Primastic aluminum cased LFP cells - do they require compression?

2,443 views

Skip to first unread message

Barry Timm

Jun 22, 2021, 10:59:57 PM6/22/21

to electrodacus

I have a 8s2p pack of 150ah LFP cells. They are configured into two vertical columns of 8 cells laid on their sides, one on top of another (8 high). Each cell is stuck with VHB tape to the cell above and below, in each column of 8 cells.

I also have the two vertical groups of cells clamped down with threaded rod to the cabinet floor, as this is in a bouncing RV.

But....I would say that the thread rod force compressing the cells is fairly mild. Certainly, I did not know or intend to "compress" the cells for any reason other than to stop them falling over in the cabinet!

It is only very recently that I'm hearing about a need to "compress" prismatic cells!

How important is this, and what kind of torque/force needs to be applied for this compression?

I may simply be able to reinforce the aluminum angle pieces that the threaded rods are clamping down, and apply more torque to the threaded rods.....if this is important to do?

Thoughts?

Dacian Todea

Jun 22, 2021, 11:38:48 PM6/22/21

to electrodacus

Barry,

Except for cylindrical cells all other type of cells require compression. So yes the prismatic cell either in plastic case or aluminium case requires compresion.

That orientation if I understand correctly is the worst possible and not recommended.

You can have the terminals facing up or layed down on the narrow side but not on the wide side as the top layers will be starved of electrolyte and there is no capillary action to help like in the other two orientations.

Barry Timm

Jun 24, 2021, 3:06:26 AM6/24/21

to electrodacus

Wow, thank you. I did not know this (obviously). I watched a supposedly knowledgable guy on Youtube assemble prismatic cells with tape only. Zero compression!

I will work to re-orient the cells as you suggest, and add compression. Do they need compression only across the wide side of the cells, or in both wide and narrow directions?

Thanks again!

Peter

Jun 24, 2021, 7:18:41 AM6/24/21

to electrodacus

Barry,

Considering EVE prismatic cells (I presume yours are similar) I like this video from Off-Grid Garage, it quite represents my current opinion: https://www.youtube.com/watch?v=FdDy8b5x7Y8

(I don't know other prismatic cell types.)

With these it's not wrong to go without compression but you can probably expect lower battery life. Which should still be quite huge.

I think if you go without compression you need to handle the problem with busbars - they should not have any tensions. Some kind of spacers between cells could be the way.

Dne čtvrtek 24. června 2021 v 9:06:26 UTC+2 uživatel Barry Timm napsal:

Barry Timm

Jun 24, 2021, 2:47:43 PM6/24/21

to electrodacus

Thanks, Peter!

While I don't have the EVE cells (mine of the 150ah cells from vendor BLS on Aliexpress), using that approx 12 psi compression force mentioned in the video, I calculate that I need to apply roughly 1000 lbs of force on my cells when they are oriented with two next to each other.

Regarding the discussion on the potential need for springs to exert the compression due to the swelling and contraction of the cells when charged vs discharged, I think this seems logically the right approach, provided the correct spring rates are used and the force is applied evenly.

I found some short, 1" springs that have a linear rate of 500lbs/in. for less than $5 each.

I may then plan to install 4 of them and compress the springs 0.5 inch, using a thick aluminum plate to spread the load on both sides of the cell pack, over the entire area. I'd use 6 x threaded rods to exert the spring compression. The springs would act upon a 3rd plate that actually compresses the one side of the cells against the static side at the other end. I will use short bolts to "contain" the springs in case any of them slip as that could cause some serious injury, I think!

Thoughts?

Dacian Todea

Jun 24, 2021, 3:08:02 PM6/24/21

to electrodacus

Barry and Peter,

.jpg?part=0.1&view=1)

Obviously cells will work even without any compression but cycle life is dramatically reduced by a factor of at least 2 or 3x

Compression is need only on the wide side of the cells. to keep the cathode and anode tightly packed.

Bellow is a open Winston LiFePO4 cell but the construction on those CATL,EVE,Lishen ... cells is the same.

.jpg?part=0.1&view=1)

The A123 System puch cell that I have are also a similar construction and they are also compressed.

There was a design document for the A123 System cells but it seems links always disappear over time so I just uploaded the document on my website see https://electrodacus.com/battery/A123_AMP20_battery_Design_guide.pdf

Check page 32 for compression vs cycle life graph where you see 3000 cycles with no compression to 20000 cycles at 12psi but anything between 5psi and 15psi will be great and at least a 3x improvement in cycle life.

