NACE MR0175

Moin - QC

Hi,

Can somebody please explain the difference between ‘’ Material According to NACE MR0175’’ & ‘’ Hardness according NACE MR0175’’

I am purchasing some material from mill, but they said that they can meet the hardness requirement only, but cannot write ‘’ Material accordance to NACE MR0175’’ on material test certificate.

Material is seamless and welded pipe.

Thanks & Regards

SM

______________________________________________________

CONFIDENTIALITY NOTICE: This electronic mail transmission may contain information that is confidential, privileged, proprietary, or otherwise legally exempt from disclosure and is intended only for the use of the recipient named above. We do not waive confidentiality in the event this mail was transmitted wrongly. If you have received this communication in error, and are not the intended recipient, you are hereby notified that you are prohibited from reading, printing, copying, or disseminating this message, any part of it, or any of the attachments it may carry. If you have received this message in error, please destroy all electronic and paper copies and notify the sender immediately of the inadvertent transmission. We would like to advise you that we would not waive any of our privilege for taking action against you in the event the confidentiality of this message has been compromised. Thank you for your cooperation

________________

This email has been scanned by the MessageLabs Email Security System.

For more information please visit http://www.messagelabs.com/email

______________________________________________________________________

Philip, Taiye (Lagos)

Hi Moin,

Material According to NACE MR0175, implies that, the material will meet NACE MR0175, standard requirement as in Mechanical properties, Tensile strength, impact values, Hardness values, corrosion resistance values, etc and material chemistry.

While Hardness according to NACE means, the material will meet only Hardness requirement of NACE MR0175 only

Hope these clears your doubts

Regards

Philip Taiye

Principal QA/QC Welding Engineer

(MIPs Quality Control)

DeltaAfrik Engineering Limited

2nd Floor, City Express Bank Building

Plot 1637 Adetokunbo Ademola Street

Victoria Island, Lagos Nigeria

Phone: +234-1-461-8508, +2341-461-6137 ext. 1257

Cell:

+234-(0)-803-803-1396

Fax: +234-1-262-2418

e-mail: taiye....@worleyparsons.com

*** WORLEYPARSONS GROUP NOTICE *** "This email is confidential. If you are not the intended recipient, you must not disclose or use the information contained in it. If you have received this email in error, please notify us immediately by return email and delete the email and any attachments. Any personal views or opinions expressed by the writer may not necessarily reflect the views or opinions of any company in the WorleyParsons Group of Companies."

To post to this group, send email to material...@googlegroups.com

To unsubscribe from this group, send email to materials-weld...@googlegroups.com

For more options, visit this group's bolg at http://materials-welding.blogspot.com/

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

Ramprasad Chari

--

Sivashankar Nagamanickamsundaramoorthy

From: Ramprasad Chari <rampras...@gmail.com>

To: material...@googlegroups.com

Sent: Thu, September 23, 2010 1:48:58 PM

Subject: Re: [MW:7171] NACE MR0175

Ramprasad Chari

pgoswami

Hello Syed,

If you look at the end of MR-0175,Part-2, 2003-version, the list of accepted materials for sour service are listed. There are specifications for a few seamless pipes also.

