PushPullFeeder - Error finding sprocket holes

uavfligh...@gmail.com

uavfligh...@gmail.com

mark maker

Hi Matt,

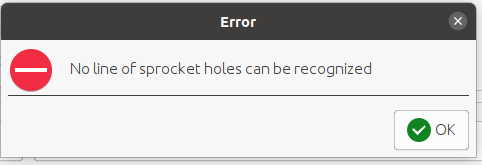

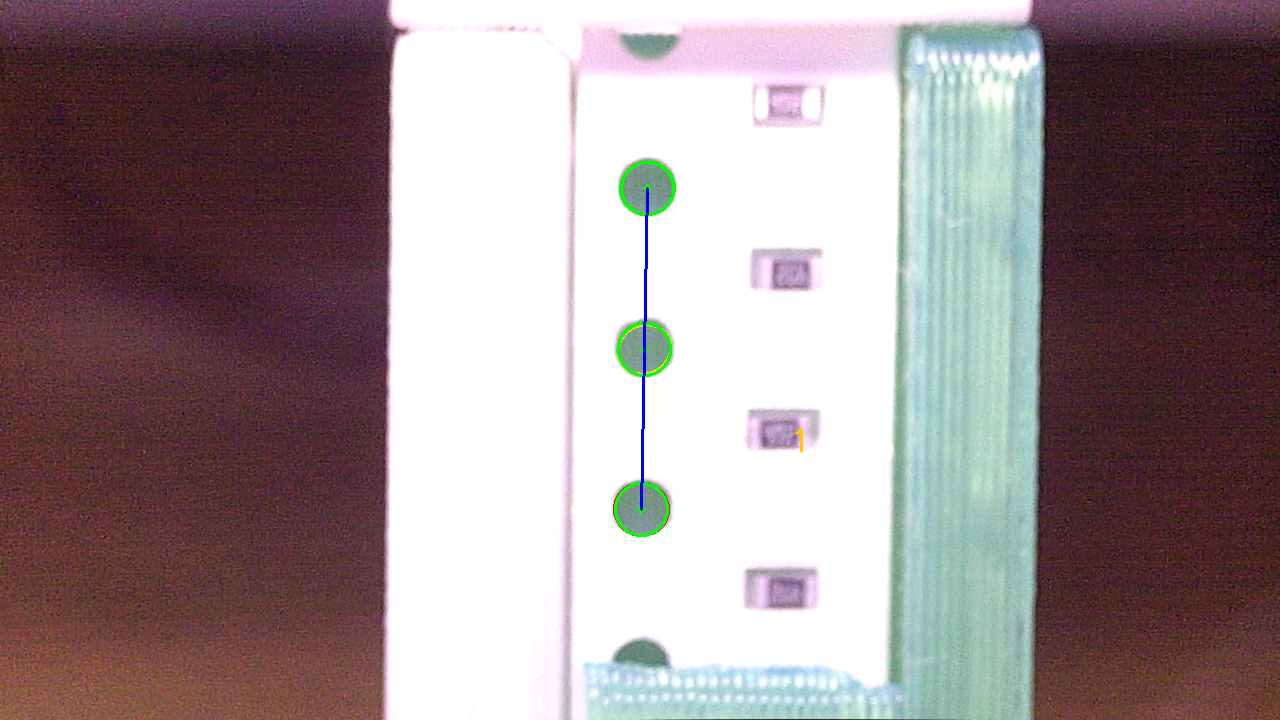

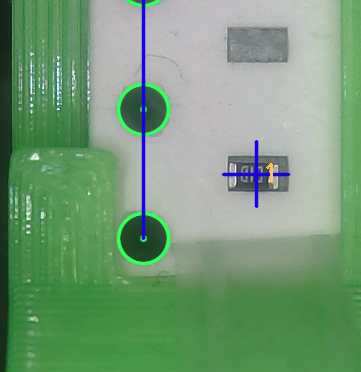

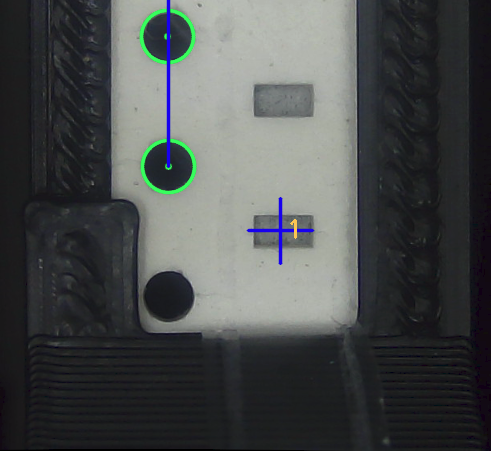

>There is a colour shift in this translation due to lighting. PIpeline was mistaking the part pockets for the sprocket holes.

