Peter's CP40 nozzle holder- Input requested

betzt...@gmail.com

Thorsten Wilmer

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ecbe5095-d7de-4fb6-ad9d-16c3fb0ac45dn%40googlegroups.com.

betzt...@gmail.com

Thorsten Wilmer

Thanks for the feedback. I assume this was for how much force you had to apply to get it to start compressing?Peter.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/b8518cc7-7813-4064-bcb8-6cc7d1f495f0n%40googlegroups.com.

Harjit Singh

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ecbe5095-d7de-4fb6-ad9d-16c3fb0ac45dn%40googlegroups.com.

Mike Menci

betzt...@gmail.com

Betz Technik Industries Ltd.

Thanks Mike, those are all of the robotdigg one right?

zart...@gmail.com

Mike Menci

betzt...@gmail.com

betzt...@gmail.com

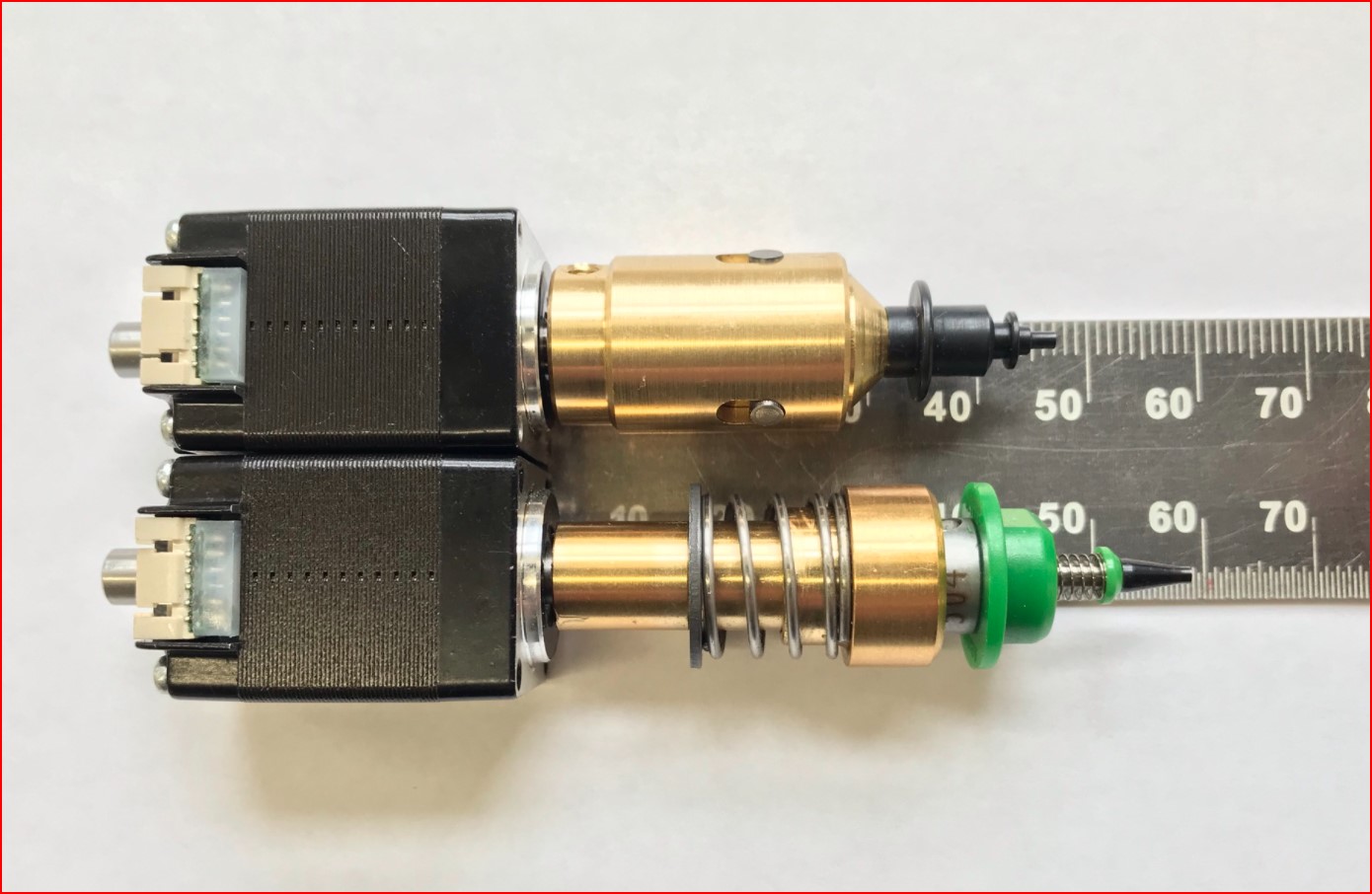

Runout seems good, just like the juki nozzle holders you can rotate them on the shaft to try out different settings to find the lowest runout. Just like the juki nozzles themselves you have to actuate the piston a few times to get them to settle into their proper position. I am not sure what I will say for runout guarantee yet, but I was able to get all 5 of the first ones under 0.001" TIR with little effort.

Here is the test video: https://youtu.be/2tJNU8Mc5cI

Approximately 40g to insert the nozzle onto the holder, and about 250g to start compressing the spring. That should make auto changing pretty easy!

I added them to the site for anyone who is interested in trying them out!

Regards,

Peter.

Jason von Nieda

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/74aeed28-54d5-4b84-9c0b-1f8fea3ea3a8n%40googlegroups.com.

Lance Endres

scott.t...@gmail.com

Mike Menci

betzt...@gmail.com

Scott Wilson

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/9QQQBeHBHw8/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/7a52da95-df3e-4699-805d-fb0a927a34can%40googlegroups.com.

Jonathan Oxer

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CA%2BQw0jxVPOBkawy%2BNBjiEVtec67uHLEgMb5Fb4jH6YwttxM3kQ%40mail.gmail.com.

Ben Holmes

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/9QQQBeHBHw8/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/7a52da95-df3e-4699-805d-fb0a927a34can%40googlegroups.com.

betzt...@gmail.com

Sandra Carroll