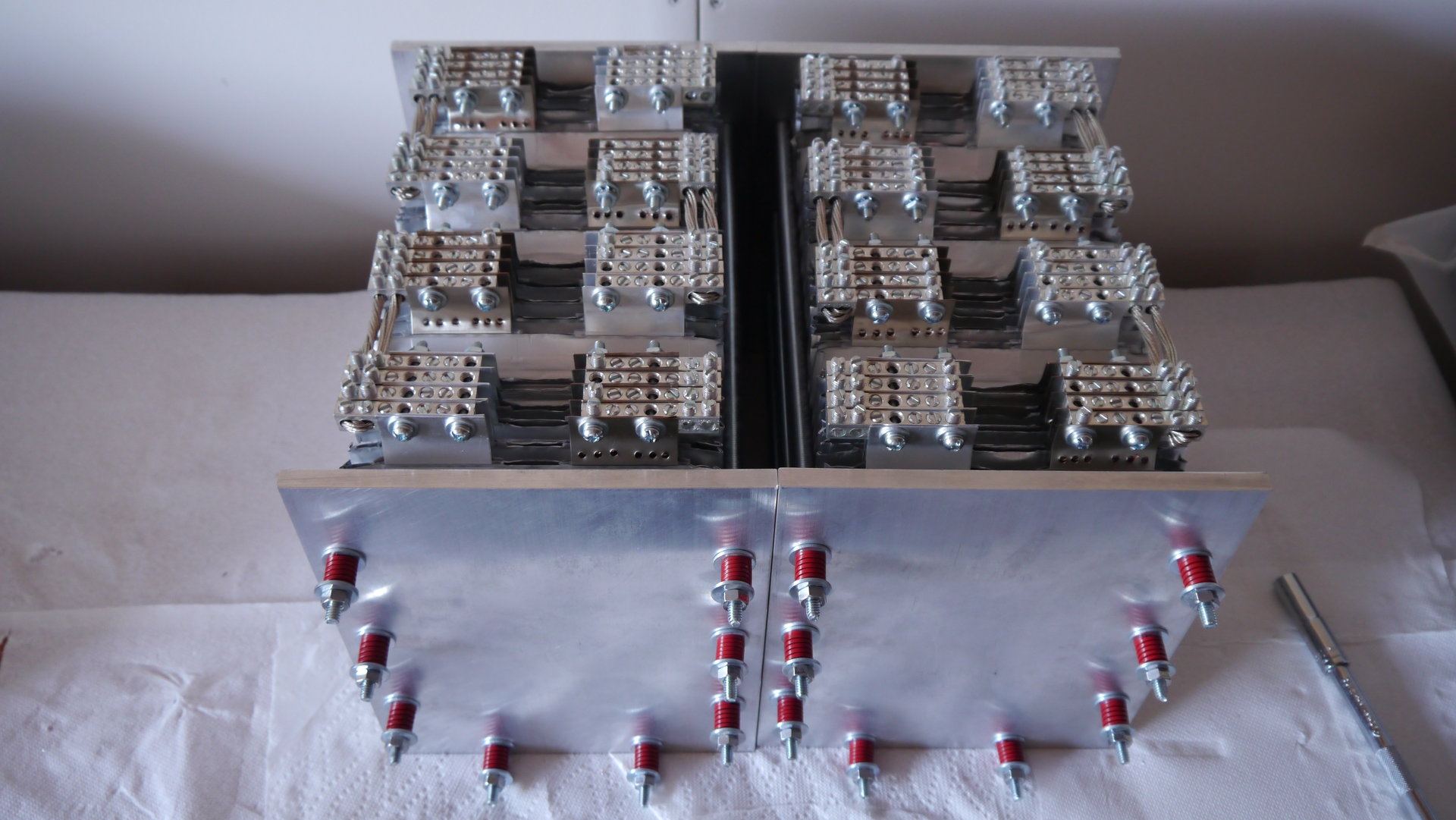

Notice I used 8 springs for my battery and thick 1cm aluminium plates to keep compression as uniform as possible. There is a clear plastic tubing on the threaded rods to electrically isolate them in case they touch cells. You may also want to use some insulated padding some sort of silicone between cells for uniformity but also so that there will not be a short between cells.

I ordered some similar cells 230Ah and if they will get here then I will do more research and I will show exactly how I will compress them.

Barry Timm

Jun 24, 2021, 3:32:27 PM6/24/21

to electrodacus

Perfect! Thanks Dacian!

I envisaged something very similar to what you show there, except I planned to have another plate on the outside between the retaining washer-nut and the springs, so that all springs are compressed together. Otherwise, very similar!

I'm glad I found out about this requirement as I had no idea it was needed!!!!

Barry Timm

Jun 24, 2021, 3:34:10 PM6/24/21

to electrodacus

I think I will use some thin silicon cutting board material between each cell. It won't have a lot of cushioning, but should be a good insulator between cells, and fairly cheap at Walmart. :)

Dacian Todea

Jun 24, 2021, 3:36:47 PM6/24/21

to electrodacus

Barry,

Barry Timm

Jun 24, 2021, 3:47:06 PM6/24/21

to electrodacus

My main issue now is trying to figure out the best orientation for the 16 cells! I don't have a lot of space in my cabinet, and may need a new ribbon cable as I cut each sense wire to the exact length for each cell (another mistake! :) ).

