GTV rocker box repair?

SED Sci

Jerome Kimberlin

It really depends on how much wear and what it looks like. A permanent

fix would be to remove the bronzes and bore the whole thing, then make

new bronzes. If you mill the mating surfaces very much, then the ends

where the seals are would be oval and would have to be machined.

Neither of these fixes are very easy.

What I might do is to coat the surfaces where the bronzes sit with

Moglice, JB Weld or Devcon then put some glassine weighing paper between

the lid and bronze and clamp the whole thing back together for 24 hrs or

so. You can clean off the unwanted epoxy after you take it apart.

JerryK

SED Sci

Jerome Kimberlin

You know that aluminum oxidizes almost immediately after it is cleaned?

If you are going to use some sort of epoxy, the surface has to be wire

brushed with a stainless brush right after cleaning and within about 30

seconds after wire brushing. Think TIG welding procedures.

I have 'fixed' a couple rocker boxes by making new bronzes. The

aftermarket bronzes are sometimes OK, sometimes useless as far as size

goes, so I never used them. So I can't think of any good way to do a

repair in another way. I have also done away with the felts on the

rocker boxes and replaced them with rubber seals which don't leak.

Cheers,

JerryK

SED Sci

SED Sci

SED Sci

John O Regan

--

You received this message because you are subscribed to the Google Groups "Guzzi Singles" group.

To unsubscribe from this group and stop receiving emails from it, send an email to guzzi-single...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/guzzi-singles/451d8a27-ec2b-411c-ab76-4202a52cf834n%40googlegroups.com.

SED Sci

Rick Yamane

If I’m understanding correctly what is happening, the only real way to fix it would be to have the cover welded up and reworked to the best possible appearance of the original. Unfortunately using an epoxy may preclude the welding because once you contaminate the aluminum with the epoxy, it is near impossible to get clean enough again to weld. Possibly the new bushes can be made up and pinned to the head and/or cover.

From: guzzi-...@googlegroups.com [mailto:guzzi-...@googlegroups.com]

On Behalf Of SED Sci

Sent: Thursday, July 01, 2021 3:57 PM

To: Guzzi Singles

Subject: Re: [guzzi-singles] GTV rocker box repair?

Hi John, Yes it is totally insufficient - not even any locating pins. I've seen 2 rockerboxes worn this way.

I used JBWeld which has a good reputation, but their may be better stuff on the market. The JBWeld failed after a few hundred miles. If had your skills and a mill I would do what you and Jerry suggest, but even then I have no confidence that thermal expansion of the aluminum rockerbox would immediately allow the upper bushing to start worming its way into the aluminum again. That's why I tried this crazy bodge. Let's hope it works.

On Thursday, July 1, 2021 at 2:47:37 PM UTC-7 John O Regan wrote:

Hi All

I have not opened the rocker box on my GTW but happily I cannot feel any play in the bushes

As the rest of the Guzzi is built like a brick outhouse I am more than surprised at the rocker arrangement shown

in the photos

To my way of thinking the area that is supported in the castings is insufficient ??

If I was to go about such a repair I would machine the alloy rocker box to remove any wear / ovality

Then make full length full size split bushes to fit the re machined housing

I am assuming the epoxy repairs involve filling the area around the bushes and then clamping the rocker box halves together?

If a suitable metal loaded epoxy was used I am a bit surprised that it failed as those epoxies can be effective ???

John

On Thu, Jul 1, 2021 at 8:04 PM SED Sci <doa...@gmail.com> wrote:

Jerry's advice is very helpful, but I don't have a mill and don't have a way to make oversized bushings, so decided to lateral.

The problem is the top half of the bushing carries the load, but is not attached to anything. If the upper bushing could be secured to the lower bushing then the problem would be solved. Maybe this will work?

