Inlet pressure loss

32 views

Skip to first unread message

Matteo Pachera

Nov 22, 2021, 9:59:51 AM11/22/21

to FDS and Smokeview Discussions

Hi,

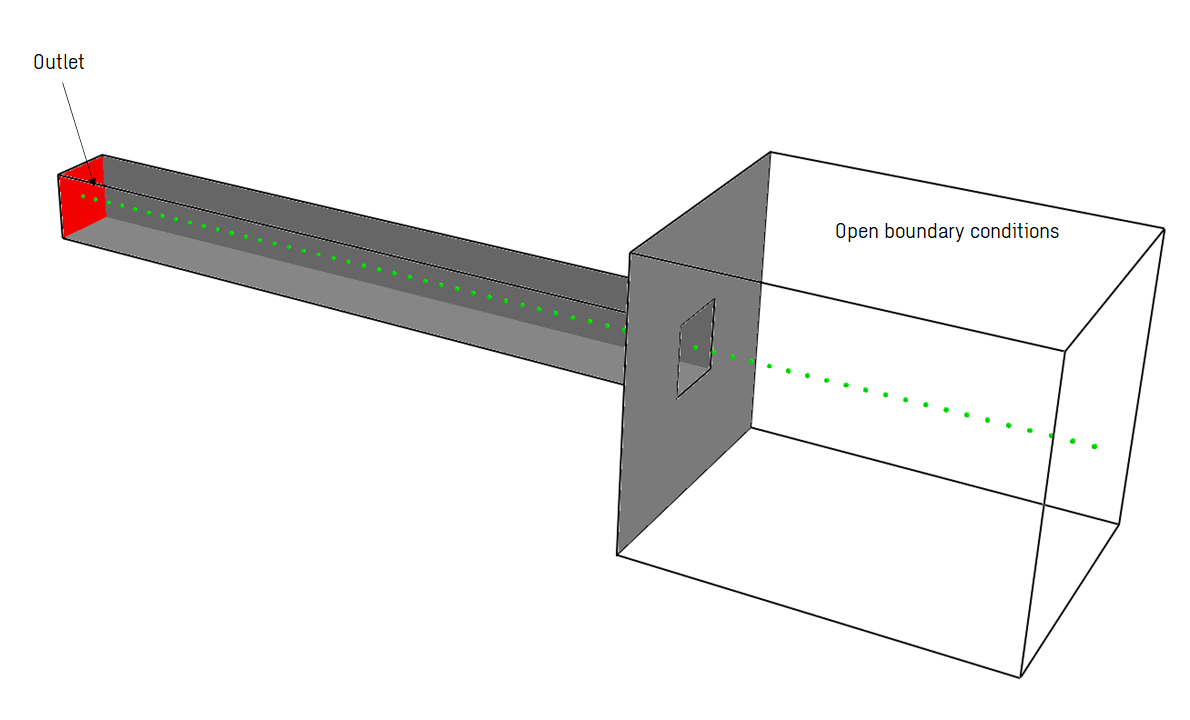

I created a simple FDS model of an inlet to check the pressure distribution with different mesh resolutions, but I got some unexpected results.