Note that I just invested a lot into improving the detection to avoid mistaking part pockets. You can now use a Circular Symmetry pipeline.

https://github.com/openpnp/openpnp/pull/1450

https://github.com/openpnp/openpnp/pull/1456

https://github.com/openpnp/openpnp/pull/1457

You might give it a try:

- get new testing version

- backup your config

- reset to the CircularSymmetry pipeline and try it "out

of the box".

It is my goal to make these pipelines work "out of the box", so if you could test your case it would be a great help towards that.😎

The code you linked has changed too, there was actually a bug

that would favor the sprocket holes from neighboring

feeders if it detected more holes there.

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0555b2c1-750f-4716-9fac-6771d551416an%40googlegroups.com.

uavfligh...@gmail.com

mark maker

Hi LAG,

I so wish I could test this locally on your machine 🤔

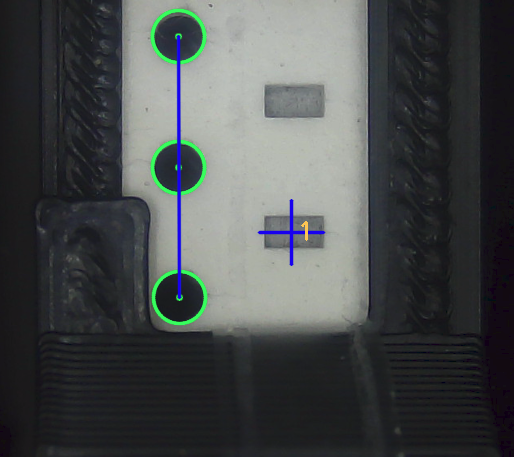

So it is guesswork, according to log. Not sure I found the

culprit. Are these the symptoms?

- If it is the only ReferencePushPullFeeder, it works. Correct?

- But if there is another ReferencePushPullFeeder that

is not yet or wrongly set up, then it fails?

Details:

https://github.com/openpnp/openpnp/pull/1466

New testing version to download/upgrade:

https://openpnp.org/test-downloads/

Let's cross our fingers! 🤞 in Swiss

German we would say "hold our thumbs"  😁

😁

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/133d0055-e4f9-487e-98cd-88d1fd9e8fd1n%40googlegroups.com.

Litterio Andrea Guainella

Litterio Andrea Guainella

mark maker

Please post the log. I specifically added new tracing to diagnose.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/18260d02-e95e-453e-a117-12df217607a2n%40googlegroups.com.

mark maker

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/309cd943-18d1-4368-959c-027e846512een%40googlegroups.com.

