RepoPNP Auto Feeders, McuOnEclipse & NXP K20 Programming

John deGlavina

These will be able to do exactly what I want. However they're programmed on a platform that I'm not familiar with. The 32bit NXP K20's and K22's. It looks like the software here is slightly more up to date

Does anyone have experience with these feeders and/or controller (tinyK20)?

Duncan Ellison

Jarosław Karwik

Marek T.

John deGlavina

Duncan Ellison

Jaume Olivé

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0fcb5cc2-0b3c-494e-8c5d-acf0e6b7fc0f%40googlegroups.com.

Michael Anton

Jon Raymond

John deGlavina

Duncan Ellison

Duncan Ellison

Duncan Ellison

Also .... Note that the UART comms are at 3.3V so you might want to grab you self some thing similar to this :

Brynn Rogers

Erich Styger

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/9685ed55-cfd6-46ad-b3eb-038579a8e817%40googlegroups.com.

Duncan Ellison

John deGlavina

John deGlavina

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

Duncan Ellison

Roberto Imai

John deGlavina

Duncan Ellison

Duncan Ellison

Duncan Ellison

John deGlavina

Duncan Ellison

John deGlavina

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/2537gsOarBc/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/37cee6d6-efbe-4090-ad0c-9fe54f46f10e%40googlegroups.com.

Duncan Ellison

To unsubscribe from this group and all its topics, send an email to ope...@googlegroups.com.

John deGlavina

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/4cfbfc88-ea97-4801-89aa-2cd1269b7b0f%40googlegroups.com.

John deGlavina

Erich Styger

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/12c3cd14-0996-49e9-a1d5-122b1510eb0c%40googlegroups.com.

John deGlavina

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

Duncan Ellison

Marek T.

Harjit Singh

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/112d5501-1817-409f-9706-7d03c48bf2ef%40googlegroups.com.

Shai

Duncan Ellison

Duncan Ellison

Duncan Ellison

On Thursday, 19 March 2020 23:23:32 UTC, Harjit Singh wrote:

Duncan, how much do the laser cut sproket's cost?

On Thu, Mar 19, 2020 at 3:11 PM Marek T. <marek.tw...@gmail.com> wrote:

--Looks very nice!Really repeatable advancement for both 2 and 4mm?

