PEI Develops Cracks

89 views

Skip to first unread message

Brian Henning

Mar 26, 2020, 12:41:25 PM3/26/20

to BuildTak

Hi,

Is anyone else experiencing cracks develop in their FlexPlate PEI surface? What, if anything, have you done about it? It seems not to cause much more than a surface imperfection, but occasionally if a part detaches the wrong way, it'll grab a cracked spot and peel the PEI a little, making the crack worse.

Thanks,

-Brian

Is anyone else experiencing cracks develop in their FlexPlate PEI surface? What, if anything, have you done about it? It seems not to cause much more than a surface imperfection, but occasionally if a part detaches the wrong way, it'll grab a cracked spot and peel the PEI a little, making the crack worse.

Thanks,

-Brian

Brian Henning

Mar 26, 2020, 1:39:53 PM3/26/20

to BuildTak

(Including more info sent to Dave)

I am using a Lulzbot Taz 5 printer. I have the magnetic plate

adhered on top of the factory build plate (aluminum with a PEI sheet

laminated on top) so my stackup becomes:

---------------------

PEI

FlexPlate steel

---------------------

Magnetic plate

PEI

Aluminum

---------------------

Things between ------------- are glued to each other.

My build plate temps are generally 60-80 C depending on material. I most commonly print PLA and PETG+. I do not treat the PEI surface in any way.

Printhead temps are around 210 - 240 C.

Filament manufacturers are eSun, Hatchbox, and Makergeeks primarily. I use eSun PETG+ filament the most because it seems to be a good balance between price and quality.

I have a print running right now so I can't take photos, but I will add some once I get a chance to do so.

Thanks,

-Brian

---------------------

PEI

FlexPlate steel

---------------------

Magnetic plate

PEI

Aluminum

---------------------

Things between ------------- are glued to each other.

My build plate temps are generally 60-80 C depending on material. I most commonly print PLA and PETG+. I do not treat the PEI surface in any way.

Printhead temps are around 210 - 240 C.

Filament manufacturers are eSun, Hatchbox, and Makergeeks primarily. I use eSun PETG+ filament the most because it seems to be a good balance between price and quality.

I have a print running right now so I can't take photos, but I will add some once I get a chance to do so.

