[Proposal] Order 2 new 3D printers for the hackerspace

226 views

Skip to first unread message

Cprossu

Mar 11, 2020, 3:44:01 PM3/11/20

to HeatSync Labs

This is a proposal to order up two new 3D printers for us to be 3D printering with. The proposal is to buy 2 3D printers not exceeding $1600 total (for both printers and needed upgrades).

Premise is both printers should be identical in case one needs to be robbed for parts to help ensure one is always working.

This proposal is open to any 3D printer make or model. If you have an opinion please put it here so everyone can evaluate it!

The following is merely my suggestion based on my own recent experience:

I would suggest they be the Creality Ender 5 as it's sort of what I've been researching, purchased, and have lived with it a while. If you have an opinion, it would be wonderful to get it.

They seem to offer an amazing amount of quality for their price, and have a Z axis similar to what the ultimaker printers use. I just don't like 3d printers that have a z axis extruder and a bed that moves forwards and backwards, don't know why!

They are currently $319 from here:

They do come with kind of a crap power supply, and although I have yet to kill mine since this thing will be abused, it makes sense to invest in a good PSU for these.

We can source the Meanwell power supplies for this for $33 or less

I'd be afraid to order these on Amazon, just because of the rampant counterfeits and generics that are sold as the real deal. There are other places (eg digikey, mouser, others) where the supply chain is at least known to be better.

Although I have not broken my extruder drive assembly, it is plastic, and the aluminum replacement is only $11 if you grab it when you get the printers...

I suggest getting a tempered glass bed for $19 as well:

Hot ends are rather cheap, so it probably would be a good idea to get a replacement while you are ordering stuff. $20 for some insurance.

They come with magnetic beds that can flip up, but I have not tried to use it. The tempered glass bed I got is warped in the center, and this seems common, but for whatever reason it does not seem to matter in my use case.

Putting official Marlin on these things is not a big issue, and here's the howto and files I used for my own printer:

Video:

Files:

The main thing was with minimal effort and minimal assembly, I was able to basically print out of the box the same night I pieced it together, which seems rare in a budget 3D printer. There seems to be a rabid community hell bent on improving this thing, and there are a lot of them out there too. I would recommend against the Ender 3 as it made some confusing design choices as to where they placed the control board, and servicing it is a bit more difficult.

So, things that are notable in my experiences, keep in mind this thing is built down to a price:

1) All things might not be tight from the factory, some fasteners may also be damaged or stripped.

2) Be sure to check all grub screws specifically on the couplets for tightness, go through the bearings and make sure they are good.

3) Make sure you align the belts not to rub on any of the aluminum extrusions

4) The tempered glass bed has a 'dip' in the middle. Reasons unknown

5) The Extrusion gear spring thing is made of plastic

6) The drivers on the stock board are rather noisy, doesn't have much storage (I'm running Marlin 1.1.9 on it) and it does not have a 32 bit processor. TH3D offers a handy snap in replacement board for $120 https://www.th3dstudio.com/product/ezboard-lite/ if that's a limiatation.

7) The belts and drives on this printer are not covered. This means while they are easy to get to if they need fixing, they are prone to dust catching and fingers getting in the way. There are some things on thingiverse to help with this, but they seem... rather clunky.

8) The Z Axis bed falls down as soon as power goes away, this is a minor annoyance, but can be rectified with a support for the X Axis threaded rod and a skateboard bearing.

9) If you want it to be enclosed, eg for printing ABS, we will have to build an enclosure/panels for it, perhaps out of acrylic.A few people have made up things, but again, they look sort of clunky.

10) It has sleeve bearing fans at 24V, I think we might be able to salvage some nicer ball bearing fans to put in it's place (eg tearapart) to replace them at no/little cost to us.

11) Some youtubers have taken the task of upgrading many components of the printer, even changing the bearings to linear ones, only to get minimal improvement on quality. From what I can see, and my own experience, there does not seem to be much to do mechanically to improve things from stock.

So if you look at getting 2 printers with 2 power supplies, 2 tempered glass beds, 2 upgraded aluminum extruder pressure thingies, 2 spare extruder assemblies, you are looking at around ballpark $810 prior to shipping/taxes. If we want to bite the bullet and grab 32 bit replacement controllers so we can run Marlin 2 out of the box and have quiet drivers, we can put that up around $1100 prior to taxes/shipping.

I will be gone from March 25th to April 1st unless the corona virus gets in the way, but I wanted to get this ball rolling.

I would love to hear everyone's input, as I know we all love 3D printers and have experiences about them that will help in deciding what we should do and what we should get.

Nate Plamondon

Mar 11, 2020, 4:02:48 PM3/11/20

to heatsy...@googlegroups.com

I strongly support replacing our printers with only two suggestions:

1) Include automatic bed levelers (ABL); never having to worry about leveling my bed has made my printing experience so much better. Every time I try to help someone with the lab's printers, the beds have been unusably maladjusted, frequently missing nuts.

2) The Ender 3 isn't vastly different in quality or features despite a lower price tag; I'm also not aware of any issues with the power supplies. For around this cost, we could get three 3s.

--

Nate Plamondon

Nate Plamondon

--

You received this message because you are subscribed to the Google Groups "HeatSync Labs" group.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/9eceb6fb-830e-4c71-aefb-193e76075797%40googlegroups.com.

Cprossu

Mar 11, 2020, 4:34:46 PM3/11/20

to HeatSync Labs

So far the complaints I have about the Ender 3 are the fact that the controller board is mounted in a way you cannot get easy access to it, the BLtouch kit is clearly an afterthought, and the fan that cools the control board is extremely poorly placed.

As far as the power supplies go, Some Ender 3's (Ender 3 Pro's) come with a meanwell power supply, but the bulk of them come with the same PSU they are using in the Ender 5, mainly the "LANDY LRS-350-24", which seem to have quality control issues.

