Story of my Liquid Nails fail, with photos

8,610 views

Skip to first unread message

ken winston caine

Aug 16, 2017, 4:54:31 PM8/16/17

to hexayurt

Fail was my fault.

1. I didn't clamp the boards after gluing.

2. I thought a 70 lb. pallet would be adequate to keep a wind gust from causing a problem during overnight cure.

3. I had assumed the Liquid Nails compound would be less viscous and more grabby and that I could spread/smear it over the entire surface of each face to join. Not possible. Instructions say to apply in a zig-zag design, so that is what I tried.

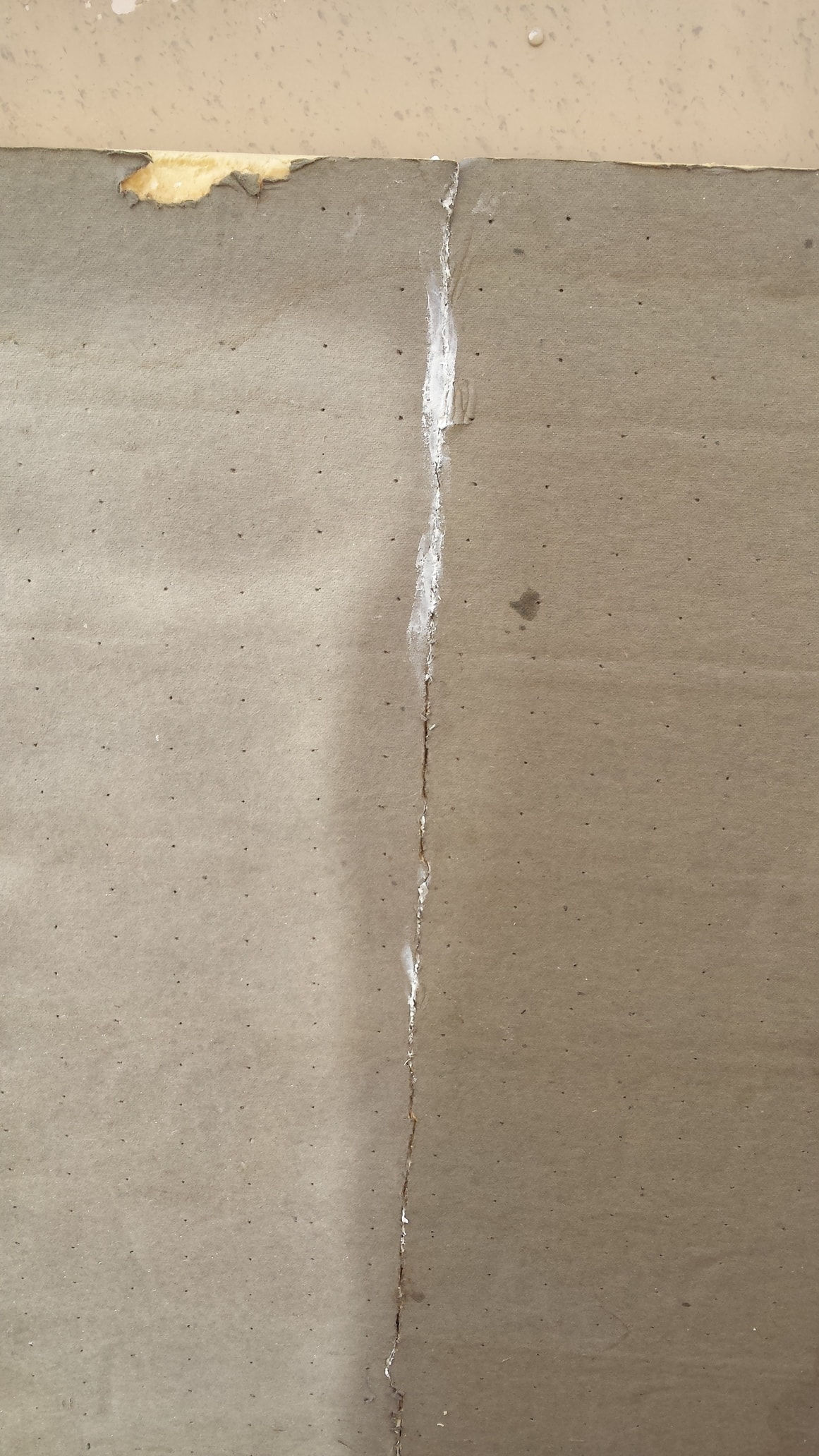

Here are the broken pieces to be joined.

Here is the product used:

The application made in recommended zig-zag pattern. Done on both faces. Is not tacky when applied. Not tacky, just stiffer, after five minutes. So I pressed the pieces together, they did not grab, so I pulled them apart and waited another five minutes and fit them together again. At that point, they should have been clamped. I did not find my clamps that day and skipped that part. At 10 minutes after initial application, the Liquid Nails still was not tacky...

Braced the attached pieces against the bus to cure overnight.

Went out in the morning to see how well the repair had come out and test its strength.? This is what I found:

Observations:

1. Liquid Nails is not spreadable for a 100% bond of all facing parts.

2. It does not set up quickly and become tacky.

3. Parts will not grab together and must be clamped during cure.

4. A 70 lb pallet will not brace and protect a 4" 4x8 Polyiso board from a Northern New Mexico wind gust.

5. Because Liquid Nails must be clamped during cure, and will not spread to cover 100% of faces to be attached, it is not practical for this purpose.

ken winston caine

Aug 23, 2017, 2:40:05 PM8/23/17

to hexayurt

REVISION: LIQUID NAILS SUCCESS

NEW TEST: Liquid Nails vs. Epoxy

NEW TEST: Liquid Nails vs. Epoxy

-1- Liquid Nails, spread thinly with putty knife, on smooth flat beveled-cut surface, with some tiny holes scratched into both facing surfaces with a wallpaper scouring tool, then clamped and cured for 24 hours, works BEAUTIFULLY! Incredible strength. And Liquid Nails claims its repairs will outlast the life of the original material. Am going to trust that.

