Drag Knife cutter and DXF2GCODE

Timothy March

I have been using DXF2GCODE to create gcode for a drag knife cutter. The features you have with this program are great for this. To be able to change start points, travel direction and reorder cuts are key elements to using a drag knife. Was wondering if you would consider adding as a option, a drag knife tool with offset input info into your program. I am including a link to a download package that I have made available on other forums on just how I use your program and a few others programs too. To achieve the needed swivel action needed for such a tool.

http://ubuntuone.com/41QpyBkkTxyKiMY5ImKYWz

Keep up the great work.

TJ March

JP

I will implement it for you; consider it as

a birthday present ;)

But you have to give me a while - not yet sure when I will do it.

But just give me a while

Tim March

I don't know what to say

Thank You, Thank You, Thank You

Tim March

--

--

You received this message because you subscribed to the Google

Groups-group "dxf2gcode-users".

To post a message, send mail to dxf2gco...@googlegroups.com

To unsubscribe, send mail to dxf2gcode-use...@googlegroups.com

See http://groups.google.de/group/dxf2gcode-users?hl=en for more options

and the dxf2gcode project page at http://code.google.com/p/dxf2gcode/

---

You received this message because you are subscribed to the Google Groups "dxf2gcode-users" group.

To unsubscribe from this group and stop receiving emails from it, send an email to dxf2gcode-use...@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Christian Kohlöffel

happy birthday to your 55 aniversery. I'm very happy that JP also buyed

into this topic and finds the time to do it for you. Otherwise i would

dig also a bit more into this topic since it is very interesting in

terms of maths. You know i also started as an maschinist programming NC

maschines and now I'm more or less far away from that but it's a good

balance to my other hobbies to dig a bit into programming in combination

with CAM. Keep on learning new things, thats a very good approach and i

think dxf2gcode is living from users like you having good ideas and

supporting in realizing it ....

JP, Tim,

i also did already made up my mind how to integrate the feature in the

best way into the code and GUI. I think it's not required to have G40;

G41 and G42 options anymore for gcode using the drag knife option right?

Therefore we can just reuse all of that realted functions to implement

the drag knife action when it's selected. Tim what is you opionion, if

this option is selected (lets say in the config file) it will

automatically generate the offseted path without any addition click or

is there the need to enable or disable this action? However i would use

the existing variable with list of geos: shape.stmove. What's your opionio?

best regards

Christian

Ps: JP what is about the sourcefrog account for the download of

dxf2gcode source and exe files. Is there a possiblity to also get

account to that server to upload updated etc.?

https://groups.google.com/forum/?hl=en#!topic/dxf2gcode-users/cDtt5yO0WKU

Tim March

You guys are fantastic! What you suggested sounds great G40, G41 and G42

would not be needed, being able to see paths for swivel action would be

a plus if that is what you mean. The CamBam.py has place for input for

final cut depth I think this should be handled by Z Final mill depth in

main interface. Values for Offset, RetractDepth, SwivelAngle will be

variables that will have to be input by user. After everything is done

and I know how to use it, I will be happy to write a document describing

proper use of new funtion.

Tim

Timothy March

Was thinking on my drive from work that a couple of other variables will be freed up in the config.cfg file, Tool_Parameters, diameter and speed. Will not need a tool diameter and spindle will not be running. As far as start_radius I am not sure how this works in DXF2GCODE, but to let you know with my drag knife I am limited to a turn radius of the tickness of the material, up to 1/4 inch. I will be flying home Friday to Michigan, currently working in Kansas City looking forward to working on my CNC that I will be using drag knife with. My wife told me the last shipment I made for parts came in ;) Attached is a picture of my design.

Tim

On Saturday, March 8, 2014 3:11:58 PM UTC-5, Timothy March wrote:

JP

It's certainly an option to disable the g40

g41 g42 when using swivel knife, if you insist. I pretty much already have it

implemented (there is really hardly any math needed for this option), but not

in the GUI only when exporting to file. With the GUI it's too much of hassle,

because of the set nearest starting point, and change of direction.

I will upload it in the weekend, I think, so feel free to put it in the GUI.

Also, I will look into adding you to the sourceforge Christian

JP

All right I have implemented the function, but it’s not yet finished (check the svn and uncomment line 862 in dxf2gcode.py).

If it needs to do a swivel action with an angle bigger than dragAngle then I set a flag (drag in ArcGeo) such that the Write_GCodefunction knows that it needs to retract to a sufficient “drag-depth”. But ATM I do not check this at Write_GCode function in Shape.py, because the source code would be a big mess (at least how I did it :P ). So this part still needs to be implemented.

