Interesting new feeder

1,543 views

Skip to first unread message

Jim Young

Mar 1, 2023, 10:50:22 AM3/1/23

to OpenPnP

I just saw this posted on the LumenPnp Discord. Looks interesting, although I've already committed myself to the 0816 feeders. I'm interested in others' comments. and thoughts.

vespaman

Mar 1, 2023, 11:18:47 AM3/1/23

to OpenPnP

So, even if I have no experience of either feeders, I prefer the cog wheel based feeders, and I think the complete forward motion solution looks more solid than the 0816.

But I don't really like the automatic feed solution, since it always means component waste. Don't really see any benefit with that in an open source project. CAN or RS485 would be my choice.

Having said that, I am contemplating a 0816 variant for my Charmhigh VB48, since I need more feeders, and I think a the full back of the machine can be populated with external feeders, and here the lower profile of the 0816 is helpful.

While 60€ might not be much, it still is a sum of money, and since it is not opensource afaict(?) it better work if one is investing in a lot of them. Also 0402 seems untested, and only 8mm? Maybe more sizes are coming, or the stl's contains also at least 12 and 16?

But good to see more feeders! There's not one that fits every setup. :-)

bing luo

Mar 1, 2023, 10:17:57 PM3/1/23

to OpenPnP

What is the significance of producing this feeder at this price? A new industrial electric feeder can be bought for 90 euros.