-2- Epoxy, surfaces prepared the same way as above, simply did not dig in to anything but the very very topmost layers of polyiso fuzz. And the adhered parts easily snapped apart after 24 hours cure time. When snapped apart, I observed the epoxy "bond" covered with maybe 1/100 inch of polyiso fuzz. Is possible that if I punched a lot of tiny 1/2" deep holes in each face and smeared on the epoxy much thicker, that I would get a strong bond. But, given the positive results with the Liquid Nails, once spread with a putty knife, and its substantially lower cost, I am not going to do any further testing with epoxy resin. Also is possible that epoxy would work better (or perfectly) with NEW polyiso boards. Mine are salvaged boards, possibly 20 or more years old. (They do age, outgas, lose R-Factor over time. And maybe mine are fuzzier along my cuts than new boards would be. I don't know.)

So ... I am going with the much less expensive Liquid Nails.

That means I must create some 30-degree-angle braces (out of 2x4s?) that I can clamp onto roof-cone sections as I glue them to hold them for the 24 hours cure time. And 30-degree-angle braces for the wall sections.

As an additional measure, am going to use an awl to punch a dozen or more 1/4" deep random holes along each face to allow for much greater material penetration in those spots to make for a stronger, more durable bond once cured.

Also, am going to test using rubbing alcohol or acetone on a cloth to lightly rub the surfaces to be joined to see if that will help clean away dusty fuzz. (Or whether it melts the polyiso.)

Also, am going to test using rubbing alcohol or acetone on a cloth to lightly rub the surfaces to be joined to see if that will help clean away dusty fuzz. (Or whether it melts the polyiso.)

On Wednesday, August 16, 2017 at 2:54:31 PM UTC-6, ken winston caine wrote:

Fail was my fault.1. I didn't clamp the boards after gluing.2. I thought a 70 lb. pallet would be adequate to keep a wind gust from causing a problem during overnight cure.

3. I had assumed the Liquid Nails compound would be less viscous and more grabby and that I could spread/smear it over the entire surface of each face to join. Not possible. Instructions say to apply in a zig-zag design, so that is what I tried. <snip>

Hunter

Aug 25, 2017, 11:13:38 AM8/25/17

to hexa...@googlegroups.com

So did you cut the edges first to prepare them for the liquid nails?

--

You received this message because you are subscribed to the Google Groups "hexayurt" group.

To unsubscribe from this group and stop receiving emails from it, send an email to hexayurt+unsubscribe@googlegroups.com.

To post to this group, send email to hexa...@googlegroups.com.

Visit this group at https://groups.google.com/group/hexayurt.

For more options, visit https://groups.google.com/d/optout.

ken winston caine

Aug 26, 2017, 12:18:13 PM8/26/17

to hexayurt

Hunter:

The "Fail" shown in the photos was with an unevenly broken polyiso board with quite ragged faces along the break. The successful followup test was done with clean-cut, smooth faces. That really does make a difference. But, still, you MUST clamp the repair, I have found.

Unfortunately, I have quite a few small, ragged breaks that need to be repaired in my 40-some sheets of used polyiso. Continuing to work with Liquid Nails on those with less than ideal results. Liquid Nails works well on cleanly cut, smooth faces and spreads thinly with a putty knife (after laying out your zig-zag pattern of Liquid Nails).

But, as mentioned in the "Fail" experiment, Liquid Nails does not "grab" and hold pieces together like a tacky adhesive would. You must apply the stuff to one surface -- spread it if you choose -- attach the pieces tightly and clamp them in place for 24 hours.

Unfortunately, I have quite a few small, ragged breaks that need to be repaired in my 40-some sheets of used polyiso. Continuing to work with Liquid Nails on those with less than ideal results. Liquid Nails works well on cleanly cut, smooth faces and spreads thinly with a putty knife (after laying out your zig-zag pattern of Liquid Nails).

But, as mentioned in the "Fail" experiment, Liquid Nails does not "grab" and hold pieces together like a tacky adhesive would. You must apply the stuff to one surface -- spread it if you choose -- attach the pieces tightly and clamp them in place for 24 hours.

UNRELATED CORRECTION: In the updated "success" test with Liquid Nails I said I would need to build 30-degree angle braces for clamping roof-cone pieces and (TYPO) 30-degree angle braces for clamping wall sections. It was supposed to say 60-degree angle braces for the wall sections.

D.V.Rogers

Aug 26, 2017, 10:06:25 PM8/26/17

to hexa...@googlegroups.com, Vinay Gupta (Hexayurt Shelter Project)

If your project is permament why not go Ferrocrete?

You need the following;

Mortar Sprayer Oregon - http://www.mortarsprayer.com/ (you can also hand trowel like stucco)

Permalath (BASF) - www.permalath.basf.com/ (or Chicken Wire)

MIX: Three Sand to one Cement -3:1 Ratio

*Portland Lime Cement Mix + Fibreglas Lathe Skin = 20year+ Hexayurt

/dvr

Vinay Gupta (Hexayurt Shelter Project)

Aug 27, 2017, 6:33:53 AM8/27/17

to D.V.Rogers, hexa...@googlegroups.com

You might want to look at Gorilla Glue too. It foams up so it pushes into contours of the surface for maximum grip. Very useful. I suspect it's pretty much like liquid nails in other characteristics.

