Tack welder qualification ASME Sec IX

Chintan

Is there any exclusive clause available in asme sec ix like aws d1.1 for tack welder qualification

Kannayeram Gnanapandithan

Kindly advice how to qualify tack welder for u stamp vessel

Is there any exclusive clause available in asme sec ix like aws d1.1 for tack welder qualification

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/ba93bbc5-f6a5-4e13-8323-ca2a3b9f44ce%40googlegroups.com.

Ramesh

Thanks and Regards

Rameshkannan Devaraj

"What you have learned is a mere handful; What you haven't learned is

the size of the world – Avvaiyar"

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4ePd-csF_2hartJVCNj_Ru_SLw0aezixSwd6U_%2B-Jk8CpQ%40mail.gmail.com.

harenath jha

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4ePd-csF_2hartJVCNj_Ru_SLw0aezixSwd6U_%2B-Jk8CpQ%40mail.gmail.com.

james gerald

Thanks & Regards

J.Gerald Jayakumar

José Juan Jiménez Alejandro

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/5181949.2489950.1583224251609%40mail.yahoo.com.

Ing. José Juan Jiménez Alejandro

Independent Consultant in Parts

and Pressure Equipment

SSI-TPI

Móvil +52 1 812 352 4606

Skype: jjjimeneza

HENNING John

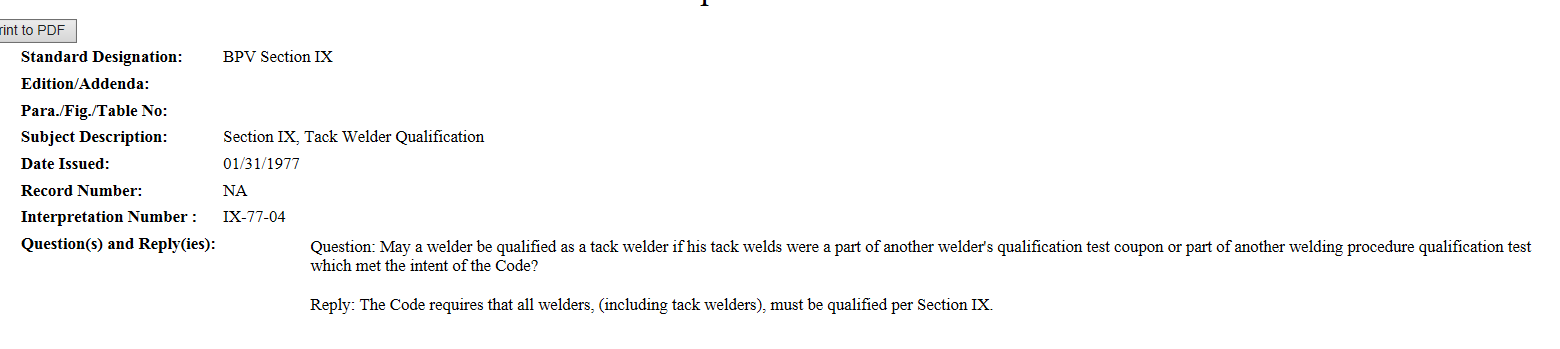

Yes – sort of – Tack welders are qualified by groove weld tests (or for fillet welds only by fillet weld test). Note Section IX, QW-303.1 states:

QW-303.1 Groove Welds — General. Welders and welding operators who pass the required tests for groove

welds in the test positions of Table QW-461.9 shall be qualified for the positions of groove welds, tack welds

in joints to be groove or fillet welded, and fillet welds shown in Table QW-461.9. In addition, welders and welding operators who pass the required tests for groove welds shall also be qualified to make fillet welds in all thicknesses and pipe diameters of any size within the limits of the welding variables of QW-350 or QW-360 and tack welds in joints to be groove or fillet welded as limited in Table QW-461.9, as applicable.

For ASME fabrication, tack welds are addressed by the fabrication (book) sections of the Code thusly. For tack welds to left in place, the welders must be qualified per Section IX, i.e. per QW-303.1 by groove weld testing (or for fillet welds only by fillet weld testing QW-303.2).

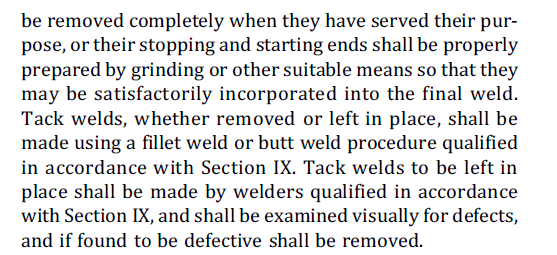

ASME Section I,

PW-31.3 Tack welds used to secure alignment shall either be removed completely when they have served

their purpose or their stopping and starting ends shall be properly prepared by grinding or other suitable means

so that they may be satisfactorily incorporated into the final weld. Tack welds, whether removed or left in place, shall be made using a fillet weld or butt weld procedure qualified in accordance with Section IX. Tack welds to be left in place shall be made by welders qualified in accordance with Section IX and shall be examined visually for defects and, if found to be defective, shall be removed.

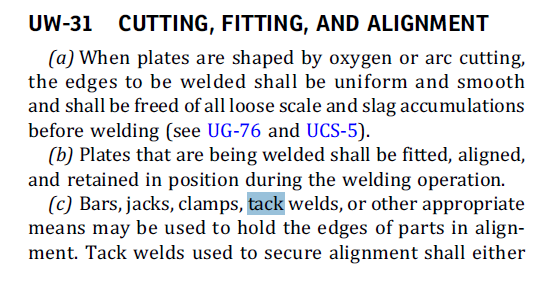

ASME Section VIII, Div. 1,

UW-31

(c) Bars, jacks, clamps, tack welds, or other appropriate means may be used to hold the edges of parts in alignment. Tack welds used to secure alignment shall either be removed completely when they have served their purpose, or their stopping and starting ends shall be properly prepared by grinding or other suitable means so that they may be satisfactorily incorporated into the final weld. Tack welds, whether removed or left in place, shall be made using a fillet weld or butt weld procedure qualified in accordance with Section IX. Tack welds to be left in place shall be made by welders qualified in accordance with Section IX, and shall be examined visually for defects, and if found to be defective shall be removed.

ASME B31.1 Power Piping, 127.4.1

(C) Tack welds permitted to remain in the finished weld shall be made by a qualified welder. Tack welds

made by an unqualified welder shall be removed. Tack welds that remain shall be made with an electrode and

WPS that is the same as or equivalent to the electrode and WPS to be used for the first pass. The stopping and

starting ends shall be prepared by grinding or other means so that they can be satisfactorily incorporated

into the final weld. Tack welds that have cracked shall be removed.

Hope this helps. Code is fun – enjoy!

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4ePd-csF_2hartJVCNj_Ru_SLw0aezixSwd6U_%2B-Jk8CpQ%40mail.gmail.com.

General Data Protection Regulation (GDPR)

We respect and protect your privacy to provide you with our services. Please read https://www.hamon.com/customer-data-protection-notice (Customer) and https://www.hamon.com/seller-data-protection-notice (Supplier) how we process your personal data.

Thank you for your cooperation.

______________________________________________________________________