Are those standard ribbon cables that I can buy anywhere? What are they called?

Dacian Todea

Jun 24, 2021, 4:20:13 PM6/24/21

to electrodacus

Barry,

I build those cables from 3M ribbon cable and 2x6pin IDC connectors.

The 3M model model number is 3365/12 but it seems the 10ft length is out of stock https://www.digikey.ca/en/products/detail/3m/3365-12-100/9479175 there is 5ft but that may be to short for you as I provide 6ft on original cable https://www.digikey.ca/en/products/detail/3m/3365-12-100/9479176

Connector is like this https://www.amazon.ca/2-54mm-Female-Header-Socket-Connector/dp/B07SC8Q3Z3 and will just be pressed on the cable (small vice or something similar) I have a special crimping tool but that is to expensive for one cable.

I can of course ship you another cable but shipping is more expensive than the cable.

Barry Timm

Jun 24, 2021, 4:42:53 PM6/24/21

to electrodacus

Thank you again, Dacian.

I keep saying it, but I'll say it again....I don't know how you manage to find the time to perform the level of support that you do.

It is pretty astonishing, and the very best that I've ever encountered, in any industry or hobbyist environment.

I am a VERY big fan of Electrodacus products and your support!

I am a VERY big fan of Electrodacus products and your support!

Barry.

Peter

Jun 24, 2021, 5:57:25 PM6/24/21

to electrodacus

Dacian,

can I ask you for little more info on your compression solution?

1) How thick are your threaded rods? 6, 8, ? mm?

2) Those springs you used - could you send the link? I am very curious what kind of parameters I should look for when getting springs.

3) How did you proceed when tightening the springs? So that it is not too much or too little. Did you use a torque wrench?

I am expecting 24 EVE cells, I will order the material for compression in advance.

Dne čtvrtek 24. června 2021 v 22:42:53 UTC+2 uživatel Barry Timm napsal:

Barry Timm

Jun 24, 2021, 8:00:15 PM6/24/21

to electrodacus

Peter, FWIW, I calculated the spring rate needed as follows.

My cells are 6" x 7" = 42 sq inches. I will be compressing two of them together, so 84 sq inches.

Aiming for 12 psi, that means 84 x 12 = 1008 lbs of force needed.

Assuming I will use 4 springs, I am looking for straight rate springs with a spring rate of roughly 250lbs/inch.

I found some nice, short, springs with a rate of 500lbs/inch, thus I need to compress them only 0.5 inch for the required 1000lbs of force for 12 psi.

Thoughts?

Dacian Todea

Jun 25, 2021, 2:16:17 AM6/25/21

to electrodacus

Peter,

1) ~6mm (they are imperial 1/4")

2) I got those almost 5 years ago and I do not remember from where probably eBay.

3) Springs have parameters (or you can test) they will say what is the max force needed to fully compress them and the height uncompressed and fully compressed or they may say force per mm of compression.

3) Springs have parameters (or you can test) they will say what is the max force needed to fully compress them and the height uncompressed and fully compressed or they may say force per mm of compression.

I also wait for 24 EVE cells the 230Ah model if they will send them to me due to my remote address.

Barry,

I will compress just one cell in line is not a good idea to attempt to compress two groups of cells as they will have quite a bit of tolerance and they will not be equal thickness plus compression will not be very uniform.

The weight of the entire pack may also be to high that was the reason I have split my A123 System battery in to two groups so I can move them around easier.

