Cleaning_of_wooden_parts

347 views

Skip to first unread message

Drndicka.sk

Sep 12, 2021, 4:38:30 PM9/12/21

to Cider Workshop

Hi all,

this is my first post to this group, even following it already for few years. I do really love to read it, as often I learn things which I didn't even know I needed ;o).

Recently I bought older Voran120P2 pack press. It is in quite a good condition, but I would like to properly clean/sanitize the wooden racks and press plates, as I don't know how properly this was done.

Any experiences from your side re. taking care about your wooden press components will be highly appreciated.

Thank you.

Michal

Andrew Lea

Sep 14, 2021, 5:19:33 AM9/14/21

to cider-w...@googlegroups.com

I have had a similar Voran press for 20 years. I just clean the racks and press plates with water every time after use, and more thoroughly at the end of every season. I let them dry before I store them. Sometimes I have sprayed acidified SO2 solution on the racks (and let it dry out) but generally not.

I would not suggest using chlorine based sanitisers on wood for fear of generating chlorophenol taints.

I’m quite happy if wild yeasts survive on my press racks as an inoculum for next season. In any case I always use measured SO2 in my juice to take care of any microbes that I don’t want.

Other people may have other ideas ;-)

Andrew

——————————

Wittenham Hill Cider Page

On 12 Sep 2021, at 21:37, Drndicka.sk <mic...@drndicka.sk> wrote:

Hi all,

--

--

Visit our website: http://www.ciderworkshop.com

You received this message because you are subscribed to the "Cider Workshop" Google Group.

By joining the Cider Workshop, you agree to abide by our principles. Please see http://www.ciderworkshop.com/resources_principles.html

---

You received this message because you are subscribed to the Google Groups "Cider Workshop" group.

To unsubscribe from this group and stop receiving emails from it, send an email to cider-worksho...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/cider-workshop/8282b61a-015e-4155-b112-9d567d0d3e58n%40googlegroups.com.

Drndicka.sk

Sep 16, 2021, 3:59:38 AM9/16/21

to Cider Workshop

Hi Andrew,

thanks much for the hints. Appreciate.

Michal

Dátum: utorok 14. septembra 2021, čas: 11:19:33 UTC+2, odosielateľ: Andrew Lea

Ray Blockley

Sep 20, 2021, 8:08:54 AM9/20/21

to Cider Workshop

Michal,

Just throwing this in as an idea:

A few years back, Gail & I spent the day working with & helping Rose Grant of "Cider By Rosie" based in Dorset, UK.

After first cleaning her wooden racks (as Andrew suggests), while pressing she would keep the racks submerged in clean, fresh water in a suitable sized container - she used a clean new "blue" or Engineering brick to weigh them down to keep them submerged.

At the end of a day's pressing, Rose would blast the racks with fresh water from a hose pipe & put them back into the water, weighed down until the next pressing.

A few years back, Gail & I spent the day working with & helping Rose Grant of "Cider By Rosie" based in Dorset, UK.

After first cleaning her wooden racks (as Andrew suggests), while pressing she would keep the racks submerged in clean, fresh water in a suitable sized container - she used a clean new "blue" or Engineering brick to weigh them down to keep them submerged.

At the end of a day's pressing, Rose would blast the racks with fresh water from a hose pipe & put them back into the water, weighed down until the next pressing.

It worked for Rose & also ensured none of the juice would be absorbed into the wooden racks.

After all pressing was completed, she'd clean the racks well as Andrew describes, then dry them VERY thoroughly before storing for the following season.

It worked for Rose?

Ray

Nottingham UK

Nottingham UK

To view this discussion on the web, visit https://groups.google.com/d/msgid/cider-workshop/9cc7e2d1-65ff-4b39-8505-09aa3b0d6c83n%40googlegroups.com.

Drndicka.sk

Sep 21, 2021, 9:59:58 AM9/21/21

to Cider Workshop

Hi Ray,

This sounds like a clever trick, as no air gets to the racks when you are pressing for multiple days.

I used to clean it after each day, so this will save us the part which is not my favorite ;o).