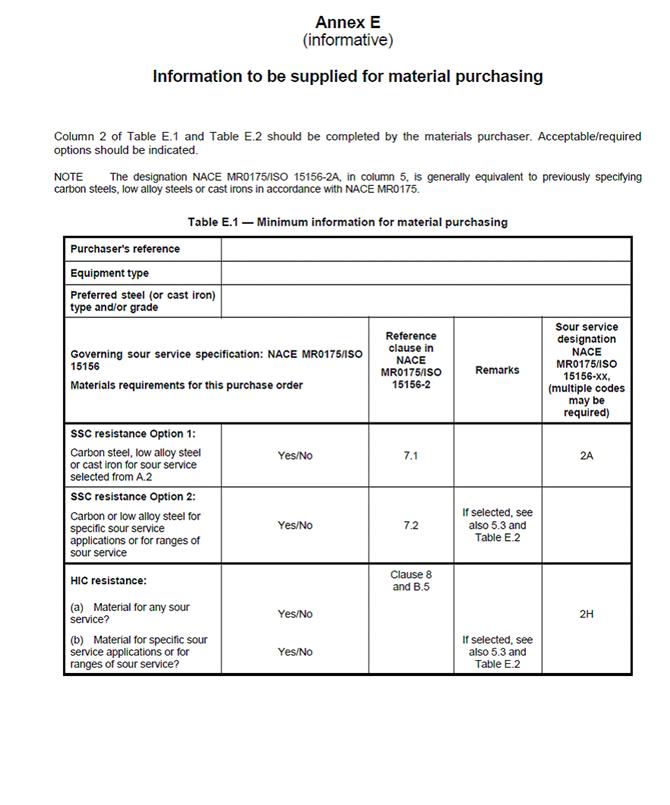

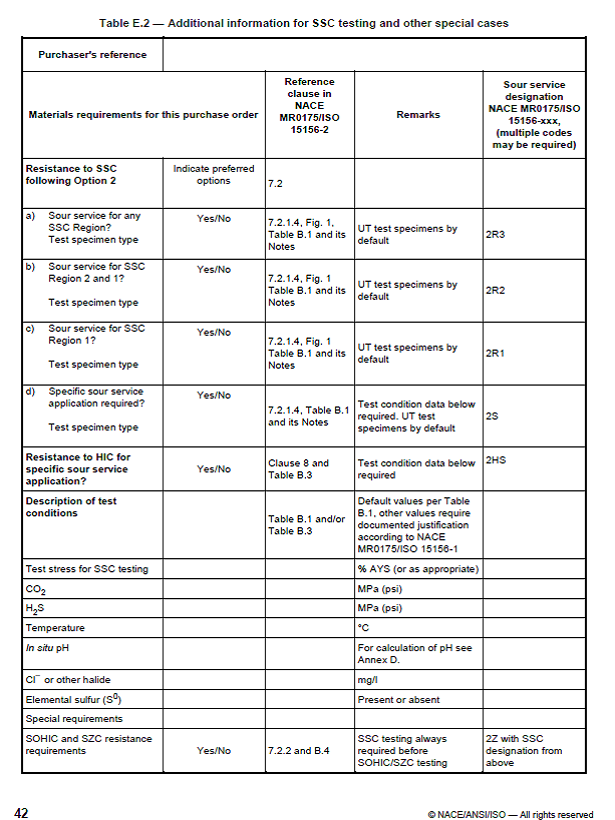

Coming back to your query: Material According to NACE MR0175’’—Implies that all the requirements of MR-0175 have been met by the manufacturer and the material is fit for sour service. If one goes through in details, MR-0175 provides the guidelines of what tests to be asked for sour services. See the sample below-ANNEX-E.

The second option specified by your manufacturer:- Hardness according NACE MR0175—does not make any real sense, this means they would conform to 22 HRC(248VHN) hardness requirements as required by the spec at the point of supply.

What’s the specification of Pipes to be purchased??. If it’s covered in MR-0175then the supplier has to stick a manufacturing and Q.A program meeting NACE MR-0175.If it’s newer materials, it requires qualification to MR-0175.

It would be good if you read the MR-0175 and specifically ask for the applicable clauses, for your application, then it will put the mills on the hook.

Thanks.

Pradip Goswami,P.Eng.

Welding & Metallurgical Engineer/Specialist

Email-pgoswami@sympatico.ca,

5 Purchasing information

5.1 The preparation of material purchasing specifications might require co-operation and exchange of data between the equipment user, the equipment supplier and the material manufacturer to ensure that the material purchased complies with NACE MR0175/ISO 15156-1 and this part of NACE MR0175/ISO 15156.

5.2 The following information shall be provided:

· preferred material types and/or grades (if known);

· equipment type (if known);

· reference to this part of NACE MR0175/ISO 15156;

· acceptable bases for selection of materials for SSC resistance (see Clause 7);

· requirements for HIC resistance (see Clause 8).

5.3 The equipment user and the equipment supplier/material manufacturer may agree that carbon or low alloy steels other than those described and/or listed in Annex A may be selected subject to suitable qualification testing in accordance with Annex B and NACE MR0175/ISO 15156-1. The qualification requirements may be extended to

include resistance to SOHIC and SZC.

If the purchaser intends to make use of such agreements, extensions and qualifications, the appropriate additional information shall be clearly indicated in the materials purchasing specification. This information may include

· requirements for SSC testing (see 7.1, 7.2),

· service conditions for specific sour service application, and

· other special requirements.