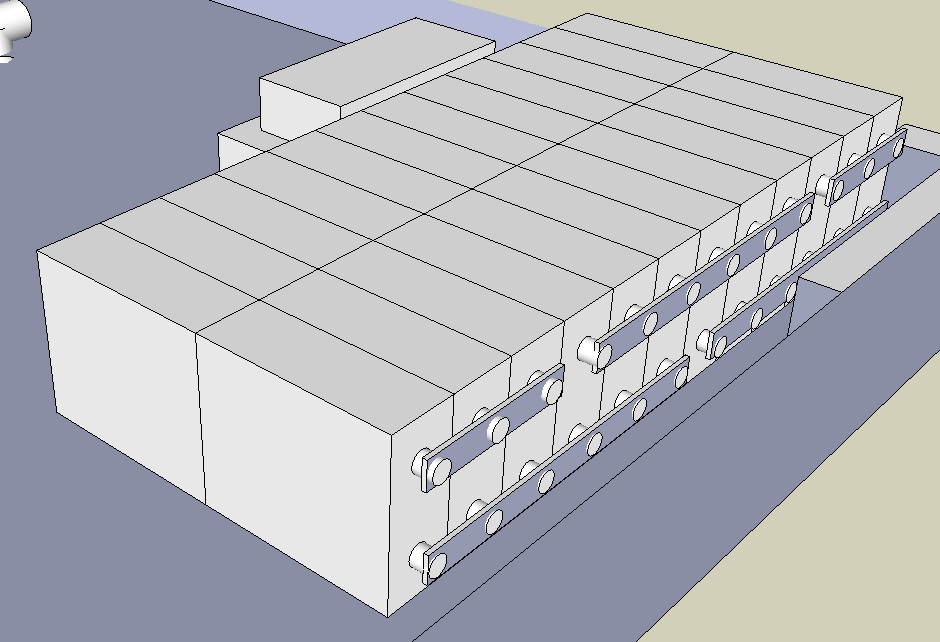

For the 24 cells 8s3p I will compress groups of 6 cells 2s3p and have 4 of this so they are relatively easy to handle.

Barry Timm

Jun 25, 2021, 9:19:05 PM6/25/21

to electrodacus

Good points, thanks Dacian. I will cut the plates in half and do the same. Unfortunately, I've ordered the springs already and as they are very high rate (500lbs/inch) I can not realistically use more than 4 of them in total (compressed 0.5 inch) so that means only 2 psrings per group of compressed cells...which does not provide me a stable base for compression. I may have to bite the bullet and buy 250 lbs/inch springs to allow 8 springs in total, compressed 0.5 inch for 1000lbs of force total, 500lbs per group of cells.

Peter

Aug 29, 2021, 3:26:29 PM8/29/21

to electrodacus

Barry, thank you very much for your guide with springs!

Dacian,

I have studied that Battery Pack Guide by A123 that you shared - awesome resource!

It also says that cells are expanding for about 1% depending on SOC. Is this really measurable? I guess if yes, at least one end of the battery should be on some kind of sliding bed/support, right? Maybe you solved it with that paper towel?

I am worried with battery expansion in my RV.

My pack 8S3P has length 840 mm (2.7ft) so it can potentially expand 8.4 mm.

I presume battery in car must be properly fixed. Instead of rods I think more viable solution for car could be battery box with "sliding ground" and flexible walls which handle compression. In these walls I am going to utilize big springs.

So I am thinking about solution that battery is not fixed but is floating in fixed box with flexible walls.

I have seen people building battery boxes from plywood, is it safety risk to put plywood next to LFP battery?

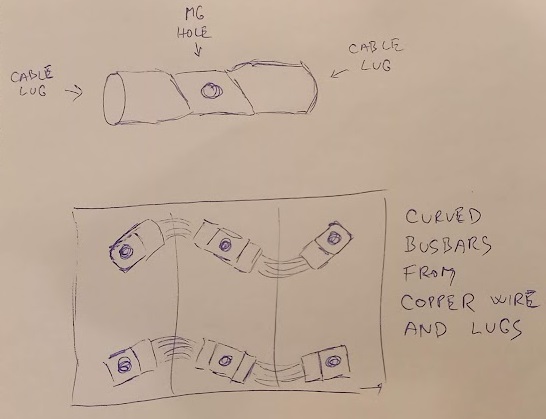

As busbars I am going to use thick cable (50mm2 / AWG 7 for 200A) with self made double-sided copper tinned lugs (from copper tube). I will try to make connections with little curves to allow breathing of cells.

What do you think about that? I have never seen this solution and my own ideas sometimes scare me.

Dne sobota 26. června 2021 v 3:19:05 UTC+2 uživatel Barry Timm napsal:

Dacian Todea

Aug 29, 2021, 3:50:30 PM8/29/21

to electrodacus

1% is not as insignificant as you may think. The role of compression is not to allow the cells to expand or expand significantly lees.

I will not recommend having the cells in that orientation. It is not the worse but is best they are standing up.

Peter

Aug 29, 2021, 4:10:06 PM8/29/21

to electrodacus

Yes, my point was that 1% is very significant and implies complications with fixing the battery in the car. That's why I am choosing the battery box approach with flexible sides.

What do you think about that busbar solution?

Yes, I agree, standing cells would be probably better. I risk this orientation due to the elegant placement of the battery in the floor (the floor itself will be the lid). There are few vanlife celebrities who successfully use prismatic cells in this orientation. I consulted this with Basen/CATL, they said its OK and sent me this classic picture:

Dne neděle 29. srpna 2021 v 21:50:30 UTC+2 uživatel electr...@gmail.com napsal:

Dan Karau

Aug 30, 2021, 9:40:36 PM8/30/21

to electrodacus

Peter

Is that a typo! 7 AWG for 200 A? In my books, 7 gauge is only good for 40 or so amps. http://assets.bluesea.com/files/resources/newsletter/images/DC_wire_selection_chartlg.jpg

Reply all

Reply to author

Forward

0 new messages