Sometimes you get a good one, sometimes you get a bad one. If we decide to get Ender 3's I would suggest we invest in power supplies too, it's cheap insurance to have a quality power supply in something that can catch fire.

Also RE: ABL:

I helped add a BL Touch kit to a regular Ender 3 for one of our 3D print night members, and it was terrible. Installation was fiddly, parts had to be shaved to fit (the LCD splitter board did not even fit, and the enclosure would not close up), and programming was a horror show with the chinese tools and software. I don't think it was even working right when he left sad to say. I was left thinking I should have just gotten Marlin on it instead I think. https://www.creality3dofficial.com/products/creality-bl-touch I could not justify the extra $49 for something that makes the printer harder to use and work on.

The official kit was here:

To unsubscribe from this group and stop receiving emails from it, send an email to heatsy...@googlegroups.com.

Nate Plamondon

Mar 11, 2020, 5:31:10 PM3/11/20

to heatsy...@googlegroups.com

The controller isn't particularly easy to reach, but it's not exactly hard, either. They also fixed the fan placement in the newer revisions.

That's the ABL kit I got, and I had no trouble installing it or using it since; maybe you got a dud? I absolutely recommend upgrading to Marlin in the process.

--

Nate Plamondon

Nate Plamondon

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/95587ac1-1953-4a1e-803e-56c9fe007276%40googlegroups.com.

Cprossu

Mar 12, 2020, 12:23:45 AM3/12/20

to HeatSync Labs

Also, should point out that the E5 has a little more height in it's build volume (300mm vs 250mm) and everything is easily gotten to on the bottom.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/95587ac1-1953-4a1e-803e-56c9fe007276%40googlegroups.com.

Mike Wolfson

Mar 12, 2020, 9:56:01 AM3/12/20

to HeatSync Labs

I don't have a strong opinion about which printers we purchase for the lab, but I think this is a smart proposal and I support it.

-MIke

Rick Blake

Mar 12, 2020, 11:27:42 AM3/12/20

to Heatsync Labs

If this will be decided tonight, I'll be just a little late but should be there.

While I'd prefer a new Ultimaker x2, the Enders are equally recommended.

If this waits to the next HYH, I'll be sure to be there.

--

You received this message because you are subscribed to the Google Groups "HeatSync Labs" group.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/5d92ce33-be9b-4bda-b826-3b11c7b2364e%40googlegroups.com.

Nate Plamondon

Mar 12, 2020, 12:16:40 PM3/12/20

to heatsy...@googlegroups.com

It's way too late for tonight's HYH, so we'll vote on it next time.

My opinion on E3 vs E5 is not strong. I'll be happy either way.

--

Nate Plamondon

Nate Plamondon

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/CALSEc_cx5xNSa5aTVqLuxYfFKkdeEH9h4%3DdLuw7Gb_neOcS%3Dww%40mail.gmail.com.

Max Sprinkle

Mar 12, 2020, 12:30:59 PM3/12/20

to heatsy...@googlegroups.com

So, I've got an Ender3 (not pro). It was a bit of a PITA to get set up. It continues to be quirky, but less so with a few upgrades (UPtanium ABL, PrinterMods Direct Drive, Silica Glass bed) I am running Marlin and have the quiet stepper board installed as well (that's actually a really nice upgrade). I run this connected directly to my PC via USB.

It does produce nice prints in PLA+ and ABS (I primarily print in ABS) and I have not successfully gotten it to print PETG.

The ABL is, IMHO, I must-have upgrade. My resin printer is spoiling me with it's plug and print simplicity. It's just limited in build volume.

This is a good proposal, provided that we can keep them running smoothly.

~Max

On Thu, Mar 12, 2020 at 8:27 AM Rick Blake <rick...@gmail.com> wrote:

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/CALSEc_cx5xNSa5aTVqLuxYfFKkdeEH9h4%3DdLuw7Gb_neOcS%3Dww%40mail.gmail.com.

Nate Plamondon

Mar 12, 2020, 1:51:16 PM3/12/20

to heatsy...@googlegroups.com

Another thing I've been considering is putting them all on their own Octoprint server. This would allow better management and tracking, as well as eliminating the need to shuffle SD cards, all for the cost of a few RasPis. If you don't want to add that to this proposal, I'll work on that separately.

--

Nate Plamondon

Nate Plamondon

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/CAG67gx6TFhXL76xQ_pvJVESfzKUdiTVSGhRLj%2BQ9r8D6%2BxdKJg%40mail.gmail.com.

Ron Watkins

Mar 12, 2020, 2:04:14 PM3/12/20

to heatsy...@googlegroups.com

I have some spare RPI-3's if you need them.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/CAMkKC26bMGuu9mJUACVwYxRM3PFMW-Yqs8bpGaLqkpzf1X%2BK7w%40mail.gmail.com.

Ron Watkins

602.743.5272

602.743.5272

Cprossu

Mar 12, 2020, 2:39:46 PM3/12/20

to HeatSync Labs

I left quite a bit of wiggleroom in the budget, so it can be a part of the proposal. We will print the cases on the printers themselves though. and a part of my thinking of getting the 32bit micro was to improve octoprint @Nate. I noticed that the same print sent to my printer takes 20 minutes longer (2hr 15 minute print otherwise) than it would if I used the SD card.

The answer I got was due to the processing power of the basically arduino based board. Getting this thing to Marlin 2 with a fancy interface would likely help with that. We will need some t-nuts and fasteners though that the lab doesn't have. Not sure where to order those.

Thus my new proposed list of stuff would be:

Printer (proposed)

EZBoard Lite v1.2 controller replacement (proposed)

ABL (proposed)

More decent Power Supply (proposed)

Raspberry Pi 3B (not B+) with a adequate power supply - $35 + $7.50

Tempered Glass Bed (Proposed)

Extra Extruder assembly (Proposed)

https://www.creality3dofficial.com/collections/head-extruder/products/assembled-extruder - $20

T-nut kit (Proposed)

Extruder Pressure Upgrade (Aluminum)

$630 per printer prior to taxes and shipping. Seems reasonable for what it will be if we get all the cool tech parts working while having the old stuff as spares. A brand new shiny Ultimaker 2+ will run $2,499 for a comparison.Did I miss anything?

