Focal plane, lighting and homing questions

Sahiru Hettiarachchi

Sahiru Hettiarachchi

Michael Anton

mark maker

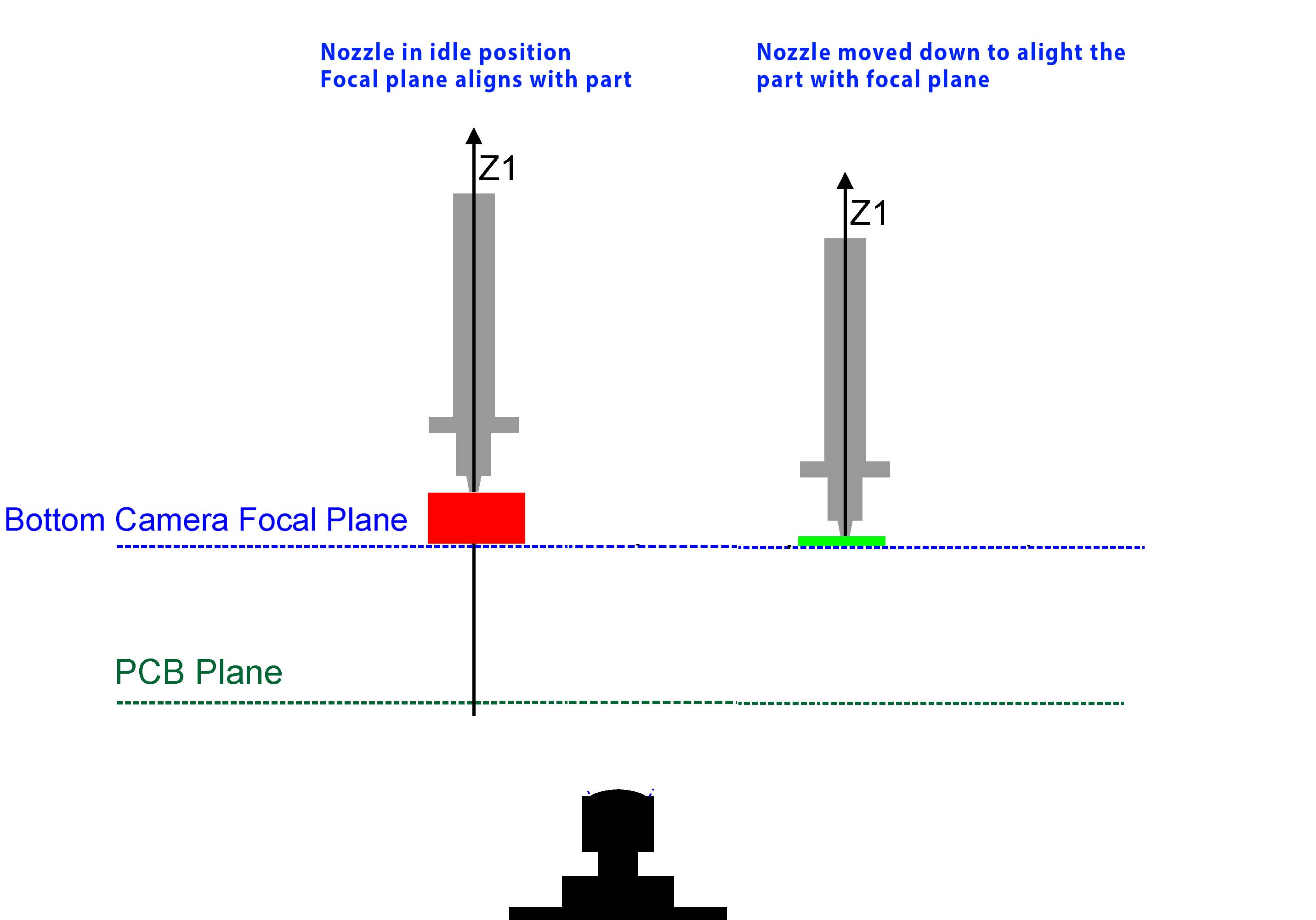

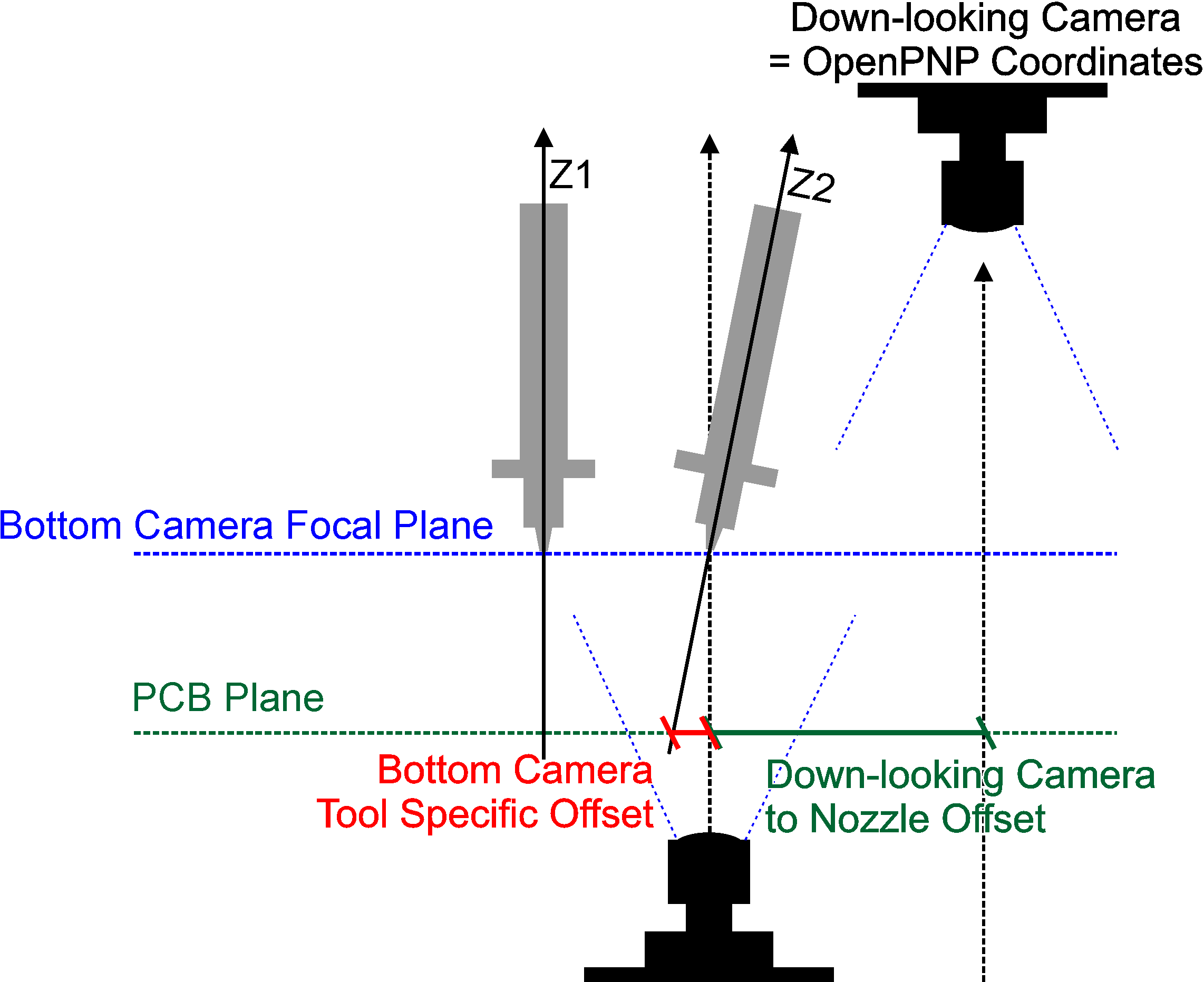

Michael is right, choose the focal plane so it is the same as the PCB surface. That's the ideal setting. It will physically cancel out any tilt errors in the nozzle Z axes.

OpenPnP will hold the part above the camera, so its underside

aligns with the focal plane, i.e. it adds the part height

to the Z.

> Or can openPNP work with something out of focus too and this really does not matter?

Yes it can, if you enable nozzle tip calibration. Then

any tilt errors in the nozzle Z axes are compensated by the

software. Whether the software compensation is any worse

than using the same Z, I don't actually know.

Generally, it is more important to make absolutely

sure the homing fiducial is at PCB Z. I also strongly

recommend to have the primary calibration fiducial at PCB Z.

https://github.com/openpnp/openpnp/wiki/Vision-Solutions#calibration-rig

In addition, it is favorable to have the feeders also roughly at

PCB Z. One could argue that the part underside should

align with PCB Z, because that is what we will be relevant when

doing bottom vision and when the part is placed on its pads.

However, don't panic if that is not the case. It is only relevant

for tall parts and tall parts usually have clunky contacts, so

placement need not be super accurate (self-alignment in reflow).

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0cea68ab-236c-4ff4-9e06-596100e29bb6n%40googlegroups.com.