ATM I have placed the function in dxf2gcode.py (updateshapewithswivelknife loc 885) such that you can see directly the result of the swivelknife option, but this code can be placed almost everywhere. If you now change the starting point of the shapes, then they are not updated, what it should if you want this option in the GUI. Because the starting point and the end point should be update such that your knife stays in the same direction each time.

Also keep in mind in the current situation you cannot mill with different infeed and final mill depth (because now with non-closed shapes it wants to cut backwards, what your knife can’t do without changing the end and starting point, or it needs to do an exact copy of the first run)

So still a few points that should be fixed/implemented. If someone wants to do that or has an nice idea please tell/go ahead

Timothy March

Sent from my iPhone

--

Christian Kohlöffel

just had some time to test it. For me it works on several simple lines

etc. However i very often get the followin error message:

File "D:\MyWorkspace\DXF2GCODE\trunk\source\Core\ArcGeo.py", line 89,

in __init__

lo = sqrt(pow(r, 2) - pow(m, 2))

ValueError: math domain error

Looking in it in higher detail shows problems with the following arc:

ArcGeo

Pa : X ->171.793 Y ->155.000; s_ang: None

Pe : X ->173.207 Y ->155.000; e_ang: None

O : None; r: 0.707106781187

ext : None; length: None

Core.ArcGeo __init__ 87 : - r: 0.707106781187; m:

0.707106781187

this arc seems to have a too small radius in order to find a valid

center ....

Hope this helps a bit.

Best regards

Christian

Christian Kohlöffel

the following to Point.py correct it:

def unit_vector(self, Pto=None):

"""Returns vector of length 1"""

diffVec = Pto - self

l = diffVec.distance()

if l==0.0:

return Point(1,1)

else:

return Point(diffVec.x / l, diffVec.y / l)

Can you confirm this failures with more complex shapes? I used test.dxf

from svn.

regards

Christian

JP

Well yes and no. I would say this is not

the fault of my program but the fault of the dxf file. Many of those dxf files

on the svn are terrible created. If I reproduce those shapes with autocad I got

no error at all. So I can really create al kind of difficult shapes without a

single error (if you need some example files, let me know).

The point.py "fix" you shouldn't use. That is not a fix but a try to

circumvent the true problem. How the hack can you have a geo with length

zero... That should not be possible, i.e. it means the dxf file is wrong.

The only true error you get is when you have points in the dxf file. but yeah..

how should deal with points if you use a knife. But again this does not give

traceback error, but it will just give a path that is not correct.

So honestly, I cannot reproduce the errors at all (if I have created the dxf file

decently, i.e. use autocad).

Christian Kohlöffel

i understand what you mean, so you prefer not to catch such failure and

trust on the user making correct dxf files, right? Thats also OK for me.

Someday i may try to catch such failures during import in order to solve

such issues too.

regards

Christian

JP

Yup that's correct, but if you really want to catch all those errors, then when importing is certainly the place for it.

BTW I did found an error with 2pi>abs(angles)>pi, but I have fixed that.

Timothy March

Sent from my iPhone

Christian Kohlöffel

to be honest, i did nothing just was testing a bit. Everthing was done

by JP, so thx. a lot for that. As a next step i may integrate the code

from JP in the way i explained it (If JP is OK with that), but first of

all i think next step will be that you test is :-) ....

regards

Christian

JP

I think that would be great if you could do that Christian. Do remember that every time you change the direction or the start point of the shape you have to update the complete shape (which could be quite time consuming if you have to deal with many shapes – e.g. layer select etc).

And that the mill depth has to be changed every time the flag, drag (in ArcGeo), is set. This is needed because when this flag is set the knife makes a strong turn, which is not possible when it is too deep in the material; but it still has to “hit/cut” the material, because it has to drag, otherwise the knife will not change direction.

Thanks for finishing it

Tim March

Great work JP, I would be honored to test it when you are ready.

Tim

--

Christian Kohlöffel

regards

Christian

Timothy March

Sent from my iPhone

On Mar 19, 2014, at 2:06 PM, "Christian Kohlöffel"

Timothy March

Just wanted to make sure you understand that I will be testing DXF2GCODE with the control software that I will be using to run my CNC

in simulation mode. My CNC is not finished yet. I am in Kansas City working at this time and only go home every other weekend. Last weekend when I was home I was able to get a good start on putting CNC together. Next step is to build vacuum table base.