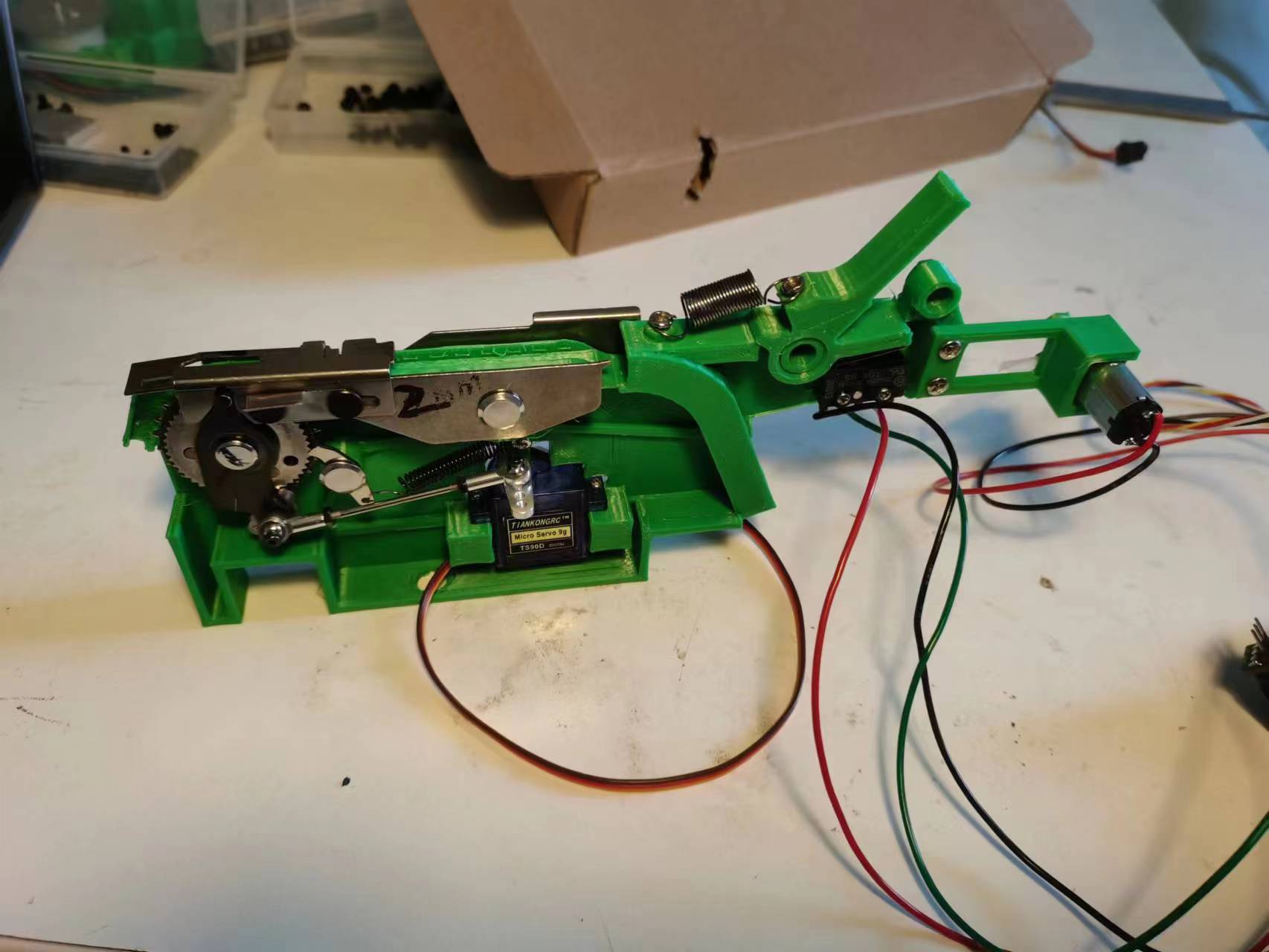

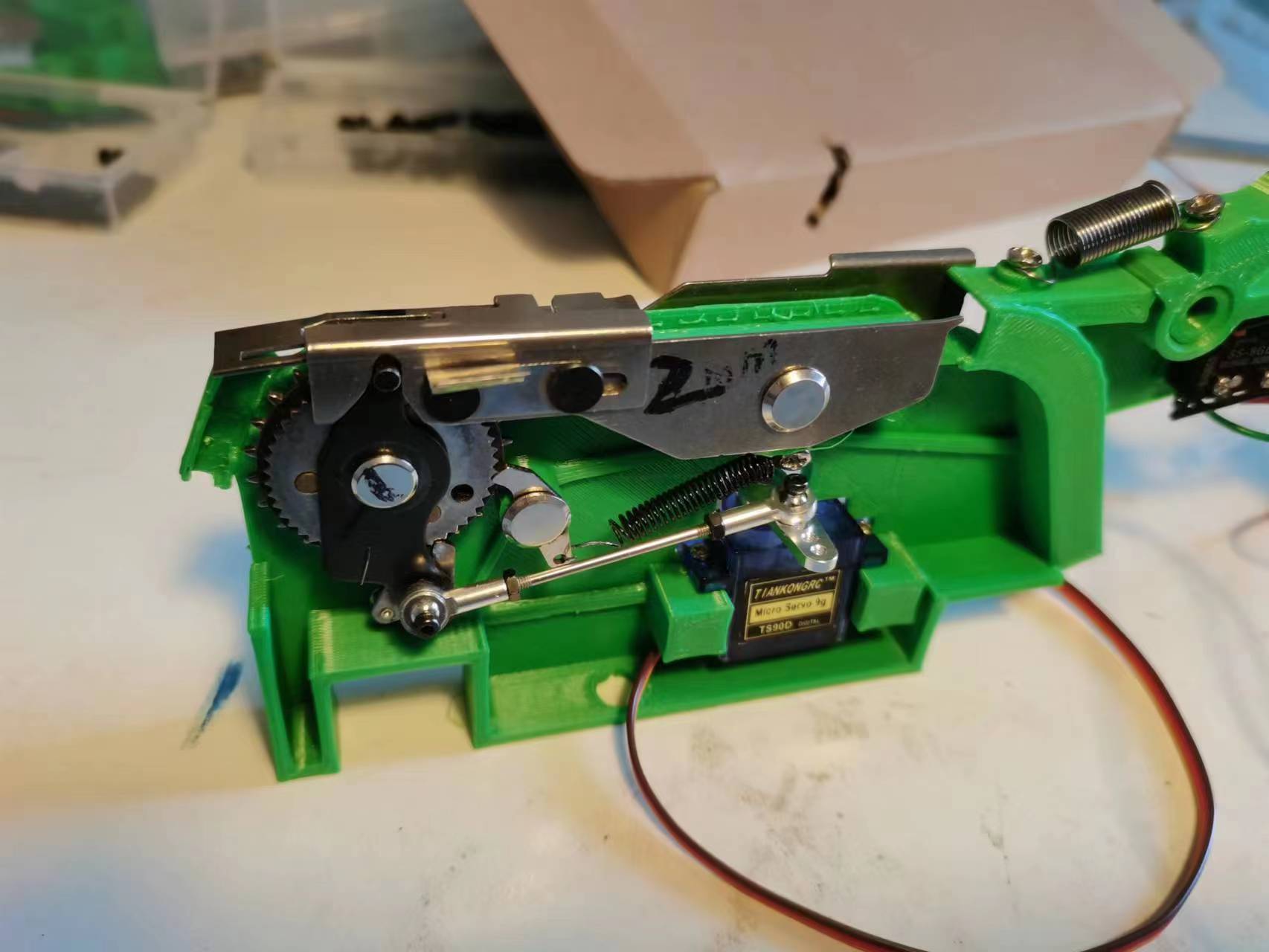

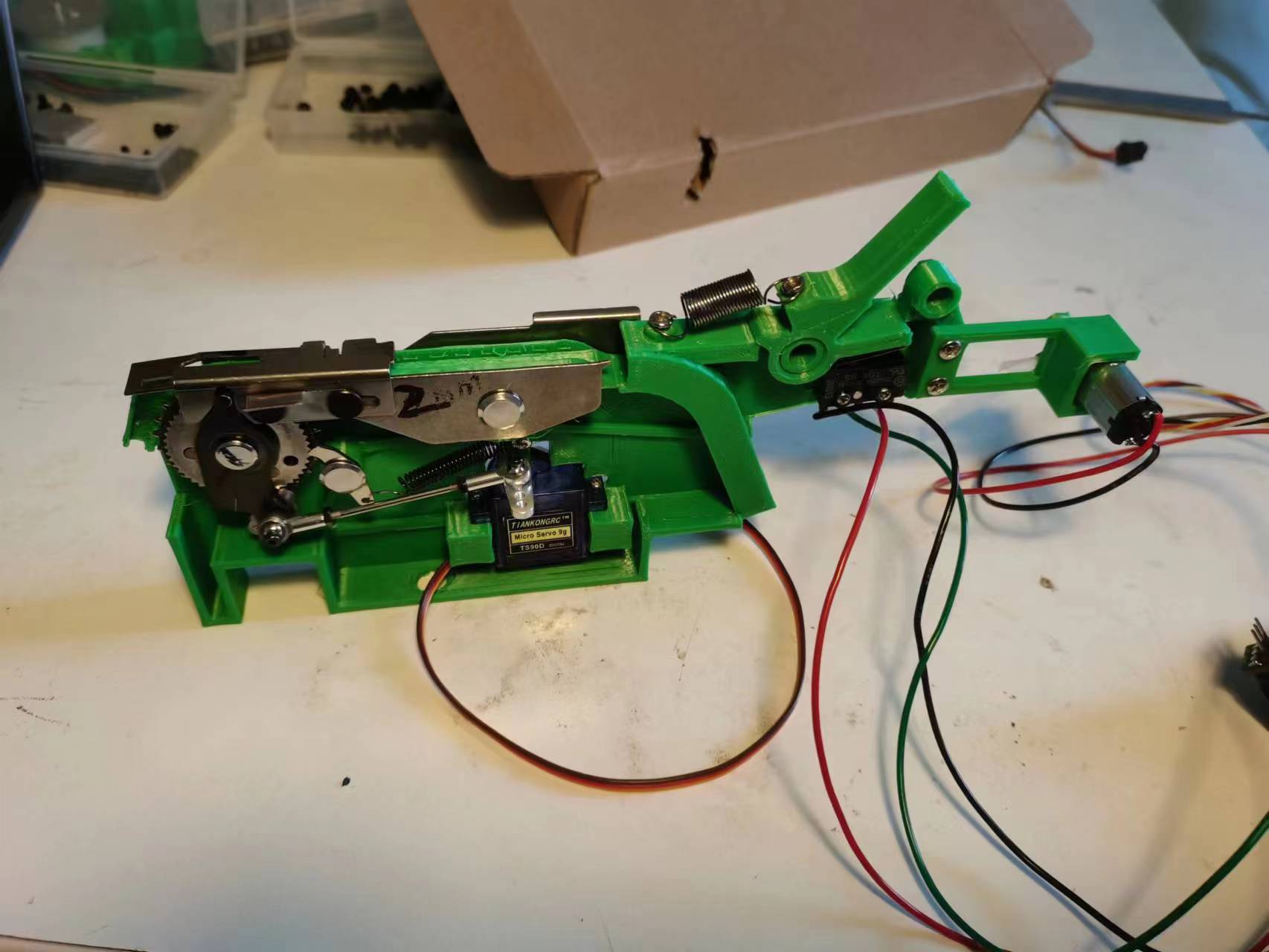

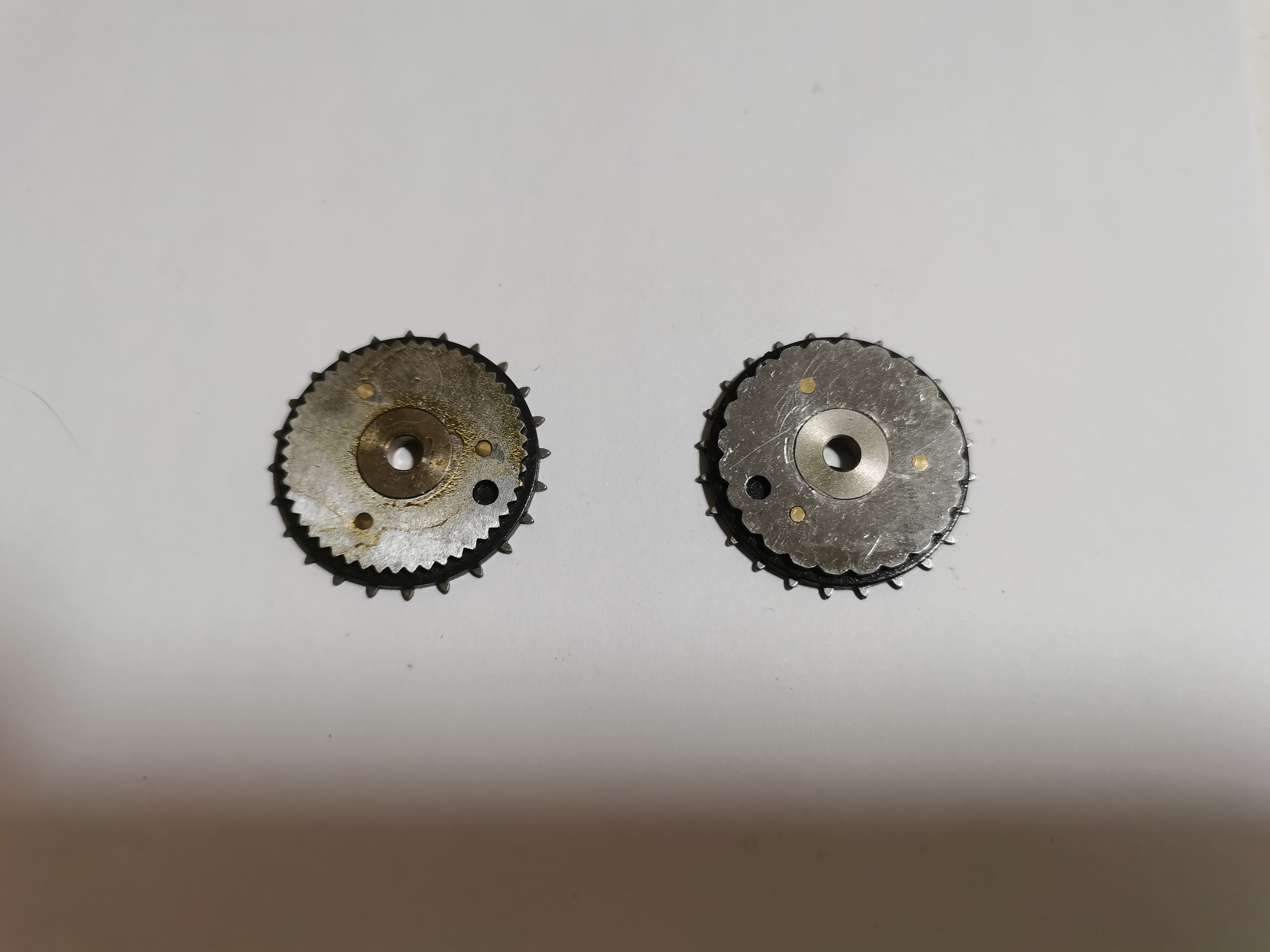

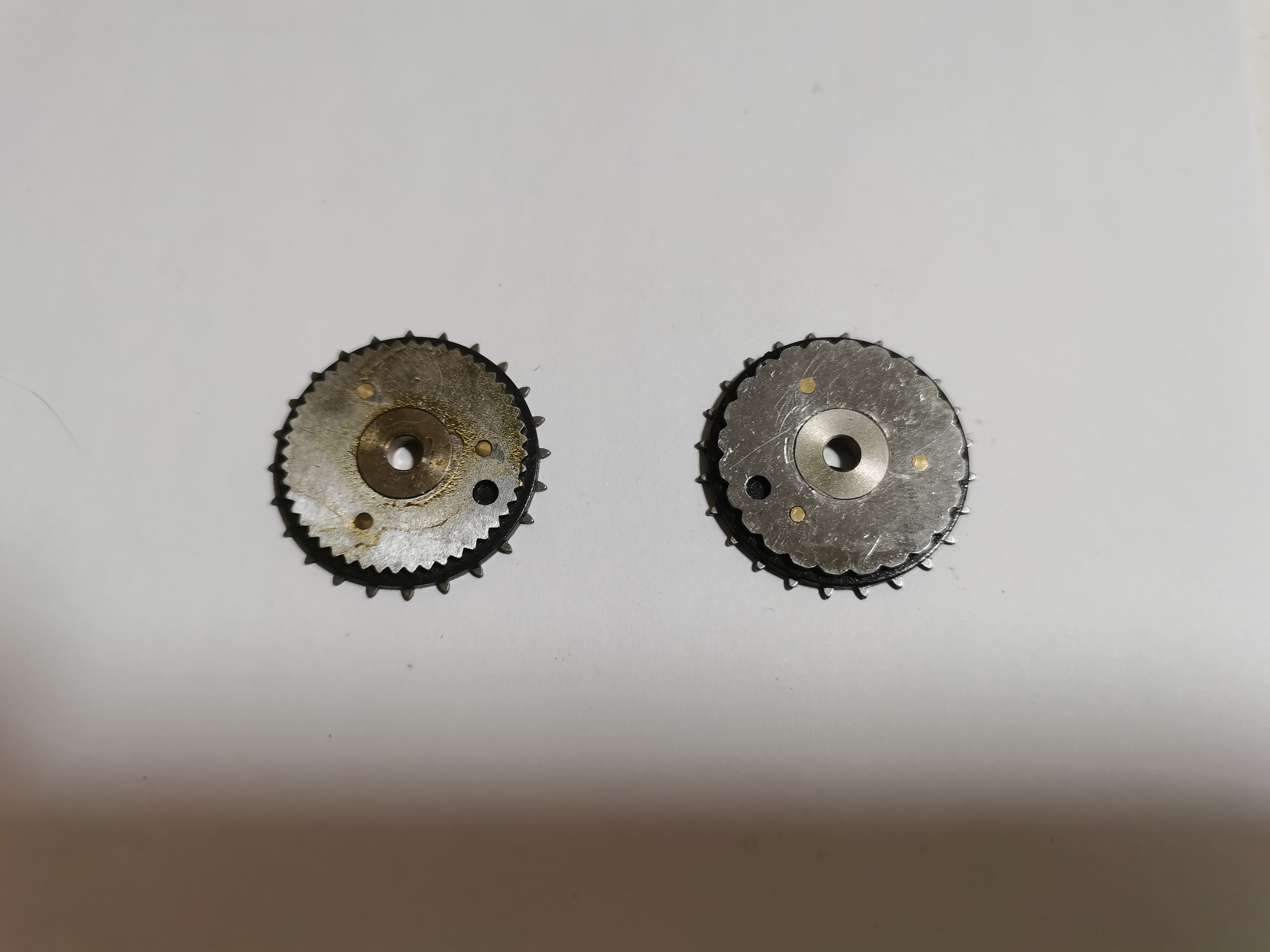

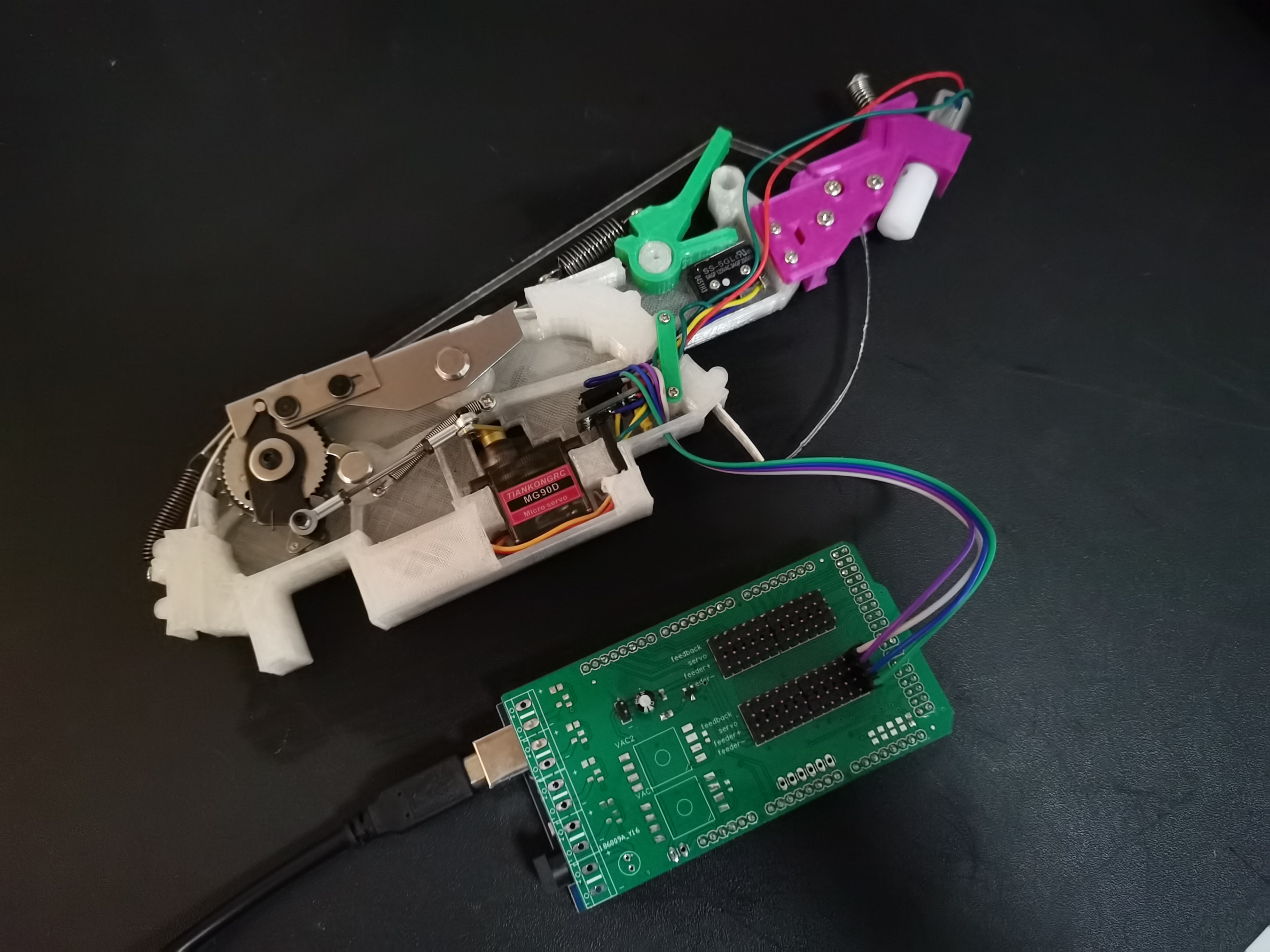

After I saw Mike Menci's poor man feeder, I tried to improve it. I bought Yamaha pneumatic feeder (CL8 * 2mm, CL8 * 4mm) puller gear and other accessories from the factory, and then printed the main body by myself, using SG90 servo instead of cylinder to drive it. It costs only $10. Like 0816 feeder, MEGA2560 can drive it, and the code is also universal.

