MDF in the laser cutter

25 views

Skip to first unread message

AaronCrook

Jun 1, 2023, 5:25:58 AM6/1/23

to Leeds Hack Space

Hello all.

I have a peg board project I would like to complete that would involve laser cutting some 6mm MDF.

I would like some clarification on the acceptable grade of MDF allowed.

Looking around there are 3 grades, there is no such thing as "Laser MDF".

- There is a "lower" formaldehyde emissions grade ,'E1'. Which is marketed as "Laser grade". Example: 6mm Laser Compatible Medite MDF, 600mm x 400mm sheet – Kitronik Ltd

- There is standard grade MDF

- There is moisture resistant (MR) MDF.

I happen to have in my stock, a nice half sheet of 6mm MR MDF which would make a nice big single peg board, and would mean not spending on additional material.

But if this grade not advised, then is standard grade MDF OK? Or is E1 grade, the only grade allowed.

Thanks Aaron.

AaronCrook

Jun 2, 2023, 3:07:51 AM6/2/23

to Leeds Hack Space

I've done some further research on the the formaldehyde content of MDF and MR MDF.

The

formaldehyde really depends on the manufacturer of the board.

Happily the MR MDF I have is from my local timber merchant rather than a Wickes or B&Q so know the manufacturer. It Medite MR MDF.

Its "E1" and CARB2 (Another safety standard around use of formaldehyde) compliant.

So I think I'm Ok to try a cut on the laser and see how it performs.

Thank Aaron

Mark Wainwright

Jun 2, 2023, 3:59:05 AM6/2/23

to leeds-ha...@googlegroups.com

Morning Aaron,

Sorry only just picked this up

The formaldehyde content is important when it comes to your and our health in the Hackspace but what you will find is the majority of any sheet material purchased in the UK and Europe is either E1 or E2.

