Reflow oven chose ?

mojalovaa1

All so interested me some used small desktop reflow oven if can buy in EU but under max 1000 Euro prices .

alexander...@gmail.com

I have mentioned being very happy with this machine once before in this channel however I have no affiliation with the company other than being a customer.

Lisandro B

evilwulfie

you make the mods.

I have been using it for over a year with decent results

Matt Brocklehurst

Keep checking eBay they come up from time to time!

Sent from my iPhone

> You received this message because you are subscribed to the Google Groups "OpenPnP" group.

> To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

> To post to this group, send email to ope...@googlegroups.com.

> To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/81cc57ed-90ec-55c0-3e06-1adf7cb391ef%40gmail.com.

> For more options, visit https://groups.google.com/d/optout.

mojalovaa1

All so I m interested for some small desktop version reflow oven with 3 zone or more but that can soldering lead free paste .

Trampas Stern

Paul Kelly

Any, non conveyor based, IR oven is junk. And the conveyor based ones may well be junk too.

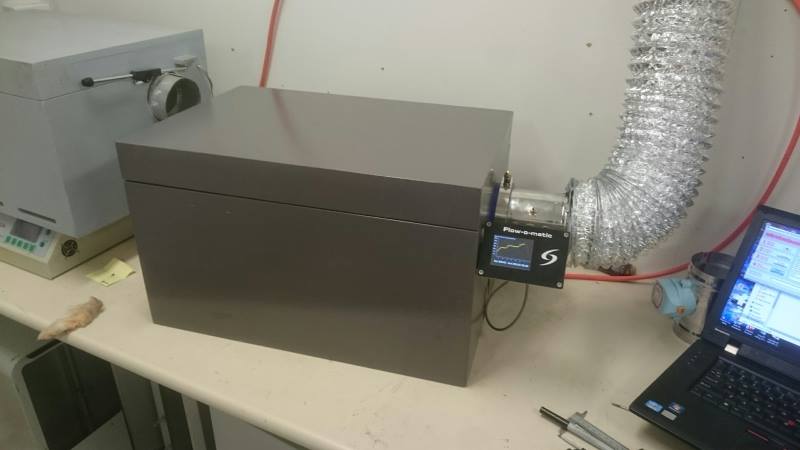

We have two convection ovens that we built for not much money and they work extremely well.

We use the elements and fans from fan forced ovens inside a toolbox that is inside wooden box lined with rockwool.

Done thousands of boards in them.

Don’t forget fume extraction. You’ll have the worst headache ever the next day if you do!

PK

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ee91216d-7d37-4f52-b20d-8b7c7f42de91%40googlegroups.com.

mojalovaa1

Paul Kelly

I made a video (too lazy to type) https://www.youtube.com/watch?v=u83dPxrnl00

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/39c1a8a6-b202-4b07-bca3-2fd932110143%40googlegroups.com.

Matt Brocklehurst

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/000301d32461%249a6d5340%24cf47f9c0%24%40com.

mojalovaa1

Thanks allot for video , look me like very nice oven , have you some video that we can see process and all so time for soldering ?

I'm look few version IC heater oven , and all so I'm make one with 4x800W IC heater , but better options is have 8x400W heater and 3 thermocouple one on buck side , one on middle and one on front side , and control it 3+3+2 heater (3x buck + 3x middle + 2 front ) .

With that principle like is yours is little problems with high temperature from down side ?

Have you some picture with finished product ?

Paul Kelly

Hi PK

Thanks allot for video , look me like very nice oven , have you some video that we can see process and all so time for soldering ?