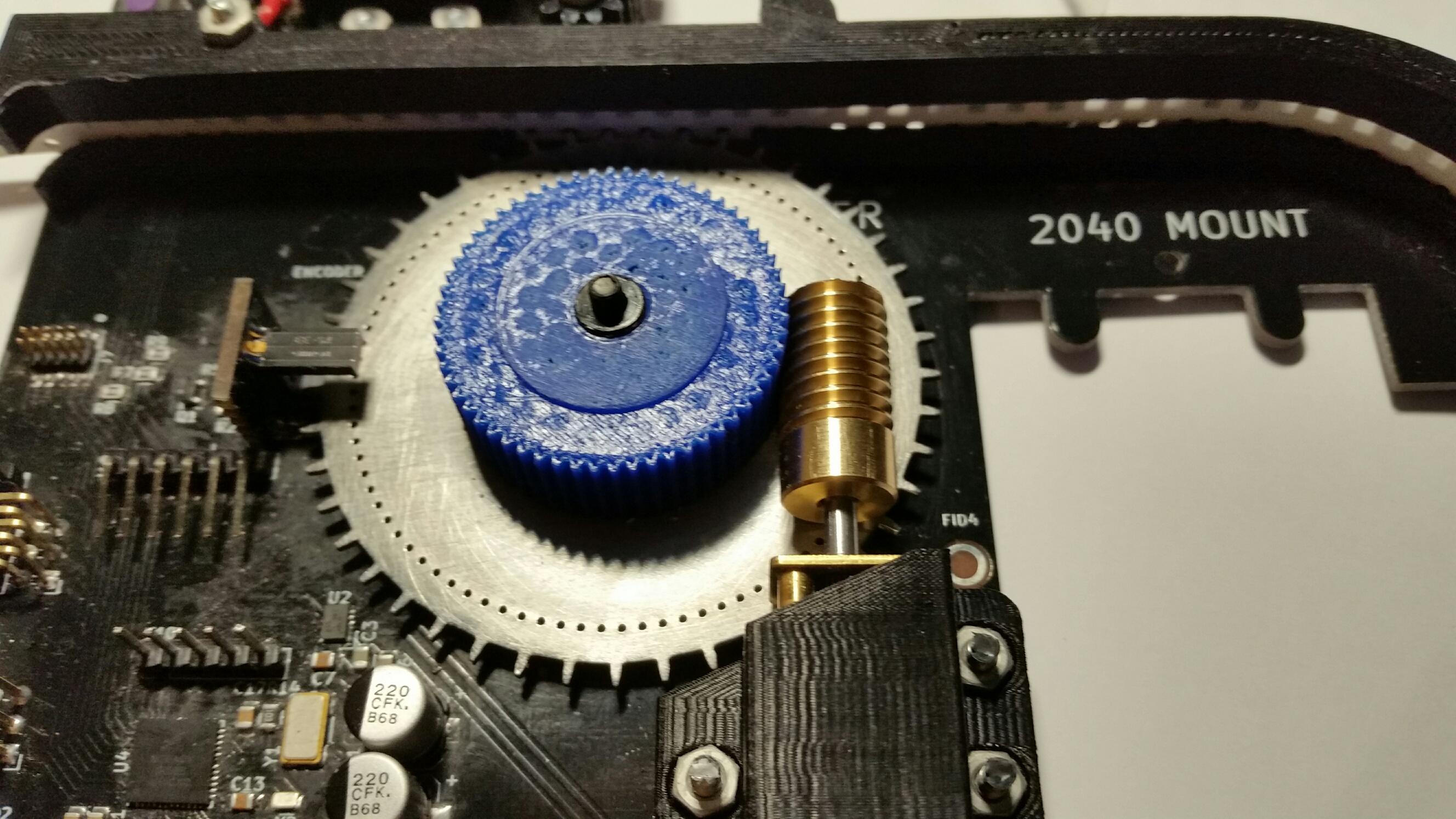

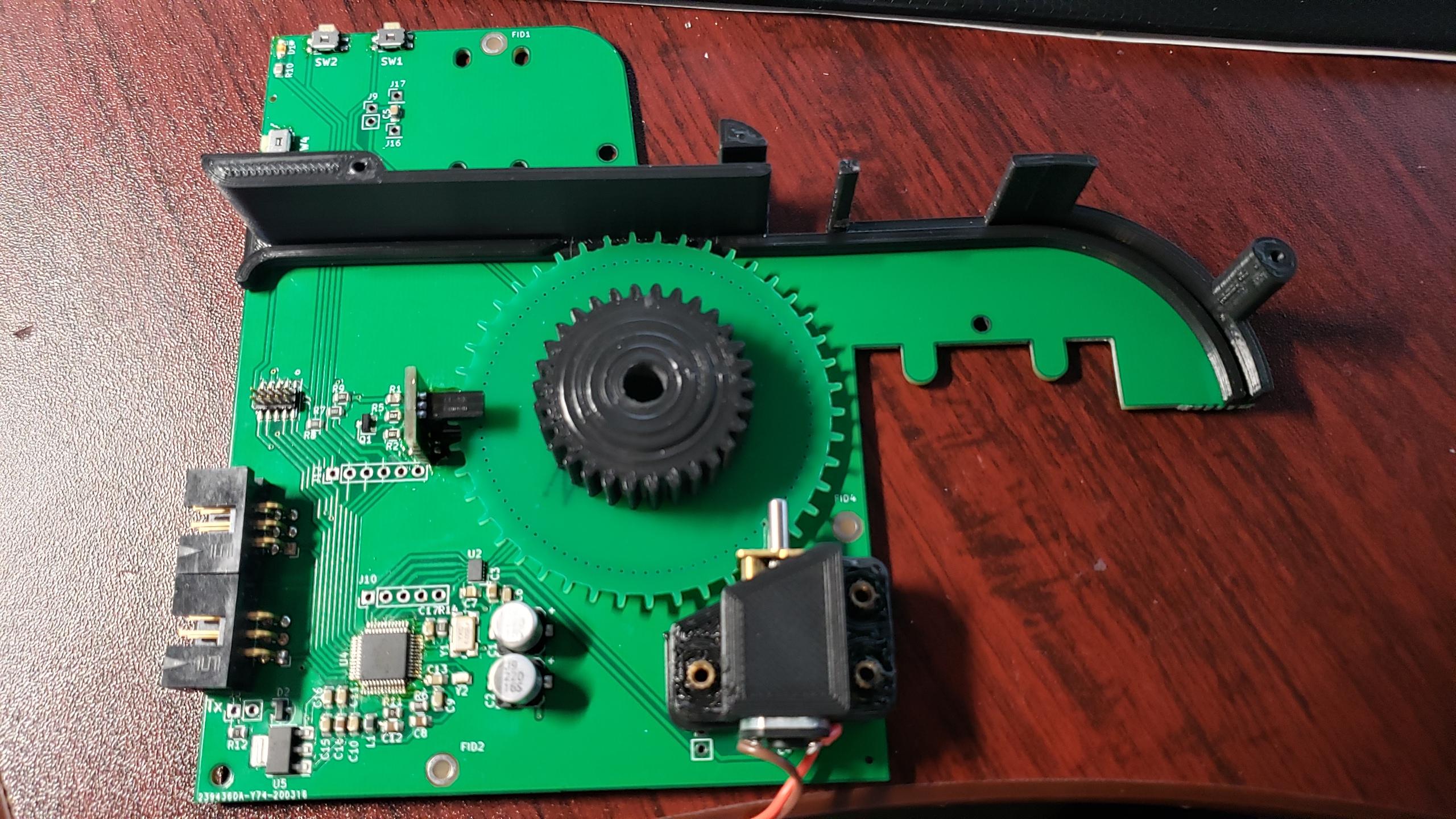

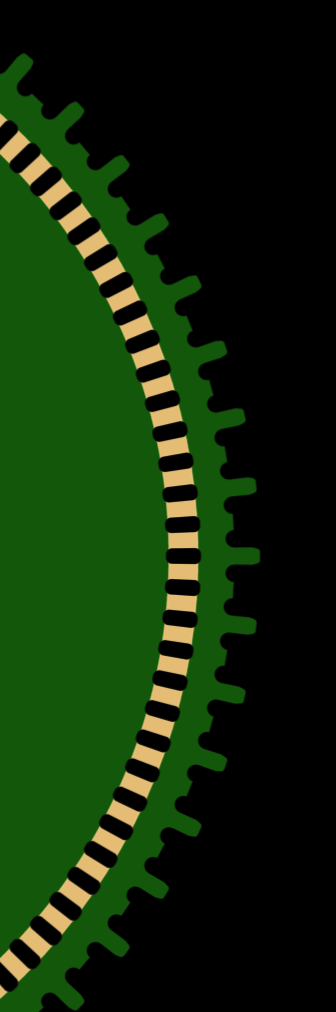

W dniu czwartek, 19 marca 2020 23:09:09 UTC+1 użytkownik Duncan Ellison napisał:Sprockets now sorted :-)I always thought this would be the hardest mechanical issue to resolve and I was right. A combination of laser cut sprocket (polished) and a custom PLA 3D printed spur gear with dogs to engage on the sprocket and some epoxy resin glue.

Seems to feed quite nicely.

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

Marek T.

Duncan Ellison

Marek T.

Marius Liebenberg

On Friday, March 13, 2020 at 3:18:26 AM UTC+2, Jaume Olivé wrote:

Dear all,I use a very simple design, derived from this project:It's formed only by a 3d printed-body, a servo motor (converted to a DC motor driven by a H-bridge), a CAN-based control board, and a hole sensor (micro-switch or light sensor). No gears, no springs. The idea is to move the servo until a hole is detected.El jue., 12 mar. 2020 a las 19:52, Duncan Ellison (<duncan_...@colnewater.com>) escribió:@John deGlavinaHa! So it looks like you are also too far down this rabbit hole to reverse out - LOL.I actually thought this would be a nice test of the machine to build these as there's something nice about the machine assembling part of itself :-) and it's a good test, if it can place these it can place anything. So yes, I'm planning to populate all 40 boards. I've got a proper stencil printer and a conveyor reflow oven, so that part it shouldn't be a challenge once I've got it dialled in.I'm literally finishing up the translation of the documents myself, so if anyone else wants them in English - I doubt that anyone will ever document the design of their feeders like this one (!).Good call on changing the board although I'm 2 out of 2 good placements on the TQFP48s so far. They aren't actually so bad as the leads actually appear at the edge of the package and you can get a small iron in to touch up the solder if needed. And I've already changed both H-Bridges with a hot air pencil as I placed them upside down (ooops).To answer your other questions2) Any reason you 3d printed the sprocket instead of just ordering a 1mm PCB?Just to see if it was possible really and there's lead time involved in PCBs. Also I did just order a couple from OSHPark last night and they work out a bit expensive. Simon Huber just milled them from FR4 on the School's machine, but I don't have that luxury.I'm aiming to actually get these laser cut as a batch with an additional two holes to act as a dog for the spur gear to key into.I bought brass worm gears on Ali to replace