TECAN Evo Clinical - DiTi not properly mounted on LiHa

Panagiotis Chanos

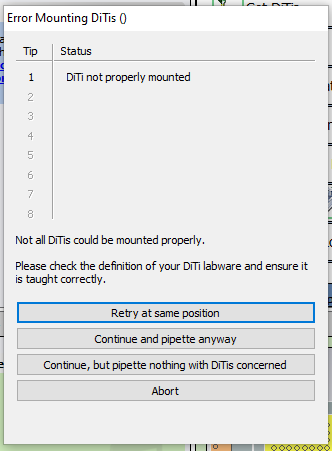

After finishing the teaching session I tried to pick one tip from the SBS box using the “Get DiTi” direct command from the Evoware standard menu. Although the cone went in the tip, mounted it and lifted it up without any problems, I got the following error message from Evoware standard.

I have tried to talk to TECAN helpdesk but after a lot of emails bak and forth it seems they do not have an idea and they suggested we order one of their technicians to look into it on site.

I was wondering whether anyone has had a similar experience and whether there is a way to overcome this problem.

Thank you for your time.

All the best,

Panos

Rikke Rasmussen

--

-- You received this message because you are subscribed to the Google Groups DIYbio group. To post to this group, send email to diy...@googlegroups.com. To unsubscribe from this group, send email to diybio+un...@googlegroups.com. For more options, visit this group at https://groups.google.com/d/forum/diybio?hl=en

Learn more at www.diybio.org

---

You received this message because you are subscribed to the Google Groups "DIYbio" group.

To unsubscribe from this group and stop receiving emails from it, send an email to diybio+un...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/diybio/70d5fd07-1522-4b16-846b-b8f8685caa15n%40googlegroups.com.

Panagiotis Chanos

Rikke Rasmussen

To view this discussion on the web visit https://groups.google.com/d/msgid/diybio/86e4053a-af97-4a99-8fb3-1286156201ecn%40googlegroups.com.

Dan Kolis

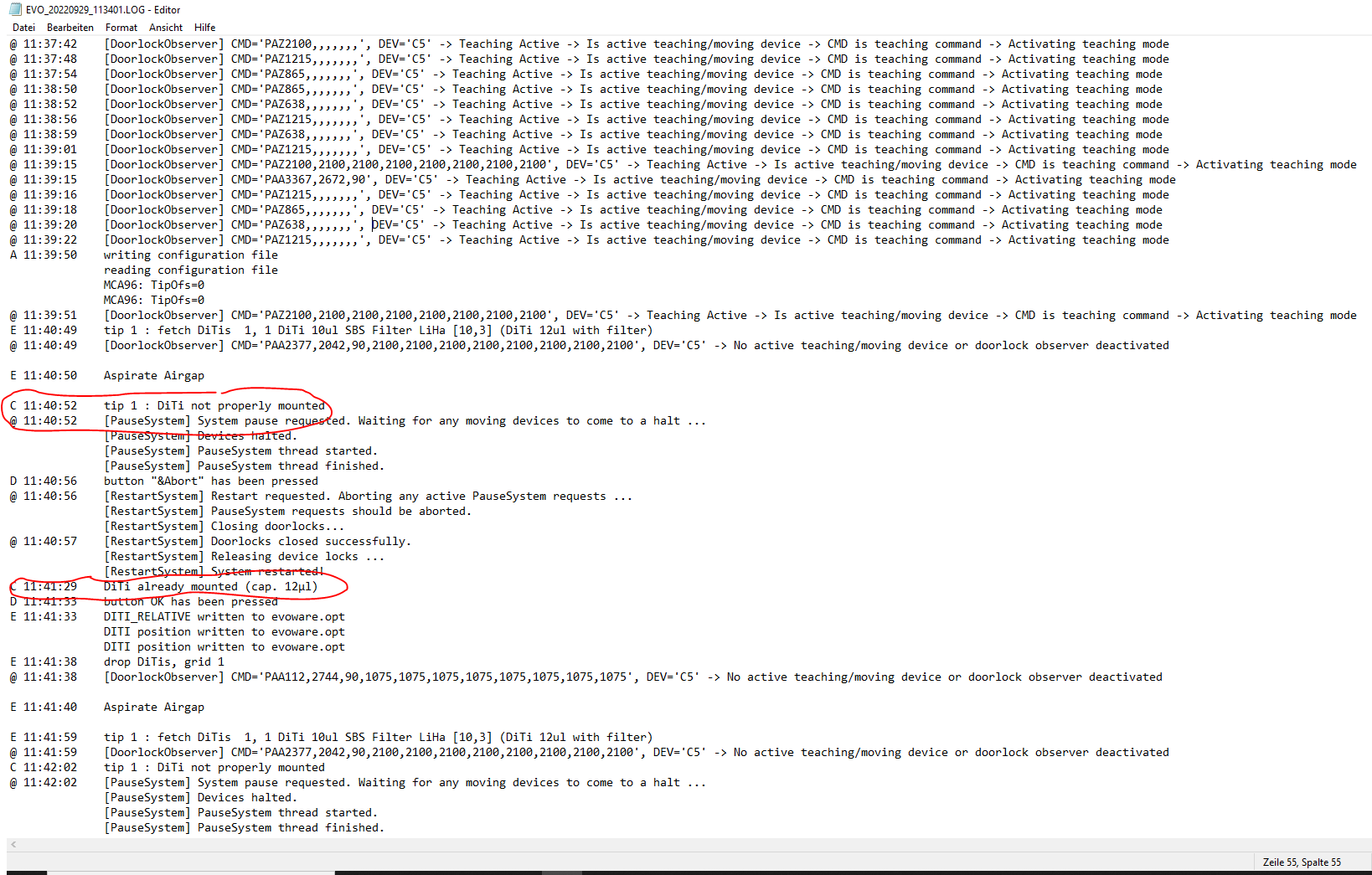

Any thing packed with menus and a 490 page PDF writes a fat file someplace on XYZ attempts, which transducer doesn't like a thing.. Here's the manual and an extract hinting at a log file ( for example ):

https://www.tecan.com/hubfs/394802_en_V2_3%20Application%20Software%20Manual%20Fdm%20EVOlution-1.pdf

16.5.6 Log Files The log file contains information on configuration changes and other data which have been created, edited or saved. It documents pipetting and records user actions and changes to parameter values, etc. The log files are written to a specified directory (default location \Program Files\Common Files\Tecan\Logging\...)