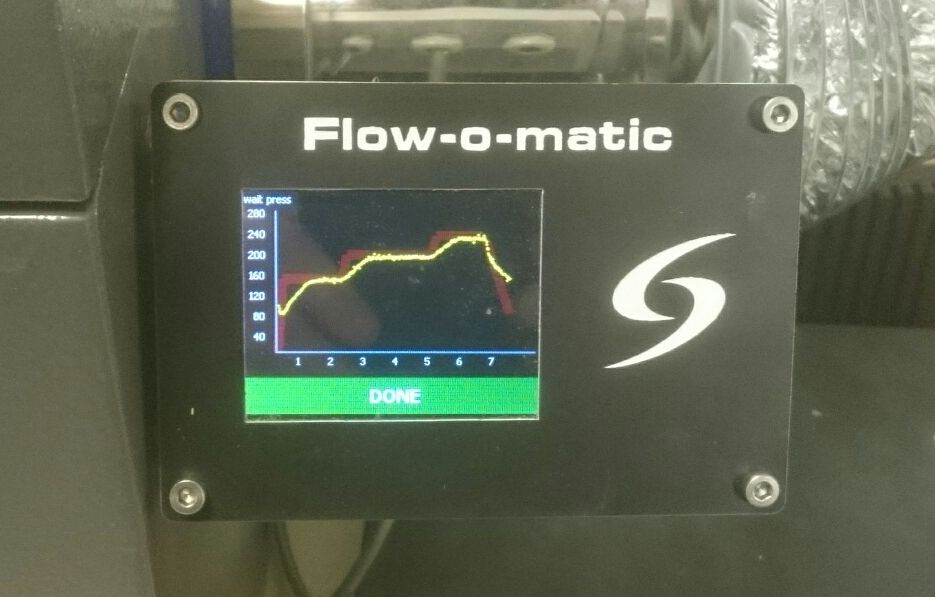

All reflow controllers, including ours, allow you to program the temperature curve for any duration. The challenge is achieving reasonable ramp up times (ie the time it takes to go from a 150degreeC soak temperature to a 280degreeC reflow temperature) if your oven cant ramp quickly, then your boards will spend too much time at higher temperatures and you will have problems. This is why you need a LOT of power. For an oven the size of ours, a single phase power outlet is only just enough. Here’s a shot of the controller after a run.

The programmed reflow curve has step changes in temperature, so you can clearly see the ramp times. These are just about OK. We run lead free paste and our cycle time is 7 and half minutes.

I'm look few version IC heater oven , and all so I'm make one with 4x800W IC heater , but better options is have 8x400W heater and 3 thermocouple one on buck side , one on middle and one on front side , and control it 3+3+2 heater (3x buck + 3x middle + 2 front ) .

None of that matters anywhere near enough as having a great big fan blowing large amounts of very hot air around to even out the temperature. The hot air needs to be the main source of board heating

With that principle like is yours is little problems with high temperature from down side ?

There is some direct IR heating of the boards from below, but the fan evens most of it out. Again, the most important thing is the big fan..

Have you some picture with finished product ?

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/24c4d8e3-9098-4e48-adb5-54d9c63026ca%40googlegroups.com.

Daniel Dumitru

Nice !

Paul Kelly

J We built the flow-o-matic. There’s nothing hard about PID control of a small oven. It’s based on one of these: https://shop.mikroe.com/mikromedia-3-pic18fj

We like them because the USB bootload process is so fast that we didn’t have to bother writing code to change the profile curve using the touchscreen. It’s just an array that we change in the source and reflash.

Happy to share the code…. But there are a few alternatives available that will work fine.

PK

From: ope...@googlegroups.com [mailto:ope...@googlegroups.com] On Behalf Of Daniel Dumitru

Sent: Tuesday, September 5, 2017 1:05 AM

To: ope...@googlegroups.com

Subject: Re: [OpenPnP] Re: Reflow oven chose ?

Nice !

Virus-free. www.avast.com |

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAPU3koO22Vm7obD8%2B_X_Vb6jjYJ0nSWEdz2gjiUXpeYLBgxvUg%40mail.gmail.com.

Daniel

Cristian Nicola

Paul Kelly

Daniel, you are correct that both our ovens and a conventional convection oven use the same components. There are three key differences in construction though:

1. The volume of our ovens is about 1/3 of the volume of a convection oven of the same power.

2. Our ovens have better insulation

3. Our ovens have active ventilation controlled by the system

1 and 2 mean that we can heat up the oven quickly, we get about 80degC per minute ramp rate. This isn’t great, but it’s good enough. Check that your convection oven can do at least that.