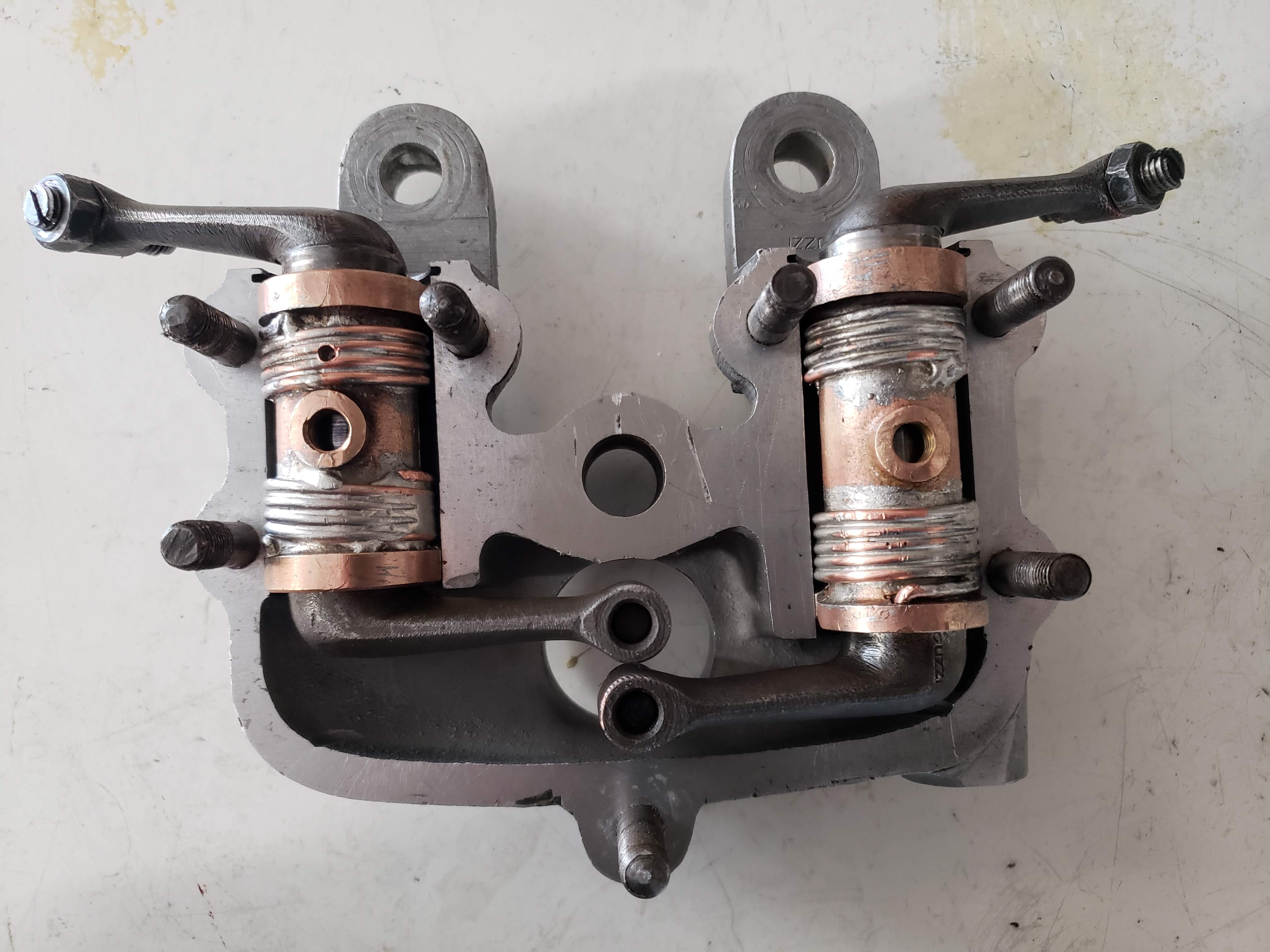

I tinned the bushings.

Drilled small anchor holes in the bushings and wrapped them with copper wire and soldered the wire to the bushings.

The cover was sanded down on a flat plate to take up more clearance until there was a slight spring fit. The ends of the bushings were then sealed with RTV silicone.

Wish me luck!

On Tuesday, June 29, 2021 at 9:45:47 PM UTC-7 SED Sci wrote:

Here are some pictures of the problem. The bushing is split in the same plane as the rocker box.

The lower bushing is held in the lower half of the rocker box by a bolt. The top half of the bushing carries the load from the pushrod and valve spring, but is only held by the curvature of the aluminum cover. The top bushing is free to squirm against the aluminum cover - there are no bolts or locating pins. The upper bushing wears into the rocker box cover resulting in lots of noise and oil leaks.

To view this discussion on the web visit https://groups.google.com/d/msgid/guzzi-singles/13cbfd92-72d2-475b-b550-64e2b9741831n%40googlegroups.com.