All software and hardware are open source.

After I saw Mike Menci's poor man feeder, I tried to improve it. I bought Yamaha pneumatic feeder (CL8 * 2mm, CL8 * 4mm) puller gear and other accessories from the factory, and then printed the main body by myself, using SG90 servo instead of cylinder to drive it. It costs only $10. Like 0816 feeder, MEGA2560 can drive it, and the code is also universal.

All software and hardware are open source.

Ian Arkver

Mar 2, 2023, 3:34:11 AM3/2/23

to OpenPnP

Nice. Have you got links to where someone outside China can buy all these parts for $10 ?

bing luo

Mar 4, 2023, 1:30:10 PM3/4/23

to OpenPnP

https://www.youtube.com/watch?v=tC2oPf5Ro9E

https://www.youtube.com/watch?v=OzqBcYExlio

Watching the videos of its working for 0402 resistor, I need a few days to purchase accessories, and then I will sell them for $13 if someone needs. You can also find it anywhere according to my list. SG90 servo and N20 reducer motors are everywhere, but the accessories of Yamaha CL8 feeder are not very easy to find. This old pneumatic gear feeder structure is low price, fully open source, can be built and improved by yourself.

Watching the videos of its working for 0402 resistor, I need a few days to purchase accessories, and then I will sell them for $13 if someone needs. You can also find it anywhere according to my list. SG90 servo and N20 reducer motors are everywhere, but the accessories of Yamaha CL8 feeder are not very easy to find. This old pneumatic gear feeder structure is low price, fully open source, can be built and improved by yourself.