Tim

Christian Kohlöffel

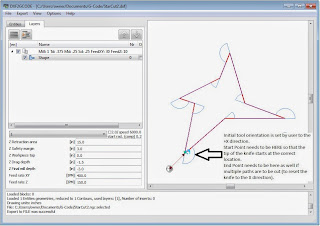

i think it's fair enought to use the simulation for now. I did put the Gui together (see attached figure of my last export). The basic functions are implemented. I would suggest you try it and report. With the more advanced functionallity i prefer to wait until your maschine is working. In order to test it you need to have the python environment installed and get the most updated version from the trunk. For more details how to do that see links below. (Dont hesitate to ask if there are any problems with installation)

https://code.google.com/p/dxf2gcode/wiki/DevelopmentEnvironment

https://code.google.com/p/dxf2gcode/wiki/DevelopmentEnvironment_Win7

https://code.google.com/p/dxf2gcode/source/checkout

Please find some parts of the config options i used below (in blue :-)). You need to change maschine type to drag_knife. the other options are partly not implemented (e.g. dragDepth).

regards

Christian

Ps: Please be kind with my englisch, i'm not a native speaker as you are ...

[General]

write_to_stdout = False

live_update_export_route = False

default_SplitEdges = False

default_AutomaticCutterCompensation = False

maschine_type = drag_knife

[Drag_Knife_Options]

# dragDepth is not used by now as well as dragAngle. May be done later.

dragAngle = 20.0

dragDepth = 0.0

Tim March

I need a little help. I have installed all requirements for python environment no problems. In your previous message you referred me to link https://code.google.com/p/dxf2gcode/source/checkout

On that page it says:

svn checkout http://dxf2gcode.googlecode.com/svn/trunk/ dxf2gcode-read-only

I have installed TortoiseSVN when I try SVN Checkout the Non-member URL http://dxf2gcode.googlecode.com/svn/trunk/ dxf2gcode-read-only

dose not work.

Regards

Tim

Timothy March

Sent from my iPhone

<drag_knife1.jpg>

Tim March

Seen what I did wrong after viewing my post on google groups pasted to much in,(dxf2gcode-read-only) got it downloaded.

Tim

Feel like a dumb me

Timothy March

JP & Christian

The GUI looked great and work well for selecting start points and changing directions, I thought screen updated very well. There are a couple of problems though, the first DXF file I tried with DXF2GCODE was the shape of a star. The GUI showed where I had selected the start point but in the g-code start point started after the end of the last arc which was at the end of path. This closed shape should not have had a swivel action at start point or at the end of path, which is the start point. Also there needs to be a place for inputting of drag knife offset,( distance from center line of spindle to tip of blade), which would determine the radius of arc for swivel action. The drag knife offset would be different if a different size blade was used or from one drag knife brand to another. The path for swivel action looked very good, just that arcs were very large, JP I think you nailed the math. Need to add bladeOffset, dragAngle and dragDepth. Second file was of some scallops results looked the same as first file with same problems. The third file is of a model airplane fuselage more complex with different layers. I have attached archive containing nc and DXF file for all tested. In addition nc files that I created using the old method to get swivel action so you could compare paths, take a look at them on a simulator.

Regards

Christian Kohlöffel

Just checked the issue with the different starting points. I can not

confirm that. Just attached 2 parts of the exported files for same dxf.

So the starting point is there like i selected it.

First export with selected starting point at ~ X-10 and Y-15

(* SHAPE Nr: 1 *)

N70 G0 X -9.000 Y -15.000

Second export with selected starting point at ~X50 and Y10

(* SHAPE Nr: 1 *)

N70 G0 X 51.000 Y 10.000

Wheater there is a swivel action or not, this is part of the algorithm

provided by JP. I'm not sure that i did fully understand it up to now

(didn't look into detail). Maybe JP can support here. This function is

implemented now in the scipt source/Gui/StMove.py function

make_swivelknife_move.

The drag knive offset is defined by the already existing parameter of

the tool diameter. The offset is defined by diamter/2, which is the radius.

hope this helps.

Best regards

Christian

Attached please find the function:

def make_swivelknife_move(self):

"""

Set these variables for your tool and material

@param offset: knife tip distance from tool centerline. The

radius of the

tool is used for this.

