Ken Huebner

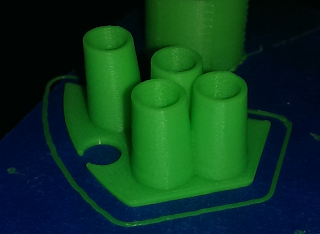

Attached is my thin wall test part STL and BFB files. I print it upside down with large flat region on bed.

Ken Huebner

funBart

When slicing with 0.05mm oversample and 1mm crowning I seem to get descent results with your stl.

- for large blobs or missing segments: Destring settings on the Material tab not tweaked well

- for small blobs: Seam hiding not tweaked well

Colen Casey

if you truely are printing it like it loads into kisslicer (base on top ) rotate it 180degrees and put the base on the bottom this might do wonders for you

Timmay

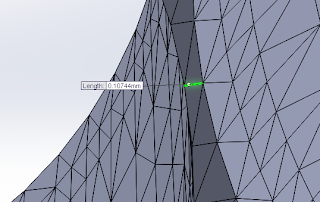

That said, you're also asking KISSlicer to slice (and your printer to print) a surface that is 0.107mm wide with a nozzle (I'm assuming) that's at least 0.35mm wide:

Short of under-extruding with extremely unpredictable results, there's no way a printer with a 350um orifice can print something that's 107um wide. Also, the hole in the base layer is under 0.2mm wide at points:

The smallest width of plastic a printer with a 0.35mm orifice can realistically put down is 0.35mm*. In order to make that part connect, the slicer would have to guess whether you wanted the intended hole a bit smaller to account for the width of the path, or make the part's outside a bit bigger to accommodate the path. The slicer can't possibly know what's more important to you: making the hole the exact size it is in the STL, or making the outside wider than the STL actually has it. The solution is to either dial in the settings of the slicer as close as you can and accept the results, or redesign the part keeping in mind the physical dynamics of slicing and printing.

*It's actually larger if you want it to stick to the preceding layer, but for argument's sake this will suffice.