Printing on cold glass with PLA

Infinityplusplus

Enginwiz

Does anybody know where to buy it on the old continent?

However - last week I saw a bottle of Garnier Fructis Extra (Nuclear?) Hold hairspray and

put it in my shopping cart. Is anybody using it successfully to print PLA on a cold glass plate?

lassikin

AKron

cool is when it cools down you can hear the part cracking off the

glass, and when it's cooled the piece lifts off as if it was just set

on there with no adhesion. The more I use PLA the more I like it,

although being able to use other materials is pretty cool, too. I've

been printing in ABS this weekend, and now that the Kapton tape is all

messed up I think I'll flip the plate, and go back to PLA for awhile.

-Andy

Infinityplusplus

abellasr

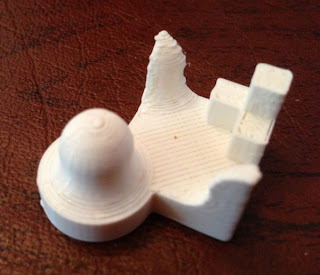

Yesterday my son said he wanted to print in clear PLA but forgot it at his house. I remembered I had a sample roll we picked up at Maker Fair 2011 in the garage. When I retrieved it, I discovered the bag had a big rip in it. We figured we would try it anyway (let's see, that's 1.5 years in unheated garage air) and it printed three different objects just fine. Go figure?

Here are some pics of a couple (of the ten or so) things we printed yesterday.

Eighty

I'm stunned by the clarity of the clear prints you posted. May I ask what settings you used? Mine usually turn out with lots of air pockets, and therefore not nearly as glassy.

Enginwiz

Is the surface of your glass plate just shiny flat glass or is it etched or sandblasted?

Thank you for opening up this thread. Printing PLA directly on a cold glass plate

coated with inexpensive hair spray sounds very promising.

I have to solve a levelling issue with my glass plate first. Then I will try

out the Garnier fructis spray directly on the glass plate.

Infinityplusplus

abellasr

On Sunday, March 31, 2013 3:28:38 PM UTC-4, Eighty wrote:

Abellasr,

I'm stunned by the clarity of the clear prints you posted. May I ask what settings you used? Mine usually turn out with lots of air pockets, and therefore not nearly as glassy.

Printing at 220 degrees. .4mm nozzle. Zero infill. no shells, .22 layer height

Enginwiz

Infinityplusplus

I have now done several prints straight to the cold glass with the Aquanet and I am very happy with the results. I have done a few bigger prints and they did not get knocked off the platform, and it held well enough for me to print the fragile http://www.thingiverse.com/thing:64941, and still just popped off the plate without breaking. One on the owls I actually had to tap on the base a bit to get it free, it was stuck pretty good and so flat I could not get anything under it.

Enginwiz

I finally found "Aqua Net Professional Hair Spray Extra Super Hold 3 Unscented" on www.amazon.de and ordered a bottle.

xenogea...@gmail.com

Enginwiz

Infinityplusplus

Steven Vaccaro

Enginwiz

Infinityplusplus

On Saturday, April 6, 2013 12:34:17 PM UTC-7, Arik Czerniak wrote:

guys, noob question

what is it about the hairspray that makes this happen? which component/chemical? why is it only these 2 specific brands?

Steven Vaccaro

thanks!!

PhGeis

Could you pls post the full German selling name of the Garnier stuff.

Live close to Frankfurt so that would be easiest for me. Gone try even on heated BP and with ABS as soon as my 2x arrives!

Enginwiz

John Armbruster

On Sunday, March 31, 2013 3:28:38 PM UTC-4, Eighty wrote: