatically update the bottom camera position by

the amount of the adjustment.

You can look into the log and filter by INFO level messages to

see the most important updates.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/d3d3faed-744c-4ebe-b9a0-96b6061eb70en%40googlegroups.com.

fxframes

fxframes

ma...@makr.zone

It seems your preliminary nozzle head offsets that you set when you moved your nozzle to the primary fiducial, are not accurate in X, Y, perhaps even in Z. I'm speaking about this step in the video:

https://youtu.be/md68n_J7uto?t=109

I'm very interested in knowing if this is a bug. So please help me diagnose it, by answering some questions to exclude other reasons (this is in no way a "test" 😃, there is no doing it "right" or "wrong", I know the realities of DIY projects 🤣):

- Since you performed that calibration step (above): have you

never changed the offsets by hand?

- moved or crashed the Zmax endswitch?

- changed the controller settings?

- moved the calibration rig?

Now for fixing it:

First go to the nozzle and look at the offsets. Write them down. Is Z = 0?

You can re-do this step by switching on the Include Solved?

checkbox on the Issues & Solutions tab.

Then select the "Nozzle N1 offsets for the primary fiducial"

issue and press Reopen.

Then follow the instructions to re-do it.

Then compare the offsets with the ones

you've written down. Report back, please.

Check, if your bottom camera is still at the right spot, i.e. the nozzle tip centered in its view, if you press this button:

Report back.

If not, you might have to re-do the following Issues & Solutions steps too. Please report any recurring anomalies. 🤔

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f28eeaf5-c525-4ad7-a0eb-8229d0a7126bn%40googlegroups.com.

Zdenko Stanec

Zdenko Stanec

ma...@makr.zone

Thanks for that feedback. I'll have a look again.

I wish I had a multi-nozzle machine myself, for testing 😅

_Mark

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/dBg7txMB0R0/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/bd1766d7-3c09-4301-a581-822318ca387dn%40googlegroups.com.

ma...@makr.zone

Hi Zdenko

I'm looking at the code and I don't see any problems. But this stuff is complex, I'm not saying there are no bugs 🤯😵💫

So I would be extremely interested in the original log, when you

had the problem. Note, OpenPnP keeps a 100 old logs around, so I

guess you could find it. Look in the

$HOMEDIR/.openpnp2/log/ dir.

If you have grep or similar, search for " head offsets to "

$ grep "head offsets to" *

OpenPnP.86.log:2021-08-27 19:41:13.061 VisionSolutions INFO: Do not set nozzle N1 head offsets to (-78.651874, -22.788375, 0.000000, 0.000000 mm) as these are close to existing offsets (-78.667792, -23.036375, 0.000000, 0.000000 mm) and existing offsets might already have been be calibrated.

OpenPnP.86.log:2021-08-27 19:42:57.236 VisionSolutions INFO: Set nozzle N1 head offsets to (-79.667987, -23.035969, 0.000000, 0.000000 mm) (previously (-78.667792, -23.036375, 0.000000, 0.000000 mm))

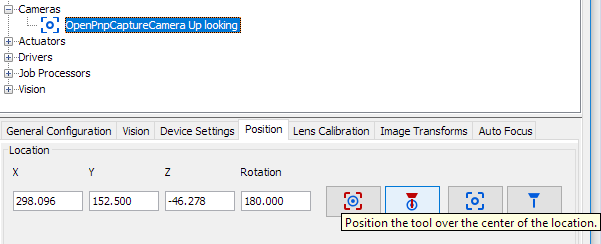

OpenPnP.86.log:2021-08-27 19:42:57.236 ReferenceNozzle INFO: Set camera Up looking head offsets to (297.324473, 152.579977, -46.677500, 180.000000 mm) (previously (298.324668, 152.579571, -46.677500, 180.000000 mm))

OpenPnP.86.log:2021-08-27 19:48:04.343 ReferenceNozzle INFO: Set camera Up looking head offsets to (297.189211, 152.670605, -46.278000, 180.000000 mm) (previously (297.189211, 152.670605, -46.278000, 180.000000 mm))