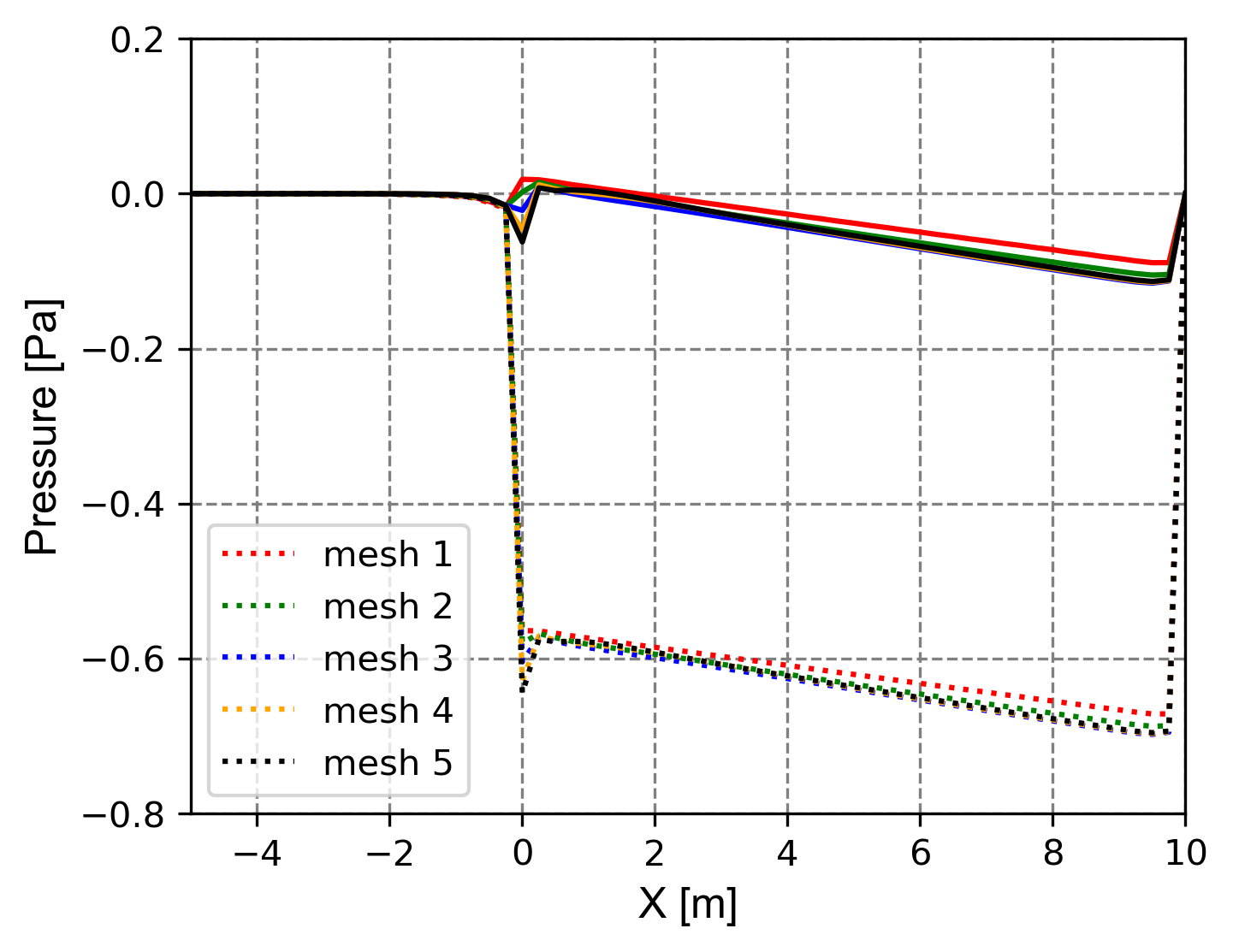

I placed an extractor (1m/s) at the end of the duct and I monitored the pressure. I expected a total pressure drop of about 0.3 Pa at the contraction section assuming that the loss coefficient is 0.5. However, when I plot the static and the total pressure distribution along the duct and in the open zone I saw that the total pressure remains almost unchanged.

I obtained these results using different mesh resolutions:

mesh 1: 4 elements across the duct

mesh 2: 8 elements across the duct

mesh 3: 16 elements across the duct

mesh 4: 32 elements across the duct

mesh 5: 48 elements across the duct

However, I don't see many differences in the outcome of the simulation.

In attachment there is an input file, I tried to use the same set up as in the validation case Backward_Facing_Step.

Now I don't know if I'm missing something in my input file, in the refinement level of the mesh or in the physics behind the case.

Thanks in advance for any feedback.

Matteo

P.S. I tried also to reverse the flow modelling an outlet and I then get a loss coefficient of 1.

Kevin McGrattan

Nov 22, 2021, 10:04:19 AM11/22/21

to fds...@googlegroups.com

Start an issue on the Issue Tracker.

Matteo Pachera

Nov 22, 2021, 10:32:12 AM11/22/21

to FDS and Smokeview Discussions

Thank you Kevin, I will submit an issue.

Reply all

Reply to author

Forward

0 new messages