Secondary Z fiducial nozzle misalignment

Litterio Andrea Guainella

mark maker

Hi LAG,

I read your post a few times, but I do not understand what the actual problem is?

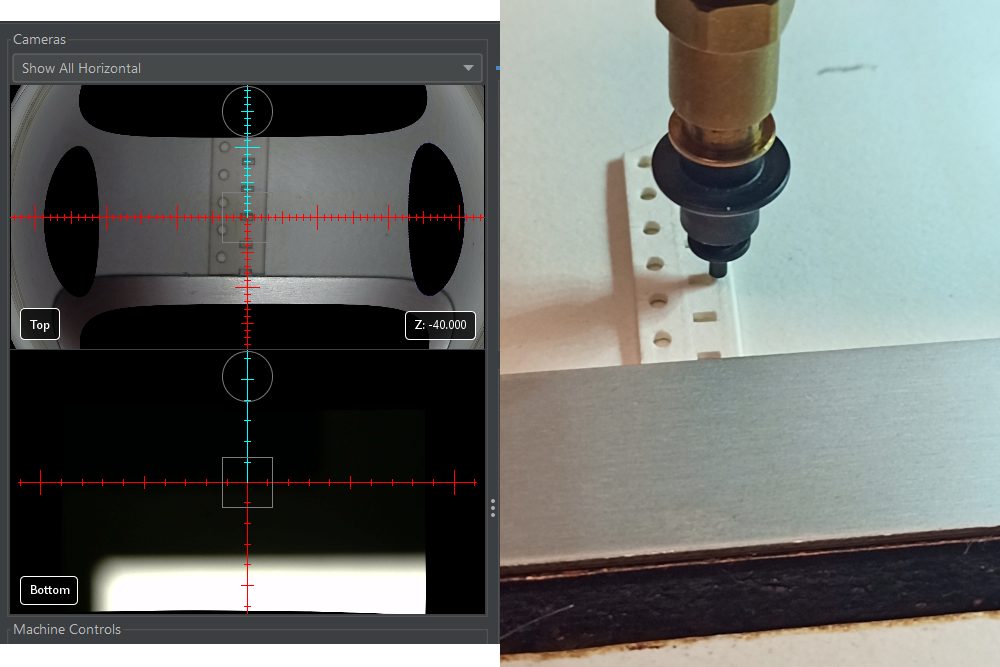

The images look good, the virtual Z is indicated on the camera

view as -20.1mm, which means your PCB would be at ~-42mm which

sounds about right for a Liteplacer, that I guess this is. The

ticks on the cross-hairs look good, they seem to align 4mm with

the sprocket hole pitch.

So everything seems to work alright. What is the problem?

Obviously the image is a bit blurred but that should not bother computer vision. If not, try this alternative pipeline here, assuming you use the ReferenceStripFeeder:

https://github.com/openpnp/openpnp/wiki/DetectCircularSymmetry#referencestripfeeder

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/db4473e6-0704-4951-ad14-f21b02d654ecn%40googlegroups.com.

Litterio Andrea Guainella

As you can see from 2nd image the nozzle not centered in part when I simulate pickup.

The horizonal black band was caused from led bar near table (the ceiling is lower than normal and this affects the camera vision).

Now I haven't problem with cvpipeline so I just used default but thank you for your suggest.

mark maker

Ah, now I understand. So the problem might either be a tilt in

the Nozzle Z axis or the camera Z axis (view axis).

But tilt in the camera is unlikely, as it happens with both

Advanced Camera Calibration and without. Please confirm

that you performed the camera calibration with the newest

version, i.e. after the

disable-tangential-distortion-correction="true"was established.

Right? (it is not sufficient to update, you need to perform the

calibration again, after updating OpenPnP).

Then just to be sure, let's confirm it is not just a problem of the feeder's specific programming:

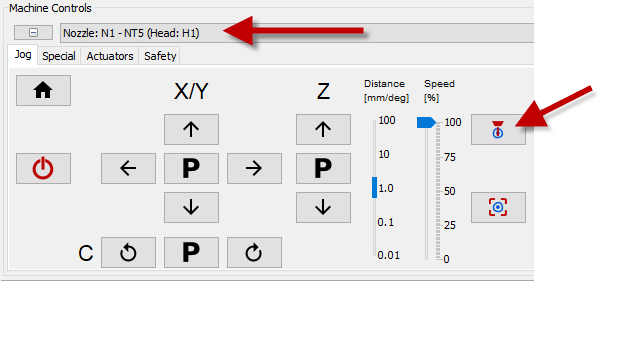

Center the camera on the feeder (like the corner of a pocket or something you can judge), then use this button:

Does it show the same offset?

If yes, then tilt in your Nozzle is almost sure.

I don't think you can adequately measure this with a bubble

level. In fact I don't know an easy way.

@Others, how do you measure if the Z

axis is not tilted?

20mm difference in Z is a lot. I can only repeat: try to use

the same Z as for the PCB.

Why do your strip holder need to be 20mm high? This takes a lot

of 3D printing time!

Have a look at BlindsFeeder for contrast. They're super fast to print, add minimal Z height (only as much as the part height) and can (optionally) cover the parts, so they don't fall out, are faster to pick (vision only once per job), can optional have OCR/Barcode/QR code.

https://github.com/openpnp/openpnp/wiki/BlindsFeeder

And despite the Liteplacer being ready, you can't use Contact

Probing, because the tape strips are only suspended on the

sides, and would be poked-through if probed, or parts would surely

topple out from vibrations.

https://github.com/openpnp/openpnp/wiki/Contact-Probing-Nozzle

I know, you already printed the feeders... but maybe you should still reconsider 😉

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/b87cb17d-d80b-4c9d-9f28-8dc8ba85c6a2n%40googlegroups.com.

Litterio Andrea Guainella

tonyl...@gmail.com

mark maker

tony> If we did the confetti trick at both the primary and secondary fiducial height we could measure it😉

After Advanced Camera Calibration, and assuming it did detect the camera view axis tilt accurately, yes! It would be easy to add. I'll keep that in mind.

LAG> For avoid any problem I deleted .openpnp2 folder before installation.

You really do not need to do that each time, unless you

completely wrecked the config. Usually, just reopening all the

subsequent Issues & Solutions items is sufficient.

For most things, Issues & Solutions is permanently

monitoring your settings, i.e. the suggestions are not

"one-shot". If settings do not match according to its logic, it

will alert you, again. This is true for maybe 80% of the

settings it can propose.

For the rest, there are some (like the calibration steps) that

need to be re-opened explicitly, if the machine has

changed, because it cannot detect that. Very few solutions are

"one-shot": Issues & Solutions will only propose them if they

are empty/missing. This is for machine specific stuff, where

I&S can only guess. Like some machine specific G-code

commands. If in doubt just delete these and a new proposal will

come.