I'm not trying to go for the cheapest stuff, just want to make something

here that will hopefully stand the test of time. This will leave us

with an extra controller board, power supply, and a plastic extruder

pressure thing to use in case the fancy stuff fails too (emergency

parts!). This is all included in my long term calculation of use

Mike Wolfson

Mar 12, 2020, 3:02:17 PM3/12/20

to heatsy...@googlegroups.com

Yes, include Nate's thing so we don't need to use SD Cards!

-Mike

-Mike

On Thu, Mar 12, 2020 at 10:51 AM Nate Plamondon <nplam...@gmail.com> wrote:

You received this message because you are subscribed to a topic in the Google Groups "HeatSync Labs" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/heatsynclabs/x5iwoCGOclw/unsubscribe.

To unsubscribe from this group and all its topics, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/CAMkKC26bMGuu9mJUACVwYxRM3PFMW-Yqs8bpGaLqkpzf1X%2BK7w%40mail.gmail.com.

***************************************************************************

Mike Wolfson Phoenix, AZ, USA

Mike Wolfson Phoenix, AZ, USA

***************************************************************************

Cprossu

Mar 12, 2020, 3:18:52 PM3/12/20

to HeatSync Labs

On Thursday, March 12, 2020 at 12:02:17 PM UTC-7, Mike Wolfson wrote:

Yes, include Nate's thing so we don't need to use SD Cards!

-Mike

That's what this is for:

John Schneider

Mar 12, 2020, 3:48:12 PM3/12/20

to heatsy...@googlegroups.com

“We will need some t-nuts and fasteners though that the lab doesn't have. Not sure where to order those.”

McMaster-Carr will have all the t-nuts and fasteners you’ll ever need.

--

You received this message because you are subscribed to the Google Groups "HeatSync Labs" group.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/dd4322ec-9228-41bf-9996-14e82fe8d80c%40googlegroups.com.

Smith H.

Mar 12, 2020, 11:25:10 PM3/12/20

to HeatSync Labs

I’ve been hearing good things about the AnyCubic Chiron which has a 400x400x450 build volume. I know that’s large, and anything THAT big would likely be a multi-day print, however it would enable larger flat/long parts.

It’s likely to be my next printer.

It’s likely to be my next printer.

Cprossu

Mar 13, 2020, 3:28:49 PM3/13/20

to HeatSync Labs

Neat printer for sure. Looks like they got most of the bugs out of the last versions of it too. Having a large format 3d printer would be handy, and that one is a pretty good value. I think we may look into getting one of these at some point after the community builds around this printer and we can know what mods work/don't work and what long time ownership looks like as far as stresses go.

For now I want to replace our small scale printers. Downsides to a big printer would be a large bed comes with large bed leveling issues (more warping, fiddly to dial on), tey are good at plowing through filament, meaning a failed print could potentially use up a lot of material. A couple of large scale fail prints could make it not economical to run the 3d printing station as we have, they take up more space, and finally they could be taken up days at a time for a single print.

On the last figuring the printer price, I forgot to put 2 quality microSD cards in my proposed budgeting for the 3D printers for the octoprint pi's, so figure $20 there. We discussed one other thing last night, but I have forgotten it, my bad!

Kyle Granat

Mar 21, 2020, 8:10:04 PM3/21/20

to HeatSync Labs

Thanks Cprossu for all your hard work on this proposal. I'm totally in favor of it (though sadly I work Thursday nights so I won't be able to vote on it)

Having two of the same printers will make repairs so much easier, and help make sure at least one printer is running as much as possible.

I'd like to commit to setting up the Raspberry Pis / Octoprint and setting up what we need for the lab. I've been working on some various queuing / requesting octoprint interfaces. There are also some good LCD options for printing without a computer.

I've really love the BL touch probe for my home printer, and I'm happy to help with any install / configuration or anything else. The only weak point in my experience is the probe tip - if not taken care of they can bend. That being said, you can get them separately for about $3 a piece from the manufacturer. Also depending on the damage it is possible to bend them back.

All of that in mind, I can write up a procedure for checking the probe before printing that we ask people to follow.

On Wednesday, March 11, 2020 at 12:44:01 PM UTC-7, Cprossu wrote:

Cprossu

Mar 21, 2020, 11:05:21 PM3/21/20

to HeatSync Labs

Totally awesome! Speaking of which, I think we should move to decide how we're going to actually conduct the next HYH.

Change in my travel plans, I will actually be available on the HYH day, but due to self isolation and our current policies, probably better to try and do this sucker by remote.

I'll post something here and in slack about potential ideals.

Nate Plamondon

Mar 28, 2020, 7:22:14 PM3/28/20

to heatsy...@googlegroups.com

This proposal passed at HYH, and has been approved by the station champion.

--

Nate Plamondon

Nate Plamondon

--

You received this message because you are subscribed to the Google Groups "HeatSync Labs" group.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/bd1d9f38-98a3-474e-a9f8-15040c6baf60%40googlegroups.com.

Cprossu

May 9, 2020, 3:59:14 PM5/9/20

to HeatSync Labs

All parts except:

qty 2 TH3D EZBoard Lite V1.2

qty 2 Raspberry Pi 3 Model B

qty 2 Adafruit Pi power supplies

have been ordered.

We have been talking about getting metal heatbreaks for these too. Anyone have a favorite and cheap drop in option/opinion for ender 3/ender 5?

To unsubscribe from this group and stop receiving emails from it, send an email to heatsy...@googlegroups.com.

