5th Smart Extruder Thermal Analysis and Clogging

453 views

Skip to first unread message

joshu...@ieee.org

Dec 16, 2014, 12:21:19 AM12/16/14

to makerbo...@googlegroups.com

I am a 5th Gen user and like many of you, I had my shares of clogging with the smart extruder. I recently notice a pattern where:

- Clogging occurs much more frequently in geometries requiring many retractions

- Clogging occurs predominantly in between the heat sink fins and the heating block within the Teflon tube. I've made this observation while clearing out the plastics with acetone by disassembling the extruder.

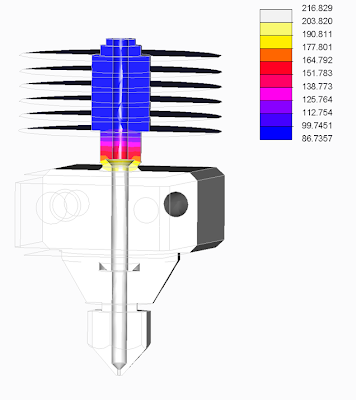

Based on the images from Barry Chuck's photo album where he compared the temperature zones between the 5th gen versus the MK7/8, I asked myself what is the temperature gradient from the heating block all the way to the top of the heat sink. So I decided to do a simple thermal analysis with the problem setup as shown in the image below:

I don't have access to a fluid dynamic simulator, so I have to guess what the convection coefficient is for the heat sink fins (but even if I do, it is dependent on the air flow of the fan which I have no clue what it is). I ran three simulations with zero air flow (as a baseline), 10W/m^2K, and 20W/m^2K applied on the heat sink fins. The results are shown below where the unit is in degrees Celsius:

Zero Air Flow

10W/m^2K

20W/m^2K

As you can see, there is always a section in between the fins and the heating block where the filament could melt (around 170C to 190C). Assuming that 20W/m^2K is a reasonable estimate (which allows us to reach around 80C as shown in Barry's photo), then during retraction a portion of the molten plastic will get pulled up to the Teflon tube and then solidifies. So here are the questions I have for the community:

- Suppose that the filament solidifies within the Teflon tube, shouldn't the extruder still be able to extrude since the melted filament still conforms to the inner surface of the Teflon tube? Or is the inability to extrude caused by the friction developed in between the Teflon and the solidified filament (the reason I ask is that I thought Teflon is supposed to be anti-slip)?

- My background is actually in antenna and I only have cursory knowledge in fluid dynamics. If anyone in the community is an expert in thermal simulations, please speak up if my assumptions are incorrect.

I spent a fortune on this printer so I am eager to improve, if not solve the clogging situation within the confine of the existing mechanics.

Mikey Canup

Dec 17, 2014, 9:10:42 AM12/17/14

to makerbo...@googlegroups.com

What you posted is way above my pay grade but I can say this. We are on our 3rd set of extruders. We have qty 2 fifth gen printers. And with the latest we received this week and the very latest firmware we noticed a marked improvement. I am cautiously optimistic but as I missed the window to return these I am in the same boat as you.

tramalot

Dec 18, 2014, 6:14:23 AM12/18/14

to makerbo...@googlegroups.com

I do not own a 5th, BUT every time I have called mb they did me fair, just go loaded

tramalot

Dec 18, 2014, 6:20:30 AM12/18/14

to makerbo...@googlegroups.com

tramalot

Dec 18, 2014, 6:40:36 AM12/18/14

to makerbo...@googlegroups.com

and they could shrink the power supply, and theoretically shrink the size of the heaters. boxes of rocks, coal

Reply all

Reply to author

Forward

0 new messages