Sidewall drop data

113 views

Skip to first unread message

Allan in Portland

Jun 29, 2012, 10:15:23 PM6/29/12

to bq...@googlegroups.com

Greetings,

List member Philip Williamson and I are putting together a Tire Pressure App that will compute the optimal air pressure for your tires based on the weight of you, your bike, your gear, and the frame geometry.

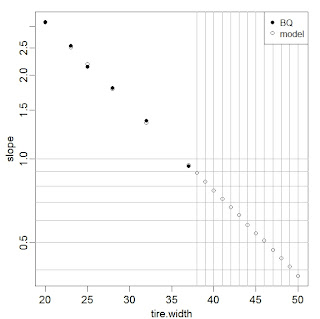

For those interested in gory details, I computed the slope and intercept for each tire width in BQ's published chart. Since the slope was clearly the biggest factor (they pretty closely converged with the same intercept at about 16lbs of load and 10PSI), I plotted the slopes from the widths we had, did a linear interpolation for widths between the measured points, and eye-balled a logarithmic curve for extrapolating to tires wider than 37mm. While I'm pretty happy with the pressure numbers we're getting, I'd be even more happy if I had some measured data points in the 42-55 mm range.

So, has anyone made their own sidewall drop measurements for wider tires?

BTW, we're pretty juiced about this app. We've been working on it evenings and weekends for a couple months and it's almost done. We hope to get it pushed out to all the usual Android marketplaces next week. I had planned to wait mentioning it on the list until after it was actually available, but now that we are so close, I decided to slightly ruin the surprise in the interest of more rigorous pressure computations. Also, if this goes well we're intending to do an iOS version (definitely) and then follow-up with a Sheldon-esque gear calculator app.

Thanks much,

-Allan

Joe V

Jun 30, 2012, 9:03:24 PM6/30/12

to bq...@googlegroups.com

I don't have any data but if you can't find any for wider tires, I should be able to give you optimal extrapolation values if you post the intercept/slope values for the data you do have. (I get paid for statistical work; I ride for free.)

Joe

Allan in Portland

Jul 1, 2012, 9:01:17 AM7/1/12

to bq...@googlegroups.com

Cool. I curious how they'll come out.

| tire width (mm) | slope (PSI/kg) | |

| 20 | 3.1 | |

| 23 | 2.55 | |

| 25 | 2.14 | |

| 28 | 1.8 | |

| 32 | 1.37 | |

| 37 | 0.94 | |

| 43 | 0.85 | |

| 50 | 0.8 |

43 & 50 mm are my estimates, the rest are measured from the chart printed in BQ.

Thanks,

-Allan

Joe V

Jul 2, 2012, 8:04:35 PM7/2/12

to bq...@googlegroups.com

Hi, Allan,

I'll be interested to see if anyone will make some direct measurements!

Here is what I found:

1. The data very strongly show that log(slope) is linearly related to tire width (technical details leading to this conclusion not shown...)

Here is the regression summary, where I used log = ln, that is, the natural log

Estimate Std. Error t value Pr(>|t|)

(Intercept) 2.52687 0.03621 69.78 2.53e-07

tire.width -0.06965 0.00129 -54.01 7.04e-07

---

Residual standard error: 0.01794 on 4 degrees of freedom <-- this means the unexplained var'n has about a s.e. of 2% (which could partly be due to variation from reading the numbers off the table?).

Multiple R-squared: 0.9986, Adjusted R-squared: 0.9983

2. The results I get are as follows, where "slope" is the slope prediction (that is, i used the formula from the above to get log(slope) estimates, and then I exponentiated them.

tire.width slope slope.BQ

1 20 3.11 3.10

2 23 2.52 2.55

3 25 2.19 2.14

4 28 1.78 1.80

5 32 1.35 1.37

6 37 0.95 0.94

7 38 0.89 NA

8 39 0.83 NA

9 40 0.77 NA

10 41 0.72 NA

11 42 0.67 NA

12 43 0.63 NA

13 44 0.58 NA

14 45 0.54 NA

15 46 0.51 NA

16 47 0.47 NA

17 48 0.44 NA

18 49 0.41 NA

19 50 0.38 NA

As you can see, my estimates for 43 and 50 mm are quite a bit lower than yours.

Here are two graphs of the results. The first is linear in slope, the second is logarithmic (so a straight-line fit), with horizontal lines at each 0.1 units and vertical lines at each 1 unit in the region of interest.

I'll be interested to see if anyone will make some direct measurements!

Joe

Wayne

Jul 3, 2012, 9:08:13 AM7/3/12

to Bicycle Quarterly Readers' Review

An poster on rec.bicycles.tech did extensive careful measurements of

tire drop data. I don't have time to search and find the link however

I saved a copy of it on my PC at the time and have copied the thread

below. Formatting makes it difficult but still possible to read.

Wayne

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

1 of 13 12/23/2007 6:16 PM

some tire drop data Options

Recently Visited Groups | Help | Sign in

rec.bicycles.tech Search this group Search Groups

16 messages - Collapse all

carlfo...@comcast.net View profile More options Sep 28, 4:17 pm

Some recent threads and an email today led me to measure how much a

fairly typical tire rose as I inflated it.

The results suggest that some people are fooling themselves.

First, some data from dial indicator measurements of a loaded tire's

height rise in thousandths of an inch from 40 to 130 psi, measured

from top of nominal 700x25c tire.

Tire measured 1.020" to 1.030" wide at top between 80 to 130 psi.

Total load on tire was ~85 pounds, resting on a scale, but the tire

stood on a concrete floor for the test.

inch mm inch

psi rise rise change

--- ----- ---- ------

40 0.000 0.00 n/a

50 0.021 0.53 0.021

60 0.038 0.97 0.017

70 0.052 1.32 0.014

80 0.063 1.60 0.011

90 0.076 1.93 0.013

100 0.088 2.24 0.012

110 0.100 2.54 0.012

120 0.110 2.79 0.010

130 0.120 3.05 0.010

My quick and dirty table shows only that the top of a roughly 1.020"

wide tire rose ~0.120 inches from 40 to 130 psi under an 88 pound

load.