Nate Plamondon

May 10, 2020, 12:46:51 PM5/10/20

to heatsy...@googlegroups.com

I went with the $8 upgrade from TH3D. Needs oiling, so far, but seems to do the trick.

https://www.th3dstudio.com/product/tough-titanium-heatbreak-for-creality-machines-tough-dual-hotend/

--

Nate Plamondon

Nate Plamondon

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/1e05241b-acfa-43f6-aa11-319c65e7e090%40googlegroups.com.

Cprossu

May 10, 2020, 10:30:13 PM5/10/20

to HeatSync Labs

That looks fantastic and is a economical solution for sure.

Do you think having an oiler on it (and I guess canola oil around unless you recommend we use a different oil) would be something that would be sustainable in a lab environment?

Does this apply to all plastic filament we would be running?

When the EZBoard Lite's are back for sale, I think we'll get a couple of these, and also get a filament out sensor while we are at it.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/1e05241b-acfa-43f6-aa11-319c65e7e090%40googlegroups.com.

Jot Powers

May 11, 2020, 10:30:37 AM5/11/20

to HeatSync Labs

I think flaxseed oil is probably the best, simply based on the research for seasoning cast iron.

Cprossu

Jun 2, 2020, 7:32:07 PM6/2/20

to HeatSync Labs

Thought I would give everyone an update really quick. Dave said parts are coming in, still waiting on the printers.

In the meantime I have purchased 2 SKR Mini E3 V1.2 control boards to play with and see if they will be something we can use at the lab in case the TH3D EZBoard Lite V1.2's never ever get back in stock. They were only $28 a piece, so I didn't see how I could lose.

There was worry that they might have counterfeit components, however it seems that was an unfounded fear, all of the parts on mine looked to be high quality, and most important the part numbers did not wipe off with isopropyl alcohol.

That being said, I modified my Ender 3 Pro first, as that is what the firmware that comes with them is loaded with, and making/compiling the 32bit firmware is different from the 8bit boards they initially came with. You could just use the Arduino IDE and it had everything you needed to flash the bootloader, compile Marlin, etc. These 32 bit boards us a ST micro STM32F103RCT6 and the suggested way to compile programs for these is to use 'PlatformIO' and 'Visual Studio Code', 2 things that I do not have experience with.

Everything has been tested by others, it's just a matter of me figuring out what needs to go in platform.ini, and what code needs to be commented/uncommented for everything to work. I would rather use straight marlin from their GIT if possible instead of Big Tree Tech's github, but we shall see if I can pull it off. Then you just have to get it on a microsd card, and the microcontroller has a sd card bootloader on it that will pull the file off and get the code running on the printer...

This board uses TMC2209 stepper drivers that are soldered in place.

First thoughts: WOW HOLY COW! MY STEPPER MOTORS ARE QUIET! HOW IS THIS POSSIBLE? I CAN'T HEAR ANYTHING! OH COOL I CAN ADJUST MY Z AXIS BY .025MM STEPS!!!!!

It is mostly plug and play. The only wiring difference is that the board cooling fan (FAN 0) and the parts cooling fan (FAN 1) are swapped compared to the original board. This means you want the parts cooling fan in FAN 0 and the power supply fan plugged into FAN 1. Not a big issue. What is a big issue though is the clearances of certain board components to the mounting screws. You really have to pay attention if you don't want anything to short out. They just did not leave enough wiggle room. Looking at the changes they made to the V2 board, they clearly have figured this out. They also apparently changed some of the heater power handling parts to increase capacity and reduce heat on the control board. BTW did I mention the stepper motors are unnaturally quiet?

Once I compile vanilla Marlin to work with my Ender 3 Pro (or give up trying and just go to the Big Tree Tech fork), I will then convert my Ender 5 over to the other board I bought, use the same steps (only replacing the config files with those for a Ender 5), and it should be good to go. That is the plan.

Therefore it is of my opinion that the SKR Mini E3 V1.2, although it is a good product, is not what I want to leave at the lab. I want to make sure that control board swaps can be done easily and without thinking about it too much! If the TH3D EZBoard Lite V1.2's do not show up by the time SKR Mini E3 V2 boards are easy to get though, we'll go with the SKR Mini E3 V2 (which should resolve my initial complaint).

You can see a photo album of my experience here:

Rick Blake

Jun 2, 2020, 8:22:55 PM6/2/20

to Heatsync Labs

I've been using a Mini E3 v1.2 with my Rigidbot, and it has been terrific, the problems I have are temperature and my inexperience. I paid $49 for board and TFT24, you cannot beat that easily, and I was tired of RAMPS being so delicate. Never looking back.

If you need advice on VSC and platformio I can post my stuff. I'm not expert, but I can get it running. Make a shortcut to the 'STM32F103RC_bigtree_512K' folder where the compiled firmware.bin lands. Ctrl+Alt+B builds and compiles. Or is it compile and build? SO confusing... (:

And yes, the steppers are QUIET!

I've Attached my platformio.ini, it's fairly obvious. You may need to touch it up for your setup.

Some of the quirks:

- The 12864 emulation mode will give you a corrupted screen easily, just bed leveling can do it.

- When you're tired of the firmware reloading every time you boot, rename it to firmware.cur because somehow the renaming sequence intended to run after a load doesn't... It will reload that firmware forever. Or do as I learned, change the extension to the date, just in case you need a running config to revert to. Saves 30 seconds on some setups.

- Static discharge when touching display the will freeze or reboot the display. Most of the time the printer will keep on printing. Static to the printer frame will reboot it often...

- I have no desire to let git ruin my setup, and did not integrate it beyond the minimum. Ugh.

- It is a trick to get the SD card reader on the display to work.

- And like all Marlin stuff, it seems you can indeed format a microSD card in a way that it cannot be read. I have no idea how.

- I would not hesitate to build these for the lab, my experience with the board has been great. I think ferrite cores on the display cables and grounding would be good, and I could experiment with mine to determine how to ground - I have a static-rich environment.

- And I will be moving up to Marlin 2.0.5.3 mainline soon. Let you know how bad it is.