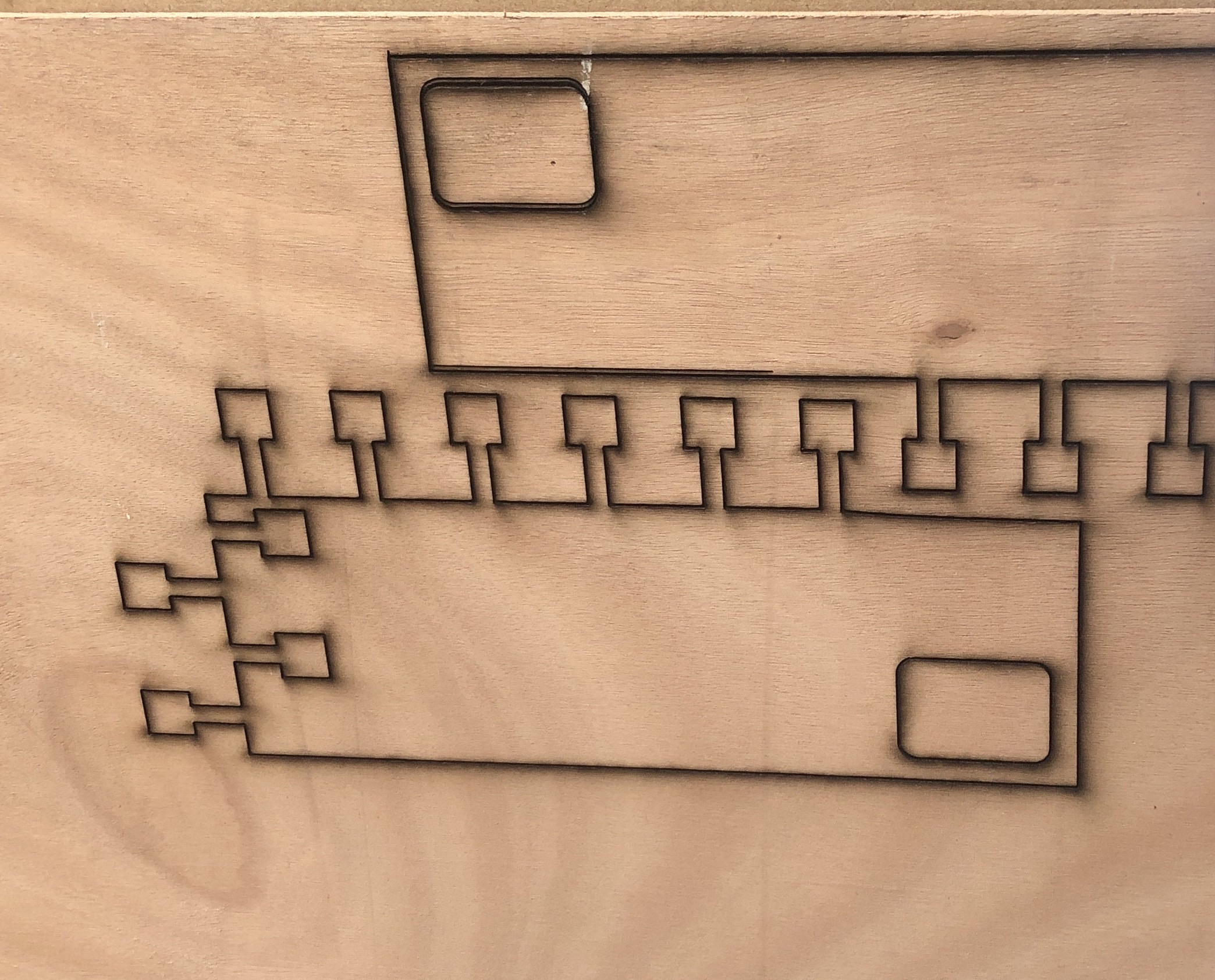

The main factor when it comes to the health of the laser is the type of glue used. Glues used to make a sheet material moisture resistant (MR) or for exterior use do not burn nicely creating smoke and soot as can be attested to by one of our other members who bought what he had been told was laserable ply only to find it filled the laser with black smoke (pic below).

The formaldehyde content is important when it comes to your and our health in the Hackspace but what you will find is the majority of any sheet material purchased in the UK and Europe is either E1 or E2.

The main factor when it comes to the health of the laser is the type of glue used. Glues used to make a sheet material moisture resistant (MR) or for exterior use do not burn nicely creating smoke and soot as can be attested to by one of our other members who bought what he had been told was laserable ply only to find it filled the laser with black smoke (pic below).

It is preferred that only material that is classed as interior use which uses interior class 1 glue is used in the laser as this burns better and reduces the amount of maintenance the laser requires. Bonding Class 2 (humid conditions) and Class 3 (exterior use ) are harder to burn and burn darker. The pic shows an attempted cut which not only wasn't successful but filled the laser chamber with smoke, which in turn made it harder for the beam to penetrate and required the lens to be cleaned afterwards.

also be careful when asking for class 1 sheet material as this is sometimes confused with class 1 fire rating which is the highest rating.

So unfortunately it looks like you shouldn't use your sheet of MR, however I'd be happy to do a test cut on it when we are both around so that we can prove it either way and clean the lens etc if necessary.

also be careful when asking for class 1 sheet material as this is sometimes confused with class 1 fire rating which is the highest rating.

So unfortunately it looks like you shouldn't use your sheet of MR, however I'd be happy to do a test cut on it when we are both around so that we can prove it either way and clean the lens etc if necessary.

--

You received this message because you are subscribed to the Google Groups "Leeds Hack Space" group.

To unsubscribe from this group and stop receiving emails from it, send an email to leeds-hack-spa...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/leeds-hack-space/3bda7991-e391-4f97-b6a1-181ce31daedcn%40googlegroups.com.

AaronCrook

Jun 2, 2023, 5:44:13 AM6/2/23

to Leeds Hack Space

Thanks for the the information Mark. I was initially worried about the make up of the glue as a blocker to my idea. Glad that risk is acceptable.

I agree with you the next problem is whether the MDF cuts cleanly and does not compromise the laser. I do I have some small offcuts we can test with.

I don't need super clean cuts. There is just will a lot of them, it is a peg board after all, so the laser is the suitable tool for automating it. But if the smoke issued form the cuts compromises the lenses then it is not viable.

Regards Aaron

Reply all

Reply to author

Forward

0 new messages