For those interested in arbitrary figures, 15% of a tire width of

1.020" is 0.153", or 3.9 mm.

Presumably, someone could measure the diameter of a tire hanging in

mid-air and inflated to some arbitrary pressure, load it with some

weights, measure the change, and call it tire drop.

But this would require such an elaborate test rig that it would be

extremely difficult for any normal poster to even _try_ to make a

practical measurement of the difference between 90 psi and 100 psi.

After all, the difference between 90 and 100 psi with an elaborate

test rig using a dial indicator was only 0.012", about a hundredth of

an inch.

Incidentally, it is highly unlikely that pressure and a 700x25 tire's

rise have the straight linear relationship that some people suggest,

at least not over a 40 to 130 psi range with an 88 pound load.

I expect that beautifully smooth graphs of pressure and rise are just

as theoretical, oversimplified, and mistaken as similar predictions

for contact patch area, which does not follow the often-mentioned

tire-pressure/load = area prediction.

(Actual measurements of contact patches show that they fail to shrink

as much as predicted with higher pressures and fail to expand as much

Jan Heine

About this group

Subscribe to this group

This is a Usenet group - learn more

Discussions

+ new post

Sponsored Links

Bike Tires Clearance

Michelins, Continental, Tufo, More

No Sales Tax, Same Day Shipping

www.BikeTiresDirect.com

Tire Alerts - Low Prices

Keep Your Tires Inflated Correctly.

Increase efficiency, Save Gas Today

TerraPass.com

Tire Inflation

Optimizing Tire Pressure

Car Care Articles and Advice

www.autoMedia.com

See your message here...

Related Pages

Needy kids get chance to ride

Pittsburgh Tribune-Review - Dec 21, 2007

By Jessica LaDow Rich Kragness hoisted a small

Spider-Man bike onto ...

School, bicycle business create partnership focusing

on health, safety

Baltimore Sun - 15 hours ago

Northfield Elementary has joined Race Pace Bicycles

in a partnership ...

Tire fire erupts in Cumberland County

6abc.com - 8 hours ago

FAIRFIELD TOWNSHIP - December 23, 2007 --

Firefighters in Cumberland ...

Rideable Bicycle Replicas

www.hiwheel.com

Women Want Their Own Gear

New study indicates that small men's gear isn't the fit

most women ...

www.ergoweb.com

oldroads.com - Menotomy Vintage Bicycles

oldroads.com

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

2 of 13 12/23/2007 6:16 PM

as predicted with lower pressures. They stubbornly stick to a

preferred size.)

Cheers,

Carl Fogel

Reply to author Forward

Tim McNamara View profile More options Sep 28, 8:27 pm

In article <oltqf3td4ftpiiishe2kcimc8vhn5jf...@4ax.com>,

- Show quoted text -

Interesting data from Fogel Labs again; thanks, Carl. I don't have the

original article about the 15% drop figure right here to read again.

IIRC the 15% drop figure came from research by Jim Papodopolous, but

how

it was arrived at I don't know. It's a number that looks suspiciously

arbitrary (how many things in the world work out to such a nice even

number?).

Reply to author Forward

carlfo...@comcast.net View profile More options Sep 28, 9:24 pm

On Fri, 28 Sep 2007 21:27:22 -0500, Tim McNamara

- Show quoted text -

Dear Tim,

I don't know where the popular 15% figure came from or from what point

it was measured--just the weight of the front end of a bike resting on

the tire is about 10% of the typical load.

Maybe there's a clever measuring technique that was somehow confirmed

by rolling resistance tests, but it's going to have to be awfully

clever to handle differences of about a hundredth of an inch between

90 and 100 psi.

Here's a link that came in my email to a chart that graphs some kind

of 15% drop correlated with pressure for various tire sizes:

http://bp1.blogger.com/_d-Yj0VDKhWQ/RnwLUoA9sVI/AAAAAAAAAJ4/225Ym5qYK...

The graph seems to show some simple linear calculations, not actual

data points from measurements.

I suspect that actual measurements would show the straight line theory

is simply wrong.

If a tire were a piston in a car engine, then adding a 100 pound

weight (including piston) would drive a piston with an area of 1

square inch down until the pressure rose to 100 psi.

But a bicycle tire is significantly different from a metal piston in a

metal chamber.

When we load a tire, the bottom of the "piston chamber" is the

reasonably unyielding metal rim.

But on either side of the tire, the C-shaped tire walls deform outward

against the air pressure trying to keep them in their current shape

about an inch wide on a 25 mm tire, the minor axis of the toroid (your

thumb and finger going around the tire).

Meanwhile, the tire also deforms, much less against the gigantic "O"

of the tire viewed the long way around, the major axis of the toroid.

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

3 of 13 12/23/2007 6:16 PM

In effect, the tire is more like a long, narrow trampoline than the

top of a metal piston, and it distorts in a much more complicated

fashion.

This is why the simple area = load / pressure load equation fails to

predict what happens at high and low pressures for 700c x 25 tires.

The same explanation probably applies to how high a tire rises or

falls according to pressure. The sides of the tire act as scissors

jacks, applying increasing pressure at the edge of the contact patch

as pressure drops and the sides deform more and more.

As I've mentioned before, what made me suspicious of simple

straight-line predictions was knowing that a 4-inch wide trials tire

can carry a 400-pound load in a wheelstand down a paved road with only

4 psi and no way to spread out more than 4 inches. The oversimplified

equation predicts:

400 lbs / 4 (lbs/inch^2) = 100 ^ 2 = 4 x 25 inches

But a 4 x 18 trials tire is only about 26 inches in diameter, so a 25

inch long contact patch is impossible. The sidewalls had to be

exerting considerable force as springs, which seems reasonable, since

it takes considerable force to pull (or push) the wall of an inflated

tire out of shape.