So it is only these few that you need to keep in mind.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f159d11f-88e5-48fe-9da4-0290172c862dn%40googlegroups.com.

tonyl...@gmail.com

mark maker

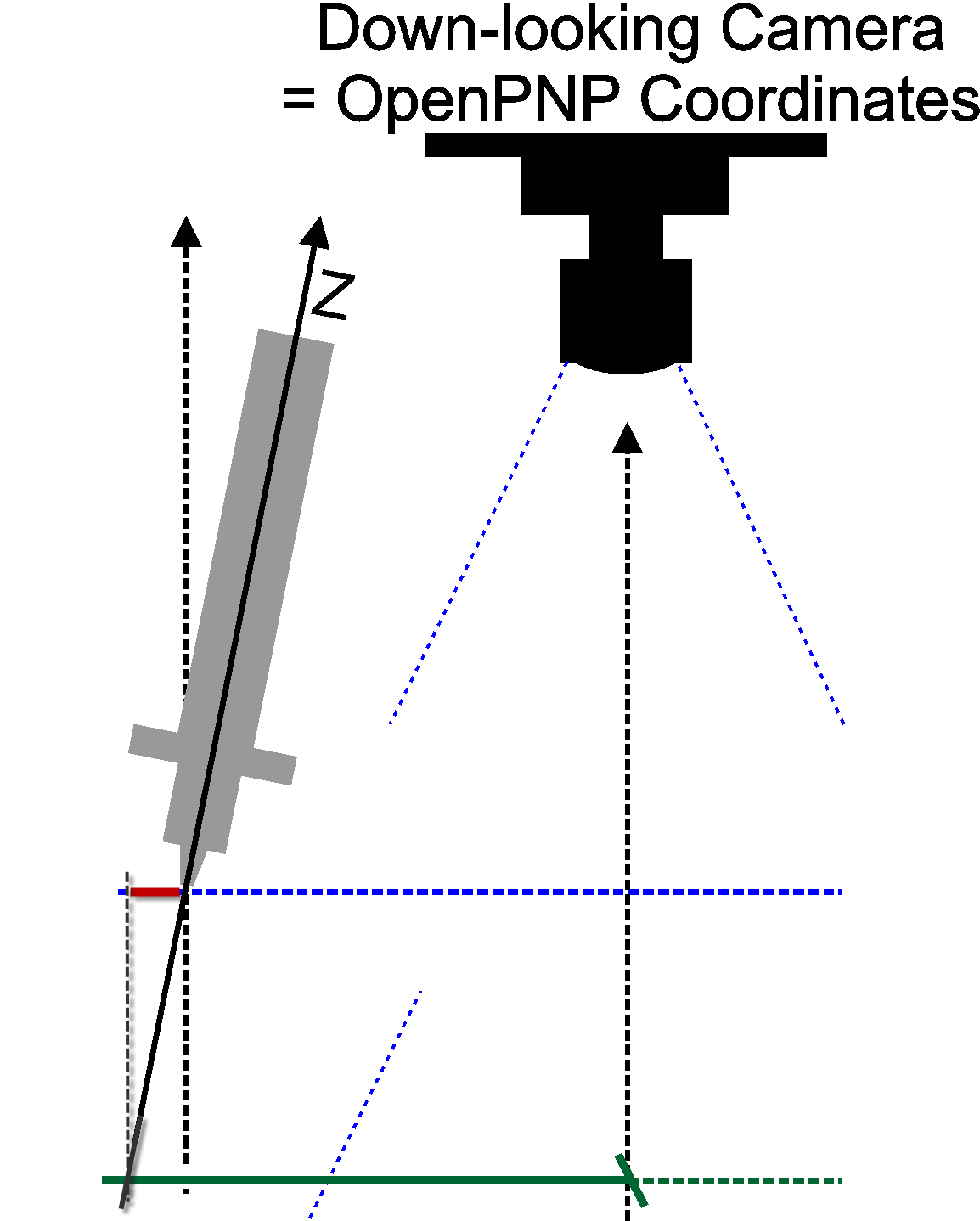

I don't understand. It is true that the down-looking

camera tilt and the nozzle tilt cannot be distinguished from two Z

level confetti calibrations, right?

For example, these two (exaggerated) constellations will exhibit the same apparent delta:

Or do you suggest to first just determine the overall tilt and

then only adjust (as a computation) the nozzle tilt for

the camera tilt, once the Advanced Calibration was done? That

would be possible, I guess.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/213325b1-dd48-4b7d-8a04-f5d82b08f88cn%40googlegroups.com.

bert shivaan

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/fec660c3-8602-cbb2-a1ce-1a671d82471c%40makr.zone.

tonyl...@gmail.com

bert shivaan

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/e33ce1c8-a8b2-4361-9170-3b272df21ba8n%40googlegroups.com.

mark maker

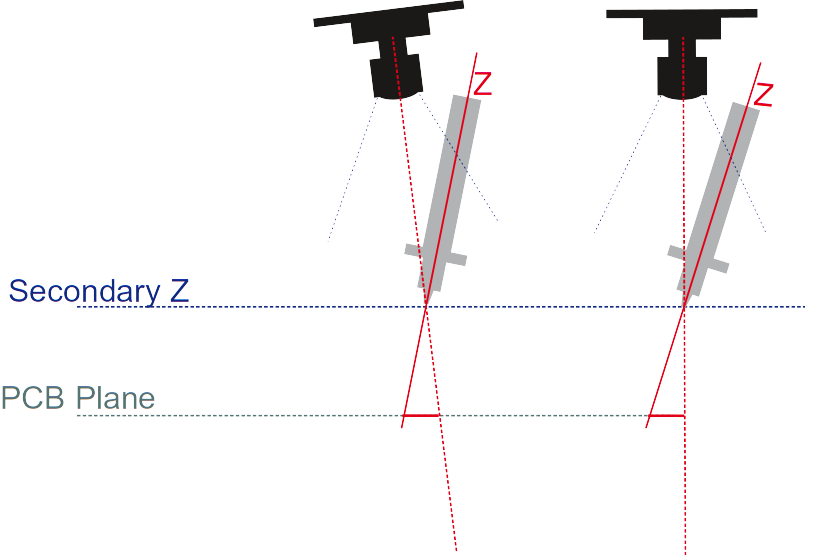

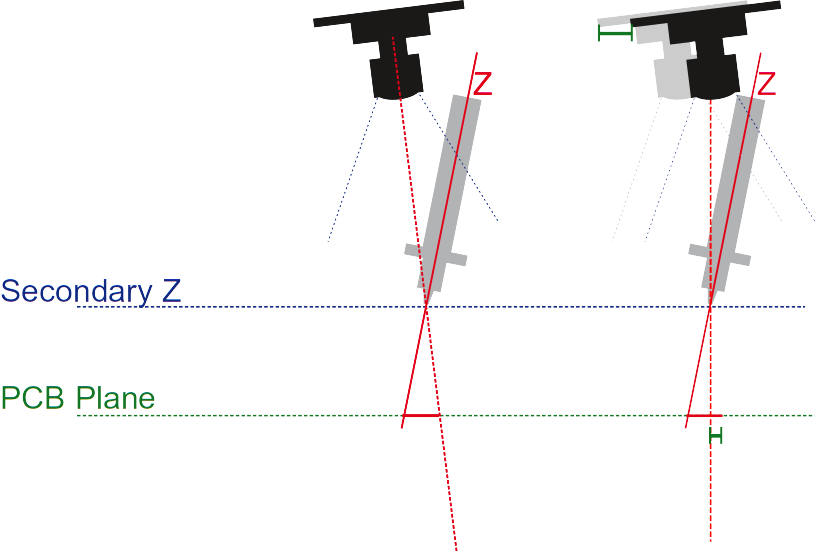

@Tony> it doesn't really matter whether one or the other or both are tilted

Yes this is true (but see cncmachineguy's valid point, later).