OpenPnP.86.log:2021-08-27 19:49:15.956 CalibrationSolutions INFO: Set nozzle N1 head offsets to (-78.760991, -23.206832, 0.000000, 0.000000 mm) (previously (-79.667987, -23.035969, 0.000000, 0.000000 mm))

OpenPnP.86.log:2021-08-27 19:49:15.956 ReferenceNozzle INFO: Set camera Up looking head offsets to (298.096206, 152.499741, -46.278000, 180.000000 mm) (previously (297.189211, 152.670605, -46.278000, 180.000000 mm))

OpenPnP.87.log:2021-08-27 19:15:04.807 ReferenceNozzle INFO: Set camera Up looking head offsets to (298.224473, 152.679977, -46.677500, 180.000000 mm) (previously (298.224473, 152.679977, -46.677500, 180.000000 mm))

OpenPnP.87.log:2021-08-27 19:22:50.299 VisionSolutions INFO: Set nozzle N1 head offsets to (-78.767987, -22.935969, 0.000000, 0.000000 mm) (previously (-78.667792, -23.036375, 0.000000, 0.000000 mm))

OpenPnP.87.log:2021-08-27 19:30:20.212 ReferenceNozzle INFO: Set camera Up looking head offsets to (298.324668, 152.579571, -46.677500, 180.000000 mm) (previously (298.224473, 152.679977, -46.677500, 180.000000 mm))

OpenPnP.89.log:2021-08-27 17:54:10.656 ReferenceNozzle INFO: Set camera Up looking head offsets to (376.953127, 175.527047, -46.162500, 0.000000 mm) (previously (298.256154, 152.256221, -46.162500, 0.000000 mm))

OpenPnP.89.log:2021-08-27 17:54:10.657 VisionSolutions INFO: Set nozzle N1 head offsets to (-78.667792, -23.036375, 0.000000, 0.000000 mm) (previously (-78.696973, -23.270826, 0.000000, 0.000000 mm))

OpenPnP.90.log:2021-08-27 17:42:38.037 ReferenceNozzle INFO: Set camera Up looking head offsets to (298.256154, 152.256221, -46.162500, 0.000000 mm) (previously (298.256154, 152.256221, -46.162500, 0.000000 mm))

OpenPnP.90.log:2021-08-27 17:42:48.692 ReferenceNozzle INFO: Set camera Up looking head offsets to (298.256154, 152.256221, -46.162500, 0.000000 mm) (previously (298.256154, 152.256221, -46.162500, 0.000000 mm))

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/237197ef-b9c2-e3ea-adb1-6b3d305aaf67%40makr.zone.

fxframes

- Since you performed that calibration step (above): have you never changed the offsets by hand?

- moved or crashed the Zmax endswitch?

- changed the controller settings?

- moved the calibration rig?

On 10 Sep 2021, at 19:47, ma...@makr.zone wrote:

It seems your preliminary nozzle head offsets that you set when you moved your nozzle to the primary fiducial, are not accurate in X, Y, perhaps even in Z. I'm speaking about this step in the video:

https://youtu.be/md68n_J7uto?t=109

I'm very interested in knowing if this is a bug. So please help me diagnose it, by answering some questions to exclude other reasons (this is in no way a "test" 😃, there is no doing it "right" or "wrong", I know the realities of DIY projects 🤣):

- Since you performed that calibration step (above): have you never changed the offsets by hand?

- moved or crashed the Zmax endswitch?

- changed the controller settings?

- moved the calibration rig?

Now for fixing it:

First go to the nozzle and look at the offsets. Write them down. Is Z = 0?

<comppiblipdepppk.png>

You can re-do this step by switching on the Include Solved? checkbox on the Issues & Solutions tab.

Then select the "Nozzle N1 offsets for the primary fiducial" issue and press Reopen.

<alehnjpkhocjihmb.png>

Then follow the instructions to re-do it.

Then compare the offsets with the ones you've written down. Report back, please.