3 means we can cool at more than 100degC per minute. The only way to do that with a convection oven is by opening the door. At which point you get a lung full of flux fumes. Believe me when I say that you’ll only do that once..

Make sense?

PK

From: ope...@googlegroups.com [mailto:ope...@googlegroups.com] On Behalf Of Daniel

Sent: Thursday, 7 September 2017 12:50 AM

To: OpenPnP <ope...@googlegroups.com>

Subject: Re: [OpenPnP] Re: Reflow oven chose ?

Please tell me : a standard of the shelf electrical convection oven would work ? I have the impression that it's the same thing.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/781b67b1-6460-44e4-a37c-e5452767b3ba%40googlegroups.com.

DAniel Dumitru

Now I realize how many mistakes I have done. (interesting thing it's that I was planning to buy one chinese oven)

I have a friend that tells me that it's using something like in picture below. BAsically it's an aluminum plate with a 2000W heater .

Indeed that tube heating resistor has a big inertia. What do you think about this ? Putting this on an enclosure and a an exhaust fan would be better than IR/halogen heater ?

br,

Daniel

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/07f001d32750%24d1d9dfa0%24758d9ee0%24%40caswa.com.

For more options, visit https://groups.google.com/d/optout.

Paul Kelly

Thermal lag will cause you problems.

You might get OK results just using it as a skillet reflow surface. But you still need to deal with the fumes

Just type “fan forced” into ebay.

I found these:

On the first page. I’m sure there will be suppliers in your country.

Two details I didn’t mention..

There is a sheet of 5mm fiber cement between the stainless insert (the bit with the ramps on the ends) and the bottom of the tool box.

There is a small muffin fan drawing cool airflow through the space between the toolbox and the bench. This is where the fan motor and SSR are..

PK

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/bb38d62c-5e3f-179e-ba59-f689ef4c6b76%40gmail.com.

Daniel

Paul Kelly

THank you for details PK.

IT seems that those spare parts are very popular in Australia. HEre ovens are very much on natural gas.

Coming back to your solution :

at time 3.50 : you mention an air intake on left side.

on the other side , on right hand , it's a motorized valve.

It’s an air conditioning damper (which is just a fancy word for a lightweight butterfly valve). Here it is on ebay http://www.ebay.com.au/itm/4-Stainless-Steel-220V-AC-Electric-Solenoid-air-Valve-Damper-Tight-Water-Steam-/401324589119?hash=item5d70cf403f you can see where I’ve modified it a bit to keep the plastic part away from the metal body. I also replaced the plastic bushes with some bronze ones.

How come that air does not get out on the left side ?

Because hot air only rises and there’s nowhere for it to rise to go when the damper is closed.

You don’t need anything as big as those holes. I’m sure a 50mm valve would be fine. In the first one we built we used those sliding petals. They worked fine… for a while. Now that oven uses a metal disk in a wooden box. The disk gets lifted by an RC servo. That works fine too..

PK

BR,

Daniel

On Thursday, September 7, 2017 at 9:32:53 AM UTC+3, PK wrote:

Thermal lag will cause you problems.

You might get OK results just using it as a skillet reflow surface. But you still need to deal with the fumes

Just type “fan forced” into ebay.

I found these:

On the first page. I’m sure there will be suppliers in your country.

Two details I didn’t mention..

There is a sheet of 5mm fiber cement between the stainless insert (the bit with the ramps on the ends) and the bottom of the tool box.

There is a small muffin fan drawing cool airflow through the space between the toolbox and the bench. This is where the fan motor and SSR are..

PK

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/8eab9523-7c00-4745-9d81-ff3e183a3d1f%40googlegroups.com.

Trampas Stern

Of course you still need the convection heater assembly and fan, cheapest I found is around $70 used on ebay.

SMdude

Do you place your boards directly on the tray or have you got something that holds the panel up off the tray?

I use some 1/4" aluminium dowl on the corners of my panels and if needed some to support the middle so the board can't sag.