Thanks much,

Michal

Dátum: pondelok 20. septembra 2021, čas: 14:08:54 UTC+2, odosielateľ: raymond...@gmail.com

gareth chapman

Sep 23, 2021, 11:53:16 AM9/23/21

to Cider Workshop

I switched to HDPE sheets a few years ago

Ray Blockley

Sep 23, 2021, 12:43:56 PM9/23/21

to Workshop-Cider

I switched to them nearly a decade ago, straight after buying my Voran.

To view this discussion on the web, visit https://groups.google.com/d/msgid/cider-workshop/cffc7bab-89f0-43fc-b2ef-2dd88fd2cfaan%40googlegroups.com.

Drndicka.sk

Sep 26, 2021, 3:26:21 AM9/26/21

to Cider Workshop

I was thinking about HDPE racks, as some of mine (wooden) are anyhow in bad condition and need to replace them.

Did you made them by your self in some special way, or did you bought the original once from Voran?

I was also looking a bit around re. the "sprayed acidified SO2 solution" mentioned by Andrew. I mean just for the first washing cycle of my racks. However I am a bit struggling what to look for exactly, or is there a special way you prepare this solution?

Thanks much,

Micha;

Dátum: štvrtok 23. septembra 2021, čas: 18:43:56 UTC+2, odosielateľ: raymond...@gmail.com

Bartek Knapek

Sep 26, 2021, 4:06:57 AM9/26/21

to cider-w...@googlegroups.com

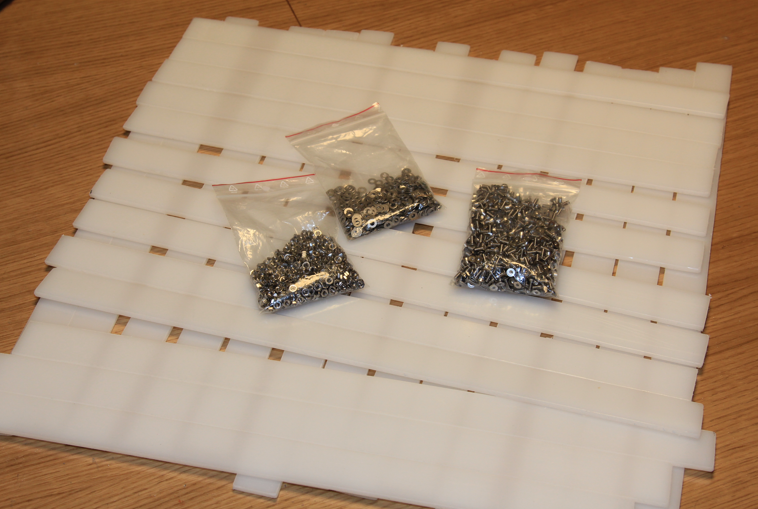

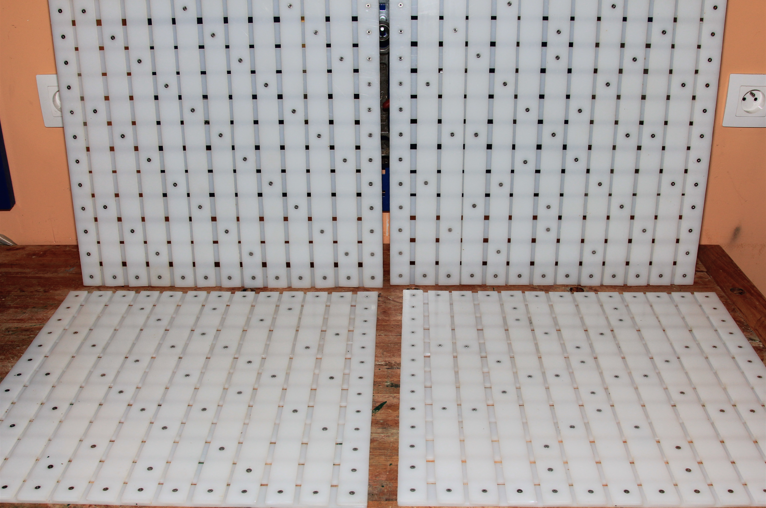

I did HDPE racks myself.