--

You received this message because you are subscribed to the Google Groups "HeatSync Labs" group.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/e2880287-f704-4955-8d95-3ccf30fda6fd%40googlegroups.com.

Cprossu

Jun 2, 2020, 9:04:35 PM6/2/20

to HeatSync Labs

Thank you for your input! I was thinking of maybe going for those snazzy TFT screens, but for now we're going with the old school displays that come with the Ender 5's. I'm still going for functionality over sparklies for the time being.

Although I think you can use those touchscreens or the one with the knob with the EZBoard lite's, it's not exactly a supported config just yet.

I guess I'll let the community do some more beta testing and see if anyone comes out with something different. My understanding is those TFT color screens contain their own microcontroller, own system, and just interface to the control board the same way a computer/raspberry pi would. I've decided that I'll probably use the Raspberry pi we're pairing with each unit to provide that in the future though.

It's sure been a lot of work you've put into that Rigidbot, I am very happy to see that thing finally getting there! I learned a lot of lessons from your printer that I have taken extremely seriously when helping others with their printers, when I got my printers, and most recently in making the determinations on what I wanted to see the hackerspace get and modify.

Rick Blake

Jun 2, 2020, 9:23:42 PM6/2/20

to Heatsync Labs

Well Octo is a good solution for touch menus I think. The 12864 mode works fine with the 1.2, touch doesn't give me anything I need.

I've been tuning the RB and may have discovered it needs about 120% feedrate. Who knew. PETG is beautiful but very finicky. Now to get right piece of glass and get the inductive probe working... But thanks. I think it's good to be an object lesson on how not to... Huh...

--

You received this message because you are subscribed to the Google Groups "HeatSync Labs" group.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/e95ff284-f06e-4b15-a189-7161cfac373a%40googlegroups.com.

Cprossu

Jun 2, 2020, 9:40:05 PM6/2/20

to HeatSync Labs

Thanks to everyone that came in with broken 3D printers at heatsync, strange tales of woah, and trying to just keep our own printers printing, I ended up having cold feet getting my very own printer for a good 4 years. It was not until I really started understanding what I was looking at until I stopped running away from them and started trying to approach them logically.

Certainly we are not yet to a point I can drop off a 3D printer to someone, give them a few instructions, and expect them not to run into any sort of issue. These things are still just as much of an art as they are a science. We're to the point a lot more is standardized, materials are getting better, and a lot of faulty or complicated methods have fallen to the wayside. I will say with PETG, as little as 3C, playing with travel speeds, or really paying attention wherever there is a travel can make all the difference between extreme failure and amazing results. Slicer settings are starting to matter to me more than the printer itself.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsy...@googlegroups.com.

Rick Blake

Jun 2, 2020, 10:24:04 PM6/2/20

to Heatsync Labs

Yup. I dialed down 1st layer travel to 20mm/s. Both the BTT and RB communities gave me a lot of useful, conflicting advice. Sprayed the glass. This is such great stuff, is you ask the right question you get every possible answer...

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/0b59fa7a-93c3-492d-8a13-d8f0612988db%40googlegroups.com.

Cprossu

Jun 2, 2020, 11:55:55 PM6/2/20

to HeatSync Labs

I am still having a tough time believing this is the same printer mechanically.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/0b59fa7a-93c3-492d-8a13-d8f0612988db%40googlegroups.com.

Rick Blake

Jun 2, 2020, 11:57:26 PM6/2/20

to Heatsync Labs

Those drivers are amazing.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/934fb2c9-6c18-41f4-87e8-9d6db5ead90e%40googlegroups.com.

Cprossu

Jun 4, 2020, 2:45:51 PM6/4/20

to HeatSync Labs

Good news! The Th3d boards I wanted to use got back in stock, Dave has ordered both of them!

We also got Filament Sensors too with them. I am going to hold out on the titanium heatbreak for now. I think I've already bit off as much as I can chew!

Happy times!

Those drivers are amazing.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/934fb2c9-6c18-41f4-87e8-9d6db5ead90e%40googlegroups.com.

Rick Blake

Jun 9, 2020, 5:05:53 PM6/9/20

to Heatsync Labs

CPro, did you get your Marlin squared away?

On another topic, I want to donate some fresh filament for the new printers. What's the preferred brand? Preference for ABS/PLA/PETG/others?

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/78e59b1f-23e7-448c-9a1c-8ef0c008771do%40googlegroups.com.

Cprossu

Jun 10, 2020, 6:10:46 PM6/10/20

to HeatSync Labs

I don't have to get marlin squared away now, since we've got the original boards I wanted coming in. I will just use the Big Tree Tech branch for my own printers, and I can go through the code myself and decide if I am comfy with it. When it comes to the lab printer, I wanted straight marlin though, or some firmware that had outside support (not inside china though). We will be using the TH3D official firmware on the printers, and hopefully it shall serve us well. I've heard great things about it.

Want to say Hatchbox seems to be nice. I've had stupid good luck with eSUN, but who knows. We'll surely hear from others. Before you donate filament, we need a solution to keep it dry. The current filament storage area is underneath an ongoing water leak (after it storms).

Got any ideas for a dry storage solution? Thinking a plastic box with descendant right now. We will need a few humidity/temp sensors to put in the box, unless we want to do something super awesome with a micro and have it logged or shown on a lcd... This really needs it's own topic, I might do that now.

1.75mm of course, if buying PETG avoid clear. Glow in the dark filament eats brass nozzles even though it's fun.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/78e59b1f-23e7-448c-9a1c-8ef0c008771do%40googlegroups.com.