5.4 Annex C describes how to calculate the H2S partial pressure and Annex D gives guidance on how to determine the pH-value of a fluid.

5.5 The information required for material purchasing shall be entered on suitable data sheets. Suggested formats are given in Annex E.

hemant solanki

On Tue, 28 Sep 2010 01:12:39 +0530 wrote

>

Hello Syed,

If you look at the end of MR-0175,Part-2,2003-version, the list of accepted materials for sour service are listed. Thereare specifications for a few seamless pipes also.

Coming back to your query: MaterialAccording to NACE MR0175’’—Implies that all the requirementsof MR-0175 have been met by the manufacturer and the material is fit for sourservice. If one goes through in details, MR-0175 provides the guidelines ofwhat tests to be asked for sour services. See the sample below-ANNEX-E.

The second option specifiedby your manufacturer:- Hardness according NACE MR0175—does not make anyreal sense, this means they would conform to 22 HRC(248VHN) hardnessrequirements as required by the spec at the point of supply.

What’s thespecification of Pipes to be purchased??. If it’s covered in MR-0175thenthe supplier has to stick a manufacturing and Q.A program meeting NACE MR-0175.Ifit’s newer materials, it requires qualification to MR-0175.

It would be good ifyou read the MR-0175 and specifically ask for the applicable clauses, for yourapplication, then it will put the mills on the hook.

Thanks.

Pradip Goswami,P.Eng.

Welding & MetallurgicalEngineer/Specialist

Email-pgoswami@sympatico.ca,

5 Purchasinginformation

5.1 Thepreparation of material purchasing specifications might require co-operationand exchange of data between the equipment user, the equipment supplier and thematerial manufacturer to ensure that the material purchased complies with NACEMR0175/ISO 15156-1 and this part of NACE MR0175/ISO 15156.

5.2 Thefollowing information shall be provided:

·preferred materialtypes and/or grades (if known);

·equipment type (if known);

·reference to thispart of NACE MR0175/ISO 15156;

·acceptable basesfor selection of materials for SSC resistance (see Clause 7);

·requirements forHIC resistance (see Clause 8).

5.3 Theequipment user and the equipment supplier/material manufacturer may agree thatcarbon or low alloy steels other than those described and/or listed in Annex Amay be selected subject to suitable qualification testing in accordance withAnnex B and NACE MR0175/ISO 15156-1. The qualification requirements may beextended to

include resistance to SOHIC and SZC.

If the purchaser intends to make useof such agreements, extensions and qualifications, the appropriate additionalinformation shall be clearly indicated in the materials purchasingspecification. This information may include

·requirements for SSC testing (see7.1, 7.2),

·service conditions for specific sourservice application, and

·other special requirements.

5.4 Annex Cdescribes how to calculate the H2S partial pressureand Annex D gives guidance on how to determine the pH-value of a fluid.

5.5 Theinformation required for material purchasing shall be entered on suitable datasheets. Suggestedformats are given in Annex E.

From: material...@googlegroups.com[mailto:material...@googlegroups.com] OnBehalf Of Ramprasad Chari

>Sent: Monday, September 27, 201012:00 AM

>To:material...@googlegroups.com

>Subject: Re: [MW:7209] NACE MR0175

If the mill supplying a seamless pipe is pre-qualified to supply NACEpipes,you need not carry out SSC test.Mill shall indicate NACE conformance ontheir TC including Hardness values.Everything depends on the customer'srequirements.Many a times it is seen that Gas/liquid is not 'sour' with partialpressure of H2S so low that NACE does not apply but still customerinsists for NACE conformance.As I have indicated in my previous mail,if yourcustomer permits you,you can carry out SSC test on a pipe as per TM0177standard and conform Nace compliance through lab test reports includinghardness.You can go one step further and get micro test done as per ASTM E-45method D and confirm absence of 'elongated MnS inclusions'.If the mill confirmsNACR compliance,you do not have to carry out any other tests unless yourcustomer has asked you additional specific tests.

Regards

Aarpee

On Sat, Sep 25, 2010 at 6:03 PM, Sivashankar Nagamanickamsundaramoorthy<poovai...@yahoo.com>wrote:

Hi Mr.Aarpee,

Wheather SSC test is required for the Seamless pipes for theconfirmationto the NACE requirements ?.