V>

On Sun, 27 Aug 2017, 03:06 D.V.Rogers <d...@allshookup.org> wrote:

If your project is permament why not go Ferrocrete?You need the following;Mortar Sprayer Oregon - http://www.mortarsprayer.com/ (you can also hand trowel like stucco)Permalath (BASF) - www.permalath.basf.com/ (or Chicken Wire)MIX: Three Sand to one Cement -3:1 Ratio*Portland Lime Cement Mix + Fibreglas Lathe Skin = 20year+ Hexayurt/dvr

On Sun, Aug 27, 2017 at 2:18 AM, ken winston caine <ken.wins...@gmail.com> wrote:

Hunter:The "Fail" shown in the photos was with an unevenly broken polyiso board with quite ragged faces along the break. The successful followup test was done with clean-cut, smooth faces. That really does make a difference. But, still, you MUST clamp the repair, I have found.

Unfortunately, I have quite a few small, ragged breaks that need to be repaired in my 40-some sheets of used polyiso. Continuing to work with Liquid Nails on those with less than ideal results. Liquid Nails works well on cleanly cut, smooth faces and spreads thinly with a putty knife (after laying out your zig-zag pattern of Liquid Nails).

But, as mentioned in the "Fail" experiment, Liquid Nails does not "grab" and hold pieces together like a tacky adhesive would. You must apply the stuff to one surface -- spread it if you choose -- attach the pieces tightly and clamp them in place for 24 hours.UNRELATED CORRECTION: In the updated "success" test with Liquid Nails I said I would need to build 30-degree angle braces for clamping roof-cone pieces and (TYPO) 30-degree angle braces for clamping wall sections. It was supposed to say 60-degree angle braces for the wall sections.

--

You received this message because you are subscribed to the Google Groups "hexayurt" group.

To unsubscribe from this group and stop receiving emails from it, send an email to hexayurt+u...@googlegroups.com.

ken winston caine

Aug 27, 2017, 2:21:26 PM8/27/17

to hexayurt

Yes, Vinay. It is supposed to be good with polyiso. Originally had rejected it because of its cost and that it requires clamping. But think I have solved the clamping issue. Have already bought about 240 oz. of Liquid Nails for this project. But think I will run a small test with some Gorilla Glue I have on hand.

Was hoping to have this shell up by the time everyone gets back from Burning Man, but because of a number of variations I am doing, it is going to take longer.

Am toying with a design for minimal 2x4 support for the roof that I may be incorporating in coming days. It would require some notching in the tops of the walls and would allow for an add-on OSB overhang for aesthetics, summer sun blocking, and guttering/water catchment. If I can make that design work in my head and on paper, adding the actual overhang and guttering will be a next-spring project. As well as adding an additional roof coating then.

Am "poor man's fiberglassing" the cut boards for added strength and weatherization. Monday need to make calls to see if I can find a free or near-free source of old bed sheets for that. (Hospitals? Hotels?) I don't have nearly enough fabric (other than burlap bags that I've collected from coffee grinders and they are too thick for this purpose).

And do not have the budget for it now, but WISH I could afford to create a French drain foundation for it. And know that later I will wish that I had. But I've been wanting to build this thing for more than 10 years and I've gathered enough of the pieces now to get it going and have two months of mostly warm enough weather to be outside doing it. Have more time than money right now. So am moving ahead with what I've got. Don't know what I'm going to do for foundation drainage and to keep the eventual mud-clay floor protected from beneath.

But, Hi-Ho. It's underway.

Was hoping to have this shell up by the time everyone gets back from Burning Man, but because of a number of variations I am doing, it is going to take longer.

Am toying with a design for minimal 2x4 support for the roof that I may be incorporating in coming days. It would require some notching in the tops of the walls and would allow for an add-on OSB overhang for aesthetics, summer sun blocking, and guttering/water catchment. If I can make that design work in my head and on paper, adding the actual overhang and guttering will be a next-spring project. As well as adding an additional roof coating then.

Am "poor man's fiberglassing" the cut boards for added strength and weatherization. Monday need to make calls to see if I can find a free or near-free source of old bed sheets for that. (Hospitals? Hotels?) I don't have nearly enough fabric (other than burlap bags that I've collected from coffee grinders and they are too thick for this purpose).

And do not have the budget for it now, but WISH I could afford to create a French drain foundation for it. And know that later I will wish that I had. But I've been wanting to build this thing for more than 10 years and I've gathered enough of the pieces now to get it going and have two months of mostly warm enough weather to be outside doing it. Have more time than money right now. So am moving ahead with what I've got. Don't know what I'm going to do for foundation drainage and to keep the eventual mud-clay floor protected from beneath.

But, Hi-Ho. It's underway.

To unsubscribe from this group and stop receiving emails from it, send an email to hexayurt+unsubscribe@googlegroups.com.

To post to this group, send email to hexa...@googlegroups.com.

Visit this group at https://groups.google.com/group/hexayurt.

For more options, visit https://groups.google.com/d/optout.

--

You received this message because you are subscribed to a topic in the Google Groups "hexayurt" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/hexayurt/eJWdrlkJMTo/unsubscribe.

To unsubscribe from this group and all its topics, send an email to hexayurt+unsubscribe@googlegroups.com.

Hunter

Aug 28, 2017, 12:40:26 AM8/28/17

to hexa...@googlegroups.com

Heh, and of course I see my threads were cut in half and you already mentioned drainage. Perhaps just two by fours or pallets for the initial season?