I have compared all industrial feeders(Pneumatic and electric) . and found that they all have a pressing cover that can slide back and forth to prevent the components jump out. Whether gear or press cover , It is difficult to make by self , so I have to buy them from the factory.

I tested it today. The feeder controller code of 0816 can be used to drive it without any modification. That is to say, it can be used in parallel with the 0816 feeder. I modified the working mode of the N20 motor because I felt that the traction force of the 0816 was not enough, which might cause the plastic belt to not peel off normally.

Jonathan Oxer

Mar 4, 2023, 4:31:53 PM3/4/23

to ope...@googlegroups.com

Good work! I like the idea of using an existing gear mechanism which has been made to good precision, combined with 3D printed parts.

You said this is open source. Where is the design? It's not in the Microsmt repo on Github.

When you are ready I would like to buy some to try.

Jon

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/d346dabf-05a6-4445-afb4-9880e6b1021dn%40googlegroups.com.

vespaman

Mar 5, 2023, 1:51:25 AM3/5/23

to OpenPnP

Yes, that looks like a proper solution!

If only I could something like that on my chmt48. Hmm.

- Micael

Klaus

Mar 7, 2023, 6:02:38 AM3/7/23

to OpenPnP

I like the approach using proven precision parts together with 3d printed parts. The videos look very good.

If the feeder spare parts are available for reasonable price I would definitely give it a try.

BR

Klaus

bing luo

Mar 23, 2023, 10:03:57 AM3/23/23

to OpenPnP

I used this feeder to place 0402 without any problems. Watch the video

https://www.youtube.com/watch?v=AYR47ebTovY .