Check, if your bottom camera is still at the right spot, i.e. the nozzle tip centered in its view, if you press this button:

<kjligjbhhcacmhlk.png>

fxframes

ma...@makr.zone

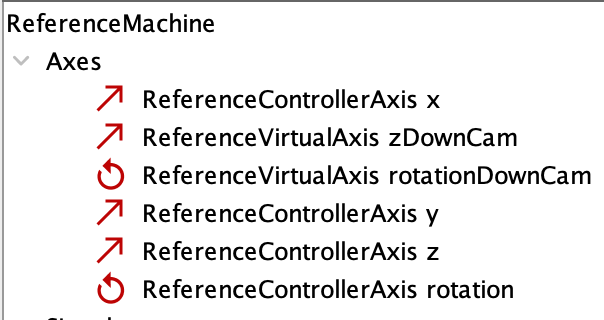

> A question before reporting on the rest, it seems I have two different Z axes for the nozzle and the camera. Is this right? I can’t remember why this is so.

Yes, the camera has a virtual Z and Rotation axis. If it

had the same physical Z axis as the nozzle, it would move

when going to a location with Z coordinate, causing crashes. Do not set it to the same axis.

Use cases etc. explained here:

https://github.com/openpnp/openpnp/wiki/Machine-Axes#referencevirtualaxis

The virtual Z axis has become very important for this:

Thanks for the precise description, I finally found and fixed that bug!

Will make a fix/upgrade soon.

Workaround: Set the Offsets to zero before using that

solution. Sorry about that.

_Mark

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/dBg7txMB0R0/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/11CE5BDF-EC3F-4C90-9A35-0C2316ED8AA8%40gmail.com.

ma...@makr.zone

1. The Actuator Problem: You have probably used the Nozzle

solution, right?

This will assign a vacuum sensing actuator by default:

But that should be ok to leave like this, even if you don't have them (yet). So I will change it, to not report that issue when all nozzle tips have Measurement Method = None.

2. The tab problem: I believe this is a bug of the theming

(Appearance) that was recently brought in.

Like I said in the Github Issue, I have tried everything to fix

it. The problem is definitely not the code doing it:

https://github.com/openpnp/openpnp/issues/1199

I'll think about adding a switch in the machine.xml to disable

the status indicator.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/d52a6ed3-ff58-4fc3-90b0-6aac8151bac8n%40googlegroups.com.

ma...@makr.zone

Ok, regarding the tabs: in the next testing version:

- Start and Exit OpenPnP (so the new machine.xml version is

written).

- Open your machine.xml

- Search for show-indicator

- Set to "false"

- Save

- Restart OpenPnP

...

<home-after-enabled>true</home-after-enabled>

<solutions show-indicator="false"

target-milestone="Calibration">

<dismissed-solutions class="java.util.HashSet">

...

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/d52a6ed3-ff58-4fc3-90b0-6aac8151bac8n%40googlegroups.com.

ma...@makr.zone

Thanks to all testers for the feedback! 👍👍👍

Hi everybody,Another one: Automatic Machine Calibration using Issues & Solutions - Round 6This one (finally) deploys 3D Units per Pixel Calibration to all vision operations! One piece of hard work 😅 😅 😅Including a brand-new Wiki page:Other stuff described here:This PR touches vision feeder classes AdvancedLoosePartFeeder, ReferenceDragFeeder, ReferenceLeverFeeder and quite possibly others that use vision that I don't personally use.These are untested, so I need your help.Sooner or later these changes will enter the regular OpenPnP version, so up-front testing is crucial for those that use these classes.Overview still here:

fxframes

ma...@makr.zone

Hi fxframes,

thanks again, for the testing effort. Sorry about that!

Silly me, I used a simplified test case, where the homing

fiducial is the same as the primary calibration fiducial, hence I

did not notice. Stupid rookie test case mistake.

I'll fix it as soon as possible.

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/53d3ebf7-6f69-4b3d-8314-fc0eae5a18ecn%40googlegroups.com.

ma...@makr.zone

Fixed!

Please upgrade. Again, sorry for that, and thanks for the patient testing 😅

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/4d061fff-7152-ba32-ce6e-4d28bdb89f1c%40makr.zone.

fxframes