Cabinz Admin

Aug 28, 2017, 4:28:31 AM8/28/17

to hexayurt, ken.wins...@gmail.com

As Vinay says, gorilla glue does the job well, but I agree with you that it's too expensive . Here at Cabinz for glueing composite door off cuts with rigid foam cores, we use a much cheaper Pu glue like the gorilla stuff . It;s called Lumberjack by Everbuild. I use the 5 min stuff its less than £10 for 750 ml

http://www.ebay.co.uk/itm/Everbuild-Lumberjack-Wood-Adhesive-Glue-750g-Waterproof-Polyurethane-5-Mins-NEW-/272794773464

There is an even cheaper option that does the job - Soudal PRO 45P Polypropylene PU, but it has a smell (lumberjack does not) the bond is maybe 10-20 % less effiecient imo

Soudal PRO 45P Polypropylene PU www.ebay.co.uk/itm/6-x-Soudal-PRO-45P-Polypropylene-PU-Water-Resistant-Wood-Glue-Adhesive-750G-Fast-/262175055261

My recent experiments with mgo board & metalclad (Door edge off cut / drywall) had a new Kingspan off cut core (80mm ). I used cheap (non fire resistant ) expanding foam from a spray can to join the foil backed board edges . Also sealing edges to reduce thermal bridge in the frame

see www.cabinznet.blogspot.co.uk/2017/06/experiments-with-budget-6mm-mgo-panels.html

I tried lumberjack Pu glue first, but where the foam was cut (it was new from a timber frame house building co) it has a slightly concave edge, so the Lumberjack pu could not quite expand enough to join the gape unless I wasted loads of it , nence I went to expanding foam.

The generla disadvantage of the exp foam is that its more brittle than pu glue, so may fracture if put under stress. I tried all types of silicon sealant / liquid nails etc types before going over to pu glue.

They worked but the bond was not nearly as good imo

http://www.ebay.co.uk/itm/Everbuild-Lumberjack-Wood-Adhesive-Glue-750g-Waterproof-Polyurethane-5-Mins-NEW-/272794773464

There is an even cheaper option that does the job - Soudal PRO 45P Polypropylene PU, but it has a smell (lumberjack does not) the bond is maybe 10-20 % less effiecient imo

Soudal PRO 45P Polypropylene PU www.ebay.co.uk/itm/6-x-Soudal-PRO-45P-Polypropylene-PU-Water-Resistant-Wood-Glue-Adhesive-750G-Fast-/262175055261

My recent experiments with mgo board & metalclad (Door edge off cut / drywall) had a new Kingspan off cut core (80mm ). I used cheap (non fire resistant ) expanding foam from a spray can to join the foil backed board edges . Also sealing edges to reduce thermal bridge in the frame

see www.cabinznet.blogspot.co.uk/2017/06/experiments-with-budget-6mm-mgo-panels.html

I tried lumberjack Pu glue first, but where the foam was cut (it was new from a timber frame house building co) it has a slightly concave edge, so the Lumberjack pu could not quite expand enough to join the gape unless I wasted loads of it , nence I went to expanding foam.

The generla disadvantage of the exp foam is that its more brittle than pu glue, so may fracture if put under stress. I tried all types of silicon sealant / liquid nails etc types before going over to pu glue.

They worked but the bond was not nearly as good imo

To unsubscribe from this group and stop receiving emails from it, send an email to hexayurt+u...@googlegroups.com.

To post to this group, send email to hexa...@googlegroups.com.

Visit this group at https://groups.google.com/group/hexayurt.

For more options, visit https://groups.google.com/d/optout.

--

You received this message because you are subscribed to a topic in the Google Groups "hexayurt" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/hexayurt/eJWdrlkJMTo/unsubscribe.

To unsubscribe from this group and all its topics, send an email to hexayurt+u...@googlegroups.com.

ken winston caine

Aug 30, 2017, 2:17:01 PM8/30/17

to Cabinz Admin, hexayurt

Thank you, Cabinz. Will look into Lumberjack.

Thank you, Vinay, for bringing my attention back to Gorilla Glue. Did a little test. It performs beautifully.

This 4" polyiso has almost no tensile strength. Broke a tip off a triangle yesterday by lightly bumping into it.

Was a ragged break.

Dampened the smaller loose pieces, drizzled Gorilla Glue on the break on the larger piece. Fit the pieces together and clamped.

Wiped off some of the excess foaming while it was wet and left it overnight to cure.

Photos show what it looked like this a.m. before unclamping. Foamed glue may need to be sanded.

Removed the clamps. Tried to wiggle the repair loose using quite a bit of force with my hands. No give. It's solid. Even on a ragged break with only minimal glue coverage. (In my earlier epoxy test, that repair snapped apart immediately with the application of force.)

So, yes. Gorilla Glue is a good, if expensive, choice.

Will see if I can locate the less-expensive, similar, Lumberjack locally and test it as well.

Hunter

Aug 30, 2017, 2:26:57 PM8/30/17

to hexa...@googlegroups.com, Cabinz Admin

Have you done any tests of adhesives between the iso and the backing board? I'm imagining a large number of failures will happen at that boundary (at least for the standard burning man BiDi tape/Vinyl construction styles).

--

You received this message because you are subscribed to the Google Groups "hexayurt" group.

To unsubscribe from this group and stop receiving emails from it, send an email to hexayurt+unsubscribe@googlegroups.com.

ken winston caine

Aug 30, 2017, 2:50:22 PM8/30/17

to hexayurt, cabi...@gmail.com

Hunter, I will be testing Titebond II Pro on the backing board sometime in the next couple days. But won't be testing it *between* the polyiso and the textured paper covering. Will be testing it atop the textured paper. It is the initial layer in the "poor man's fiberglass" treatment I will be using to attempt to increase substantially the tensile strength of the insulation boards and to give them a waterproofed, hardened exterior.

If tests prove compatibility, will be rolling on PVA drywall sealant primer, and then a coat of Titebond II and then stretching out cloth fabric atop that, and saturating the fabric with heavy coats of paints.

If tests prove compatibility, will be rolling on PVA drywall sealant primer, and then a coat of Titebond II and then stretching out cloth fabric atop that, and saturating the fabric with heavy coats of paints.