One thing with the t962a is the heat up time. I have noticed that it had a fair lag on the heating ramps. I sometimes use a hot air gun through the fan vent at the back to help it warm up faster. It could be a worthy mod for these ovens, then we get a bit of hot air circulating too.

I tried a panel flat on the tray the other day, at the start of the cooling cycle the solder had only just started to melt so I opened the tray and blasted it with hot air until everything flowed.

Cheers

Trampas Stern

Paul Kelly

I am frustrated with my T962A, so I am going to build setup like PK's.

One idea I had was to use stainless food service trays for the inside, around ($30) in parts.

We used wire mesh from the gardening store J I suppose you could get fancy with it if you wanted!

Optionally if deeper box is needed you could start with one of these, you still would need a lid (or piece of sheet metal)

These actually look pretty good. You may still benefit from cramming some more insulation in there as, I guess, they are only designed for 100degC or so. But otherwise they are nice..

Of course you still need the convection heater assembly and fan, cheapest I found is around $70 used on ebay.

You can probably get a set from the rubbish tip, Look for second hand ovens from kitchen renovations?? But $70 is pretty cheap.

I was wondering if instead of servo damper if a backdraft damper would work on the outlet, and then have a fan on the inlet, which the software controls?

That one looks like it might leak a bit more than the one I used (which has a nice silicone seal) but controlling the fan on the inlet will help a lot, our ovens are connected to the workshop extraction system which runs constantly. BTW the one we used isn’t a servo damper, you just connect 240V to two of the three wires and it opens. Connect 240V differently and it closes. We use a relay…

I have ordered the parts to build mine using food warmer, and will keep you guys updated.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/3fa8dacc-cf40-42d7-935d-ef67e6ac4c88%40googlegroups.com.

Trampas Stern

Paul Jones

Do you have two different 15A circuits near each other in a convenient place? You could attach one bank of heaters to each circuit. If you want you can later convert it to 220V by wiring the heaters in series.

Paul.

From: ope...@googlegroups.com [mailto:ope...@googlegroups.com]

On Behalf Of Trampas Stern

Sent: Wednesday, 13 September 2017 9:08 PM

To: OpenPnP <ope...@googlegroups.com>

Subject: Re: [OpenPnP] Re: Reflow oven chose ?

PK, thanks for the feedback...

Cyril

On Thursday, August 31, 2017 at 5:56:44 PM UTC+3, mojalovaa1 wrote:

Hi folksI look for buy some small desktop reflow oven for electronics and LED , and on this moment look me interested T962C , but can not found some one who have experience with that oven , if some one have that oven please if can write opinions ?

All so interested me some used small desktop reflow oven if can buy in EU but under max 1000 Euro prices .

Graeme Bridge

Paul Kelly

Re the little Puhui T960. I suspect that moving the board past the heating elements (I assume this also has some convection fans) nearly completely negates any problems with hotspots.

I agree with Graeme on the costing. We budgeted about $AU500 + that much again in time for our oven. We probably spent about $1300 all up because we had to add a power circuit. I did look at local sources before we started though and there really was nothing available. This seems to be about 2/3rds of the price of one of those T960’s so it would definitely have been an option…

Power supply is a big factor in favor of tiny batch ovens. We just get by with about 2.5KW of draw which we get from two a dedicated single phase circuit.. That T960 has a peak power draw nearly double that! It’s also a 3phase (or two phase in the USA) unit which might be a problem for some.

Hmm, it does look like it’s almost entirely IR based. Still, a testimonial is a testimonial I guess.

PK

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ef6400a7-fb39-4fca-89f7-fb3ea5dfc3f8%40googlegroups.com.

Daniel Dumitru

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+unsubscribe@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ef6400a7-fb39-4fca-89f7-fb3ea5dfc3f8%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+unsubscribe@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/01e701d32d31%2438f20970%24aad61c50%24%40com.

yaddatrance

Trampas Stern

Paul Kelly

@PK: That is a very ingenious DIY reflow unit!

TA

I bet it does a great job.

It’s a good thing to have for thermal testing though. We have a separate oven and freezer. The freezer has a bottle of CO2 and a valve that dumps liquid CO2 into the freezer. We added that after bumping into some guys from Alaska at a trade show….