You kind-of make the camera view axis (with whatever tilt it has)

the "reference", all the machine's nozzles have to adhere to it.

But you have to adjust all these nozzle specific tilts, once you perform the Advanced Camera Calibration, as it's tilt compensation selects another "pixel ray" as the camera view axis. I.e. you get this:

Or are you saying we should abolish its tilt compensation?

@cncmachineguy> Could the nozzle tilt not be found by simply parking the nozzle over the bottom camera, take a snap shot at z fully retracted, then extend z fully and take another snap shot.

Same problem. Camera tilt is not distinguishable from

nozzle tilt.

But admittedly, it would be easier to implement (compared to the

confetti trick).

@cncmachineguy> Would it fail if the spot we are trying to hit is calculated position instead of captured by vision?

You have a valid point there. Whenever OpenPnP would make a move

based on taking X, Y from another Z and then perpendicularly

extending from this to another wanted location, this will incur

the camera tilt error.

In case of a (tall) BlindsFeeder, where it takes the fiducial X/Y

from down at the table, but then wants to push the cover

edge up at part height, based on "blind" geometrical

knowledge of how the feeder is made, this will falsely add the

camera tilt. In case of the BlindsFeeder this is not a

problem, because it knows it has to cope with deft errors from 3D

printing and adds a 2mm tolerance when approaching, and gives

you edge calibration with a vision feed-back loop, i.e. it

does not do it "blindly" in the end.

But for other truly "blind" geometric moves with tall structures,

this might become a problem. I'm thinking about nozzle tip

changers etc.. So I still think it would be better to simply first

calibrate camera tilt using Advance Camera Calibration (that I now

find trustworthy after the "tangential" fix) , and then

nozzle tilt to that reference. So we get true motion

geometry (or as "true" as can be achieved).

Backlash...

Note, as @Tony already mentioned, this needs special treatment

for Backlash Compensation in X/Y. It effectively has to take the final

location into account when calculating the X/Y move at Safe Z,

i.e. it need to already include the nozzle tilt compensation up

there, so any backlash counter-move can be done "up in the air"

where it is harmless (not down when pressing a part into solder

paste). Afterwards, only the Z axis will go down, no tilt

compensation along the way.

Folding the backlash counter-move into the downwards-move (saving

the extra time) would be the "luxury" solution. But because these

two concerns are currently (very) separated, it will probably not

be done anytime soon.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CA%2BKNHNxwynuS2Z%2BqV0wH%3DG7XBdmehw8gqTjyHG56vJ9mieki5w%40mail.gmail.com.

tonyl...@gmail.com

mark maker

> That can't be any worse.

True.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/fa576c5c-f8ae-42cf-be55-ba26b10cb2ben%40googlegroups.com.

tonyl...@gmail.com

Litterio Andrea Guainella

tonyl...@gmail.com

Litterio Andrea Guainella

mark maker

> i am having several problems to print it because I've

never printed PETG

Do you use adhesive spray? And enough of it? Once I did that: all problems gone.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0add3af6-21a0-4f01-8bee-d41765cb1892n%40googlegroups.com.

mark maker

Just to be clear I meant that special 3D printing spray, not "adhesive" spray.

That's the one I'm using (that's just the first one I tried and

it worked well, others may too):

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/481849c1-ebe4-f255-c586-63d885f54aed%40makr.zone.

Litterio Andrea Guainella

I am trying with Splend'or (hair spray ~ cheapest way) waiting for 3dlac to arrive.

