24 * 2 branch busbar and magnetic feeder rack for bing feeder

404 views

Skip to first unread message

bing l

Jan 5, 2025, 4:14:37 AM1/5/25

to OpenPnP

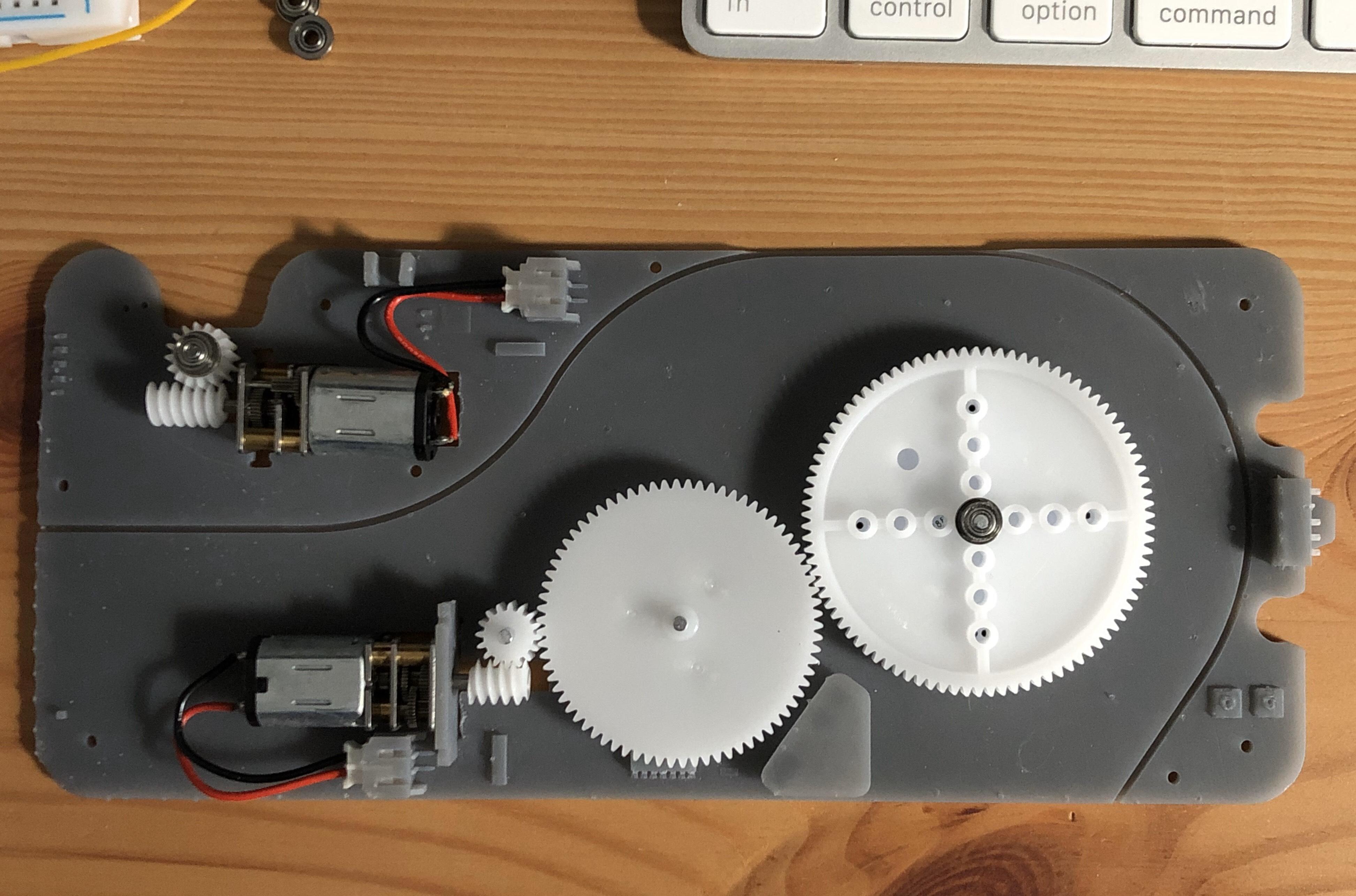

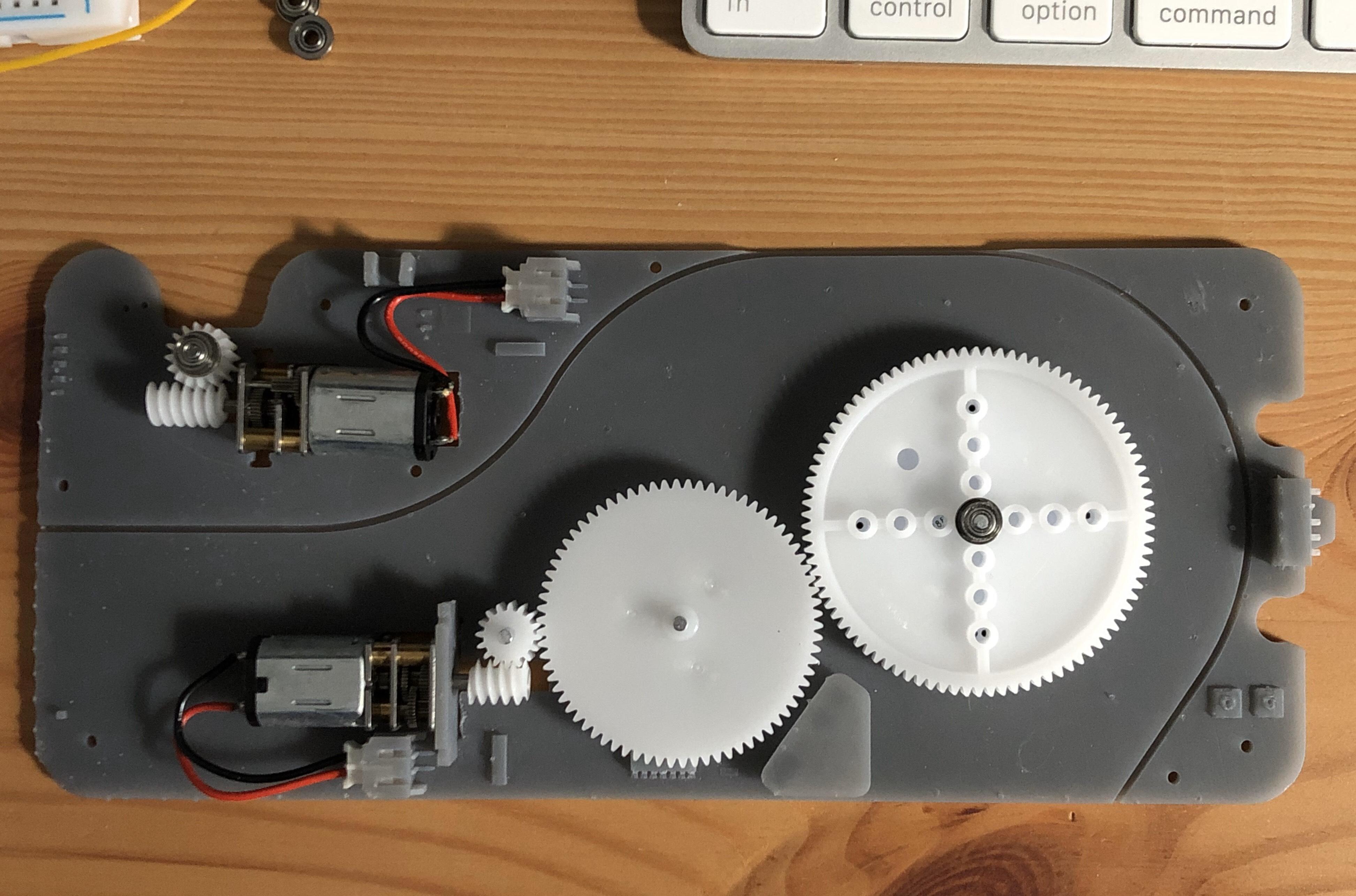

Based on user feedback, I have made two new features for Bing feeder. If you have any requirements, please download the drawings directly from our website and print the newly added 3D printed parts and PCB files.

NO.1: A MEGA2560 controller can simultaneously control 48 feeders, and the sockets are placed at the bottom of the feeders through PCB, reducing the use of many cables. PCB only provides the function of wires, without any components, so there is no communication protocol, simple configuration, stable and reliable.

NO.2: 24pcs 8mm magnetic feeder racks have been added on each side, making it easy and accurate to place the feeders in the same position each time, and then fix them with magnets.

video : https://youtu.be/GRiYnIbRVZw

Jarosław Karwik

Jan 7, 2025, 6:16:40 AM1/7/25

to OpenPnP

The magnets - is it enough to keep feeders stable ? Have you tried that long term in real production ?

I have my own version - modification. Not yet tested nor full assembled . I hope to have more time to work on it.

The cover will be modified to provide guide for connecting feeder to female pin connector ( not assembled yet)

bing l

Jan 7, 2025, 6:55:30 AM1/7/25

to OpenPnP

The magnets - is it enough to keep feeders stable ? >>>>>>>>>No problem, it's sturdy enough. This 3D printed feeder is lightweight, so four 8 * 5mm magnets are enough to lock it in place.