Cheers,

Carl Fogel

Reply to author Forward

smokeystrodt...@gmail.com View profile More options Sep 28, 9:45 pm

On Sep 28, 9:27 pm, Tim McNamara <tim...@bitstream.net> wrote:

- Show quoted text -

Thanks for the information, Carl. I think the original article came

from Bicycling magazine. Currently you can get a version of it on the

roadbikerider.com website in the member's section.

Smokey

Reply to author Forward

Jean View profile More options Sep 29, 8:43 am

"Tim McNamara" <tim...@bitstream.net> wrote in message

news:timmcn-C026A2....@news.iphouse.com...

| In article <oltqf3td4ftpiiishe2kcimc8vhn5jf...@4ax.com>,

| carlfo...@comcast.net wrote:

|

| > Some recent threads and an email today led me to measure how much

a

| > fairly typical tire rose as I inflated it.

| >

| > The results suggest that some people are fooling themselves.

| >

....snip

|

| Interesting data from Fogel Labs again; thanks, Carl. I don't have

the

| original article about the 15% drop figure right here to read again.

| IIRC the 15% drop figure came from research by Jim Papodopolous, but

how

| it was arrived at I don't know. It's a number that looks

suspiciously

| arbitrary (how many things in the world work out to such a nice even

| number?).

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

4 of 13 12/23/2007 6:16 PM

I don't know how Berto came up with the 15% figure, but I do have a

clipping from Bicycling magazine that says "Michelin and National

recommend

selecting tire size and inflation pressure so the tire height drops by

20%

when you get on the bike". How they arrived at the 20% figure was

never

mentioned.

Reply to author Forward

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

5 of 13 12/23/2007 6:16 PM

Tim McNamara View profile More options Sep 29, 11:23 am

In article <upfrf3pifcnmdij94geh0vv2o6hi171...@4ax.com>,

- Show quoted text -

Having reviewed the article in Bicycle Quarterly ("Optimizing your

tire

pressure for your weight," BQ Vol 5, Issue 4), the 15% figure was

referenced from an article by Frank Berto (2004. Under Pressure.

Australian Cyclist March/April 2004, p. 48). I was not able to locate

the article on the Australian Cyclist Web site.

Heine measure loads on three bicycles with a rider seated on the bike

(randonneur bike, racing bike and "city" bike) and found that the

weight

distribution (% front/rear) was 45/55, 30/60 and 35/65 respectively.

Heine's article references that a 15% "tire drop" is recommended by

"several tire manufacturers." That statement is cited to Berto's

original article and no more specifics are given. The chart with the

nice linear relationships is also attributed to Berto.

> Maybe there's a clever measuring technique that was somehow confirmed

> by rolling resistance tests, but it's going to have to be awfully

> clever to handle differences of about a hundredth of an inch between

> 90 and 100 psi.

My guess would be to load the wheel through a frame or fork and

measure

the drop from the top of the tire to the ground, with an arrangement

similar to how a doctor measures your height. It would indeed need to

be carefully calibrated, perhaps some dial arrangement could be used.

> Here's a link that came in my email to a chart that graphs some kind

> of 15% drop correlated with pressure for various tire sizes:

>

http://bp1.blogger.com/_d-Yj0VDKhWQ/RnwLUoA9sVI/AAAAAAAAAJ4/225Ym5qYKT

> o/s1600- h/BQ_berto_inflationgraph.jpg

> The graph seems to show some simple linear calculations, not actual

> data points from measurements.

> I suspect that actual measurements would show the straight line

> theory is simply wrong.

That is the graph included on p 29 of BQ 5,4. It is attributed to

Berto's article in Australian Cyclist. Without being able to read the

Berto article, there isn't any way to understand how Berto came to

create that graph. I agree that such a linear relationship between

inflation and tire drop is probably unlikely, although it's

conceivable

that the relationship might be close to linear within the normal range

in inflation pressures. If you look at the Avocet rolling resistance

data, the curve of the relationship between inflation pressure and

rolling resistance flattened quite a bit at higher pressures.

Maybe you can Google up the source article by Berto, or perhaps there

is

some Australian or New Zealand or Tasmanian participant in the

newsgroup

who can provide that information.

Reply to author Forward

* * Chas View profile More options Sep 29, 12:58 pm

"Tim McNamara" <tim...@bitstream.net> wrote in message

news:timmcn-2DA059....@news.iphouse.com...

- Show quoted text -

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

6 of 13 12/23/2007 6:16 PM

Years ago I remember seeing a study that showed only a 5%-7% reduction

in

rolling resistance between 85 PSI and 110 PSI in a variety of tires.

Since most of us rode sewups in goathead country we opted to run at 85

PSI

to 90 PSI and got a lot less flats ( refer to Carl Fogel's test of

tire

puncture vs. pressure ).

Chas.

Reply to author Forward

Gary Young View profile More options Sep 29, 1:23 pm

- Show quoted text -

Jan Heine, publisher of the magazine where the graph appeared, posted

a

response on the ibob mailing list:

"The graph with the linear relationships quoted in the link below

[i.e., Carl's link, above] came from Bicycle Quarterly. It was based

on

actual measurements by Frank Berto, and his measurements did line up

roughly on a straight line (I have seen the original measurements). He

built a test rig, which he described many years ago in Bicycling

Magazine.

The graphs are extrapolated toward the ends...

The discrepancy between Carl Fogel's measurements and Frank Berto's

might be easy to explain. They measured different things. Carl

measured the rise of the tire with increasing pressure. I am not

surprised that this is not linear - the tire cannot expand

indefinitely.

Frank Berto measured how much pressure he needed for different

weights to achieve the same tire deflection of 15%. The 15% came from

tire manufacturers' recommendations. In Bicycle Quarterly's real road

tests, we found that performance decreased significantly once the

"tire drop" was more than about 13-15%. With less tire drop, higher

pressures did not yield significant performance benefits.