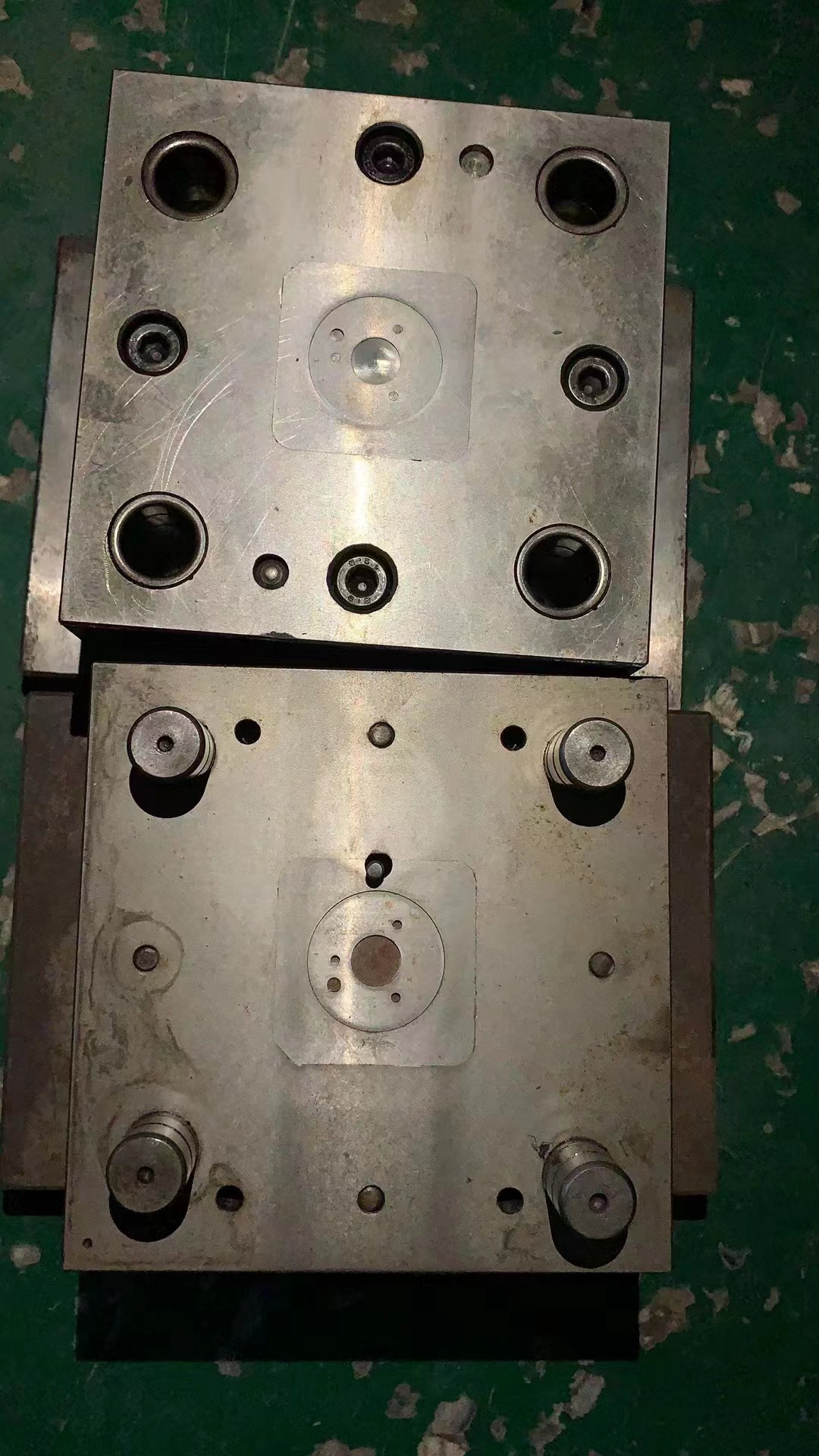

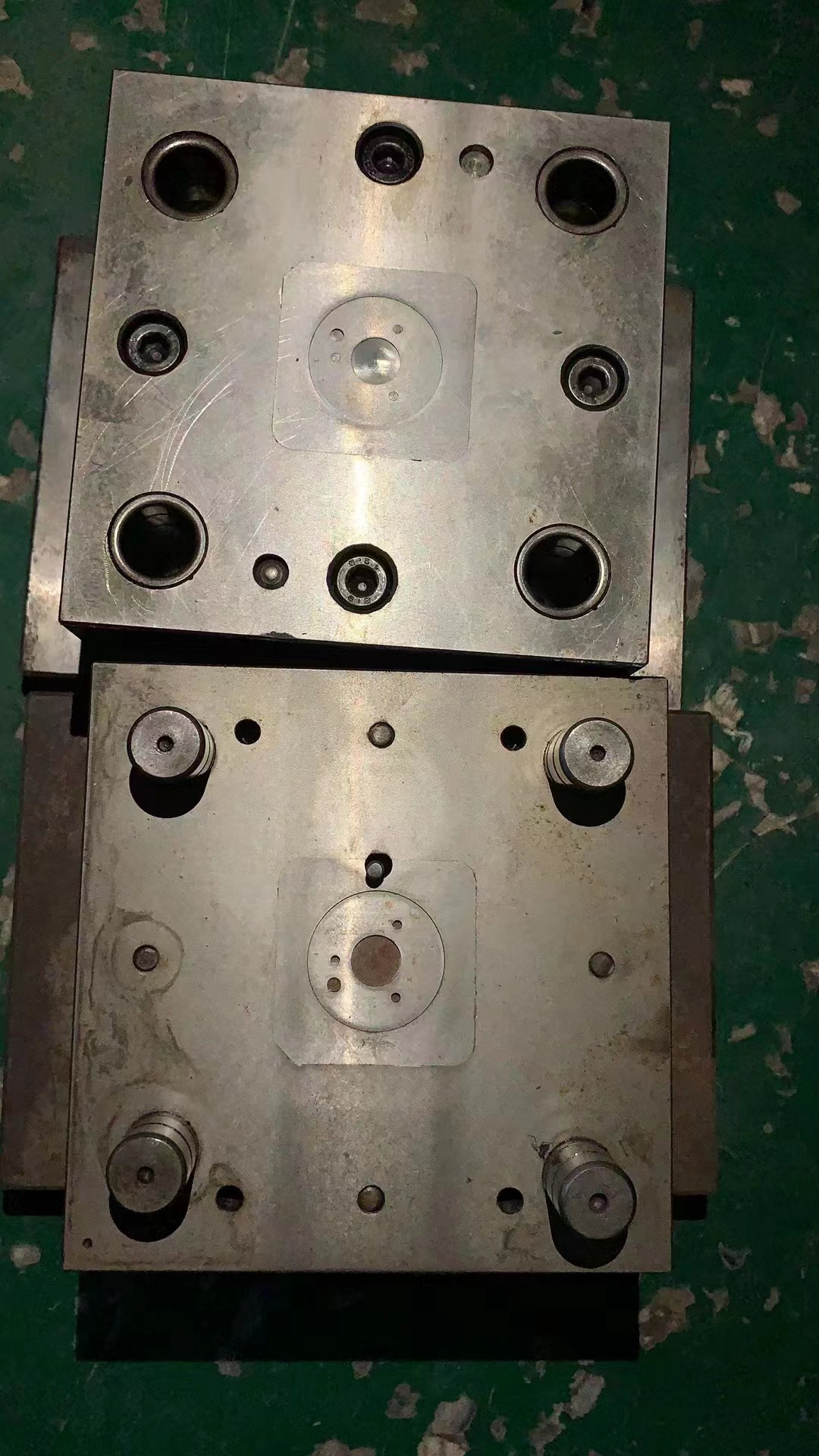

I plan to order some accessories to make some feeders, but the factory manager told me that these accessories have been discontinued, and he only has dozens of sets, so he sells them very cheap. Because the speed of the pneumatic feeder is too slow, it has been eliminated. I found the mold which is ready to be discarded in his debris room and started production again.

MisterFixIt1952

Apr 1, 2023, 5:47:56 PM4/1/23

to OpenPnP

Hi Jon. I've looked at most of the DIY feeders and I also like the factory feeder parts as a basis for the feeders. They just look more robust over the long haul and at $17 US each that is the best price I've seen for this kind of kit. I also really like the clockwork advance mechanism. I had previously purchased some metal feed wheels and some small solenoids (to replace the pneumatic originals) to make my own design but these are a much better solution, at least cost wise. I just ordered 1 each of the 2mm & 4mm to try out. I still haven't given up on the solenoid solution but since this is still a partial DIY solution I might play around with the final product. I would like to see a better/thinner solution for the take up reel. You would have to step these reel motors, as designed, to mount them side by side, making random placement difficult.