Marco Blancato also designed a very beautiful version, but because its PCB pins are at the front, it cannot adapt to my PCB busbar. At present, it can only be directly connected to MEGA2560 via cable.

One advantage of using magnets is that you can only grasp the top of the feeder. Then it doesn't require a lot of force to remove or install it. So you can completely avoid touching the two feeders on both sides.

Marco Blancato also designed a very beautiful version, but because its PCB pins are at the front, it cannot adapt to my PCB busbar. At present, it can only be directly connected to MEGA2560 via cable.

Jarosław Karwik

Jan 7, 2025, 8:44:59 AM1/7/25

to OpenPnP

Well, I think I will adapt my version to magnets as well - but with small change, borrowed from my other machine

This will have to be a bit different for Bing feeder, but the idea is to 'fix' the front upper part of it - as this gives significant increase in rigidity of the attachment. Feeders in the picture are really 'soft' and become usable only when attcahed to the machine.

I made new control board with LPC11C22FBD48_301 (with embedded CAN transciver). I plan to use CAN, but the board also has connector for standard serial commands e.g. from FTDI pin compatible USB/serial boards.

Why do you keep using separate MEGA2560 boards if single chip ( well - two chips if you need USB/serial conversion) ?

Mike Menci

Jan 7, 2025, 9:25:46 AM1/7/25

to OpenPnP

Jarosław Karwik

Jan 7, 2025, 9:37:56 AM1/7/25

to OpenPnP

Yeah, they are nice - just that I have to adapt to current solution as I have parts for ~30 feeders

bing l

Jan 7, 2025, 11:00:43 AM1/7/25

to OpenPnP

Why do you keep using separate MEGA2560 boards if single chip ( well - two chips if you need USB/serial conversion) ?>>>>>>>>>>

Because I have sold a lot of MEGA2560 compatible boards in the past, if previous users also want to use this upgraded feeder, they only need to reprint the feeder shell, customize the PCB bus board, replace the new firmware, and purchase magnets. This cost is very low.

bing l

Jan 7, 2025, 11:07:41 AM1/7/25

to OpenPnP

I think it's better to print it by self. I have posted a step file for one slot, No matter how many slots you need, just to array them in SolidWorks. From 1 to 100. The price of 4 8*5mm magnets is 0.2 US dollars.

bing l

Jan 7, 2025, 11:12:44 AM1/7/25

to OpenPnP

I made new control board with LPC11C22FBD48_301 (with embedded CAN transciver). I plan to use CAN, but the board also has connector for standard serial commands e.g. from FTDI pin compatible USB/serial boards>>>>>>

I don't use CAN or RS485 because I think they are too complicated. I hope that when the feeder doesn't work, all I need to do is check if the circuit is open. So I used the most primitive method.

在2025年1月7日星期二 UTC+8 21:44:59<jarosla...@gmail.com> 写道:

Jarosław Karwik

Jan 7, 2025, 11:14:48 AM1/7/25

to OpenPnP

Have you uploaded new files to git ? ( https://github.com/microsmt/Microsmt-PNP-hardware/tree/main )

I wanted to have a look for the modified body, but I think there is still previous version.

What kind of spacing for the feeders you got - with magnets and separation ? ( 14mm ? )

What is the price of Solidworks in China ? It is quite expensive in EU and most of us will have to use cheaper solutions.

bing l

Jan 7, 2025, 11:43:08 AM1/7/25

to OpenPnP

I wanted to have a look for the modified body, but I think there is still previous version>>>>>>>I am now sending it to your email.

What kind of spacing for the feeders you got - with magnets and separation ? ( 14mm ? )>>>>>>>The distance between two feeders is 3.8mm.

What is the price of Solidworks in China ? >>>>>>>>More than 12000 USD. the same individual cannot purchase, only using the company's.

Jarosław Karwik

Jan 7, 2025, 12:01:41 PM1/7/25

to OpenPnP

Got it thanks.

I think I will use it directly, just will add one more front slot - like on my picture. But I guess I will test it first to see the grip.

And I am not sure I was clear about my change in feeder control - I have placed MEGA2560 functionality on the PCB bus board as it seemed cleaner solution for me.

And it requires just one small CPU plus maybe CH340 for USB connections. Feeders were not changed.

Liwajaya Printing & Promotion

Jan 7, 2025, 10:19:59 PM1/7/25

to ope...@googlegroups.com

hi bing,

is there a link where i can download the firmware for this feeder.

thanks.

is there a link where i can download the firmware for this feeder.

thanks.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion visit https://groups.google.com/d/msgid/openpnp/4e62f049-e4f1-412e-85ed-60547be789d5n%40googlegroups.com.