WILL be doing some tests of compatibility between PVA and Tightbond II, and Tightbond II and aluminum acrlyic paint, and Tightbond II and latex paint, and between aluminum acrylic paint and latex paint over the next few days. And, of course, between polyiso and all of those. None of those are supposed to melt polyiso, but I want to make sure.

On Wednesday, August 30, 2017 at 11:26:57 AM UTC-7, Hunter King wrote:

Have you done any tests of adhesives between the iso and the backing board? I'm imagining a large number of failures will happen at that boundary (at least for the standard burning man BiDi tape/Vinyl construction styles).

On Wed, Aug 30, 2017 at 11:16 AM, ken winston caine <ken.wins...@gmail.com> wrote:

Thank you, Cabinz. Will look into Lumberjack.Thank you, Vinay, for bringing my attention back to Gorilla Glue. Did a little test. It performs beautifully.

<snip>

Hunter

Aug 30, 2017, 2:57:49 PM8/30/17

to hexa...@googlegroups.com, Cabinz Admin

Cool, keep us posted. This is really useful stuff to know.

--

ken winston caine

Aug 30, 2017, 4:01:36 PM8/30/17

to hexayurt, ken.wins...@gmail.com

Two things:

-1- About 30 minutes of Googling suggests to me that Everbuild Lumberjack wood glue is sold in the UK and not in the U.S. Can be ordered from the UK via eBay and various sites. So I won't be testing it this time around because I will be well into gluing before an overseas order would arrive.

-2- RE: Gorilla Glue and other polyurethane wood glues. Read on a couple boat-building sites that while the foaming action appears to be beneficial for filling in gaps, this is not really the case. The foaming action IS beneficial when the glue is applied thinly to one of two pieces to be attached and the other face is wet down, and then the pieces are tightly fit together and clamped. In that case, foaming can force some of the glue deeper into the joining wood fibers, strengthening/deepening the bond. But the hardened foam itself, filling gaps and holes between the two pieces to be bonded, actually weakens the bond between the pieces. The hardened foam is much more fragile than the areas with only a super thin coating of cured glue and no gaps.

Since I have already bought about 10 28 oz. tubes of Liquid Nails Heavy Duty Construction Adhesive (which I COULD return for refund or exchange), I think I will stick with it for this project, rather than opt for the more expensive Gorilla Glue, and rather than experiment with some other brands / compositions of polyurethane wood adhesives. I was enthusiastic about Gorilla Glue for its gap-filling tendency since many of my cuts are not perfectly straight and even. That is, I WAS, until reading the information I summarized in item 2 above.

Gorilla Glue may make a stronger bond than Liquid Nails on polyiso to polyiso faces. That's speculation on my part, but is based on the fact that both the glue and insulation board have polyisocyanurate as a key ingredient in their formulas.

-2- RE: Gorilla Glue and other polyurethane wood glues. Read on a couple boat-building sites that while the foaming action appears to be beneficial for filling in gaps, this is not really the case. The foaming action IS beneficial when the glue is applied thinly to one of two pieces to be attached and the other face is wet down, and then the pieces are tightly fit together and clamped. In that case, foaming can force some of the glue deeper into the joining wood fibers, strengthening/deepening the bond. But the hardened foam itself, filling gaps and holes between the two pieces to be bonded, actually weakens the bond between the pieces. The hardened foam is much more fragile than the areas with only a super thin coating of cured glue and no gaps.

Since I have already bought about 10 28 oz. tubes of Liquid Nails Heavy Duty Construction Adhesive (which I COULD return for refund or exchange), I think I will stick with it for this project, rather than opt for the more expensive Gorilla Glue, and rather than experiment with some other brands / compositions of polyurethane wood adhesives. I was enthusiastic about Gorilla Glue for its gap-filling tendency since many of my cuts are not perfectly straight and even. That is, I WAS, until reading the information I summarized in item 2 above.

Gorilla Glue may make a stronger bond than Liquid Nails on polyiso to polyiso faces. That's speculation on my part, but is based on the fact that both the glue and insulation board have polyisocyanurate as a key ingredient in their formulas.

ken winston caine

Sep 3, 2017, 6:34:04 PM9/3/17

to hexayurt, ken.wins...@gmail.com

http://www.homedepot.com/p/Loctite-PL-Premium-28-fl-oz-Polyurethane-Construction-Adhesive-1390594/202020474

After more mucking around, am strongly leaning toward a foaming polyurethane adhesive (of which one is Gorilla Glue).

Looks like Loctite's Premium Polyurethane Construction Adhesive is the least expensive option at $7 per 28 oz. tube.

Am realizing I have a LOT of gaps that will need to be filled, regardless of whether the fills add to the structural strength of the bond, and the foaming polyurethanes will help with that a lot. And the Gorilla Glue test showed me that the bond -- where parts fit tightly together like they should -- is very very strong. Have read now that the poly glues can actually force themselves a full two inches into the materials being glued, as they cure. That makes for a very very good bond.

Am picking up two tubes of the Loctite tomorrow and will be putting together some of the roof cone triangles with that, as a test.

If it proves out well, I'll be returning most of my Liquid Nails and paying about $3 more per 28 oz. for the Loctite Poly. Gorilla Glue is just too expensive for my project, but after reading quite a bit on these, it appears that their is little difference among the brands of polyurethane construction adhesives, so Loctite brand should work just fine. Will know more in a couple days.

ken winston caine

Sep 8, 2017, 8:43:02 PM9/8/17

to hexayurt

Loctite Polyurethane construction adhesive did NOT work out. Is NOT similar to Gorilla Glue, and did NOT foam, as I had read that it would.

More later. Just wanted to issue a quick heads-up in case anyone was considering buying it based on my earlier note.

Hunter

Sep 8, 2017, 8:47:56 PM9/8/17

to hexa...@googlegroups.com

What did the container look like? It seems that there are multiple versions.