Cprossu

Jun 14, 2020, 9:13:24 AM6/14/20

to HeatSync Labs

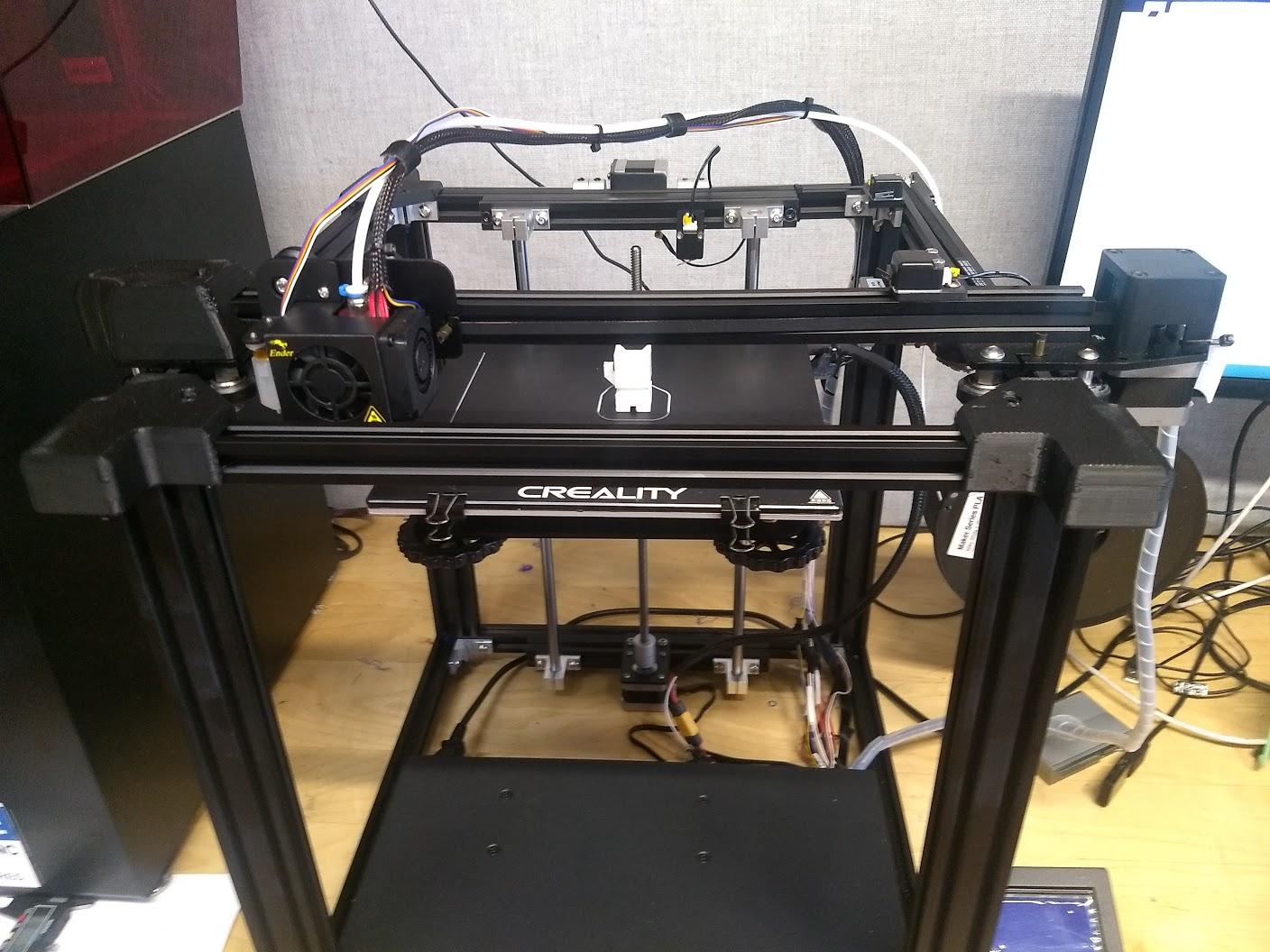

Printer number 1 is built, missing BLTouch, and I have not yet installed the filament sensor.

Don't have it 100% yet, something is up with the z axis/printbed (think a part is bent or warped, so I had to compensate pretty heavily), but it IS FUNCTIONAL! If you have a moment, go try to print things and see how it gets on! Oh also the glass printbed has a dip in the middle I will need to fix using some aluminum foil as a shim. Will do that next time I am there, but it should be workable for now. I have not checked the whole bed to see if it's sticking down, but the center should be a good bet.

You should not need to use hairspray or gluestick on the bed.

Always allow things to cool down and things should pop off the bed. If

things do not stick to the bed, first cool the bed down and clean it off

with filtered water, if you see residue on the bed, use isopropyl

alcohol on the bed. If you should require gluestick or hairspray, flip

the bed over and use the smooth side (never put any gluestick or

hairspray on the side that has the special textured surface on it.)

Cprossu

Jun 19, 2020, 9:06:52 PM6/19/20

to HeatSync Labs

Here is my build log for that printer.

Cprossu

Jul 3, 2020, 6:58:12 PM7/3/20

to HeatSync Labs

It has been nearly 4 months since this proposal was written, and Raspberry Pi 3B's are still not in stock.

The good news is much work was done getting Octoprint to function properly (even Wi-Fi!) on the Raspberry Pi 4 since I last did my research. Most of the growing pains have seemed to subside. It's still a consensus that the Pi 4 gets hotter and uses more power than a 3B would in the same application, however I think that's not a huge consideration for us.

Would everyone be okay if we substituted the Pi 4 2GB in place of the Pi 3B 1GB's and the power supplies to USB-C ones?

So instead of:

qty 2 https://www.adafruit.com/product/3055 Raspberry Pi 3 - Model B 1GB $35

qty 2 https://www.adafruit.com/product/1995 5V 2.5A Switching Power Supply with 20AWG MicroUSB Cable $7.50We get:

qty 2 https://www.adafruit.com/product/4292 Raspberry Pi 4 2GB $35

qty 2 https://www.adafruit.com/product/4298 Official Raspberry Pi Power Supply 5.1V 3A with USB C $7.50

We've been debating exactly how to handle the web-cam-age on the printers. I'm not too impressed with Logitech c270 cameras at all in my house, however I figure we can go USB webcam or we can also go with one of the Pi camera modules and get a long extension ribbon to connect to it depending on where we decide to put it. Anyone have a preference?