Regards

Siva

From: Ramprasad Chari<rampras...@gmail.com>

>To: material...@googlegroups.com

>Sent: Thu, September 23, 20101:48:58 PM

>Subject: Re: [MW:7171] NACE MR0175

Conformance to NACE MR0175 certifies material to be used for 'sour' gasapplications which implies that material is resistant to various crackingmechanisms assoiated with H2S presence in a wet gas/liquid.If the mill ispre-qualified carrying out tests as per TM0177 standard(for SSC) and TM0284(forHIC) then mill can certify conformance.Alternatively,if the client permits youcan carry out the test per heat per size to confirm conformance to NACEMR0175.For seamless pipe HIC may not be required but for welded pipe,you mayhave to carry out HIC as well as SSC test.Hardness is one of the criterion ofmax 22HRC.If hardness is not achieved in 'as 'condition in weld and HAZ,you mayhave to carry out PWHT to ensure that hardness is below 22 HRC.

Regards

Aarpee

On Thu, Sep 23, 2010 at 10:53 AM, Moin - QC <Syed...@gerabgroup.com>wrote:

Hi,

Can somebody please explain thedifference between ‘’ Material According toNACE MR0175’’ & ‘’Hardness according NACE MR0175’’

I am purchasing some material from mill, butthey said that theycan meet the hardness requirement only,but cannot write ‘’Material accordance toNACE MR0175’’ on material test certificate.

Material is seamless and welded pipe.

Thanks & Regards

>SM

>______________________________________________________

>CONFIDENTIALITY NOTICE: This electronic mail transmission may containinformation that is confidential, privileged, proprietary, or otherwise legallyexempt from disclosure and is intended only for the use of the recipient namedabove. We do not waive confidentiality in the event this mail was transmittedwrongly. If you have received this communication in error, and are not theintended recipient, you are hereby notified that you are prohibited fromreading, printing, copying, or disseminating this message, any part of it, orany of the attachments it may carry. If you have received this message inerror, please destroy all electronic and paper copies and notify the senderimmediately of the inadvertent transmission. We would like to advise you thatwe would not waive any of our privilege for taking action against you in theevent the confidentiality of this message has been compromised. Thank you foryour cooperation

>________________

>This email has been scanned by the MessageLabs Email Security System.

>For more information please visit http://www.messagelabs.com/email

>______________________________________________________________________

--

>To post to this group, send email to material...@googlegroups.com

>To unsubscribe from this group, send email to materials-weld...@googlegroups.com

>For more options, visit this group's bolg at http://materials-welding.blogspot.com/

>The views expressed/exchnaged in this group are members personel views andmeant for educational purposes only, Users must take their own decisions w.r.t.applicable code/standard/contract documents.

--

>To post to this group, send email to material...@googlegroups.com

>To unsubscribe from this group, send email to materials-weld...@googlegroups.com

>For more options, visit this group's bolg at http://materials-welding.blogspot.com/

>The views expressed/exchnaged in this group are members personel views andmeant for educational purposes only, Users must take their own decisions w.r.t.applicable code/standard/contract documents.

--

>To post to this group, send email to material...@googlegroups.com

>To unsubscribe from this group, send email to materials-weld...@googlegroups.com

>For more options, visit this group's bolg at http://materials-welding.blogspot.com/

>The views expressed/exchnaged in this group are members personel views andmeant for educational purposes only, Users must take their own decisions w.r.t.applicable code/standard/contract documents.

--

>To post to this group, send email to material...@googlegroups.com

>To unsubscribe from this group, send email tomaterials-wel...@googlegroups.com

>For more options, visit this group's bolg at http://materials-welding.blogspot.com/

>The views expressed/exchnaged in this group are members personel views andmeant for educational purposes only, Users must take their own decisions w.r.t.applicable code/standard/contract documents.

>To post to this group, send email to material...@googlegroups.com

>To unsubscribe from this group, send email to materials-weld...@googlegroups.com

>For more options, visit this group's bolg at http://materials-welding.blogspot.com/

>The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

>

Moin - QC

Dear Pradeep,

Thanks for information,

Material we intent to purchase is API 5L line pipes and A106 pipes for SOUR service, these product specification are listed in NACE MR0175.

Manufacturer has confirmed that Value of nickel content on product analysis will be less than 1%, Sulphur will be 0.004% Maximum, CE value will be less than 0.38 and material will be supplied in ‘’ Normalized formed’’ condition.

