busbars aluminium or copper?

149 views

Skip to first unread message

Steve Marotta

Jul 20, 2021, 12:13:34 AM7/20/21

to electrodacus

Hi All,

Anyone used aluminium busbar's?

I have been looking to make my own with the same ampacity aluminium being more than 1/2 of the price here in Australia.

20 x 10 copper 4m $130

30 x 10 copper 4m $200

25 x 10 alu 4m $58.17

I need max 200A current draw, looking at the ampacity charts on the web that I could find I believe the above seems suitable. Any input on the sizing would be appreciated.

It appears that my battery terminals may be Alu as well see below;

Also what are the thoughts around a product like Noalox being added to prevent corrosion, should this be applied to the interface between the terminals or not?

Thanks all.

Dacian Todea

Jul 20, 2021, 12:30:23 PM7/20/21

to electrodacus

Steve,

I will likely be using aluminium lugs (they are Sn plated so no oxidation problem) then use short pieces of flexible wires https://www.newark.com/thomas-betts/adr21/terminal-mechanical-lug-5-8in/dp/73H6590 this for example can accept up to 2/0 AWG wire that is about 67mm^2 so should be more than good for 200A and it has M6 hole to connect to the cell terminal. They are also fairly inexpensive under $2 each.

B0bD

Jul 20, 2021, 4:51:23 PM7/20/21

to electrodacus

After quite a bit of thinking and research, I used aluminum baubars in my 3P8S 840 AH build.

Couple of things, though - it is a stationary application, and I decided to not compress the cells.

Accordingly, the need for flexibility is gone - I spaced the cells so that the busbars won't ever see any stress.

Your cell terminals are definitely aluminum.

I posted some of the details on the DIY forum: https://diysolarforum.com/threads/3p8s-840-ah-build.24602/

I think NoAlOx is a good idea - I cleaned both the terminal and the busbar with a flap wheel and NoAlOx, wiped it off to get rid of any grit, then wiped on a fresh coat od the goop.

My objective was to have some squeeze out to provide a seal around the busbar-terminal joint to prevent air ingress.

Size-wise, this is a pretty good chart. https://www.aflglobal.com/productlist/Product-Lines/Conductor-Accessories/Aluminum-rectangular-bar/doc/Aluminum-Ractangular-Bus-Bar-Current-Rating.aspx

It uses 6101, which is hard to find. I used 6061, which has 1/3 higher resistivity, but at 200A, 1/4 x 1 would do - although you should have that area at the bolt hole.

BTW, I annealed the 6061 to soften it to provide a better opportunity for the busbar and the terminal to conform.

Steve Marotta

Jul 23, 2021, 2:07:01 AM7/23/21

to electrodacus

Thats a great idea Dacian,

I think I will use those for the final + and - Terminals.

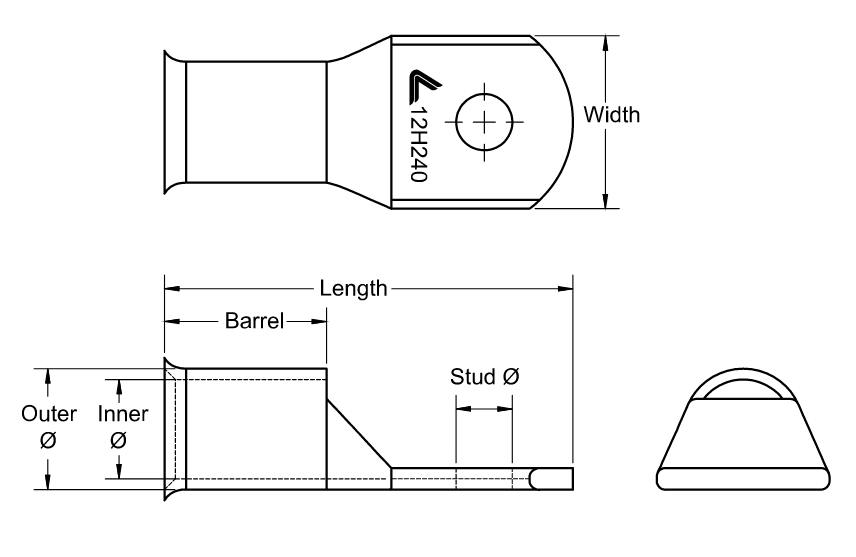

For the interconnects between batteries what are your thoughts on something like the below?

I already have a hydraulic crimper

Appreciate your thoughts.

Dacian Todea

Jul 23, 2021, 11:43:03 AM7/23/21

to electrodacus

Yes crimped connection will also work. Usually those are made of copper so may be more expensive than aluminium lugs plus you need a quality hydraulic crimper thus I did not mentioned that option.

Reply all

Reply to author

Forward

0 new messages