the 3D printed ones, but could only get 0.5M pitch, so I'll need to make a custom 3D printed spur gear.Let me know if you go down this route and I'll try to help you out with design files.4) Different gears shouldn't matter, since the controller will stop the motor based on the sprocket position, right?I think so .... but there will be a speed difference and there might be some timeout in the code, I'll need to look into that. But I'm confident enough with the tools now that won't be an issue.6) Yeah, it seems like most of everything is available. Where did you get the N20 motors? I actually have some on hand, but I'm pretty sure they are geared too low at 30rpm. I found new ones that look like they'll work at 100rpm, 6VAli. https://pl.aliexpress.com/item/32770564311.html?spm=a2g0s.9042311.0.0.27425c0fxhcC7m You are going to need 6V / 1:150 according to the documentation, I haven't got mine running yet uner processor control, but just powering them from a benchtop PSU, they seem about right.7) That's the only explanation! It's not much larger than an 0805 cap.If I didn't have the 40 boards and the ICs on hand, I'd seriously think of redesigning this. It's not like you can't find DC motor drivers in more reasonably sized packages although for the first shot at this, I didn't want to have to deal with possible code chages as well.8) Thanks! Luckily I got the right one. I noticed a few small changed between the versionsGood. If I was doing this again (and I might if these work out), I'd re-work the push switches to be vertical, so they are easier to operate from the edge of the board. I'd also sprinkle a few more LEDs around to make sure power supplies etc are good before closing up the board.9) That is what I figured I would need to program themIf / When you get to this point, let me know, there's a bunch of things you need to get in the right order to set up the tool chain. I assume that you'll just want to flash the boards and leave it at that? I wanted to delve into the firmware so that I can adjust things as I go, so I needed a full compiling toolchain.10) I was wondering about substituting that controller. Wouldn't you have to modify the code a lot to work with something 8 bit, Arduino based?No, I'm not planning to use the code, per se, just it's general functionality. I plan to replicate this as an Arduino sketch or Python or something quick and dirty, It only has to listen to USB commands and pass them on. I haven't got into that yet, but I regard that as a minimal riask part of the project.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0fcb5cc2-0b3c-494e-8c5d-acf0e6b7fc0f%40googlegroups.com.