But still they deny to declare the compliance with NACE MR0175/ISO 15156, they say that ‘’ Only hardness according to NACE MR0175/ISO15156’’ will be reported on mill test certificate.

I was trying to find out the restriction NACE MR0175 set forth for API 5L and A106 material, all I could find was restriction on nickel, sulphur and delivery condition(i.e. hot forming or Normalizing etc) which have been complied with by the manufacturer, but still they deny to declare the compliance with NACE MR0175 which left me confused.

Could you please put some light on this issue.

REGARDS,

SYED MOIN

______________________________________________________________________

This email has been scanned by the MessageLabs Email Security System.

For more information please visit http://www.messagelabs.com/email

______________________________________________________________________

--

To post to this group, send email to material...@googlegroups.com

To unsubscribe from this group, send email to materials-weld...@googlegroups.com

For more options, visit this group's bolg at http://materials-welding.blogspot.com/

The views expressed/exchnaged in this group are members personel views and

meant for educational purposes only, Users must take their own decisions w.r.t.

applicable code/standard/contract documents.

DOKKU AJAY

Mobile: +966 500071054

From: Moin - QC <Syed...@gerabgroup.com>

To: material...@googlegroups.com

Sent: Tue, September 28, 2010 4:30:48 PM

Subject: RE: [MW:7253] NACE MR0175

DOKKU AJAY

Resent, please ignore earlier e-mail as it was incomplete.

From: Moin - QC <Syed...@gerabgroup.com>

To: material...@googlegroups.com

Sent: Tue, September 28, 2010 4:30:48 PM

Subject: RE: [MW:7253] NACE MR0175

pgoswami

Hello Syed,

Materials for sour service should comply with the requirements of MR-0175.My understanding is that what NACE calls for that both manufacturer/supplier and the purchaser should be in compliance.

Purchaser or end users compliance is to specify the details as asked in Annex-E(see below).

Supplier/Manufacturer’s responsibility : Although there is no direct reference to supplier/fabricator responsibility in MR0175/ISO15156 the following sections imply responsibility.

-

cooperate and communicate in an exchange of information between the end users and materials suppliers/manufacturers concerning required or suitable service conditions. ( Clause 5. to 5.5-Purchasing requirements)

-

ensure the material purchased meets the end users requirements and the requirements of the standard. (Clause 7.0 and others, especially hardness and all required manufacturing requirements)

Both API-5L and ASTM A-106 are NACE accepted materials, which means they had undergone various qualification and acceptance steps, plus the service history in similar environment to be accepted. Hence they are very known material in sour environment. So material may not be a bothersome issue.

However at the first place if your P.O and other related contract documents calls for conformance to MR-0175, then the supplier has to conform to this and specify the same in the paperwork..

As you stated below: -But still they deny to declare the compliance with NACE MR0175/ISO 15156, they say that ‘’ Only hardness according to NACE MR0175/ISO15156’’ will be reported on mill test certificate. This does not sound convincing, looks some wishy washy stuff???

MR-0175 calls for:-Materials complying with this part of NACE MR0175/ISO 15156 shall be made traceable, preferably by marking, before delivery. Suitable labeling or documentation is also acceptable.

May be it's good to ask the supplier why this deviation? before accepting the material.

I think I've my best to clarify your doubt. Further you may use the attached guide for your future references on MR-0175.This document is an useful guidebook but without any liability.

Thanks.

THIS MESSAGE IS ONLY INTENDED FOR THE USE OF THE INTENDED RECIPIENT(S) AND MAY CONTAIN INFORMATION THAT IS PRIVILEGED, PROPRIETARY AND/OR CONFIDENTIAL. If you are not the intended recipient, you are hereby notified that any review, retransmission, dissemination, distribution, copying, conversion to hard copy or other use of this communication is strictly prohibited. If you are not the intended recipient and have received this message in error, please notify me by return e-mail and delete this message from your system. Ontario Power Generation Inc.

DOKKU AJAY

"It is the Equipment user's responsibility to ensure that any material specified for use in their equipment will be satisfactory in the service condition.

From: pgoswami <pgos...@quickclic.net>

To: material...@googlegroups.com

Sent: Thu, September 30, 2010 4:45:19 AM

Subject: [MW:7275] MW:7269] NACE MR0175

,