From the video you’re using a 10th indicator. With about 1.5 to 2 10th runout which is great.

What is the runout of the motor shaft?

Curious to know how much of that run out is the part or the shaft.

Sandra

From: ope...@googlegroups.com <ope...@googlegroups.com> On Behalf Of betzt...@gmail.com

Sent: Tuesday, April 27, 2021 3:19 PM

To: OpenPnP <ope...@googlegroups.com>

Subject: Re: [OpenPnP] Peter's CP40 nozzle holder- Input requested

Hi Everyone,

I just assembled the first 5 nozzle holders and the results seem very good.

Runout seems good, just like the juki nozzle holders you can rotate them on the shaft to try out different settings to find the lowest runout. Just like the juki nozzles themselves you have to actuate the piston a few times to get them to settle into their proper position. I am not sure what I will say for runout guarantee yet, but I was able to get all 5 of the first ones under 0.001" TIR with little effort.

Here is the test video: https://youtu.be/2tJNU8Mc5cI

Approximately 40g to insert the nozzle onto the holder, and about 250g to start compressing the spring. That should make auto changing pretty easy!

I added them to the site for anyone who is interested in trying them out!

Regards,

Peter.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/74aeed28-54d5-4b84-9c0b-1f8fea3ea3a8n%40googlegroups.com.

Betz Technik Industries Ltd.

Hi Sandra,

There is typically zero runout detectable on the shaft (from my experience). I’m not sure if that is due to the magnetics of the motor or what but it seems impressive.

It is deceiving measuring the tip of the nozzle holder as the dial test indicator can place enough pressure on the piston to deform the O-rings. I’ve found the best way to test them is just visually. It seems that when assembly goes well, there is no visual wobble at the tip. If there is a little wobble visible, usually just a hand actuation of the piston aligns everything.

Regards,

Peter.

Sent from Mail for Windows 10

Jonathan Oxer

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/64D2058F-89E4-4FEF-A308-35930595E7F5%40hxcore.ol.

betzt...@gmail.com

Harjit Singh

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f3ed71f0-3bcb-4283-a54e-5f9e1f3e4561n%40googlegroups.com.

Lance Endres