"""

offset =self.shape.LayerContent.tool_diameter/2

dragAngle = self.shape.dragAngle

startnorm = offset*Point(1,0,0)

prvend, prvnorm = Point(0,0),Point(0,0)

first = 1

#start = self.startp

#Use The same parent as for the shape

self.parent=self.shape.parent

for geo in self.shape.geos:

if geo.type == 'LineGeo':

geo_b = deepcopy(geo)

if first:

first = 0

prvend = geo_b.Pa + startnorm

prvnorm = startnorm

norm = offset*geo_b.Pa.unit_vector(geo_b.Pe)

geo_b.Pa += norm

geo_b.Pe += norm

if not prvnorm == norm:

swivel = ArcGeo(Pa=prvend, Pe=geo_b.Pa, r=offset,

direction=prvnorm.cross_product(norm).z)

swivel.drag = dragAngle < abs(swivel.ext)

self.geos.append(swivel)

self.geos.append(geo_b)

prvend = geo_b.Pe

prvnorm = norm

elif geo.type == 'ArcGeo':

geo_b = deepcopy(geo)

if first:

first = 0

prvend = geo_b.Pa + startnorm

prvnorm = startnorm

if geo_b.ext > 0.0:

norma = offset*Point(cos(geo_b.s_ang+pi/2),

sin(geo_b.s_ang+pi/2))

norme = Point(cos(geo_b.e_ang+pi/2),

sin(geo_b.e_ang+pi/2))

else:

norma = offset*Point(cos(geo_b.s_ang-pi/2),

sin(geo_b.s_ang-pi/2))

norme = Point(cos(geo_b.e_ang-pi/2),

sin(geo_b.e_ang-pi/2))

geo_b.Pa += norma

if norme.x > 0:

geo_b.Pe =

Point(geo_b.Pe.x+offset/(sqrt(1+(norme.y/norme.x)**2)),

geo_b.Pe.y+(offset*norme.y/norme.x)/(sqrt(1+(norme.y/norme.x)**2)))

elif norme.x ==0:

geo_b.Pe = Point(geo_b.Pe.x,

geo_b.Pe.y)

else:

geo_b.Pe =

Point(geo_b.Pe.x-offset/(sqrt(1+(norme.y/norme.x)**2)),

geo_b.Pe.y-(offset*norme.y/norme.x)/(sqrt(1+(norme.y/norme.x)**2)))

if not prvnorm == norma:

swivel = ArcGeo(Pa=prvend, Pe=geo_b.Pa, r=offset,

direction=prvnorm.cross_product(norma).z)

swivel.drag = dragAngle < abs(swivel.ext)

self.geos.append(swivel)

prvend = geo_b.Pe

prvnorm = offset*norme

if -pi<geo_b.ext<pi:

self.geos.append(ArcGeo(Pa=geo_b.Pa, Pe=geo_b.Pe,

r=sqrt(geo_b.r**2+offset**2), direction=geo_b.ext))

else:

geo_b = ArcGeo(Pa=geo_b.Pa, Pe=geo_b.Pe,

r=sqrt(geo_b.r**2+offset**2), direction=-geo_b.ext)

geo_b.ext = -geo_b.ext

self.geos.append(geo_b)

else:

self.geos.append(copy(geo))

if not prvnorm == startnorm:

self.geos.append(ArcGeo(Pa=prvend,

Pe=prvend-prvnorm+startnorm, r=offset,

direction=prvnorm.cross_product(startnorm).z))

self.geos.insert(0,self.geos[0].Pa)

JP

Well it precisely reacts how I wanted it - I have compared all your provided files. With the star: it starts at the correct point. The testOld actually starts too early - remember your knife "lags". And it should end with a swivel action! Because otherwise your knife does not end in the correct way... i.e. if I just let it end as in the testOld it will not be in the correct position to directly do another shape - now in this case you only have one shape but maybe I want to process right after it another gcode file... (as far as I could see cambam does it the exact same way, as I do it)

I think you should really test it on a working machine, and I'm pretty sure you will come to the same conclusions - with all your files.

Offset is already implemented check Christian's comment. (dragAngle, and dragDepth are partly implemented - still needs to be finished - now you have to add that little part of code manually)

So honestly I'm not gonna make a change... sorry. But I truly believe it's working correctly!!

Tim March

After further testing I agree with you I was always trying to figure out cut order from the drawing end. The fuselage drawing I provided in last email was not drawn correctly. I fixed mistakes that were in it and DXF2GCODE worked perfectly. Now I also know about tool setup in config file after Christian posted. Just as a note the manufacture of drag knife suggested always start cuts in a plus x attitude with blade. Maybe that is the way they have to do it with the cam software they use and sell. The drawing of the fuselage has a couple of lead in and lead out cuts I thought were needed with the old way I did swivel action to get blade ready for next cut. That effort is not needed any more with the way you set this up. You are a genius just put the blade in the attuide of first cut and let DXF2GCODE do all the work. Attached DXF file I used in my last test, nc file is results. Swivel action moves are just barely visable but with my drag knife .140" offset is all that is needed.