_______

Liwajaya Printing And Promotion

WhatsApp 0816765676

Jarosław Karwik

Jan 8, 2025, 8:18:23 AM1/8/25

to OpenPnP

Hi Bing,

Now I miss only one important (for me) feature in your machine.

Do you plan to make integrated (with feeder) spool holder ? I really like to keep it neatly together, it is much easier and faster to change and feeders like that.

I am now in the middle of adapting your latest design and I am tempted to add it myself.

pal...@gmail.com

Jan 8, 2025, 9:40:46 AM1/8/25

to OpenPnP

Hi Bing.

I also want the link to download this new version.

Thank's a lot.

Good job !!!

bing l

Jan 9, 2025, 12:12:00 PM1/9/25

to OpenPnP

I am checking the drawings and will upload them once they are checked

bing l

Jan 9, 2025, 12:16:05 PM1/9/25

to OpenPnP

Do you plan to make integrated (with feeder) spool holder >>>>>>> I wouldn't do that. I think the feeder is too light and not suitable for carrying spools.

Jarosław Karwik

Jan 9, 2025, 12:25:57 PM1/9/25

to OpenPnP

Well,

I have also other machine which is much lighter then yours ( both feeders and machine itself) and it works nicely.

I will extend one of the feeder's rear covers with extra attachment for standard spools and test it.

Mike Menci

Jan 9, 2025, 9:46:19 PM1/9/25

to OpenPnP

Use something like this

Jarosław Karwik

Jan 10, 2025, 1:47:07 AM1/10/25

to OpenPnP

Thanks Mike !

This is actually excellent solution for my machine as the size fits perfectly my machine.

I will buy one extra for unused feeders and feeder attachment bar ( simple 20x20 profile) over it.

These are also available locally, same price as Aliexpress - so I will have them next week

Mike Menci

Jan 10, 2025, 5:12:37 AM1/10/25

to OpenPnP

You might want to get some PCB storage plastic ESD safe parts as well here

bing l

Jan 10, 2025, 5:25:34 AM1/10/25

to OpenPnP

Industrial feeders made of aluminum alloy have strong locking mechanisms to lock the feeders, so they usually come with a spool.

Our feeder is very light and magnetically attached, so separating them is the best choice for us. I can move the spool freely without any impact on the feeder.

I know there will be better designers to solve this problem, but it's definitely not me. I don't have much knowledge of mechanical design.

However, these are secondary issues. Many people who have bought my feeder kit have redesigned their preferred structures. If you look at the discussions in this discussion group over the past few years, you will find that everyone is addressing the accuracy issue of the sprocket feeder. The most famous one should be the rapid feeder, which is currently the mother of many sprocket feeders,He made a lot of effort, even customizing injection molds in Shenzhen.

I don't know why it disappeared now .

Jarosław Karwik

Jan 10, 2025, 8:21:51 AM1/10/25

to OpenPnP

Thanks ,

I have bought these ESD spool containers - I will bee able to use the feeder unmodified.

I think I will only add extra guide in the front to keep them even better .

Current magnetic solution adds 3.8mm to each feeder, but I guess it is still better to leave some space between them.

I originally wanted to add pins to keep the feeders, but well - I like the new solution even if it costs that much space.

I think I will no utilize all the available slots anyway, so no harm to make it easier to setup.

bing l

Jan 10, 2025, 10:05:06 AM1/10/25

to OpenPnP

3.8mm , This spacing is OK, there is no mutual influence between them. It's easy to remove and insert because your fingers only need to grip the top of the feeder. This is the benefit of magnetic attraction.

Jarosław Karwik

Jan 14, 2025, 12:04:16 PM1/14/25

to OpenPnP

Bing,

What kind of magnets do you use ? I could not get these 8x5 ( with holes), took 8x3 however thet feel week.

bing l

Jan 14, 2025, 5:26:44 PM1/14/25

to OpenPnP

8*5mm Countersunk magnet, It can be locked with M3 screws. You must make paired purchases. The magnet for the feeder and slot must be opposite.

Jarosław Karwik

Jan 15, 2025, 2:00:24 AM1/15/25

to OpenPnP

This is really hard to get ( matched pair) - I do not see it even on Aliexpress

Most likely I will have to buy standard ones and glue them with epoxy.

bing l

Jan 15, 2025, 7:06:32 AM1/15/25

to OpenPnP

Your magnet may be too small, the magnetic force is not strong enough. You can try using a large magnet on one side. Using an iron gasket on the other side.

The polarity of the magnet is determined by the seller based on your requirements. They seem to have the specified magnetism only when they are sold.

Reply all

Reply to author

Forward

0 new messages