Maybe try there as a start. poke around and find the file that changes everytime it does anything, etc. Horribly, this thing uses a MS operating system ( shudder ). But the above anyway gets you a spot in the DIR system to look, almost for sure.... the HHMMSS time stamp is the magic juice to focus your attention(s). Everybody assumes its just a Z position, well, who knows what they have dreampt up in that thing. Esp ! if it works at one end of the table and repeats this elsewhere in XY, now what. Understanding the thing is required and its a horror show when you don't have source code.

Obviously you can just carefully iterate the programmable positions you have, but a peek at the files is maybe fewer hours of tedious work. Even if/when you make it "go" the problem is nearly certain to reoccur, you cannot find the underlying logic completely via iteration without truly incredible amounts of experimentation.

Also, knowing file names by location and name is a huge leg up when talking to the phone help people. Instead of wishing you away with a click to their program, if you mumble out a specific filename, you might get 90 seconds more help before then click "Resolved" on their tracking program.

Motion control problems are usually moderately hard to really resolve. Even when you think its fixed, you usually wrong and it re- occurs sometimes. So what, keep notes and modify everything in truly "baby steps". ex: use the original tips and see if it fails with the new Cartesian settings, make a mixed system with lots of test moves and sub in the new tips one by one, etc.

and look for the file(s) !

You cannot trust even what appears to be success, anyway. There are too many things contingent on that thing to trust what appears to be a few try success. Maybe a highly specific test situation of a few tubes in a difficult to achieve 100 steps would be worth creating as a lab control, with or without this cheaper/different tip thing problem. Tap water will do, tap water with food colouring is maybe better. Most failures like this are total, not proportional, but that would show up hopefully in a last pass qualifying step you should elucidate and execute anyway. A really interesting qualifying step migth combine pH and color and give you a baseline five tubes with a ultra accurate mixed result either a colorimitter or pH tool could measure !

Finding the singular best file it makes with the most detail is surely a happy moment. If the experimenters make careful run records, tell them to make there batch files for file saving copy out that file buried in all the Microsoft noise....

Good luck, you will resolve it; ( First time, second time, etc ) but you will get the dragon slayed with effort.

Regards,

Daniel B. Kolis

Panagiotis Chanos

Dan Kolis

Like I said, most motion control problems are slowly resolved, its unusual one observation does it. You have made some progress. You didnt mention it, but does the thing stop after the complaint entirely ?

A mere suggestion is DEFINITELY if you dont have one get a digital caliper like the cheap and just fine Mitotoyo. Maybe you have one in a tool bin, etc I mean one in the shoebox of maintenance stuff for this machine, specifically.

Mitutoyo CNC 6in 8in 12in LCD Digital Caliper 150mm 200mm 300mm Vernier Calipers Gauge Electronic Stainless Steel Measuring Tool

Saying 'have a technician etc" is ok mostly to find out how it works in more detail. Once their gone, thats it, all you get for the moment is an invoice. That is Manager X has a nice copy and paste message for you for subsequent trouble: "We do not support tips from { fill in the blank }. Bam, that's that.

A test of the shim for fun is to take it out and have a 1:1 correlation of error messages when its there or out. Your worry about the actual compliance of the material in the mix is far more ominous than positioning. Hopefully you are wrong... Of course that's adjustable 'somehow', when they made it, they had no idea how that worked and just played with it like you are doing now.

Non-wiggly shim stock might be good too, like brass you can cut with scissors, etc...

Good luck keep playing !

Panagiotis Chanos

The Z-Start value must be by set without Diti approx. 50 Steps over the Diti Edge and the golden Diti Cone (5mm).

Then Z-Max is then set to a value of 210-250 (maybe even 300) steps (or tenths of mm) from Z-Start. Remember to unlock the Z values from each other before adjusting the values.

BUT THE MOST IMPORTANT DETAIL IS THE FOLLOWING:

When the values of Z-Start and Z-max are set DO NOT MOVE THE Diti CONE TO Z-Max when teaching (by using the per "move to" button). This will definitely lead to a crash message! Instead save the settings and test the set values with the Direct Command "Get DiTis".

We observed that only when we tested the Diti Cone Z-max settings using the "move to" button, all the problems that I described in the beginning of this thread appeared.

Rikke Rasmussen

--

-- You received this message because you are subscribed to the Google Groups DIYbio group. To post to this group, send email to diy...@googlegroups.com. To unsubscribe from this group, send email to diybio+un...@googlegroups.com. For more options, visit this group at https://groups.google.com/d/forum/diybio?hl=en

Learn more at www.diybio.org

---

You received this message because you are subscribed to the Google Groups "DIYbio" group.

To unsubscribe from this group and stop receiving emails from it, send an email to diybio+un...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/diybio/d57520c8-6830-448c-a541-5c0bac462422n%40googlegroups.com.