A tip from us, take your boards out of reflow, let them sit for a day. Then put them through 2 thermal cycles to 85 deg C, opening the door to cool between cycles. For bonus points vibrate them too. This will help identify pillowing and other dry joint types that might otherwise sneak through QA.

So we picked up a SMTmax AS-5060 https://www.smtmax.com/detail.php?id=225 (Cost ~$750 for a dent-ding unit from the manufacturer)

and it works great for short board runs.

It looks good.. and seems to confirm the $1K price point for a decent small batch oven. How much of the heating is (in your estimation) done by direct IR and how much is done by convection?

PK

evilwulfie

So we picked up a SMTmax AS-5060 https://www.smtmax.com/detail.php?id=225 (Cost ~$750 for a dent-ding unit from the manufacturer)

and it works great for short board runs.

umm Looks like a T962A

Only difference is a fan inside ?

I have often thought that a fan would help out the t962.

yaddatrance

evilwulfie

up with a hot air station. all in all for my volume its fine. If i ever did 1000's i would upgrade.

the vents on the side are for the area where the PCB controller goes not the oven its self.

I may one day try a fan under the slide out tray if i can find a good high temp fan.

No room above the elements.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/5835737d-1d43-48b1-8dc5-48daf1723896%40googlegroups.com.

yaddatrance

Trampas Stern

Graeme Bridge

Paul Kelly

The T9xx models work ok if you don't mind putting some time and money into them. A friend has the little one and another one got a really big version.

IIRC "all" you have to do is, throw away the original controller and replace with a custom one or a kit,

No way. Any IR based oven will have hotspots. We’ve had batches go through a 962 and one board come out black! You must have convection heating if you aren’t going to move the boards.

The controller is actually OK, we still use it with one of our ovens.

Paul Kelly

My conveyor reflow is IR but it uses ceramic IR elements and lots of them, from memory its 23kw lol looking at the bench top chinese ovens they appear to use the quartz type elements so maybe changing to the ceramic would give a better radiation

You may be right, I’ve seen those kinds of elements used in pro vacuum formers to provide even heating. Although I suspect it’s the conveyor that makes it work. Just moving the boards will make a big difference if you have hot spots.

PK

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/83a76e6f-a2d6-48a2-82c9-a561fd0a0f2b%40googlegroups.com.

Cristian Nicola

Graeme Bridge

Trampas Stern

yaddatrance

No way. Any IR based oven will have hotspots. We’ve had batches go through a 962 and one board come out black! You must have convection heating if you aren’t going to move the boards.

The controller is actually OK, we still use it with one of our ovens.

Paul Kelly

I'd guess/hope they fixed it by now, but a few years ago, the T9XX controllers had a near fatal flaw with really bad non-linear time dilation. Depending on how hard the unit was working,

"time" would slow down or speed up, so you had to empirically generate a reflow profile.

Ah yes, having empirically generated our profiles, we went for many years without noticing this. It was only when we had the second oven next to it that we realised this was happening. DOH!

You are correct then, there are some problems with this controller.

I agree, convection is almost a requirement for reliability and painlessness, but I can totally see the attraction of a $150 reflow oven... :)

Don’t forget the $500 Porsche, and the $2000 private jet. Alas, all these things remain elusive.

If I had more time than money, I would have gone the retrofit route myself.

Not factoring in time (they take a couple of days to put together) or the fact that you may need an additional power circuit, our ovens were below AU$500 in parts. They lack some features but are (IMO) an adequate compromise.

It would be interesting to see one built on a smaller scale. There are smaller elements and fans available and I reckon that the smaller volume would give faster ramps.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/5e186a10-2b09-4cc8-a4aa-471043991cdf%40googlegroups.com.

yaddatrance

eSlavko

I sourcing information how to build reflow oven. The oven that PK does seems nice for me. But I have some question/ideas. How big need to be? I think I will never build plate bigger than 20x15cm, so inner size should be few centimeters bigger to allow air circulate. So let be 25x20 centimeters. But what about height. The bigger the longer will take to heat. Does it need to be more than 5cm height?