Please feel free to forward this clarification to rec.bike.tech.

Jan Heine

Editor

Bicycle Quarterly

140 Lakeside Ave #C

Seattle WA 98122

www.bikequarterly.com"

http://search.bikelist.org/getmsg.asp?Filename=internet-bob.10709.186...

Reply to author Forward

carlfo...@comcast.net View profile More options Sep 29, 2:24 pm

On Sat, 29 Sep 2007 12:23:39 -0500, Tim McNamara

<tim...@bitstream.net> wrote:

[snip]

>> Maybe there's a clever measuring technique that was somehow confirmed

>> by rolling resistance tests, but it's going to have to be awfully

>> clever to handle differences of about a hundredth of an inch between

>> 90 and 100 psi.

>My guess would be to load the wheel through a frame or fork and measure

>the drop from the top of the tire to the ground, with an arrangement

>similar to how a doctor measures your height. It would indeed need to

>be carefully calibrated, perhaps some dial arrangement could be used.

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

7 of 13 12/23/2007 6:16 PM

[snip]

Dear Tim,

In this case, the more careful the measurement, the sillier the

results will be. The resolution is already too fine for the subject.

There's no medical point, for example, to weighing normal adults to

within even a pound, since our weight easily varies that much

according to our last meal and visit to the bathroom. (The doctor does

not bother to have you remove your wallet, much less strip naked, when

he weighs you on his balance scales, accurate to 4 ounces.)

The "15%" tire drop figure implies resolution to at least 5%

increments, meaning that we think that 15% is what we want, not 10% or

20%.

But when compared to 10% or 20% drops, a "15% drop" means only that

somewhere between 70 and 110 psi is a good idea for tire inflation.

We hardly need elaborate charts and dial indicators to tell us that.

Here's how it works.

If a 1.000" wide tire has an absolute 15% drop of 0.150" at 90 psi

under an 85-lb load (don't ask me how to actually measure that with

repeatable accuracy), then we can apply my relative rise measurements

for a ~1" tire under the same conditions:

10 psi

theoretical measured

absolute relative

psi drop drops

--- -------- --------

x 20% 0.200" 20%

130 0.194" +0.010"

120 0.184" +0.010"

110 0.174" +0.012" \

100 0.162" +0.012" \

90 15% 0.150" 0 > 15% range

80 0.137" -0.013" /

70 0.126" -0.011" /

60 0.112" -0.014"

x 10% 0.100" 10%

50 0.091" -0.021"

Here's my test data again:

inch inch

psi rise change

--- ----- ------

40 0.000 n/a

50 0.021 0.021

60 0.038 0.017

70 0.052 0.014

80 0.063 0.011

90 0.076 0.013

100 0.088 0.012

110 0.100 0.012

120 0.110 0.010

130 0.120 0.010

In any case, inflated tires are not round to within a hundredth of an

inch. They're just slapped on aluminum rims and inflated, with the

beads creeping out roughly regularly, and then the sides bend as the

tire is loaded.

What's bending in clinchers are bias-laid plies of threads, with 66 to

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

8 of 13 12/23/2007 6:16 PM

170 threads per inch:

66 tpi 0.015"

127 tpi 0.008"

170 tpi 0.006"

A single thread is roughly as thick as a measured 10 psi difference in

tire drop.

Cheers,

Carl Fogel

Reply to author Forward

carlfo...@comcast.net View profile More options Sep 29, 2:49 pm

On Sat, 29 Sep 2007 14:23:23 -0500, Gary Young <garyyou...@gmail.com>

wrote:

- Show quoted text -

Dear Gary,

Anyone can load a tire, put a dial indicator on the top of the tire,

and measure the rise as inflation is increased in 10 psi increments.

It makes no difference whether the measurements are taken in

increasing or decreasing order.

The rise will _not_ be linear, with the effect particularly noticeable

at low pressures. If a straight line was extrapolated, that could

account for the discrepancy.

It would be fascinating to see the details of how the measurements

were achieved, since the tire deflects _most_ with the initial load.

In other words, the drop for 8 pounds of load is greatest for the

first 8 pounds (roughly the load of just a 20-lb bike on the front

tire). Measuring differences in thousandths of an inch gets awfully

tricky in practical terms out toward zero.

A 13%-15% absolute tire drop range is mentioned.

For a 1.000" tire, that's 0.130" to 0.150", a difference of 0.020".

On a ~1-inch tire, I found that a relative drop of 0.020" at ~90 psi

with an 85-lb load corresponded to a ~20 psi change in inflation.

Any bicyclist with a floor pump, a dial indicator, and some weights

can check my measurements.

You can pick up a dial indicator from Harbor Freight for about ten

bucks, less than the cost of a floor pump.

Cheers,

Carl Fogel

Reply to author Forward

* * Chas View profile More options Sep 29, 3:36 pm

"Gary Young" <garyyou...@gmail.com> wrote in message

news:U4ydnbBef9e2O2Pb...@giganews.com...

> On Fri, 28 Sep 2007 21:24:36 -0600, carlfogel wrote:

<snip>

>.....In Bicycle Quarterly's real road tests, we found that

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

9 of 13 12/23/2007 6:16 PM

> performance decreased significantly once the "tire drop" > was more than

about 13-15%. With less tire drop, higher > pressures did not yield

significant performance benefits.

Performance? Define performance. Was it an increase in rolling

resistance?

More pedal force required? Or was it anecdotal subjective opinions of

the

riders.

My personal opinion is that some riders like very hard tires and have

fooled themselves into thinking that tires run at high pressures will

MAKE

them go faster.

If I'm going to ride on a rough surface road I ride Panaracer Paselas

at

85-90PSI. If it's a smooth road surface I like Continental Grand Prixs

at

95-110 PSI. I ride sewups at 90 PSI. That's MY preference based on

ride

comfort and puncture potential.