Thank-you for the birthday persent

Tim

JP

The drag knife is now fully implemented and should work perfectly - remember to use it set maschine_type to drag_knife.

I have updated the gcode write function to support the drag depth change, also made small change with the feed rate (for all write functions) – now it no longer duplicates the previous rate, in the exported file

"Z infeed depth"/axis3_slice_depth is changed to "Z Drag depth"/axis3_slice_depth if the maschine_type is set to drag_knife.

On Tuesday, March 25, 2014 2:51:58 AM UTC+1, Timothy March wrote:

JP

After further testing I agree with you I was always trying to figure out cut order from the drawing end. The fuselage drawing I provided in last email was not drawn correctly. I fixed mistakes that were in it and DXF2GCODE worked perfectly. Now I also know about tool setup in config file after Christian posted. Just as a note the manufacture of drag knife suggested always start cuts in a plus x attitude with blade. Maybe that is the way they have to do it with the cam software they use and sell. The drawing of the fuselage has a couple of lead in and lead out cuts I thought were needed with the old way I did swivel action to get blade ready for next cut. That effort is not needed any more with the way you set this up. You are a genius just put the blade in the attuide of first cut and let DXF2GCODE do all the work. Attached DXF file I used in my last test, nc file is results. Swivel action moves are just barely visable but with my drag knife .140" offset is all that is needed.

Thank-you for the birthday persent

Tim

On 3/24/2014 6:44 PM, JP wrote:

Hi, again :|

Well it precisely reacts how I wanted it - I have compared all your provided files. With the star: it starts at the correct point. The testOld actually starts too early - remember your knife "lags". And it should end with a swivel action! Because otherwise your knife does not end in the correct way... i.e. if I just let it end as in the testOld it will not be in the correct position to directly do another shape - now in this case you only have one shape but maybe I want to process right after it another gcode file... (as far as I could see cambam does it the exact same way, as I do it)

I think you should really test it on a working machine, and I'm pretty sure you will come to the same conclusions - with all your files.

Offset is already implemented check Christian's comment. (dragAngle, and dragDepth are partly implemented - still needs to be finished - now you have to add that little part of code manually)

So honestly I'm not gonna make a change... sorry. But I truly believe it's working correctly!!

On Monday, March 24, 2014 9:04:16 PM UTC+1, Christian Kohlöffel wrote:HI Tim,

Just checked the issue with the different starting points. I can not

confirm that. Just attached 2 parts of the exported files for same dxf.

So the s

...

Timothy March

Timothy March

Have a question, in the Config file it has the following

# dragDepth is not used by now as well as dragAngle. May be done later.

dragAngle = 20.0

dragDepth = 0.0

do swivel with dragAngle greater than value

swivel height at dragDepth value

Or am I missing something to get these values to work.

Tim

...

Timothy March

As fare as the Drag_Knife_Options in Config file if not implemented yet. You have the angles all worked out very well dragAngle might not be needed. But the dragDepth value is very important because without it you could only cut very thin material. If you were to cut wood venier with blade at full depth during swivel action you would brake a blade. Or what I will be cutting most foamboard 4mm thick, you might not break a blade but you would damage the material.

Just something to think about.

Tim

Timothy March

Sent from my iPhone

--

jan.iemhoff

Yes , a picture (foto) could say more than words.

Rg.

Iemhoff

Vom Handy gesendet.

Timothy March <timoth...@gmail.com> schrieb:

JP

but yes that is implemented just import the file with the maschine_type set to drag_knife and you will see a label called drag depth. Just fill in a different depth and you will see that it goes to that depth when the angles are greater than the dragAngle. I forgot that Christian already had some variables for this declared in the config file. So I might make a config file change. But it is already fully implemented, and should work perfectly.

Timothy March

Tim

Bill Trondsen

Timothy March

Sent from my iPhone

--

JP

Setting G64 to G61 might indeed be a nice change to apply - always,- although everybody could change it to whatever they want (postpro_config.cfg)

Nice pic BTW, probably will use this to write a Wiki.

Bigman74066

Op zaterdag 12 april 2014 11:39:25 UTC+2 schreef JP:

Timothy March

--