Bought a sheet of HDPE, cut it into pieces:

Drilled and screwed with stainless:

The effect:

It took me 10 evenings (!), for 8 layers.

They are neat, easy to clean, and after a couple of seasons show only small signs of use.

BUT: HDPE is slippy and the layers easily float to the sides.

If I was (forced) to make racks again, I would seriously

consider simply glueing together stips of wood - one evening and

done.

//Bartek

W dniu 26.09.2021 o 09:26, Drndicka.sk

pisze:

To view this discussion on the web, visit https://groups.google.com/d/msgid/cider-workshop/683b9729-34dd-457e-8ae2-491e12a49defn%40googlegroups.com.

Ray Blockley

Sep 26, 2021, 5:37:28 AM9/26/21

to Workshop-Cider

Hi Michal,

I used a UK company who have the same dimensions as the original Voran racks as a standard cut size? So ordered the same number as the wooden racks plus one extra (to sit on top & protect wooden press plate). I went for 8mm HDPE.

I drilled a 20mm hole in each corner of every HDPE sheet & radiused the corners. That was it. The 20mm holes aid alignment & handling.

With my old Vigo screw-thread pack press (pre-Voran) I also machined grooves, slots, etc into the HDPE.

I found - for me - it made no real difference in juice output?

So with the Voran, I didn't bother.

The point made about the problem of slipping is valid - it can be a pain - but careful alignment & loading of the cheese, means it's never been a real problem in 10 yrs of using them with my Voran.

But - I am tempted (but still not got round to it!) to drill 4 or 5 x 20mm diameter holes in & around the centre of each sheet. I feel that would totally alleviate any slippage problems?

All this is based on my experience so do think about all other input & advice before making a decision.

Good luck.

Ray

To view this discussion on the web, visit https://groups.google.com/d/msgid/cider-workshop/683b9729-34dd-457e-8ae2-491e12a49defn%40googlegroups.com.

Ray Blockley

Sep 26, 2021, 6:31:35 AM9/26/21

to Workshop-Cider

Hi Michal.

Photos if they get through, attached.

1st image is our hand-made press from the mid-90's - HDPE racks machined with grooves. We used these racks on the Vigo.

2nd & 3rd - from 2012 of the plain 8mm HDPE racks with the Voran. NB This was the year that after pressing, I decided to drill the holes in each corner to aid handling.

1st image is our hand-made press from the mid-90's - HDPE racks machined with grooves. We used these racks on the Vigo.

2nd & 3rd - from 2012 of the plain 8mm HDPE racks with the Voran. NB This was the year that after pressing, I decided to drill the holes in each corner to aid handling.

Ray

gareth chapman

Sep 26, 2021, 5:25:33 PM9/26/21

to Cider Workshop

yep I just use plain 10mm sheets, I use a 20mm framed former exactly the same external dims as the sheets, so they line up perfectly. Not had any issues with slipping.

Never quite got the idea of slatted racks., don't quite get why you would want to squeeze all of the juice from one layer down into the one below

Never quite got the idea of slatted racks., don't quite get why you would want to squeeze all of the juice from one layer down into the one below

Andrew Lea

Sep 27, 2021, 4:48:27 AM9/27/21

to cider-w...@googlegroups.com

Nothing fancy. A typical procedure would be to dissolve 10 g each of sodium metabisulphite and 10 g of citric acid in a litre of water. Allow to dissolve fully (don’t inhale fumes!) and then transfer to a spray bottle and use as required. Allow it to dry on the racks. I would do this after physically cleaning them of apple debris, juice etc.

Message has been deleted

Drndicka.sk

Oct 3, 2021, 6:20:39 AM10/3/21

to Cider Workshop

Great, I always like simple procedures ;o).

Jus one question, as my chemistry background is not the strongest. Would it be wise to use potassium metabisulphite or it is better to use sodium metabisulphite?

Thanks much.

Michal

Dátum: pondelok 27. septembra 2021, čas: 10:48:27 UTC+2, odosielateľ: Andrew Lea

Reply all

Reply to author

Forward

0 new messages