Chas.

Reply to author Forward

carlfo...@comcast.net View profile More options Sep 29, 3:57 pm

- Show quoted text -

An email asked for details of the testing.

I wonder if other posters get as many emails as I do? Often it seems

as if people are accidentally hitting the email instead of the post

button on their newsreaders. I don't mind, but it would more fun if

they were all beautiful but lonely women.

Luckily, the test rig had been left untouched in hopes of gaining

Historic Place status, so here's a picture:

http://i24.tinypic.com/2iw4zn5.jpg

The white bathroom scales are not legal for trade, but showed ~85

pounds when shoved under the tire. They were removed for testing, lest

the tire inflation increased the contact patch area enough to cause

the scale surface to rise--remember, the measurements involved changes

as small as ten thousandths of an inch.

The yellow floor pump reads in alleged 2-lb increments. Zip ties

secure the pump head, which tended to come off during lengthy testing.

Fogel Labs has budgeted for a new O-ring.

The seat post sticks up between the jaws of the bench vise, which are

slightly open, but stop everything from toppling over. If the post had

been clamped, it might have held the front end of the bicycle down

slightly as the tire was pumped up--again, the measurements were so

tiny that such precautions were necessary.

The board was clamped to the red test frame for long-ago experiments.

Later, the weight bar was added for even stranger rituals.

The dial indicator from Sears is directly over the front axle and

contact patch. It rests on the weight bar, not the top of the tire,

partly because it was just about the right height, but mostly because

the slight expansion of the top of the tire during inflation would

have exaggerated the rise of the bottom of the tire.

A carefully machined indentation in the round weight bar assures that

the dial indicator does not slip off to the side and give false

readings. (It looks remarkably like a dent whacked with a blunt punch

and a hammer.)

The dial indicator is held by vise grips, which in turn are held in

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

10 of 13 12/23/2007 6:16 PM

place under a 10-pound weight. Vise grips were required because half

the convenient mounting lug on the back of the dial indicator was

hacksawed off in 1972 in order to fit into an awkward spot while

timing a motorcycle. I may spend ten bucks at Harbor Freight and get a

replacement, or maybe even a few bucks more for one with an adjustable

arm.

Cheers,

Carl Fogel

Reply to author Forward

anth View profile More options Sep 29, 10:42 pm

On Sat, 2007-09-29 at 12:23 -0500, Tim McNamara wrote:

> Heine measure loads on three bicycles with a rider seated on the bike

> (randonneur bike, racing bike and "city" bike) and found that the weight

> distribution (% front/rear) was 45/55, 30/60 and 35/65 respectively.

The middle figures don't add up. I'm guessing they should have been

40/60?

Reply to author Forward

Ryan Cousineau View profile More options Sep 29, 11:10 pm

In article <kddtf3drng10jfmnl02pcifrlmif8fk...@4ax.com>,

carlfo...@comcast.net wrote:

> On Sat, 29 Sep 2007 14:23:23 -0500, Gary Young <garyyou...@gmail.com>

> wrote:

> >On Fri, 28 Sep 2007 21:24:36 -0600, carlfogel wrote:

> >> On Fri, 28 Sep 2007 21:27:22 -0500, Tim McNamara

> >> <tim...@bitstream.net> wrote:

> >>>In article <oltqf3td4ftpiiishe2kcimc8vhn5jf...@4ax.com>,

> >>> carlfo...@comcast.net wrote:

[long correspondence trimmed; interested viewers are invited to check

the archives]

> Any bicyclist with a floor pump, a dial indicator, and some weights

> can check my measurements.

> You can pick up a dial indicator from Harbor Freight for about ten

> bucks, less than the cost of a floor pump.

Aha! I am on to your craven attempts to encourage the readers of rbt

to

engage in the oft-forsaken cornerstone of the Scientific Method:

reproducibility!

Well, we scholastics are on to you.

And it's a shame. I always assumed that a former literature explicator

like yourself would have had a naturally scholastic bent.

Silliness aside, I should take up your challenge, but my excuse is

that

I have too many bikes a-building right now for others.

--

Ryan Cousineau rcous...@sfu.ca http://www.wiredcola.com/

"I don't want kids who are thinking about going into mathematics

to think that they have to take drugs to succeed." -Paul Erdos

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

11 of 13 12/23/2007 6:16 PM

Reply to author Forward

carlfo...@comcast.net View profile More options Sep 29, 11:43 pm

- Show quoted text -

An odd example of measurement problems.

I took a few minutes and set up my dial calipers to hang and measure

the same tire's width as it sat in a truing stand. As I expected, the

tire widened as it was pumped up

psi width

30 0.975

40 0.985

50 0.992

60 0.996

70 0.998

80 1.007

90 1.014

100 1.018

110 1.025

120 1.029

130 1.034

140 1.040

But trying to get a good reading by rolling a dial caliper's jaws shut

on squishy rubber _felt_ a little squishy and inaccurate, even though

the results looked good.

Rather than adjusting the dial caliper to slip at less and less

resistance as its jaws closed on the rubber, I decided to try a dial

indicator, which supplies its own very gentle spring action.

Naturally, I got sidetracked and first set the dial indicator up to

measure the expansion of the top of the tire in the truing stand, not

its sideways bulge. But things turned out pretty well:

top of

psi tire

? 1.000 as low as I could get it and still feel pressure

10 0.990 probably seated a bit, moving the wrong way

20 0.994

30 0.998

40 1.002

50 1.007

60 1.011

70 1.016

80 1.023

90 1.028

100 1.033

110 1.038

120 1.042

130 1.050

140 pump head blew off

Then I set things up again in the truing stand, but turned the dial

indicator rig on the side of the tire to measure how far one side of

the tire bulged sideways as I pumped it up.

I zeroed the dial indicator, checked that everything was at right

angles, and pumped . . . Nothing.

No change at 10 psi.

I pumped to 20 psi, but still nothing happened.

