both steppers stall at normal speeds

29 views

Skip to first unread message

jet townsend

Mar 18, 2020, 5:22:07 PM3/18/20

to lasersaur

Going to go dig through the archives after I bounce this off the

collective mind...

Did a bunch of cutting yesterday, no problems.

Went to do a cut today and the X and Y motors stall at anything other

than the slowest speeds. Return-to-home works, 10mm jogs usually work,

50mm jogs often fail. If I assist the motor with a little force on the

belt everything is fine.

Because both motors fail, I'm going to rule out Geckos and motors and

predict that the PSU going slightly under power.

Any other ideas?

--

Jet Townsend, IDSA

design <http://www.allartburns.org>

hacking <http://www.flatline.net>

consulting <http://www.functionalprototype.com>

collective mind...

Did a bunch of cutting yesterday, no problems.

Went to do a cut today and the X and Y motors stall at anything other

than the slowest speeds. Return-to-home works, 10mm jogs usually work,

50mm jogs often fail. If I assist the motor with a little force on the

belt everything is fine.

Because both motors fail, I'm going to rule out Geckos and motors and

predict that the PSU going slightly under power.

Any other ideas?

--

Jet Townsend, IDSA

design <http://www.allartburns.org>

hacking <http://www.flatline.net>

consulting <http://www.functionalprototype.com>

Josh Lotts

Mar 21, 2020, 3:13:53 AM3/21/20

to lasersaur

I think you might have identified the culprit as the PSU from the sounds of it. I would also like to make a suggestion of ditching the 24 PSU altogether when it comes to driving laser gantries especially. The lasersaur has always been majorly plagued with a number or poor choices when it comes to mechanics and drive components.

That being said, I don't know how the newer machines are built these days, but the old one that we used to have was designed to utilize a direct driven 2 phase NEMA 23 for the the Y axis and a direct driven 2 phase NEMA 17 for the X. Both using 5mm belts and both being powered with a 24v PSU.

Please excuse me if I sound rude, but you need to know the facts as to why this old school setup is complete and utter garbage in every way possible for such a large machine.

If your current build has any of these things I mentioned, you would be doing yourself a great service by sending them straight to the spare parts bin for other uses.

If your current build has any of these things I mentioned, you would be doing yourself a great service by sending them straight to the spare parts bin for other uses.

If you have long term plans of any sort or would like to optimize your machine to a become a reliable and capable unit, you need to replace those inefficient and torque-less 2 phase motors for two new 3 phase NEMA 23 units with current and microstep dip switch selectable 3 phase drivers to run them with. If your unit uses the old thin 5mm belts you should also ditch those as soon as possible for 15mm replacements that provide huge gains in "tension retention" and lateral rigidity, thus majorly ridding the gantry of any felt resonance that can cause rough edges and zaggy cut/etch lines.

Ultimately direct drive large gantry machines suffer most from being under powered and over driven for two notable reasons. One, they should really implement 2:1 belt reductions to avoid dynamic load feed back as the motors start or stop abruptly. Not only does reductions reduce load factors significantly, they also double your motors resolution and allow for drivers to be set to 5K microsteps that can yield 1200dpi plus. The other major failure point however is mostly due to running a 24v psu vs a 36-48v unit. A lot of people assume that because the steppers are sold as 24v units that they aren't supposed to run on anything higher, when in actuality the 24v designation is what the minimal requirement is to function the unit. The first thing you will notice as soon as you replace the 24v PSU with at least a good 36v 9.2amp unit, is how quiet those motors become since they are no longer being starved from delivered current. You will also notice a significant difference in acceleration and high speed torque that prevents having to deal with over buffered "snail pace slow" acceleration settings that wreck havoc on corner cuts and kill any chances of ever gettng a quality raster. That is if "Lasersaur" is even capable of it to begin with at this point. When I gutted out machine and pretty much replaced everything in it a while back, they where still having trouble with etching. Thank God for Ruida or LightObject controllers!