On Fri, Sep 8, 2017 at 5:43 PM, ken winston caine <ken.wins...@gmail.com> wrote:

Loctite Polyurethane construction adhesive did NOT work out. Is NOT similar to Gorilla Glue, and did NOT foam, as I had read that it would.

More later. Just wanted to issue a quick heads-up in case anyone was considering buying it based on my earlier note.

ken winston caine

Sep 8, 2017, 9:46:03 PM9/8/17

to hexayurt

Don't think there are multiple versions, Hunter. This is all I saw on the Loctite site. What other Loctite PU construction adhesives do you find?

--

You received this message because you are subscribed to a topic in the Google Groups "hexayurt" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/hexayurt/eJWdrlkJMTo/unsubscribe.

To unsubscribe from this group and all its topics, send an email to hexayurt+unsubscribe@googlegroups.com.

Hunter

Sep 8, 2017, 11:25:08 PM9/8/17

to hexa...@googlegroups.com

I just saw a reference online to a foaming version but I haven't actually seen it in stores. It might have been someone's fever dream.

Cabinz Admin

Sep 9, 2017, 5:34:19 AM9/9/17

to hexayurt

Ken, further to my reply on this subject on your other post,

I am amazed that I cannot find a 750 ml size expanding Pu glue (like my uk lumberjack glue) on ebay or Az after a quick search.

It's a rip off buying, stuff in those 150ml sealant tubes anyway, unless you need the nozzle shape for specific purposes, anyway 750ml nozzle is similar , but a little shorter .

Be aware they have different dry times as stated on the bottle ie 5, 30 & 45 mins . I used 5 min, but if you have the time it does not really matter to me , although longer dry times may allow it to seap further into the foam edge ( I guess)

My composite door off cut supplier gave me the details of their adhesive supplier Apollo.co.uk , They sell a product almost identical to Lumberjack glue ,

perhaps they have a distributor in the US

"Apollo, the UK’s largest privately-owned liquid adhesive, sealant, coating & primer manufacturer"

If not try http://www.everbuild.co.uk/lumberjack/45-Minute-Polyurethane-Wood-Adhesive-Liquid

http://www.everbuild.co.uk/lumberjack/30-Minute-Polyurethane-Wood-Adhesive-Liquid

http://www.everbuild.co.uk/lumberjack/5-Minute-Polyurethane-Wood-Adhesive-Liquid

they now make Gator glue (sounds like gorilla glue ) but I've not tried it

http://www.everbuild.co.uk/gator-glue

This is cheap, maybe have it sent over from Uk

http://www.sealantsandtoolsdirect.co.uk/adhesives/wood_glue/everbuild_lumberjack_polyurethane_wood_glue_45_minute_750g_45minpu7_P23622.html?gclid=EAIaIQobChMImrrekuOX1gIVS7ftCh33CAvfEAQYAyABEgKtpfD_BwE

I am amazed that I cannot find a 750 ml size expanding Pu glue (like my uk lumberjack glue) on ebay or Az after a quick search.

It's a rip off buying, stuff in those 150ml sealant tubes anyway, unless you need the nozzle shape for specific purposes, anyway 750ml nozzle is similar , but a little shorter .

Be aware they have different dry times as stated on the bottle ie 5, 30 & 45 mins . I used 5 min, but if you have the time it does not really matter to me , although longer dry times may allow it to seap further into the foam edge ( I guess)

My composite door off cut supplier gave me the details of their adhesive supplier Apollo.co.uk , They sell a product almost identical to Lumberjack glue ,

perhaps they have a distributor in the US

"Apollo, the UK’s largest privately-owned liquid adhesive, sealant, coating & primer manufacturer"

Email: enqu...@apollo.co.uk

Tel : +44 (0)1827 54281

I think it was glue apollo adhesives polyurathane a9356 thqt I used, but check with them

If not try http://www.everbuild.co.uk/lumberjack/45-Minute-Polyurethane-Wood-Adhesive-Liquid

http://www.everbuild.co.uk/lumberjack/30-Minute-Polyurethane-Wood-Adhesive-Liquid

http://www.everbuild.co.uk/lumberjack/5-Minute-Polyurethane-Wood-Adhesive-Liquid

they now make Gator glue (sounds like gorilla glue ) but I've not tried it

http://www.everbuild.co.uk/gator-glue

http://www.sealantsandtoolsdirect.co.uk/adhesives/wood_glue/everbuild_lumberjack_polyurethane_wood_glue_45_minute_750g_45minpu7_P23622.html?gclid=EAIaIQobChMImrrekuOX1gIVS7ftCh33CAvfEAQYAyABEgKtpfD_BwE

ken winston caine

Sep 10, 2017, 2:58:29 PM9/10/17

to hexayurt

More on the Loctite Polyurethane Construction Adhesive story:

I used Loctitite's Polyurethane PL Premium Construction Adhesive.

The Loctite, while seemingly inexpensive for a polyurethane glue at $7 for 28 oz., is not comparable to Gorilla Glue -- which in an earlier test worked superbly in bonding polyiso to polyiso, but is extremely expensive for the purpose.

Loctite, as you can see in the photo, is not a thin, amber, translucent liquid:

It has a MUCH higher vicosity.

When squeezed from the tube onto vertical polyiso facings, it did not stick but fell to the ground.

I squeezed it into a paint tray and used a putty knife to apply it in a thin coat onto one of the two four inch by eight foot edges I was bonding. It took seven ounces to coat the face of one edge. I misted it with water before fitting the pieces together and clamping.

The official instructions say:

"Apply adhesive to one surface of the material being bonded. Press the surfaces firmly together. Materials may be repositioned within 45 minutes after applying the adhesive. If bonding two non-porous surfaces (such as foam, metal and fiberglass), add water in the form of a very light or atomized spray from a plant mister bottle to the extruded adhesive. The repositioning time will then be reduced to less than 30 minutes. Use mechanical support for 24 hours while the adhesive cures."

