Skip to first unread message

James Pelt

Sep 20, 2014, 3:53:02 PM9/20/14

to kisslicer-r...@googlegroups.com

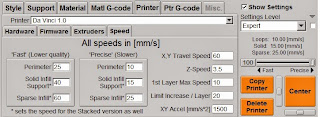

I have been working at tweaking the settings for my Da Vinci 1.0 printer, well actually there are no printer settings to tweak, rather my settings in KISslicer. I am using version 1.1.0.14, not registered (it will be, just no money atm.) I am printing a "1950's spaceship" model I downloaded from Thingiverse. scaled to 50%, and ran through the Netfabb STL repair service. I am attaching images of my current settings as well as a picture of the most recent attempt.

One thing you may notice on the Material tab, my filament diameter is set to 1.79. I used a digital caliper and checked three spots on three spools. That reading was consistent throughout. I have checked the belts and gears for play, and everything seems tight and secure. I could clean up a good bit of this with acetone, but I am afraid I will lose the finer details if I do.

Any suggestions on what to try first?

Thanks,

James

PenskeGuy

Sep 21, 2014, 12:50:26 AM9/21/14

to

First thing I'd try is uncheck: "Loops go from inside to Perimeter" You'll get more accurate surfaces that way, as the Perimeter goes down unimpeded and uninfluenced by anything. If you have fluctuating flow issues and the Loops are deposited first, they will influence the final Perimeter; just because they are there getting in the way. Might also try turning Jitter off to see what changes with the layers.

Have you run a series of calibration cube tests, both solid and thin wall?

What I see in the print, however, does look like hardware issue. The lower layers appear to be smooth. The anomalies begin and get worse as the height increases. On the layers that exhibit depressions in this view, are they protrusions on the opposite side?

Have you run a series of calibration cube tests, both solid and thin wall?

What I see in the print, however, does look like hardware issue. The lower layers appear to be smooth. The anomalies begin and get worse as the height increases. On the layers that exhibit depressions in this view, are they protrusions on the opposite side?

Isaac Thompson

Sep 21, 2014, 4:21:27 PM9/21/14

to kisslicer-r...@googlegroups.com

looks to me like you're getting some extrusion problems. make sure you have a fan cooling the upper barrel of the extruder, and a wiper on the filament to keep dust off is a good idea too. you can also try setting the speed slower and see if that helps, i get problems like this when i try to run the printer too fast

James Pelt

Sep 21, 2014, 6:00:30 PM9/21/14

to

First, I have switched to ver 1.4.5.10. My bad, I actually thought I was using the most current version--I guess I never quite got around to updating that shortcut. I reprinted the object with better results, the best yet actually except that I still have that identical problem with the Z lines. Pictures below, second picture is rotated 90°. None of the suggested changes were applied in this print.

On Saturday, September 20, 2014 11:50:26 PM UTC-5, PenskeGuy wrote:

First thing I'd try is uncheck: "Loops go from inside to Perimeter" <sic>

Might also try turning Jitter off to see what changes with the layers.

Have you run a series of calibration cube tests, both solid and thin wall?

What I see in the print, however, does look like hardware issue. The lower layers appear to be smooth. The anomalies begin and get worse as the height increases. On the layers that exhibit depressions in this view, are they protrusions on the opposite side?

Sounds reasonable on the Loops/Perimeter thing, I will uncheck that. I have played a good bit with the Jitter and it has largely helped in getting rid of the seam, with no appreciable impact on the layers.

I have printed the calibration cubes, but a while back with the factory software. However, as you said they don't show this issue because they are not big enough.

Interesting thing about the protrusions... where there is a protrusion, there is also one 180° out, and a depression at both plus and minus 90°.

On Sunday, September 21, 2014 3:21:27 PM UTC-5, Isaac Thompson wrote:

looks to me like you're getting some extrusion problems. make sure you have a fan cooling the upper barrel of the extruder, and a wiper on the filament to keep dust off is a good idea too. you can also try setting the speed slower and see if that helps, i get problems like this when i try to run the printer too fast

I am now convinced that it is a hardware issue. Possibly extrusion, possibly belt or gear slippage. I am not sure I follow the wiper/dust comment, but the printer is a factory made fully enclosed unit. The fans however... not well designed in my opinion. Only one in fact and it seems designed to cool the top of the hot end only--but with a lot of leakage. A better shroud is I think called for.

[Edit] Kind of thinking out loud here - only in text and on the Internet - If the issue were slippage of some kind, I don't think the printer would recover for the next layer. Once it was off alignment, wouldn't it stay off? Seems to me that makes it look more like an extruder issue, right?

James Pelt

Sep 21, 2014, 6:14:51 PM9/21/14

to kisslicer-r...@googlegroups.com

:) I am sitting here looking at the three pictures of the spaceship in this thread. There are zero changes in the settings between the first image and the other two. Only the software version has changed. The improvement is impressive. Just an observation.

PenskeGuy

Sep 21, 2014, 10:33:34 PM9/21/14

to kisslicer-r...@googlegroups.com

On Sunday, September 21, 2014 3:00:30 PM UTC-7, James Pelt wrote:

Interesting thing about the protrusions... where there is a protrusion, there is also one 180° out, and a depression at both plus and minus 90°.

I am now convinced that it is a hardware issue.

As am I. That there is a geometric pattern indicates this. Could be something hindering the head travel at those points. Are the layer numbers reproducible? IOW, does this happen at the same level each print? Try a small diameter cylinder that is as tall as the rocket, so you don't waste material, and note similarities, if any, between the cylinder print and the rocket.

One thing to note, when ever you change materials, a calibration cube should be run. Even spools from the same manufacturer will have differences. It you are looking for high quality prints, keeping up on calibration is essential. Not only does the material change but the hardware does as well. Nozzles open up, moving parts wear.

Reply all

Reply to author

Forward

0 new messages