Again, I don't want to sound pompous or rude in how I conveyed what I've said, but I still got a chip on my shoulder from years of dealing with a system that was seemingly broken or needed constant maintenance to be half reliable from the start, and at the end of the day most all of any worthy development of the UI and onboard software is now non existent and beyond the systems abilities to catch up with even the most basic Chinese DSP/controllers at this point.

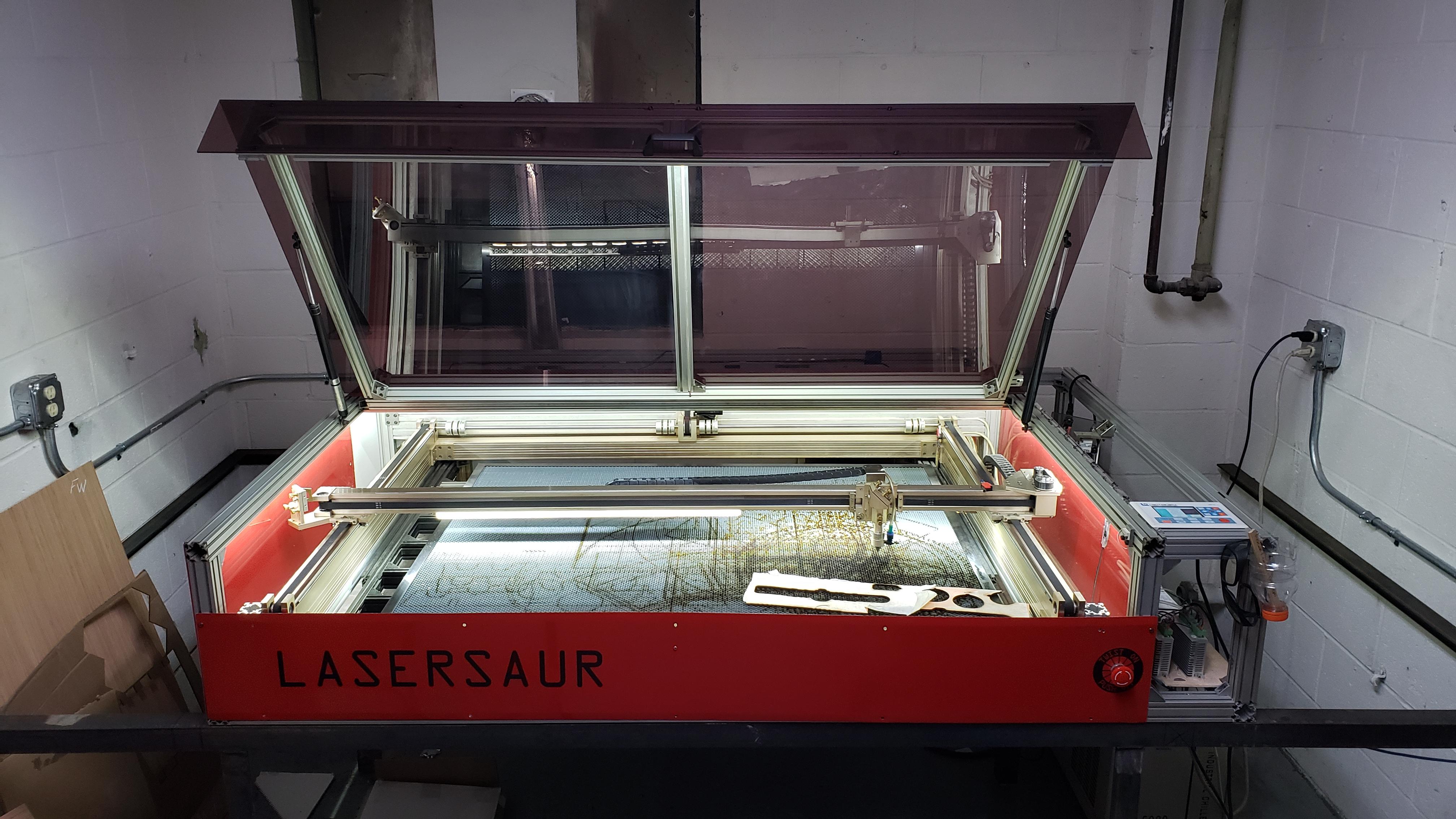

If I haven't offended you to much, I'd like to invite you over to my facebook group " Laser Builders Guild " if you really want to dive into all the possibilities of what you can do with that machine for the cheapest cost, once you've gotten tired of dealing with it. Here is a video link and a photo of our local makerspace's old Lasersaur after I did a complete retrofit overhaul of it's guts and gantry setup using modern mechanics/electronics. Quite literally the only thing left of the original is the alloy tube mounts,framing extrusion and stickers, and I gotta tell ya... I couldn't be more pleased.

jet townsend

Mar 28, 2020, 6:54:35 PM3/28/20

to lase...@googlegroups.com

I find that writing a status note often leads to me solving the problem

but not this time...

Easiest things first. Swapped in a spare 24 PSU, no change. X still

stalls at any useful speed.

The wiring between the Geckos and the steppers are the same for X and Y,

so I swapped the X and Y steppers on the motherboard to see if it was a

Gecko or a motor. But now it works, X moves along just fine for a

several minute test. Things are on the wrong axis, so cutting anything

wider on X than on Y isn't going to work. Reverted to the correct

installation and X goes back to failing under speed.

If X isn't getting enough power then how could swapping the steppers to

the mother board make any difference? Y is a much larger motor than X,

1.4Nm (2.8A) vs. .4Nm (1.5A). So if X is stalling because it is not

getting enough power from the X Gecko, how could the X Gecko drive the

larger Y motor?

Maybe there's a problem with the Geckos or one is loose? Swapped the X