And heat source. I just wondering if 1500W heat gun should be ok. So the gun should be mounted outside box and air regulated with PID controller blown into the box. On the bootom should be hole / exhaust. Can this work?

evilwulfie

i do all the modifications ( check internet ) and it is fine for small boards / runs.

it was low cost.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/b6dbfcd2-73b5-444b-94f5-092f684513bc%40googlegroups.com.

eSlavko

Dne ponedeljek, 19. februar 2018 12.19.32 UTC+1 je oseba Wulf Man napisala:

evilwulfie

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/568da375-e286-48e7-b4dd-a399a90246d5%40googlegroups.com.

eSlavko

1'st time I hear for Slumping time....

Dne ponedeljek, 19. februar 2018 14.20.21 UTC+1 je oseba Wulf Man napisala:

evilwulfie

Compared to the alternatives which i just did not have the budget for it was the only option.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/6a89c15c-c81e-48e3-a4e1-9eda57098050%40googlegroups.com.

mojalovaa1

Still have same problems with reflow oven , I wish buy some small desktop reflow oven ( best options is some reflow oven like this : https://www.youtube.com/watch?v=_C6kDTDd6H0 ) but I'm not sure what buy because have some limit with max electric energy power ( 3x16A 230V ) for complete work shop for now and all so spaces limit .

Second options is like I'm say before : https://www.ebay.com/itm/T-962C-Infrared-SMD-SMT-BGA-IC-Heater-Reflow-Ofen-Lotstation-400x600mm-2800-W/312702304773?_trkparms=aid%3D1110001%26algo%3DSPLICE.SIM%26ao%3D1%26asc%3D20131231084308%26meid%3Dce31a5ed8b6b4b118433e2782849ef08%26pid%3D100010%26rk%3D3%26rkt%3D4%26sd%3D352724873824%26itm%3D312702304773%26pg%3D2047675&_trksid=p2047675.c100010.m2109 but not have idea how that work on real job , I have one DIY version similar like that but will not work allot I think because I'm use still for constructions and have allot oxidation .

Question is :

Some one is use T962-C reflow ?

What is experience ?

Have you some problems with soldering bigger component like capacitors and similar ?

Some one is use T960 ?

What is experience ?

Have you some problems with soldering bigger component like capacitors and similar ?

I need found some compromise between prices and used spaces and electric consumption .

Juan-Antonio Søren E. Pedersen

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/beabd111-47be-4c10-bc2c-88abaf32c147%40googlegroups.com.

mojalovaa1

Some one is use that 3 version PCB , can say how work ?

Sandra Carroll

I have DIY version for 350x300 mm PCB dimension but need something for bigger panel and faster productions , I'm found all so this but is not for bigger panel PCB : https://www.aliexpress.com/item/32830878068.html

Some one is use that 3 version PCB , can say how work ?

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/5b72f590-633d-45c4-a03f-cfe1851a9881%40googlegroups.com.

mojalovaa1

If I need make allot changes then can make my own oven who will for 500% fine , but not have free time for do that .

On Sunday, July 21, 2019 at 5:50:51 AM UTC-7, Sandra Carroll wrote:

Any of the T962 series ovens can work, but out of the box they need modifications to work well. There’s plenty of doc on the web about this. If you want plug and play don’t go with a T962 series oven. If you are ok doing mods to make it work well then go for itJust my opinion

I have DIY version for 350x300 mm PCB dimension but need something for bigger panel and faster productions , I'm found all so this but is not for bigger panel PCB : https://www.aliexpress.com/item/32830878068.html--

Some one is use that 3 version PCB , can say how work ?

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

John Plocher

mojalovaa1

How much heating element have on that oven ?

You work with SMT electrolyte capacitor ?

That look me similar like this : https://www.alibaba.com/product-detail/Puhui-T937High-quality-SMT-machine-reflow_62054614025.html?spm=a2700.7724857.normalList.38.6e916639R8tMQl

I need some oven with bigger soldering area for that look for T962C or maybe , but I'm not sure , maybe can go with something like T-962A+

evilwulfie

It looks just line my t962 with a different overlay.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAKFrckoz_E%2Bwk732FTY2iCKFVE4CEDNjbGQR%2B7ZiMJ0i%3DoHNgA%40mail.gmail.com.

mojalovaa1

What you think about T962C ?

evilwulfie

they both work perfectly with the modifications.