fikret duru

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/60f13d32-e1fd-41c9-b7aa-5f56706a528e%40googlegroups.com.

Duncan Ellison

@John,

Shai

Duncan Ellison

Duncan Ellison

John deGlavina

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/2537gsOarBc/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/b6abfcfb-9a3d-4224-9b2b-5cc83ca71e50%40googlegroups.com.

Duncan Ellison

On Saturday, 21 March 2020 14:04:20 UTC, John deGlavina wrote:

Wow, that's great!Did you have any trouble aligning the optical sensor with the sprocket?

On Fri, Mar 20, 2020, 5:28 PM Duncan Ellison <duncan_...@colnewater.com> wrote:

--@John,Just to encourage you, I've just fed around 300 components without a problem and no loss in registration in the pick up window.The holes in the sprocket seem to work just fine.Duncan

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/2537gsOarBc/unsubscribe.

To unsubscribe from this group and all its topics, send an email to ope...@googlegroups.com.

Simon Gerber

Hello guys

Happy to find an active discussion on pnp feeders!

I am thinking of building an openpnp machine for myself… However I have not found a cheap automatic feeder that meets my requirements. I don’t like the solutions with hobby servos or asymmetrical and different shapes due to motor placement... But this automatic feeder from Scavenger18 seems pretty close to what I’m looking for, even though it is pretty large. ;-)

Most of you seem to have already built what they need. However, would someone be interested in an automatic feeder with the following features?

- Integrated microcontroller (probably stm32 based)

- USB connection for configuration (chip type, quantity, footprint, feeder dimension, etc.)

- Pluggable on a magnetic, power/communication rail

- Automatic slot recognition (with all infos stored on feeder)

- Smaller dimensions

- One motor solution (not 100% sure if this will cause more problems than it solves...)

unfortunately i have to warn you that i have to finish another project at the moment, so i will probably not be able to start with the PNP machine or the feeder before the end of summer.

Best regards

Simon

Am Donnerstag, 12. März 2020 13:47:42 UTC+1 schrieb John deGlavina:

I've been looking for a more robust feeder solution for a while now, and I forgot about this one, which I originally saw on the McuOnEclipse OpenPNP machine.

These will be able to do exactly what I want. However they're programmed on a platform that I'm not familiar with. The 32bit NXP K20's and K22's. It looks like the software here is slightly more up to date

Does anyone have experience with these feeders and/or controller (tinyK20)?

Duncan Ellison

Hello Simon and welcome this rather long thread :-)

Jarosław Karwik

Balázs buglyó

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f64b8e71-06bd-4578-820a-9768485da31a%40googlegroups.com.

Jarosław Karwik

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

John deGlavina

I just got the pcbs a couple days ago, and got some pieces together. The actually did the optical sensor by solding it to the main board first, the the small piece.

I also managed to get the firmware flashed to the feeder. I havent hooked up anything else yet to make sure they actually work though. Is the LED supposed to turn on with power?

Shai

Duncan Ellison

Kent Kim

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0fcb5cc2-0b3c-494e-8c5d-acf0e6b7fc0f%40googlegroups.com.

Michael Anton

John deGlavina

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/2537gsOarBc/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/d2c8524c-3ec7-428e-8392-4f0c092a063c%40googlegroups.com.