I'll let you know how they work out.

bing luo

Apr 2, 2023, 9:46:23 AM4/2/23

to OpenPnP

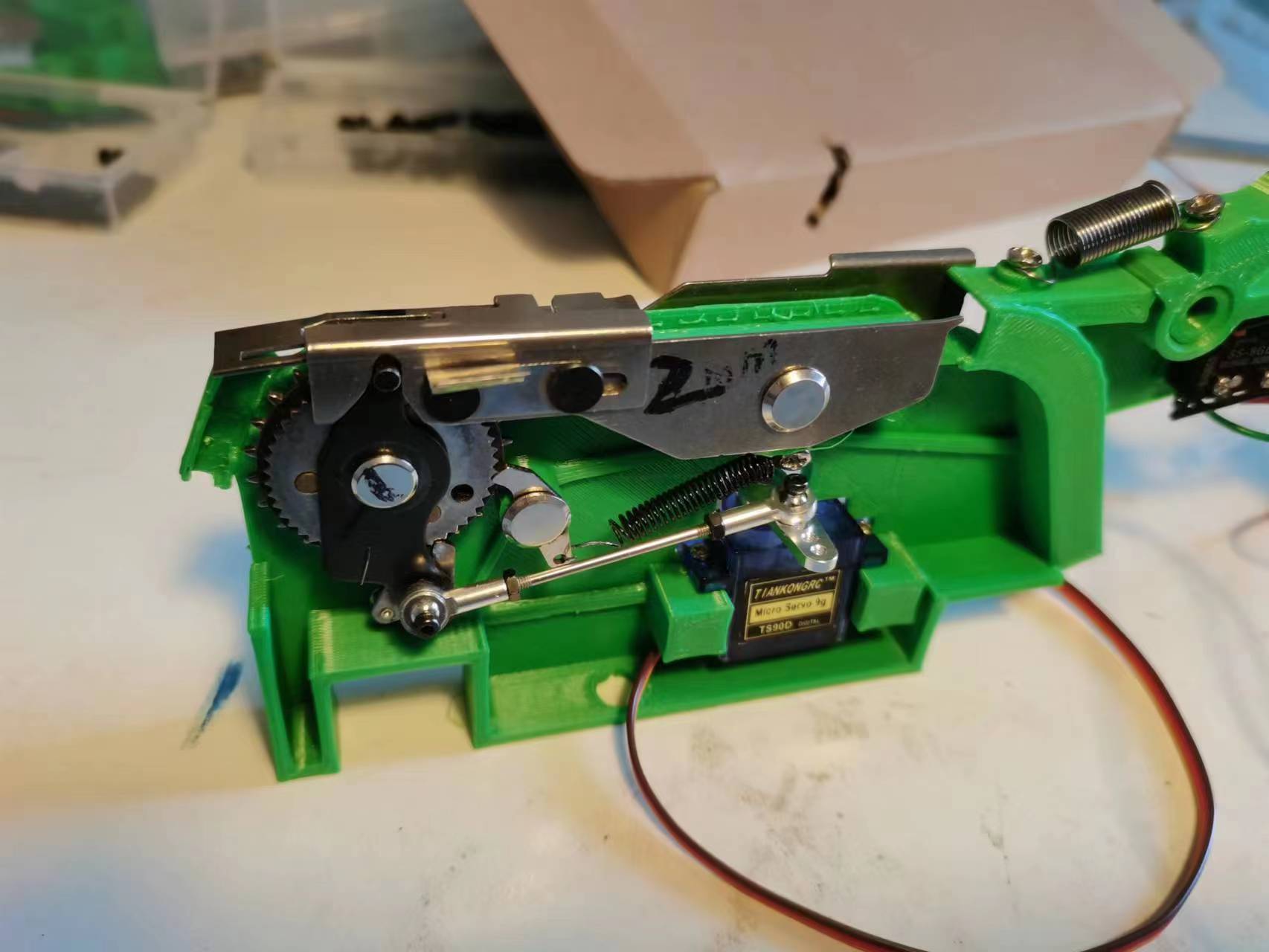

Reel gear has been changed to a 0.5 modulus POM worm, which is difficult to 3D print. Perhaps my printer is not good, so I can only use the finished POM product,it occupies a much smaller space. Due to the deceleration effect of the worm gear, the reduction ratio of the N20 motor was changed from 1:30 to 1:200, otherwise it would be very slow and unable to work.

What you will get is as the photo that has been changed to a worm drive. You need to solder the wires on the PCB yourself.

It is very simple, with no IC or program. Using a MEGA 2560 controller and 0816 code, it can directly drive 23 feeders.

Such a simple mechanical feeder has no technical content and does not require development. It is just changing the drive of an industrial pneumatic feeder from a cylinder to a servo.

It's very easy to understand. You can copy it from my photo. It's not my original creation. It's a mixture of Yamaha, 0816, and poor man feeder, so it can't sell for $60 or $90. On my website, you can download 3D drawings for direct printing. The damage to them is excessive wear and tear, which usually does not occur because they were originally used for industrial purposes and has been heat treat.

Its operation is also very simple,

1: Start the feeder system with the M610 S1 command

2: Use the M600 N23 A90 command to set the servo arm to 90 degrees and connect it to the gear.

3: Change the value of A to determine the forward and reverse angles of the gear.

4: Use M620 N23 A80 (Forward angle) B40 C115 (Reverse angles) F4 U240 V544 W2400 X0 to write the forward and reverse angle to MEGA2560

5: Call the feeder with M600 N23 F4.

6: Run the M610 and M600 commands directly after power on every time without setting the angle again.

Reply all

Reply to author

Forward

0 new messages