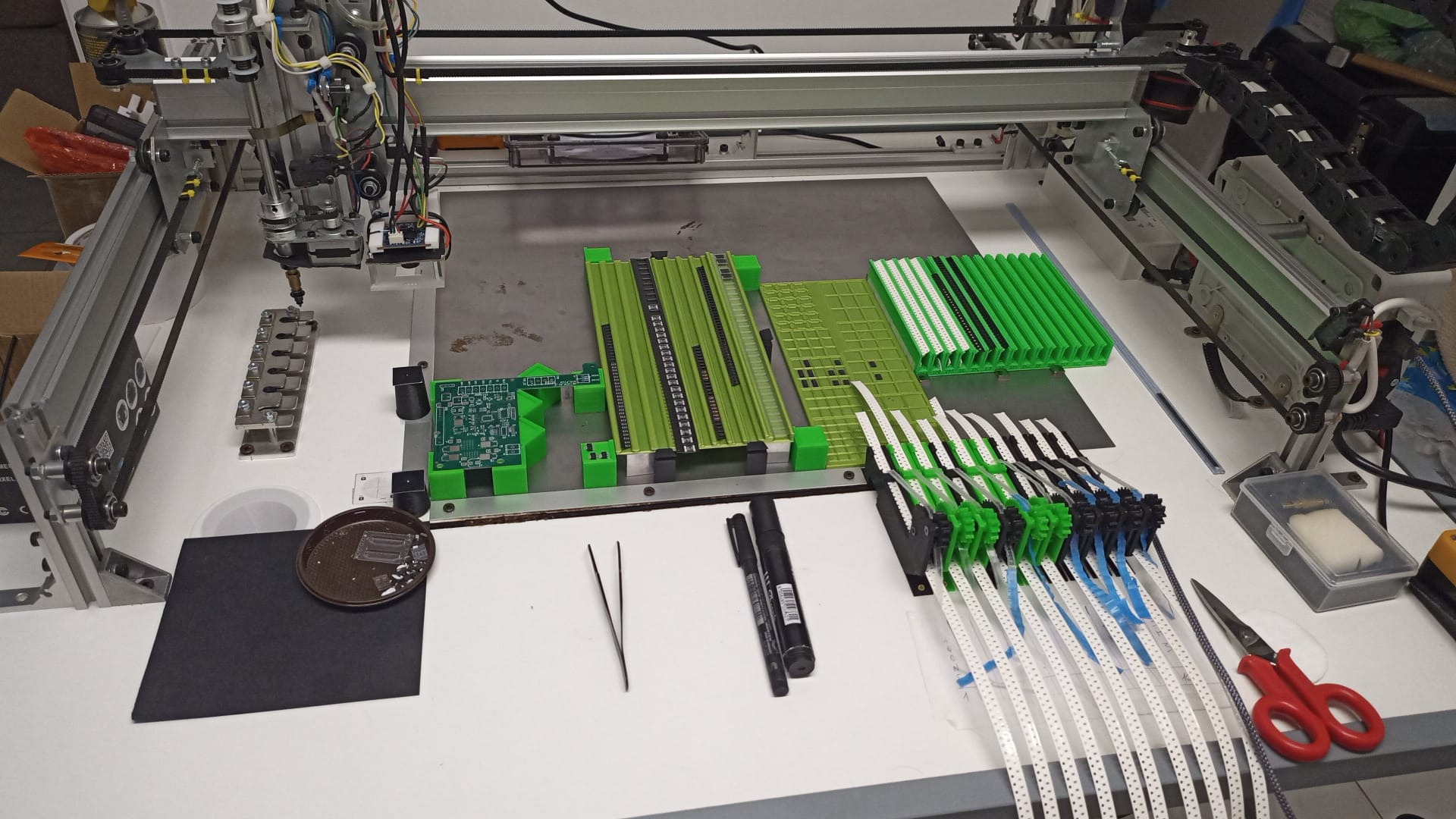

Litterio Andrea Guainella

mark maker

Hi LAG,

I can only guess.

- Your second feeder is not the "standard" distance away (tape

width + 8mm). So the very first [ + ] button will not work.

- But that's fine, you need to manually position to the pick

location then press Auto-Setup. Note, it will learn the right [

+ ] button distance as soon as you have two feeders, i.e. for

non-standard distances, the third feeder should be "one-click".

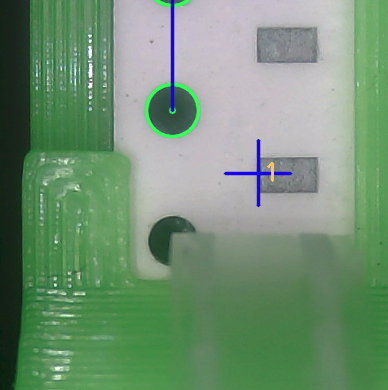

- But now you are on a green feeder. So the standard color-keyed

pipeline is likely selected.

- I can't explain why the pick location is sometimes off

vertically. I will look into this (I suspect some rounding

issue). Maybe send the machine.xml

if you still have that configuration.

- Then it is switching to black again. Wrong pipeline again.

- And the tape transport seems not entirely repeatable. The

holes are shifted (I suspect that's causing the

rounding issue)

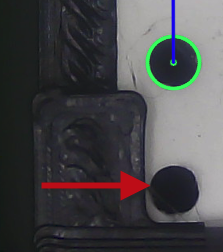

- There is also not enough sideways distance to the hole down

there, probably barely not, so it is unstable

(sometimes detected, sometimes not). The shadow there is not

helping. Maybe you can change your model there and cut a bit

away on the already printed ones.

- Sometimes the cover tape also obstructs the lowest hole.

I'm still not entirely sure if that explains all of it, so this

is not an excuse to not go on searching for bugs. And thanks for

keeping it up.

But frankly switching colors back and forth will always give problems. 😁

I guess you also have to work on reliable tape transport and

cover tape stretching, or you will have operational issues too (no

only setup). As you can see it copes with the sprocket hole

flipping most of the time during operation, i.e. it still takes

the right pick location...

... but for feeder setup, that is too shaky. I hope you

understand.

I propose you try with all the green or all the black ones

together and first make sure the sprocket holes are all visible

and at the same rough positions. Like I said the first [ + ] will

never work, due to the other-than tape width +8mm distance. But

the second [ + ] should have learned.

I'm still looking for bugs. Thanks for helping!

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/007c0e1d-99f6-4e97-84a6-20c2fc05504bn%40googlegroups.com.

Litterio Andrea Guainella