When finish I will post some image for details

Litterio Andrea Guainella

Litterio Andrea Guainella

Litterio Andrea Guainella

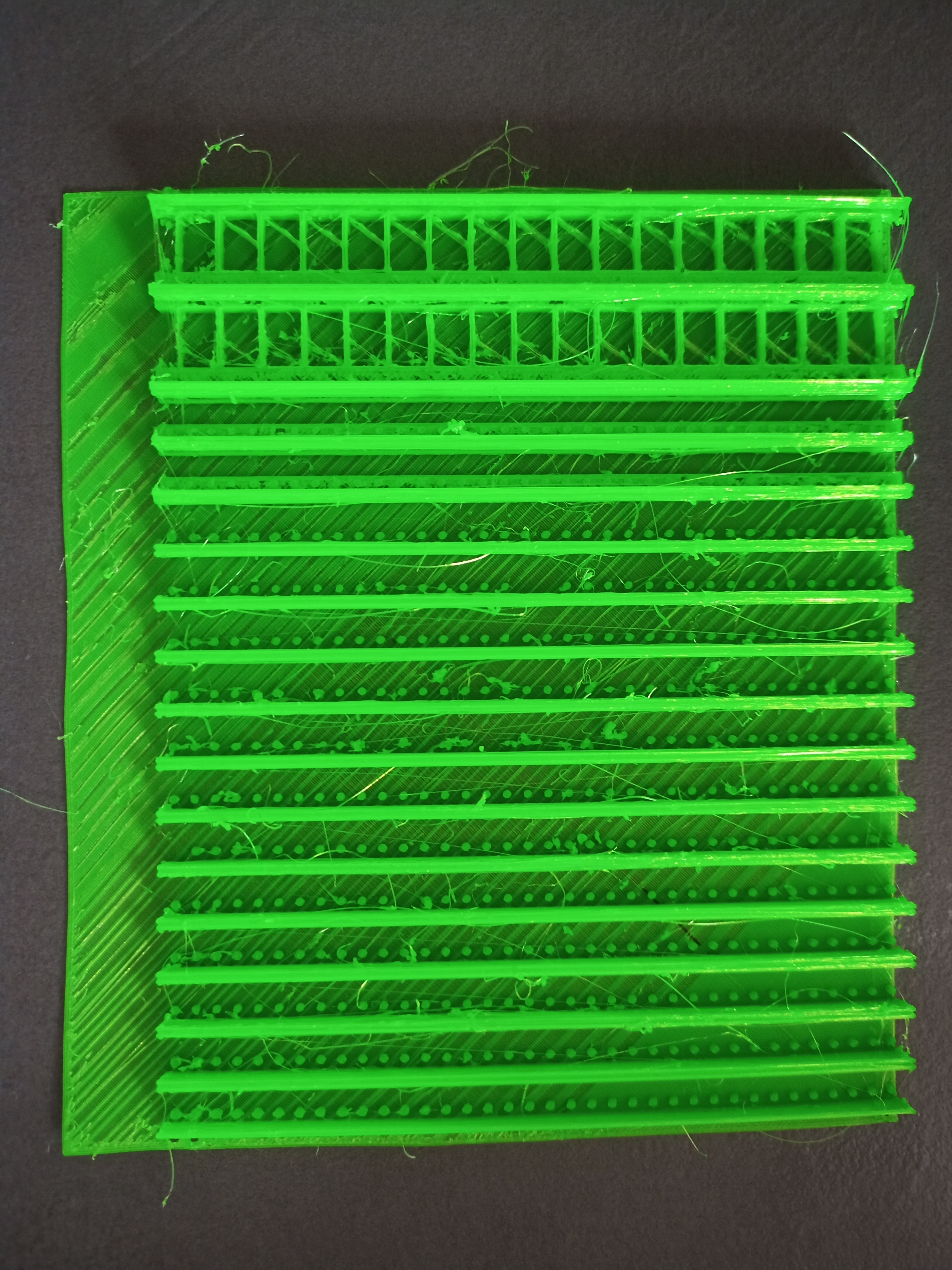

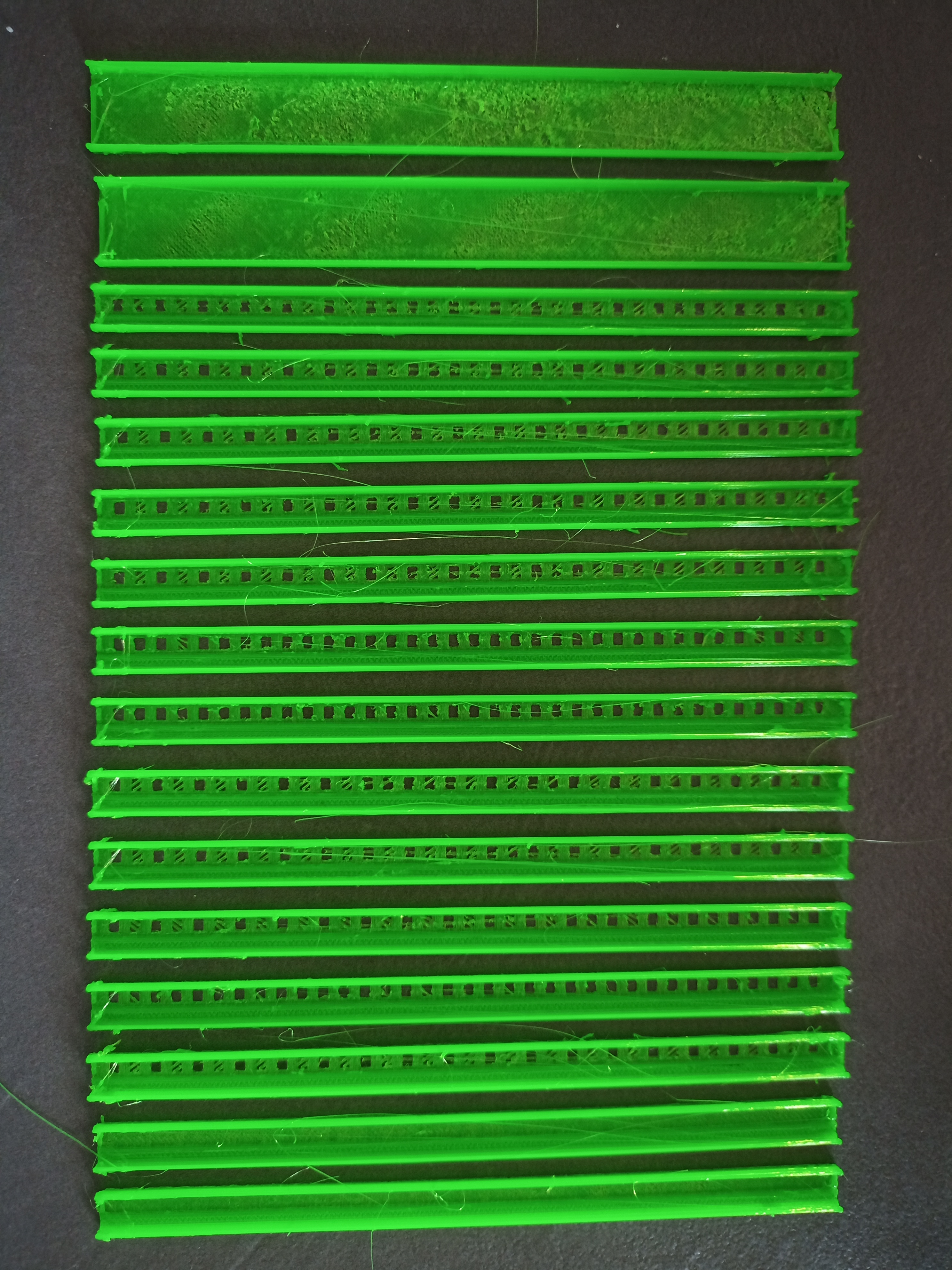

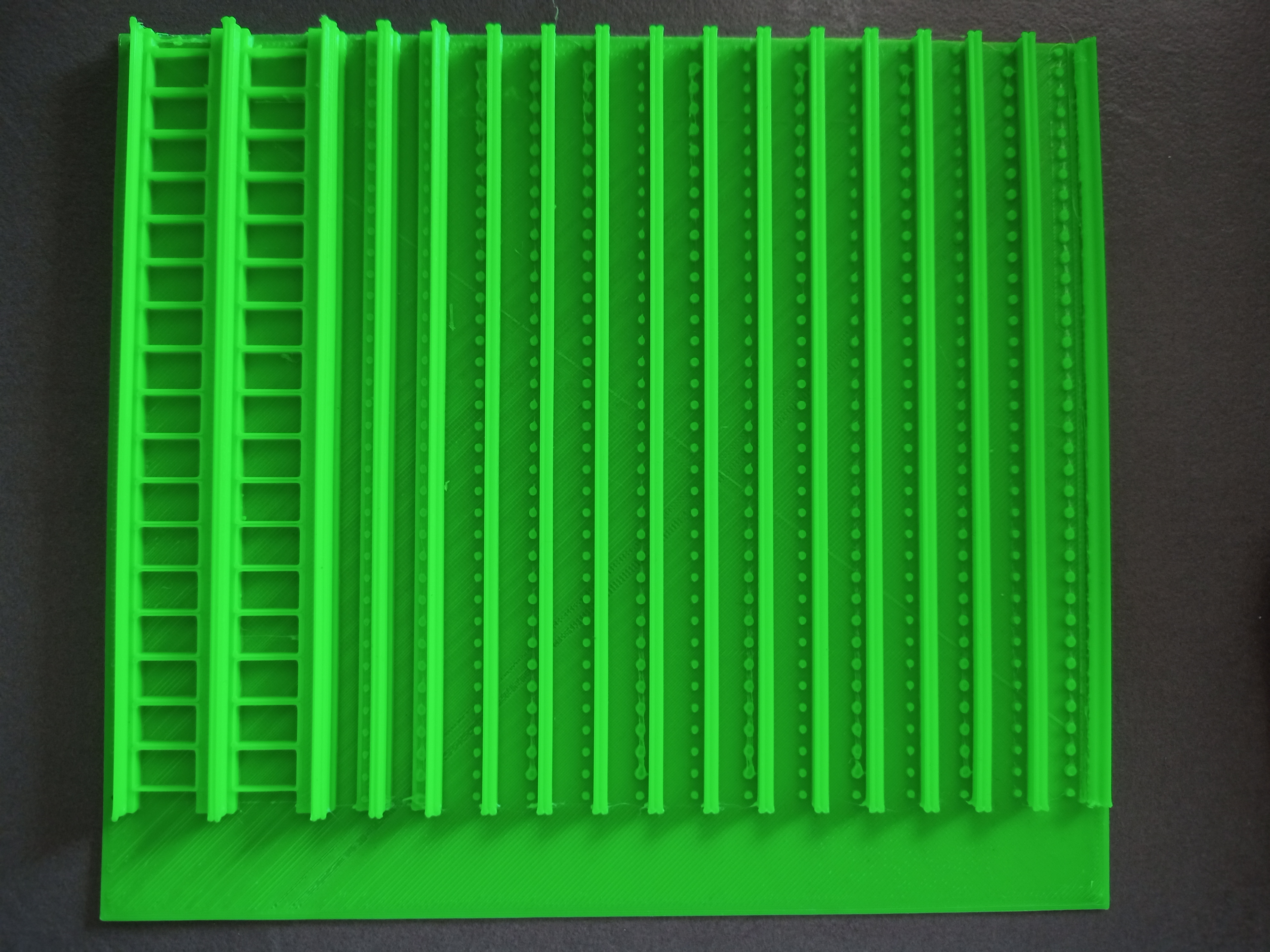

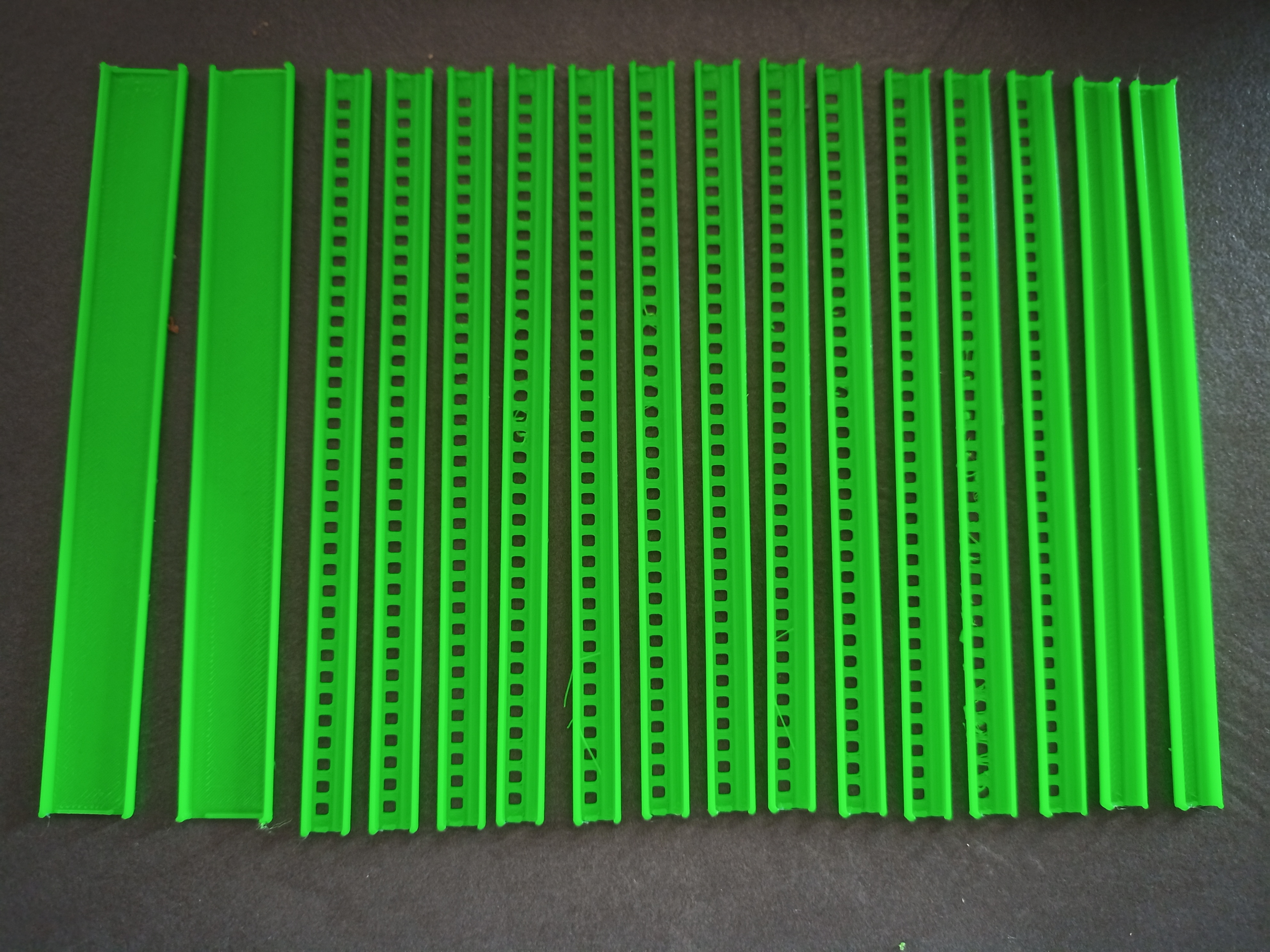

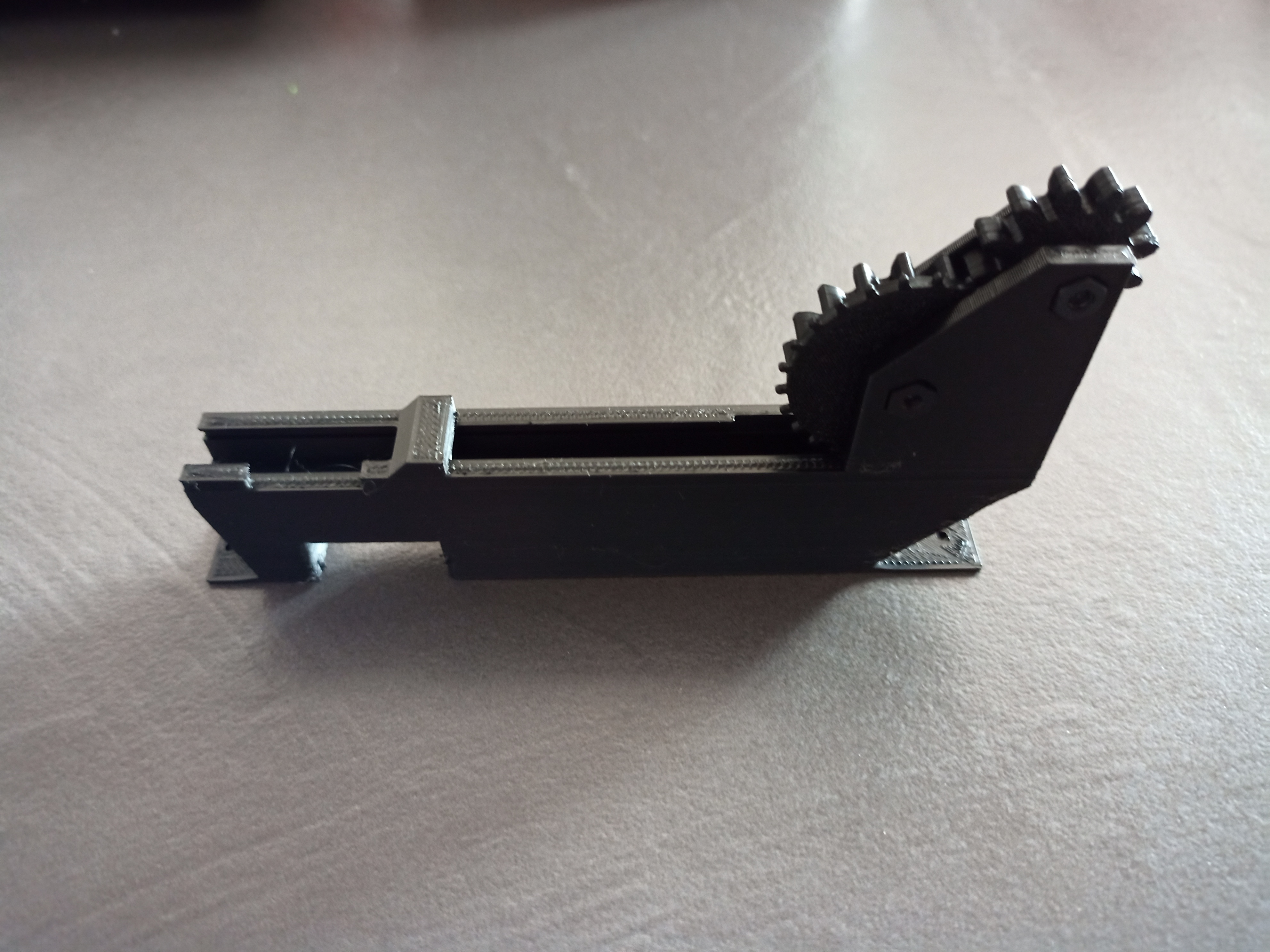

attach 1

Litterio Andrea Guainella

Litterio Andrea Guainella

Litterio Andrea Guainella

mark maker

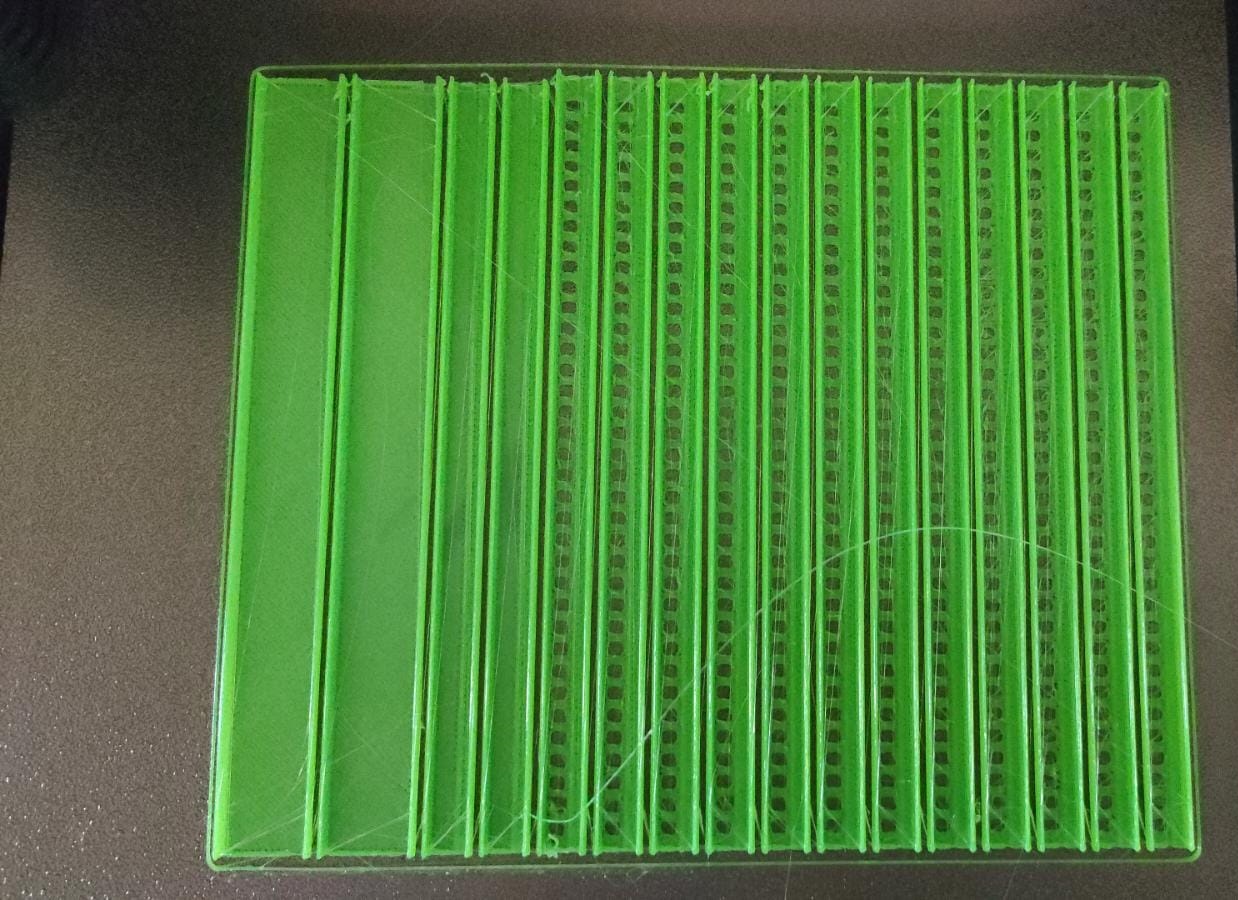

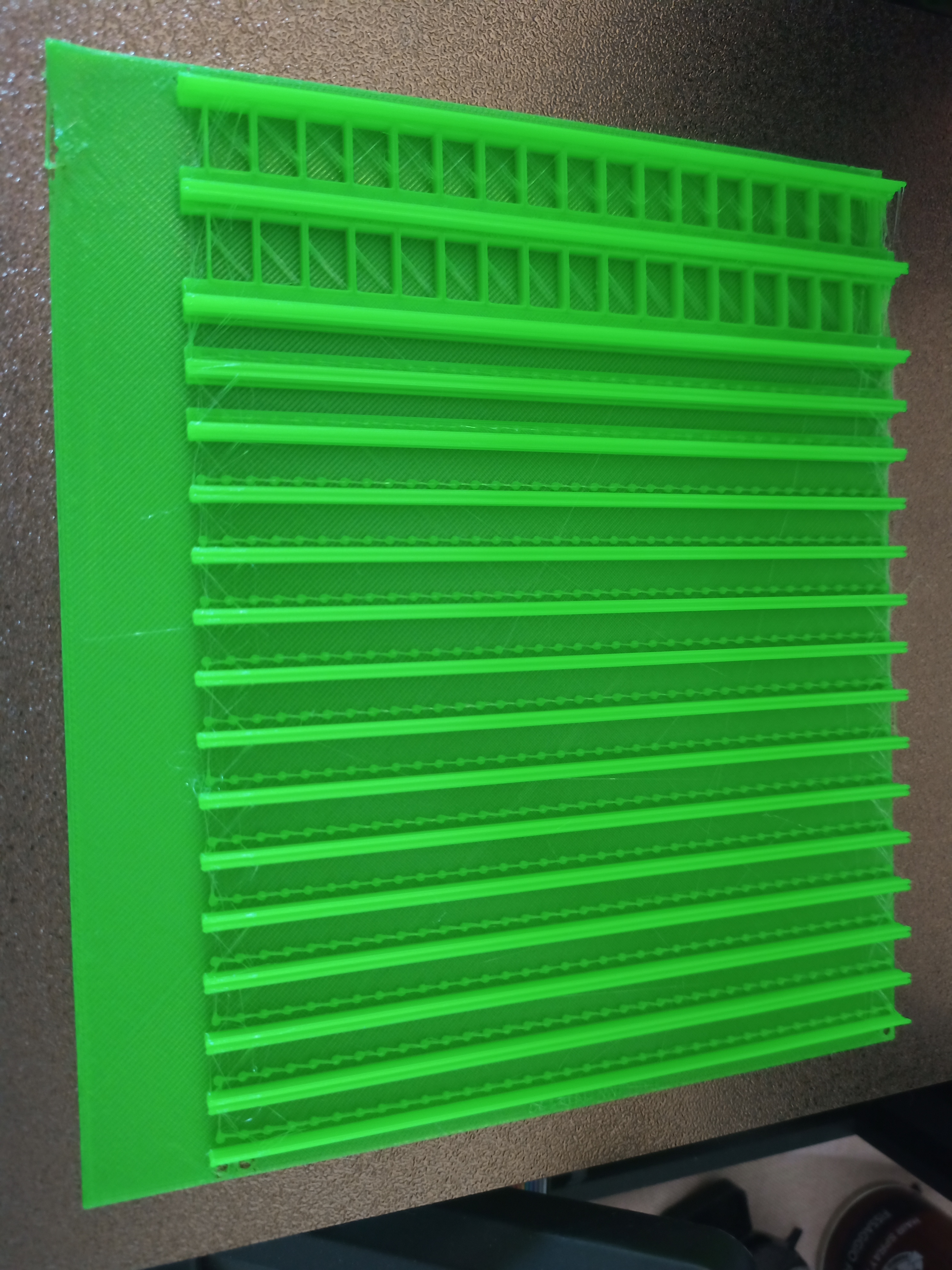

Hi Litterio,

these prints really look scary.

Although I've made quite elaborate stuff (see also the Push-Pull

Feeder), I don't consider myself a 3D printing expert,

mainly because my Prusa printer just worked (at least once I found

the spray is needed).

Sometimes I had stringing when the temperatures were not right,

but that looked more like fine "spider webs", not the thick "crazy

spaghetti" you get.

Are you sure you got the temperatures right and your printer can do these high temps without an encasing?