and Y Geckos. No improvement.

I'm really kinda stumped at this point.

but not this time...

Easiest things first. Swapped in a spare 24 PSU, no change. X still

stalls at any useful speed.

The wiring between the Geckos and the steppers are the same for X and Y,

so I swapped the X and Y steppers on the motherboard to see if it was a

Gecko or a motor. But now it works, X moves along just fine for a

several minute test. Things are on the wrong axis, so cutting anything

wider on X than on Y isn't going to work. Reverted to the correct

installation and X goes back to failing under speed.

If X isn't getting enough power then how could swapping the steppers to

the mother board make any difference? Y is a much larger motor than X,

1.4Nm (2.8A) vs. .4Nm (1.5A). So if X is stalling because it is not

getting enough power from the X Gecko, how could the X Gecko drive the

larger Y motor?

Maybe there's a problem with the Geckos or one is loose? Swapped the X

and Y Geckos. No improvement.

I'm really kinda stumped at this point.

jet townsend

Mar 29, 2020, 9:05:30 PM3/29/20

to lase...@googlegroups.com

After wasting most of a day trying to sort this out I remembered I have

a leftover driverboard from my other lasersaur project. Part swapped

everything and running as expected. I'm guessing the previous board had

some sort of intermittent fault but I have no desire to diagnose things

right now.

--jet

a leftover driverboard from my other lasersaur project. Part swapped

everything and running as expected. I'm guessing the previous board had

some sort of intermittent fault but I have no desire to diagnose things

right now.

--jet

Jonathan Buford

Mar 29, 2020, 9:12:12 PM3/29/20

to lase...@googlegroups.com

Good to hear that you at least got that sorted.

--

You received this message because you are subscribed to the Google Groups "lasersaur" group.

To unsubscribe from this group and stop receiving emails from it, send an email to lasersaur+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/lasersaur/51f8c88e-98e1-7927-16db-5680f3aaf949%40allartburns.org.

Reply all

Reply to author

Forward

0 new messages