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

12 of 13 12/23/2007 6:16 PM

At 30 psi, the needle still sat on 0.000.

I went up to 80 psi without any movement.

At 120 psi, there was a little movement, about 0.003 inches.

Mystified, I grabbed my dial calipers, closed their jaws on the stupid

tire, and let the air out of the dumb thing. A gratifying gap promptly

opened between the side of the tire and the jaws, so I knew that I

wasn't crazy--tires really do expand when inflated.

But another attempt with the dial _indicator_ produced the same

failure.

At first, I thought that the problem was just that the tire was

expanding outward, as well as sideways, and the dial indicator was

slipping down the side of the expanding tire, just enough for the loss

to cancel the gain.

Some of the failure was due to this movement in two directions, but I

suspect that real problem was the tiny bit of stiction in the dial

indicator rod as the rubber moved outward as well as sideways may have

made things worse, too, jamming the delicate mechanism.

Whatever the cause, the dial indicator utterly failed to measure the

sideways expansion clearly indicated by dial calipers.

Cheers,

Carl Fogel

Reply to author Forward

carlfo...@comcast.net View profile More options Sep 29, 11:55 pm

On Sun, 30 Sep 2007 05:10:12 GMT, Ryan Cousineau <rcous...@sfu.ca>

wrote:

[snip]

>Silliness aside, I should take up your challenge, but my excuse is that

>I have too many bikes a-building right now for others.

Dear Ryan,

Just remember that it could be a very bad thing if a bike with 80

pounds of weights at handlebar height topples over onto you.

Safety rope the rig to a work bench or arrange for a hefty vise's jaws

to cuddle a stout part of the bike frame.

But do _something_ to make sure that your carefully balanced test bike

rig can't fall over and hurt you.

I haven't had any accidents so far, and I don't want to read about

anyone else having different results.

Er, I mean anyone else having accidents. Different results are fine.

Cheers,

Carl Fogel

Reply to author Forward

End of messages

« Back to Discussions « Newer topic Older topic »

some tire drop data - rec.bicycles.tech | Google Groups

http://groups.google.com/group/rec.bicycles.tech/browse_thread/thread/...

13 of 13 12/23/2007 6:16 PM

Create a group - Google Groups - Google Home - Terms of Service -

Privacy Policy

©2007 Google

Allan in Portland

Jul 3, 2012, 6:01:49 PM7/3/12

to bq...@googlegroups.com

Thanks for those. I knew my numbers were a little high, but I didn't realize they were that high. I figured if people got pinch flats from our app that would be a bad thing. I also felt

We haven't submitted the app yet, so there's still time to adjust the calculations if we wish.

-Allan

Allan in Portland

Jul 3, 2012, 6:25:58 PM7/3/12

to bq...@googlegroups.com

Thanks Wayne. I wanted to make some of my own measurements, but have been so busy creating the App in the first place, that creating a test apparatus has not remotely been in the cards.

If the App receives a strong response, that will definitely encourage us to go back and make some measurements of our own. That and we've already got a short-list of features we'd like to add.

-Allan

Nick Bull

Jul 5, 2012, 9:10:04 PM7/5/12

to bq...@googlegroups.com

There was some discussion on the randon newsgroup about this topic and I tried several different models before finding one that I thought worked "well enough".

My starting point was to develop a data set based on the "standard" tire pressure graph that's been posted in BQ -- I just put in the "optimal pressure" for each tire size at weights of 66, 77, 88, 99, 110, and 121 pounds. The regression that worked best (adjusted R^2 of .9996) was:

PSI = J*weight/size + K*weight/(size^2) + L*weight^2/(size) + M*weight^2/(size^2) with regression results as follows, which imply:

Regression results follow:

Model: MODEL1

NOTE: No intercept in model. R-square is redefined.

Dependent Variable: ZPSI Predicted Value of PSI

Analysis of Variance

Sum of Mean

Source DF Squares Square F Value Prob>F

Model 4 407614.55097 101903.63774 29771.629 0.0001

Error 46 157.45082 3.42284

U Total 50 407772.00179

Root MSE 1.85009 R-square 0.9996

Dep Mean 84.20000 Adj R-sq 0.9996

C.V. 2.19726

Parameter Estimates

Parameter Standard T for H0: Variable

Variable DF Estimate Error Parameter=0 Prob > |T| Label

WGHTOSZ 1 14.639907 1.76404141 8.299 0.0001

WGHTOSZS 1 131.852835 44.33787004 2.974 0.0047

WT2OSZ 1 -0.070903 0.01489340 -4.761 0.0001

WT2OSZS 1 2.274180 0.38246978 5.946 0.0001

The results for each tire size & weight combo shown below compare optimal pressure from the graph (PSI) to the forecast optimal pressure (ZPSIDIR) and show the absolute percent error in ABSRERR. The regression does a good-enough job for me for my typical weight and for the tire sizes I run.