That last gray model (different feeder): is that PETG too?

I'm just asking, because PETG is a much tougher, much more

elastic and also smoother material than PLA (less friction between

moving parts), and according to the link you sent for the other

feeder, this one is printed in PETG too, specifically for

friction.

So maybe you should still invest more in trying to solve the PETG

printing issue.

I assume you know the BlindsFeeder is a completely different use

case, than the one you are now printing. BlindsFeeder can only be

used for very small runs, where you buy a few dozen of each part.

On the other hand, it can use every last one of these parts on

even very short cut strips (no waste), which might be important

for expensive parts. It is also very compact, you can put many of

them on your whole table.

The other feeder is completely different, it only makes sense when you buy whole reels or at least very long cut strips, and you don't mind wasting some of them for the needed cover tape leads etc. Plus it consumes much more space, and works only on the edge of the machine.

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/1f931b15-56ba-4b82-8129-a4aefd2cab5cn%40googlegroups.com.

Litterio Andrea Guainella

Vinay Dand

1) If possible dry out the PETG spool, many time moisture ingresses in the filament and causes this.

Best Regards,

Litterio Andrea Guainella

mark maker

> I will try as you said but I don't have an dry machine for filament. I'll have to buy one.

Instead of buying ever more things to try and make the printer work, you might consider buying a new printer. 😇

Obviously, I strongly recommend the Prusa, that thing just

works!

At €700 (kit) it has its price, I know, but it is a long-term

good investment, I already upgraded mine once, you always get the

newest model for very little extra money. I bought a second

printer and can tell the upgraded one and the new one are exactly

the same in all relevant aspects.

@Vinay, as to drying out the PETG, are you sure that can be an

explanation for such phenomenons? Wouldn't water rather show up as

bubbly surface?(again, I'm no expert).

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/87b2311e-fed7-4824-91fc-df5908216c0fn%40googlegroups.com.

Vinay Dand

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/bzLiD6QZIqY/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/8cbc2dc1-3830-91f9-5620-d3003fe01510%40makr.zone.

Litterio Andrea Guainella

I'll try to print later 2nd face (this is only cover).

mark maker

Getting better but I guess not yet good enough.

Are there no 3D printing gurus on the list who could help?

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/e1eb41db-00f8-46de-8adc-7a6edddb6744n%40googlegroups.com.

Litterio Andrea Guainella

Litterio Andrea Guainella

bert shivaan

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/fd944751-3786-410a-8ef7-52d11b15a4een%40googlegroups.com.

Litterio Andrea Guainella

I was try to search in group but I find nothing.

bert shivaan

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/1fa044c3-476e-4605-86ed-1a497d4a5ec6n%40googlegroups.com.