Rick Blake

Jul 3, 2020, 7:14:47 PM7/3/20

to Heatsync Labs

I was hoping you'd go for the Pi 4. But 2GB ought to be a minimum. Trust me. 4GB might be more than is justified.

--

You received this message because you are subscribed to the Google Groups "HeatSync Labs" group.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/75595881-1829-406b-9b1f-685dd329b190o%40googlegroups.com.

Message has been deleted

Cprossu

Jul 3, 2020, 7:33:10 PM7/3/20

to HeatSync Labs

The 2GB Pi 4 is already twice the ram we were going to get with the 3B

at the same price, and the 4GB Pi 4 is a $20 bump in price from the

original plan per printer. The 1GB one should be more than enough

considering each printer gets one to itself theoretically, and going with the 1gb one would save a bit on

power too, however I think it is worth it to have the 2GB one instead

of the 1GB one so we can do more with it. Not sure why we would spend $110 here when we were

originally spending $70 originally for both machines in terms of Rpi's.

Rick Blake

Jul 3, 2020, 7:35:03 PM7/3/20

to Heatsync Labs

I didn't mean to recommend the 4G.

On Fri, Jul 3, 2020, 4:33 PM Cprossu <cpr...@gmail.com> wrote:

The 2GB Pi 4 is already twice the ram we were going to get with the 3B at the same price, and the 4GB Pi 4 is a $20 bump in price from the original plan per printer. The 1GB one should be more than enough considering each printer gets one to itself theoretically, and going with the 1gb one would save a bit on power too, however I think it is worth it to have the 2GB one instead of the 1GB one so we can do more with it. Not sure why we would spend $110 here when we were originally spending $70 originally for both machines in terms of Rpi's.

--

You received this message because you are subscribed to the Google Groups "HeatSync Labs" group.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/590eda61-1753-48ff-aac6-6798e9b08609o%40googlegroups.com.

Cprossu

Jul 3, 2020, 7:39:17 PM7/3/20

to HeatSync Labs

Fair enough. I was busy debating if we should go with the 1GB one vs the 2GB one (for power/thermal considerations hehehe)

On Friday, July 3, 2020 at 4:35:03 PM UTC-7, Rick Blake wrote:

I didn't mean to recommend the 4G.

On Fri, Jul 3, 2020, 4:33 PM Cprossu <cpr...@gmail.com> wrote:

The 2GB Pi 4 is already twice the ram we were going to get with the 3B at the same price, and the 4GB Pi 4 is a $20 bump in price from the original plan per printer. The 1GB one should be more than enough considering each printer gets one to itself theoretically, and going with the 1gb one would save a bit on power too, however I think it is worth it to have the 2GB one instead of the 1GB one so we can do more with it. Not sure why we would spend $110 here when we were originally spending $70 originally for both machines in terms of Rpi's.--

You received this message because you are subscribed to the Google Groups "HeatSync Labs" group.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsy...@googlegroups.com.

Rick Blake

Jul 3, 2020, 7:40:42 PM7/3/20

to Heatsync Labs

They call them 'fans'. Minimal power demands, reasonably simple to implement.

😁

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/4b8b1085-4530-4744-b86b-d91ae70877ado%40googlegroups.com.

Cprossu

Jul 13, 2020, 12:44:43 PM7/13/20

to HeatSync Labs

Quick update, both bed levelers in transit, and the second printer will be shipping soon. Yay.

Cprossu

Aug 15, 2020, 10:15:09 PM8/15/20

to HeatSync Labs

UPDATE:

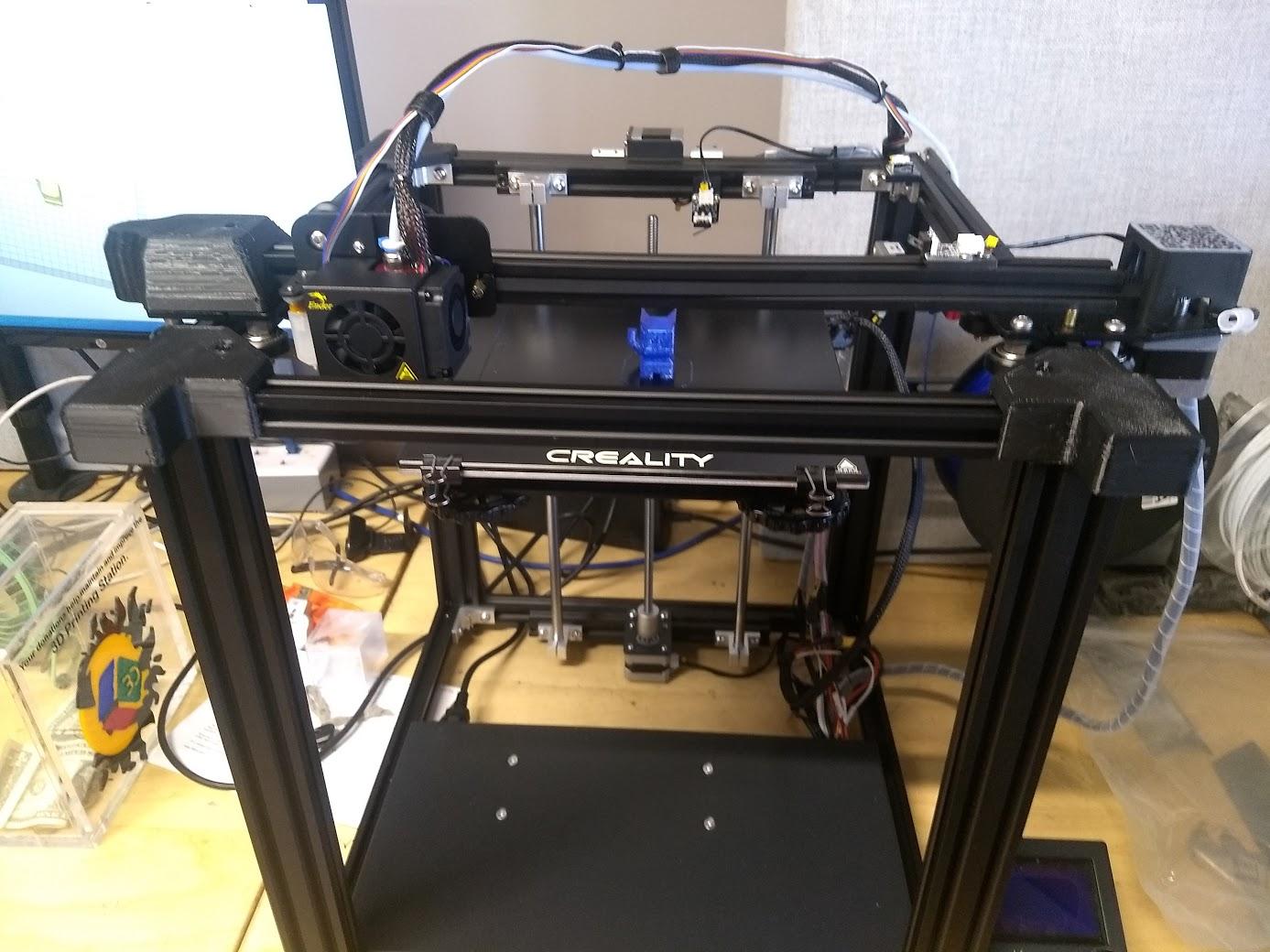

Both Ender 5 printers are built now, and both have automatic bed leveling too!

We've got Raspberry Pi 4's to make into octoprint units, and we have yet to decide if we're going for Raspberry Pi camera modules for them, or webcams.

Cases need to be figured out an printed, and both units are now up to the task of doing just that (yay!)

I have put the choocher away for the moment, I did not have the energy to try and improve it, and I quickly realized replacing that teflon spacer thing in the ultimaker 2 looks almost as complicated as building an entire ender 5 up, so I decided to leave before the bottom of the lab hit triple digits, and before the sun went down.

Again, a reminder, if you must use hairspray or glue (you shouldn't)

use only the smooth side (flip the glass over to the side that doesn't say creality), and clean up after yourself when you are done.

Thankfully it seems that with elbow grease the nasty stuff comes off, but you should not need any additional stuff on the bed for it to adhere if the settings are right, and it should be even way easier now with the auto bed leveler.

You can print to either Ender 5 printer from the profile in cura for the Ender 5. It has been modified to include the G 29 command under the machine options (After the G28 command).

If you are using your own computer or slicer, make sure you update your profile to put in a G29 command after it homes, so it then uses the auto bed leveler!! If you don't all that snazzy tech will be ignored, and you best hope the bed is leveled well enough manually. I have to say, this is getting addicting, this is the 3rd Ender 5 printer I've built that had the very first print come out and not fail in any way.

So, the only 'sticking' point is the Z axis on both printers squeaks particularly when they move up a small amount. I've tried many home remedies and voodoo rituals to remove this behavior, but nothing I've done has eliminated the noise all the way, and it keeps coming back. This is due to the fact they changed the leadscrew pitch compared to the one I have at home. They doubled the density, which is a good thing for accuracy and also a good thing because after the print is done, the bed doesn't fall down under it's own weight..

Due to this, I am thinking the printers will be likely named "SqueakZ 1 and SqueakZ 2" if I can't get them to stop their disruptive behaviors.

Mike Wolfson

Aug 17, 2020, 1:41:45 PM8/17/20

to HeatSync Labs

This is super awesome, so excited to see the new printers in the space...I volunteer help write simple documentation about how to print with them.

Ie. I will help write the FAQ.

-M

-M

Message has been deleted

Cprossu

Aug 17, 2020, 5:29:34 PM8/17/20

to HeatSync Labs

I'd love help with it @ Mike! I have PM'ed you details of the google doc

I started working on a few months ago for that purpose inside of slack. Not enough to

share publicly just yet, and I don't really know how I want it to go

other than being able to be printed in a 3 ring binder and provide a

sort of log of what's been done to the printer and how to use it. Object

will be to include a thumb drive or two with all the files (manual

included) just in case the cloud fails.

Cprossu

May 30, 2021, 12:48:36 AM5/30/21

to HeatSync Labs

Whoops, totally forgot about this. Wonder what I sent out! Well we've got some pretty cool documentation we've been working on

Antonio's worked his butt off giving us this wonderful document which covers an astounding amount:

I walked a new member through setting up the slicer for our printers, and decided it was good enough to try and archive/save, and this presentation is the result:

https://docs.google.com/presentation/d/1hIzNXnzyKcZ72FZfIjRNc_31ttX5xweDO2w8Z8ogAhk/edit?usp=sharing

Just want to add that these printers are nearing a year old now.

In my opinion this experiment has been a huge success! There is a much larger community for these printers too now so there's a wealth of cheap upgrades that didn't exist when we built them. Nearly all of these are bolt on and easy to add too!

Just want to add that these printers are nearing a year old now.

In my opinion this experiment has been a huge success! There is a much larger community for these printers too now so there's a wealth of cheap upgrades that didn't exist when we built them. Nearly all of these are bolt on and easy to add too!

Rafael

May 30, 2021, 12:59:27 AM5/30/21

to heatsy...@googlegroups.com

Thank you both, this seems very nice and neat documentation for introductory and reference purposes.

Appreciate it.

--

You received this message because you are subscribed to the Google Groups "HeatSync Labs" group.

To unsubscribe from this group and stop receiving emails from it, send an email to heatsynclabs...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/heatsynclabs/7e863222-1f7e-438a-8e92-a66a26c2da3en%40googlegroups.com.

Rafael Karosuo

Ing. Computación

Ing. Computación

Reply all

Reply to author

Forward

0 new messages