Was expecting to see expanding/foaming action as with Gorilla Glue, but there was none. And in fact, Loctite doesn't promise any, only that it will not shrink.That was my first disappointment. My misunderstanding.

While cleaning my putty knife, I smeared a bit on another piece of polyiso on which I was going to test its compatibility with my paints and primers and sealants. It was dried and hardened to touch within 15 minutes -- without being water-misted. That was a second disappointment. Loctite said you have 45 minutes of repositioning ability without misting and 30 minutes with.

Also will note that it had no tacky, grabbing properties at all, when spread in a thin coat.

But my biggest disappointment was the next day when after cure time had passed, I unclamped the "bonded" pieces. As I lifted slightly on one side to reach and release a second clamp, I heard a cracking noise and the boards split apart at the bond.

This very likely could be due to my having "troweled" it on in a thin coat with a putty knife. Perhaps it would have bonded more strongly if I had been able to position the board so the face to which the glue was to be applied was horizontal instead of vertical and had squeezed onto it a 3/8" inch bead of material and then misted that and let it squish and spread a bit as I squeezed the two pieces together to clamp. But that would possibly have used the full 28 oz tube just to zig-zag one beadline along the 4-inch wide, eight-foot length. And would not have given me the full face-to-face bonding I got with the Gorilla Glue experiment and earlier successful Liquid Nails experiment. And would have made using Loctite for this project potentially even more expensive than using Gorilla Glue for it.

My impression is that Loctite polyurethane Premium Construction Adhesive is not a good choice for permanently attaching polyiso boards to one another. To keep my project moving forward at this point before winter sets in, I can't devote time to more tests of more materials. So I am going to go with the Liquid Nails.

Placed too much faith on a line in this article about polyurethane adhesives expanding and filling gaps as they cure:

"While it’s true that polyurethane glues expand as they cure (the squeeze-out actually foams up like aerosol insulation), glue experts agree that polyurethanes cannot fill a gap larger than 1 or 2 millimeters. After a millimeter or two the foam has no strength, so it is merely a cosmetic filler."

And I believed another article that said all polyurethane glues are basically the same.

They aren't.

They aren't.

I used Loctitite's Polyurethane PL Premium Construction Adhesive.

The Loctite, while seemingly inexpensive for a polyurethane glue at $7 for 28 oz., is not comparable to Gorilla Glue -- which in an earlier test worked superbly in bonding polyiso to polyiso, but is extremely expensive for the purpose.

Loctite, as you can see in the photo, is not a thin, amber, translucent liquid:

When squeezed from the tube onto vertical polyiso facings, it did not stick but fell to the ground.

I squeezed it into a paint tray and used a putty knife to apply it in a thin coat onto one of the two four inch by eight foot edges I was bonding. It took seven ounces to coat the face of one edge. I misted it with water before fitting the pieces together and clamping.

The official instructions say:

"Apply adhesive to one surface of the material being bonded. Press the surfaces firmly together. Materials may be repositioned within 45 minutes after applying the adhesive. If bonding two non-porous surfaces (such as foam, metal and fiberglass), add water in the form of a very light or atomized spray from a plant mister bottle to the extruded adhesive. The repositioning time will then be reduced to less than 30 minutes. Use mechanical support for 24 hours while the adhesive cures."

Was expecting to see expanding/foaming action as with Gorilla Glue, but there was none. And in fact, Loctite doesn't promise any, only that it will not shrink.That was my first disappointment. My misunderstanding.

While cleaning my putty knife, I smeared a bit on another piece of polyiso on which I was going to test its compatibility with my paints and primers and sealants. It was dried and hardened to touch within 15 minutes -- without being water-misted. That was a second disappointment. Loctite said you have 45 minutes of repositioning ability without misting and 30 minutes with.

Also will note that it had no tacky, grabbing properties at all, when spread in a thin coat.

But my biggest disappointment was the next day when after cure time had passed, I unclamped the "bonded" pieces. As I lifted slightly on one side to reach and release a second clamp, I heard a cracking noise and the boards split apart at the bond.

This very likely could be due to my having "troweled" it on in a thin coat with a putty knife. Perhaps it would have bonded more strongly if I had been able to position the board so the face to which the glue was to be applied was horizontal instead of vertical and had squeezed onto it a 3/8" inch bead of material and then misted that and let it squish and spread a bit as I squeezed the two pieces together to clamp. But that would possibly have used the full 28 oz tube just to zig-zag one beadline along the 4-inch wide, eight-foot length. And would not have given me the full face-to-face bonding I got with the Gorilla Glue experiment and earlier successful Liquid Nails experiment. And would have made using Loctite for this project potentially even more expensive than using Gorilla Glue for it.

My impression is that Loctite polyurethane Premium Construction Adhesive is not a good choice for permanently attaching polyiso boards to one another. To keep my project moving forward at this point before winter sets in, I can't devote time to more tests of more materials. So I am going to go with the Liquid Nails.

Message has been deleted

ken winston caine

Oct 4, 2017, 3:46:14 PM10/4/17

to hexayurt

Have inquires out now about ordering from UK. Awaiting to hear if it can be shipped to the U.S., cost and time-frame.

Have yet to find a satisfactory adhesive other than Gorilla Glue. (Gorilla Glue takes 24 hours to cure and must be clamped all that time. Creating satisfactory clamps for the hexayurt angles and large pieces of 4" thick polyiso is proving to be beyond my skill level, I am afraid. Am getting discouraged with finding an adhesive I can work with that will do the job.