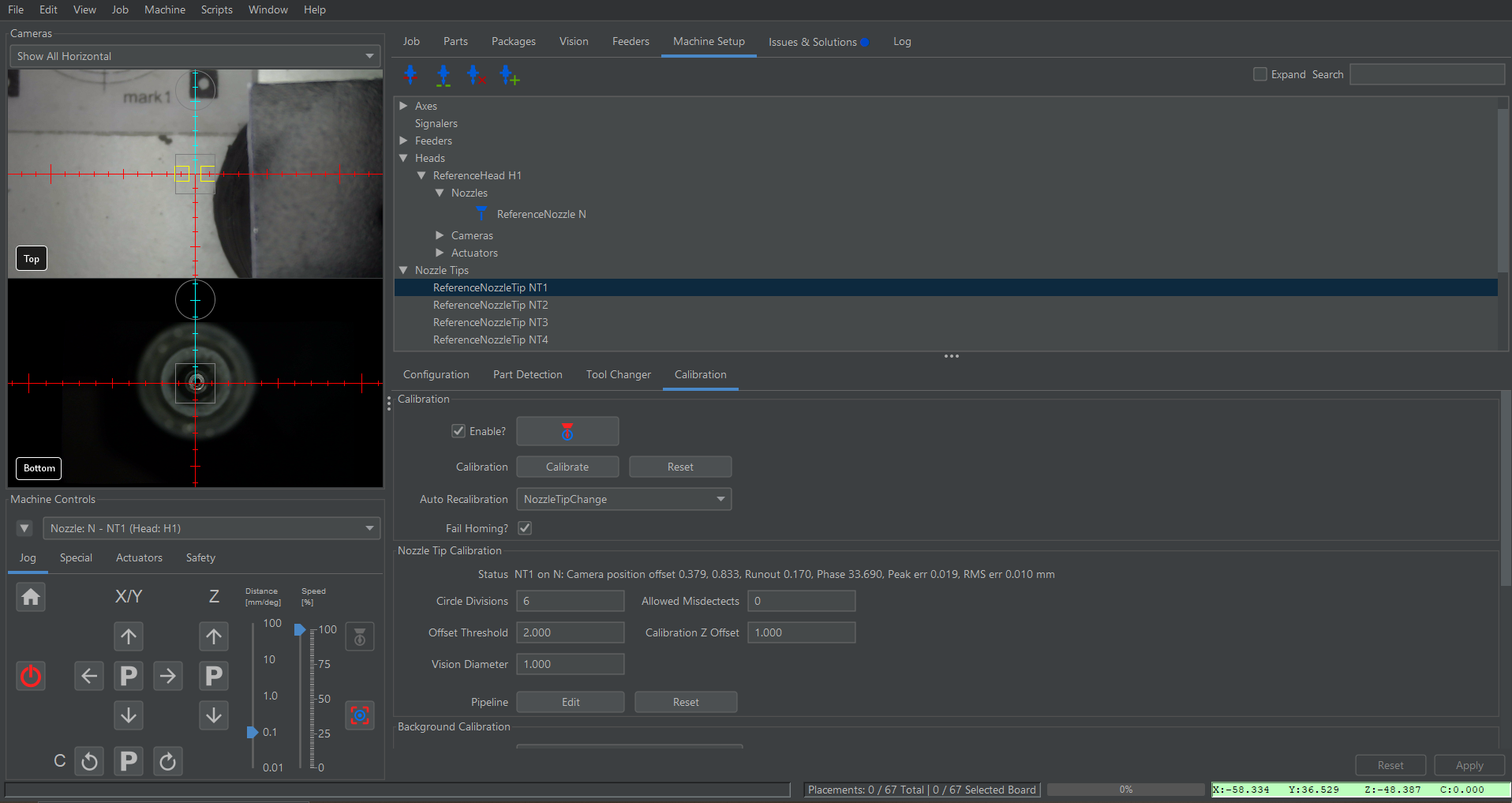

Litterio Andrea Guainella

mark maker

Hi LAG,

Try this:

- I am assuming you re using Issues & Solutions to

use the Advanced Camera Calibration. Disable it on the camera

and then press Find Issues & Solutions to get it

proposed again.

- exit OpenPnP

- edit machine.xml

- double-check that you find these settings in both cameras:

disable-tilt-correction="false" disable-distortion-correction="false" disable-tangential-distortion-correction="true"

- search for up-looking-secondary-offset-Z-mm=

- change the value (default 2mm) to something larger, where the

nozzle tip is still not too blurred and the nozzle tip circular

feature still roughly the same size (so it gets detected).

- Maybe a larger Z difference will improve the tilt compensation

accuracy. Please report back if possible.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/a55367fd-efd8-4ad6-8aa6-1e0f05c98045n%40googlegroups.com.

Litterio Andrea Guainella

thank you for your suggest. Now I have just dissassembled both camera so I can't try this procedure.

I will try this when finish mount new ELP cameras.

tonyl...@gmail.com

Litterio Andrea Guainella

Litterio Andrea Guainella

tonyl...@gmail.com

Litterio Andrea Guainella

Litterio Andrea Guainella

mark maker

> Mark - your points 5 through 7 only really apply to

up-looking cameras - correct?

Correct.

> If I understand the OP's problem, it is with the down-looking camera and/or the nozzle's Z-axis.

Oh, I must have misunderstood. I was aware that the original

problem is a difference in nozzle offsets on the two different Z

levels. Which might hint at either nozzle Z tilt or (wrongly

calibrated) top camera tilt. But now I assumed he was talking

about seeing the nozzle displace in X/Y when looking up with the

bottom camera and jogging in Z. After rereading his post, I see

that I'm probably mistaken.

So yes, my steps 5 - 7 do apply to the bottom camera

and using it to check for nozzle tilt. i.e. seeing

whether the nozzle displaces in X/Y when moving in Z.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/7a17be1c-db26-4495-b88e-6c9d73cda476n%40googlegroups.com.

Litterio Andrea Guainella

tonyl...@gmail.com

Litterio Andrea Guainella

Detected Backlash: 0.173mm

Selected Method: OneSidedPositioning

Sneak-up Distance: 0.000mm

Speed Factor: 0.25

Applicable Resolution: 0.0125 mm

Detected Backlash: 0.106mm

Selected Method: DirectionalSneakUp

Sneak-up Distance: 0.226mm

Speed Factor: 0.25

Applicable Resolution: 0.0124 mm

mark maker

Hi LAG,

I hope you keep your spirit up! 💪 😁 👍

I think there are many things that can make a Liteplacer not

work. The construction is really very simple and also outdated.

For instance all the gantries are tensioned with these eccentric

spacers (3). If you make them too tight the gantry will not

slide well, which could be one of many explanations that your

steppers stall. But if you make them too lose, the gantry will

wobble and vibrate, which might in turn stall the stepper when you

go very fast, the vibration creating so much friction.

https://liteplacer.com/the-machine/assembly-instructions/gantry-back-plate-step-2-lower-v-wheels/

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/e4a2728e-b0e5-46b7-8adc-8f697bf044a3n%40googlegroups.com.