On 7/21/2019 9:20 AM, mojalovaa1 wrote:

What is yours opinions and experience for that T962?

What you think about T962C ?

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/88e36e43-78c7-4e85-bdd9-11ce7f04bd8a%40googlegroups.com.

mojalovaa1

evilwulfie

On 7/21/2019 11:16 AM, mojalovaa1 wrote:

Can you please say me what need change and how much that cost and how much time need for make changes ?

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/eb4c8993-60b4-4359-9d4a-56604559dc93%40googlegroups.com.

mojalovaa1

My DIY reflow have air circulation and not have allot problems with temperature profile , now I'm not sure what will be smart , buy new or again make my own :(

On Sunday, July 21, 2019 at 4:18:12 PM UTC-7, evilwulfie wrote:

Can you please say me what need change and how much that cost and how much time need for make changes ?--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

Randy Park

On Sunday, 21 July 2019 12:20:48 UTC-4, mojalovaa1 wrote:

What is yours opinions and experience for that T962?

What you think about T962C ?

Trevor Boicey

Both of them I modified using the web site just mentioned. The cost to modify is almost nothing, a roll of kapton tape, a $2 temperature sensor IC, wire, and solder.

I would consider a larger one, but I would have to run a new 220v circuit so it would be a bit of a hassle. So I'm staying put at the moment.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/3fdbe7c5-d1fa-708f-c09f-185236fa8c83%40gmail.com.

Jarosław Karwik

W dniu poniedziałek, 22 lipca 2019 15:49:07 UTC+2 użytkownik Trevor Boicey napisał:

I started with the T962 and upgraded to the T962A.

Both of them I modified using the web site just mentioned. The cost to modify is almost nothing, a roll of kapton tape, a $2 temperature sensor IC, wire, and solder.You also need a serial programmer if you don't already own one, they are $10 or so at most on the big web sites.For me both ovens worked well enough. The smaller one didn't work well around the edges but worked for the boards in the middle of the tray. The larger one seems to work better all around.

I would consider a larger one, but I would have to run a new 220v circuit so it would be a bit of a hassle. So I'm staying put at the moment.

On Sun, Jul 21, 2019 at 7:18 PM evilwulfie <evilw...@gmail.com> wrote:

Can you please say me what need change and how much that cost and how much time need for make changes ?--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/eb4c8993-60b4-4359-9d4a-56604559dc93%40googlegroups.com.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

Javier Hdez.

Javier Hdez.

Javier Hdez.

Brynn Rogers

On Sunday, July 21, 2019 at 6:18:12 PM UTC-5, evilwulfie wrote:

evilwulfie

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/e438b030-6344-4f04-b5ac-37d1557ea257%40googlegroups.com.

Trampas Stern

I have the T962A and have done all the modifications and it almost works. It still will leave parts of board near edges unsoldered.

Brynn Rogers

On Monday, July 22, 2019 at 11:20:10 AM UTC-5, evilwulfie wrote:

just clicked on it works fine for me dunno know what to say.

On 7/22/2019 8:46 AM, Brynn Rogers wrote:

--

On Sunday, July 21, 2019 at 6:18:12 PM UTC-5, evilwulfie wrote:

This link is not working for me - I get a 'not found' page from github...

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

mojalovaa1

SOME ONE IN EUROPE SALE T-960 REFLOW OVEN , NEED BE NEW AND BUY FROM COMPANY who can give official offers to me ?

Contact me to : eltron...@gmail.com

Thanks for help .

Jarosław Karwik

W dniu czwartek, 25 lipca 2019 16:04:36 UTC+2 użytkownik mojalovaa1 napisał:

HI

SOME ONE IN EUROPE SALE T-960 REFLOW OVEN , NEED BE NEW AND BUY FROM COMPANY who can give official offers to me ?