Have yet to find a satisfactory adhesive other than Gorilla Glue. (Gorilla Glue takes 24 hours to cure and must be clamped all that time. Creating satisfactory clamps for the hexayurt angles and large pieces of 4" thick polyiso is proving to be beyond my skill level, I am afraid. Am getting discouraged with finding an adhesive I can work with that will do the job.

Really like the idea of a 5-minute set time, as offered by Everbuild. Forces me to work FAST, but also allows me to hold the pieces in place, eliminating the need for clamping the angled pieces.

Discovered that my 2012 tests with asphalt emulsion were not with polyiso but with EPS. It sticks wonderfully to polystyrene. Doesn't want to stick to polyiso at all.

Had thought the Liquid Nails I cited earlier would do the job, but have found it only wants to work on perfectly smooth, perfectly straight edges and not a one of my bevels meets those criteria.

Discovered that my 2012 tests with asphalt emulsion were not with polyiso but with EPS. It sticks wonderfully to polystyrene. Doesn't want to stick to polyiso at all.

Had thought the Liquid Nails I cited earlier would do the job, but have found it only wants to work on perfectly smooth, perfectly straight edges and not a one of my bevels meets those criteria.

Hope to have heard back by tomorrow regarding whether the Everbuild Wood Adhesive PU 5-Minute Liquid can be shipped to me in the U.S. Have been waiting two days for an answer from one seller. Now am contacting home-improvement building supply stores in the UK and am awaiting their responses.

Have found that I can buy a 36-ounce size of original Gorilla Glue for $32 on Amazon. That's much more affordable than the sizes available locally. But still presents the clamping problem for me.

Cabinz Admin

Oct 4, 2017, 6:20:06 PM10/4/17

to hexayurt

Good Luck Ken,

I've found my bottle from Apollo.co.uk glue that seems the same as lumberjack or gorilla glue. On label it says "Joinery (a9331) Solvent Free Wood adhesive (1K MCPU)

Mine is 30 mins, butthey can mix it to any curing time . it's in 1 litre bottles cost approx £13 maybe 1- 1.5 yrs ago

I wondered if you have Men in SHed projects in the Usa now > for those unfamiliar with them, they are like Maker spaces, usually for men over 50, but its widened to women, veterans & youth groups, Went crazy n U k & Ireland we now have 430 groups in uk .

I did a brief talk the other week to the Uk southern region, they were very receptive to my talk & we donated 1.5 tonnes of Composite door off cuts , a lot of which they have already used.

I mentioneed hexayurts & some groups were considering building a few for a car festival event

https://www.reddit.com/r/TheRedPill/comments/2l9rov/mens_shed_in_usa_can_it_work/

menssheds.org.uk/the-dawn-of-usa-sheds/

Cabinz Donates and Arranges Delivery of 800kg of Composite Door Off cuts to Hastings & St Leonards Men in Sheds

https://cabinznet.blogspot.co.uk/2017/09/cabinz-arranges-delivery-of-800kg-of.html

https://cabinznet.blogspot.co.uk/2017/08/approx-600kg-of-composite-door-grp-roof.html

https://en.wikipedia.org/wiki/Men's_shed

I've found my bottle from Apollo.co.uk glue that seems the same as lumberjack or gorilla glue. On label it says "Joinery (a9331) Solvent Free Wood adhesive (1K MCPU)

Mine is 30 mins, butthey can mix it to any curing time . it's in 1 litre bottles cost approx £13 maybe 1- 1.5 yrs ago

I wondered if you have Men in SHed projects in the Usa now > for those unfamiliar with them, they are like Maker spaces, usually for men over 50, but its widened to women, veterans & youth groups, Went crazy n U k & Ireland we now have 430 groups in uk .

I did a brief talk the other week to the Uk southern region, they were very receptive to my talk & we donated 1.5 tonnes of Composite door off cuts , a lot of which they have already used.

I mentioneed hexayurts & some groups were considering building a few for a car festival event

https://www.reddit.com/r/TheRedPill/comments/2l9rov/mens_shed_in_usa_can_it_work/

menssheds.org.uk/the-dawn-of-usa-sheds/

Cabinz Donates and Arranges Delivery of 800kg of Composite Door Off cuts to Hastings & St Leonards Men in Sheds

https://cabinznet.blogspot.co.uk/2017/09/cabinz-arranges-delivery-of-800kg-of.html

https://cabinznet.blogspot.co.uk/2017/08/approx-600kg-of-composite-door-grp-roof.html

https://en.wikipedia.org/wiki/Men's_shed

dylan toymaker

Oct 5, 2017, 1:21:10 PM10/5/17

to hexayurt

So I wanted to offer a different idea than glue for edges...

I was a at a building conference, for a "best practices in Passive House 2.0 construction" seminar, and they were using a lot of foam board insulation on the outside of conventionally framed stick building. Their (this engineering firm who consulted on and observed several different passive house builds) preferred method to get the super high R values was to sheet the outside wall of the stick frame (2x6 generally) with 3/4 plywood, and then attach 4-12" worth of hard foam board insulation (thickness per climate requirements). they attached the board with vertical lathe and long screws - so the foam was laid out horizontally, x number of vertical strips of 1x3 or something like laid on top and screwed through to the plywood. the rigidness of the foam plus 12-16" spacing of screws made the tension triangulation strong enough that any kind of siding up to and including stucco could be hung on top of the lathe with no functional sag (measured in the .0Xmm angular deflection). corners were held by a cap long enough to get screwed into the plywood.

this creates a compression fit of all the corners, no need to deal with glues, and fast screw bonds. It requires more wood material, and then some precision corner cutting of it, but gives you a significantly stronger building.

lmk if this is clear enough of a description.

Dylan

ken winston caine

Oct 5, 2017, 1:48:23 PM10/5/17

to hexayurt

Thank you. Will email Apollo, too.

Not aware of a Men in Sheds invasion here.

...

Reply all

Reply to author

Forward

0 new messages