Thanks,

-Brian

Brian Henning

Mar 26, 2020, 6:31:29 PM3/26/20

to BuildTak

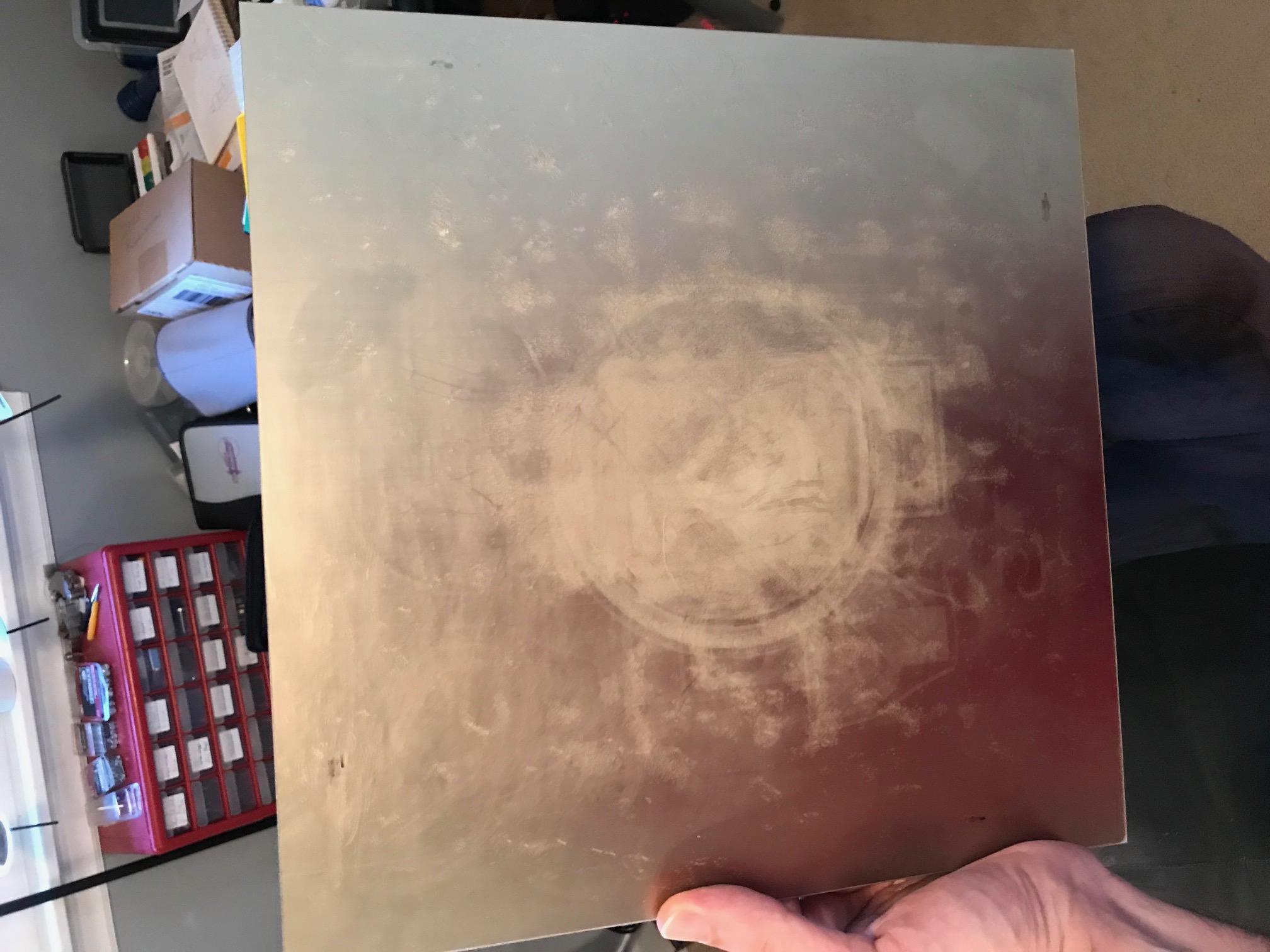

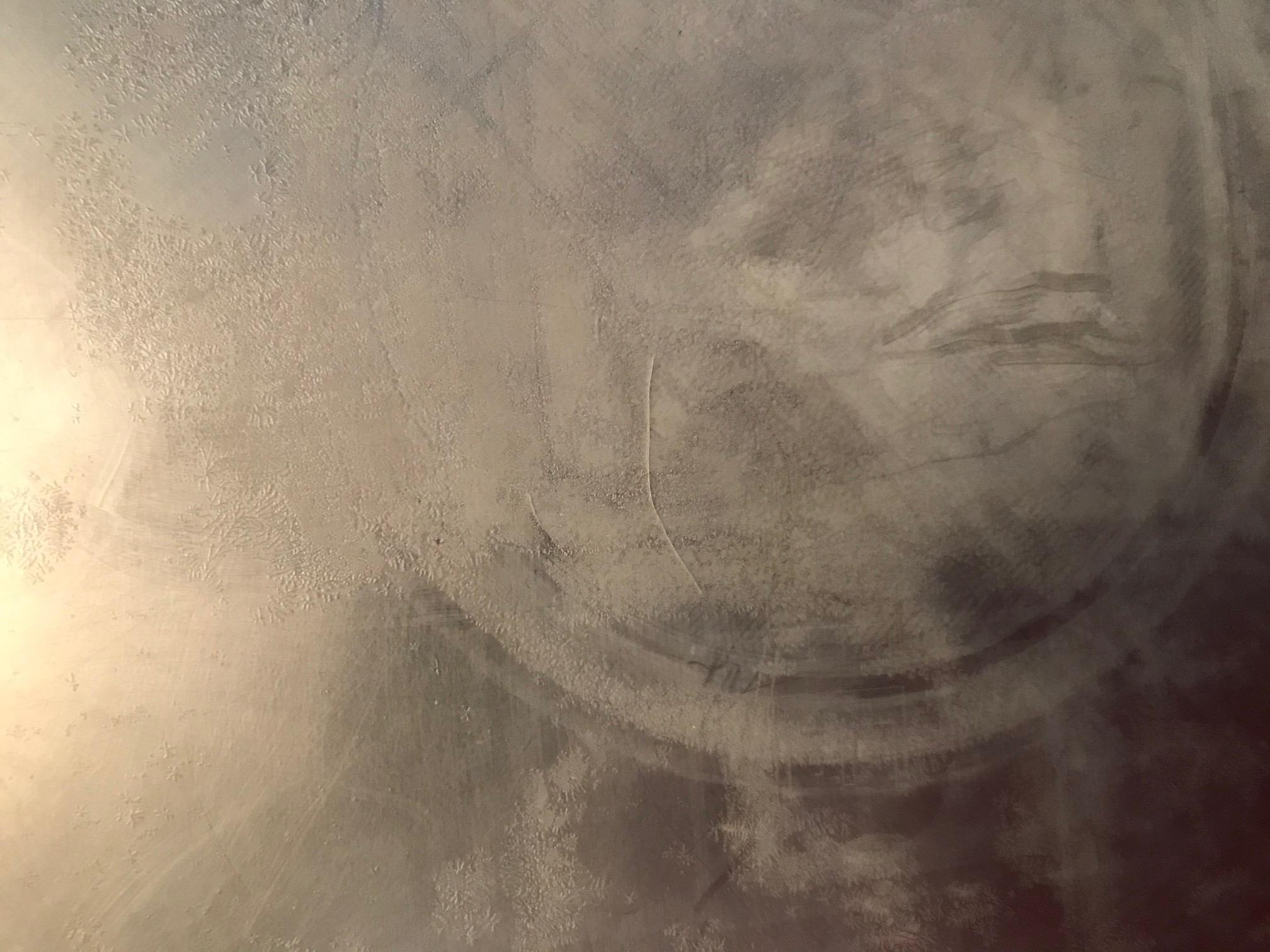

Here's a couple photos. The crack you can see is about 3 cm long; there are a couple others around 1 cm (they're only visible when the light hits just right).

Up close:

R Brown

Mar 26, 2020, 11:41:00 PM3/26/20

to BuildTak

I've also seen some cracking in the center on my 12" square

PEI flex plate. Sheet is about 20 months old, cracks showed up

after about a year. Print ABS mostly, 80C bed temp. I think I may

lower that temperature once I replace the current sheet. I avoid printing

parts in the center. I place them in front then rotate the

plate 90* each print to equalize the wear. Aside from the

cracks, the sheet is still in great shape. Printer is a Type A Machines Series 1 Pro with added 1/4" alum. plate atop the original glass, then magnet on top of that.

Brian Henning

Mar 27, 2020, 2:05:28 PM3/27/20

to BuildTak

In response to a direct e-mail from David Perez:

I'm not really sure how old my current PEI-covered FlexPlate is. I want to say somewhere between 1 and 2 years of moderate usage. Unfortunately I don't have a record of when I actually purchased it, and none of my attempts to log into my account on buildtak.com were successful (I tried the password reset with pretty much all of my e-mail addresses and none worked).

Reply all

Reply to author

Forward

0 new messages