OBS SIZE WEIGHT PSI ZPSIDIR ABSRERR

1 20 66 78.0 79.391 1.78281

2 20 77 95.0 94.435 0.59453

3 20 88 109.0 109.998 0.91537

4 20 99 125.0 126.078 0.86261

5 20 110 139.0 142.677 2.64513

6 20 121 153.0 159.793 4.43997

7 23 66 65.0 63.759 1.90962

8 23 77 77.0 75.415 2.05792

9 23 88 90.5 87.366 3.46255

10 23 99 103.0 99.612 3.28959

11 23 110 115.0 112.151 2.47705

12 23 121 128.0 124.985 2.35515

13 23 132 140.0 138.114 1.34731

14 23 143 152.0 151.536 0.30496

15 25 66 55.0 56.069 1.94368

16 25 77 65.0 66.094 1.68253

17 25 88 77.0 76.312 0.89288

18 25 99 87.0 86.726 0.31547

19 25 110 98.0 97.333 0.68079

20 25 121 109.0 108.134 0.79418

21 25 132 120.0 119.130 0.72494

22 25 143 130.0 130.320 0.24617

23 25 154 140.0 141.704 1.21729

24 28 66 48.0 47.213 1.63881

25 28 77 57.0 55.394 2.81687

26 28 88 65.0 63.665 2.05451

27 28 99 72.5 72.024 0.65665

28 28 110 82.0 80.472 1.86284

29 28 121 90.5 89.010 1.64621

30 28 132 99.0 97.637 1.37670

31 28 143 108.0 106.353 1.52488

32 28 154 117.0 115.158 1.57404

33 32 66 37.5 38.716 3.24169

34 32 77 43.0 45.173 5.05259

35 32 88 51.0 51.631 1.23694

36 32 99 58.0 58.090 0.15572

37 32 110 65.0 64.551 0.69069

38 32 121 71.0 71.013 0.01835

39 32 132 78.0 77.476 0.67147

40 32 143 85.0 83.941 1.24619

41 32 154 91.0 90.406 0.65224

42 37 66 30.0 31.360 4.53302

43 37 77 36.0 36.370 1.02914

44 37 88 40.0 41.319 3.29836

45 37 99 45.0 46.206 2.68103

46 37 110 49.0 51.032 4.14663

47 37 121 53.0 55.796 5.27453

48 37 132 58.0 60.497 4.30590

49 37 143 62.0 65.138 5.06066

50 37 154 68.0 69.716 2.52362

My starting point was to develop a data set based on the "standard" tire pressure graph that's been posted in BQ -- I just put in the "optimal pressure" for each tire size at weights of 66, 77, 88, 99, 110, and 121 pounds. The regression that worked best (adjusted R^2 of .9996) was:

PSI = J*weight/size + K*weight/(size^2) + L*weight^2/(size) + M*weight^2/(size^2) with regression results as follows, which imply:

| J= | 14.63991 |

| K= | 131.8528 |

| L= | -0.0709 |

| M= | 2.27418 |

Regression results follow:

Model: MODEL1

NOTE: No intercept in model. R-square is redefined.

Dependent Variable: ZPSI Predicted Value of PSI

Analysis of Variance

Sum of Mean

Source DF Squares Square F Value Prob>F

Model 4 407614.55097 101903.63774 29771.629 0.0001

Error 46 157.45082 3.42284

U Total 50 407772.00179

Root MSE 1.85009 R-square 0.9996

Dep Mean 84.20000 Adj R-sq 0.9996

C.V. 2.19726

Parameter Estimates

Parameter Standard T for H0: Variable

Variable DF Estimate Error Parameter=0 Prob > |T| Label

WGHTOSZ 1 14.639907 1.76404141 8.299 0.0001

WGHTOSZS 1 131.852835 44.33787004 2.974 0.0047

WT2OSZ 1 -0.070903 0.01489340 -4.761 0.0001

WT2OSZS 1 2.274180 0.38246978 5.946 0.0001

The results for each tire size & weight combo shown below compare optimal pressure from the graph (PSI) to the forecast optimal pressure (ZPSIDIR) and show the absolute percent error in ABSRERR. The regression does a good-enough job for me for my typical weight and for the tire sizes I run.

OBS SIZE WEIGHT PSI ZPSIDIR ABSRERR

1 20 66 78.0 79.391 1.78281

2 20 77 95.0 94.435 0.59453

3 20 88 109.0 109.998 0.91537

4 20 99 125.0 126.078 0.86261

5 20 110 139.0 142.677 2.64513

6 20 121 153.0 159.793 4.43997

7 23 66 65.0 63.759 1.90962

8 23 77 77.0 75.415 2.05792

9 23 88 90.5 87.366 3.46255

10 23 99 103.0 99.612 3.28959

11 23 110 115.0 112.151 2.47705

12 23 121 128.0 124.985 2.35515

13 23 132 140.0 138.114 1.34731

14 23 143 152.0 151.536 0.30496

15 25 66 55.0 56.069 1.94368

16 25 77 65.0 66.094 1.68253

17 25 88 77.0 76.312 0.89288

18 25 99 87.0 86.726 0.31547

19 25 110 98.0 97.333 0.68079

20 25 121 109.0 108.134 0.79418

21 25 132 120.0 119.130 0.72494

22 25 143 130.0 130.320 0.24617

23 25 154 140.0 141.704 1.21729

24 28 66 48.0 47.213 1.63881

25 28 77 57.0 55.394 2.81687

26 28 88 65.0 63.665 2.05451

27 28 99 72.5 72.024 0.65665

28 28 110 82.0 80.472 1.86284

29 28 121 90.5 89.010 1.64621

30 28 132 99.0 97.637 1.37670

31 28 143 108.0 106.353 1.52488

32 28 154 117.0 115.158 1.57404

33 32 66 37.5 38.716 3.24169

34 32 77 43.0 45.173 5.05259

35 32 88 51.0 51.631 1.23694

36 32 99 58.0 58.090 0.15572

37 32 110 65.0 64.551 0.69069

38 32 121 71.0 71.013 0.01835

39 32 132 78.0 77.476 0.67147

40 32 143 85.0 83.941 1.24619

41 32 154 91.0 90.406 0.65224

42 37 66 30.0 31.360 4.53302

43 37 77 36.0 36.370 1.02914

44 37 88 40.0 41.319 3.29836

45 37 99 45.0 46.206 2.68103

46 37 110 49.0 51.032 4.14663

47 37 121 53.0 55.796 5.27453

48 37 132 58.0 60.497 4.30590

49 37 143 62.0 65.138 5.06066

50 37 154 68.0 69.716 2.52362

Allan in Portland

Jul 6, 2012, 12:13:10 PM7/6/12

to bq...@googlegroups.com

On Thursday, July 5, 2012 6:10:04 PM UTC-7, Nick Bull wrote:

There was some discussion on the randon newsgroup about this topic and I tried several different models before finding one that I thought worked "well enough".

Interesting analysis. That's a whole lot more than I'd ever be able to pull-off. :-) However, I notice the errors get considerably larger with wider tires and lower weights. Unfortunately, that's exactly the area we are trying to extrapolate into.

There are two problems to solve for any Spreadsheet/Program/App/etc:

1) How best to fit the published data to a formula

2) How best to extrapolate (ie. predict) from published data to wider tires

I have a good handle on 1) because the published data was a set of lines so I've implemented a table look-up of a set of slopes & intercepts. (Of course this treats the published data as true and unassailable, but we have to start somewhere.)

In any case, if you have something you like and works for you, that's great. I won't argue anyone out of anything they've tested and know they like.

Regards,

-Allan

Allan in Portland

Jul 6, 2012, 12:16:41 PM7/6/12

to bq...@googlegroups.com

Meant to add... (argh, the google interface is such a POS.)

On Friday, July 6, 2012 9:13:10 AM UTC-7, Allan in Portland wrote:

Concerning 2), I like using ln to predict the slopes of wide tires because e is one of those constants that seems to permeate the physical world and the slopes we do have seem to fit a ln regression very well.

-Allan

On Friday, July 6, 2012 9:13:10 AM UTC-7, Allan in Portland wrote:

On Thursday, July 5, 2012 6:10:04 PM UTC-7, Nick Bull wrote:There was some discussion on the randon newsgroup about this topic and I tried several different models before finding one that I thought worked "well enough".

Interesting analysis. That's a whole lot more than I'd ever be able to pull-off. :-) However, I notice the errors get considerably larger with wider tires and lower weights. Unfortunately, that's exactly the area we are trying to extrapolate into.

There are two problems to solve for any Spreadsheet/Program/App/etc:

1) How best to fit the published data to a formula

2) How best to extrapolate (ie. predict) from published data to wider tires

I have a good handle on 1) because the published data was a set of lines so I've implemented a table look-up of a set of slopes & intercepts. (Of course this treats the published data as true and unassailable, but we have to start somewhere.)

Concerning 2), I like using ln to predict the slopes of wide tires because e is one of those constants that seems to permeate the physical world and the slopes we do have seem to fit a ln regression very well.

-Allan

Nick Bull

Jul 8, 2012, 7:18:16 PM7/8/12

to bq...@googlegroups.com

Yes, I agree my approach seems not to be doing as well as I'd like for the bigger tire sizes (lower weights are unfortunately not as relevant as I'd like at the moment ...). For bigger tire sizes, more data points might be helpful to push the regression in the direction of the bigger tire sizes. And that's where you started the whole thread, with a request for data ...

I've never been particularly enamored of "e" and "ln" in regressions -- many people use ln to detrend data, but in fact even the detrended data can still have a unit root. Take white noise, grow it at 5 percent per year, detrend it using ln, run a regression, and you'll see that the detrended data look like they have a meaningful correlation. But it's still just white noise!

It's still very cool that e^(i*pi)+1=0 combines some of the most deeply meaningful constants in one simple equation!

Nick

I've never been particularly enamored of "e" and "ln" in regressions -- many people use ln to detrend data, but in fact even the detrended data can still have a unit root. Take white noise, grow it at 5 percent per year, detrend it using ln, run a regression, and you'll see that the detrended data look like they have a meaningful correlation. But it's still just white noise!

It's still very cool that e^(i*pi)+1=0 combines some of the most deeply meaningful constants in one simple equation!

Nick

Joe V

Jul 13, 2012, 5:55:05 PM7/13/12

to bq...@googlegroups.com

I just took a look at the data you supplied, Nick. It was good of you to supply it. So, let's assume that is the "truth" for now.

Here is the formula I derived. Nick, this is empirical, and I may be able to do better given that you used weight/size type ratios, but I'm guessing it won't do much better than this. (However, I couldn't understand why ratios with different powers as you had would make sense, so I am guessing yours is empirical as well?)

1. Rescale weight and size to weightS=(weight-100)/50 and sizeS=(size-30)/10. This is really not needed, but it makes the coefficients have more reasonable-sized values.

2. Use these coefficients in the model. (Allan, if this is not clear let me know. It's the same idea that Nick showed you.)

Estimate

(Intercept) 5.323418

weightS 1.159610

sizeS -1.256772

weightS^2 ) -0.186693

sizeS^2 0.319017

weightS*sizeS -0.370594

3. This gives fitted values of psi^0.4. So, to get the fitted values for psi, just take these values and raise them to the 1/0.4 power.

The 0.4 power was not statistically different from the 0.5 power, which probably is better connected to a physical system,. but I did the fits with 0.4.

Nick, when I took your psi and fitted values and used the formula to convert them to a root mse (your Minitab o/p), I obtained 1.98 instead of the 1.85 you have on your o/p listing. Not sure why--this should not be due to round-off error. (Also, FYI, when you use Minitab and don't fit an intercept, the R^2 value is redefined, as the Minitab o/p notes. That resulting R^2 value is higher that what we normally think about as R^2, so that 0.9996 is unrealistic.)

Here are the results. First graph is your data, Nick, with one line ("connect the dots") for each tire size (sizes not shown, but are the ones you looked at and should be obvious). Note that the points are sometimes not too smoothly connected, so a smooth fit cannot (and probably should not) be perfect.

Second graph is same as the first, but with the fits from your equation included. The third graph is the same as the first, but with the fits from the above equation used. The fourth graphs is the absolute errors (not relative errors--that is, the graph is in psi units) for the old and new fits, with an x=y line added

Allan, in case you want to use this equation, I hope this is clear enough. If not let me know. As a check, you can use the following to verify your fits with mine.

Joe

size weight psi fits sizeS weightS

1 20 66 78.0 80.05 -1.0 -0.68

2 20 77 95.0 94.02 -1.0 -0.46

3 20 88 109.0 108.60 -1.0 -0.24

4 20 99 125.0 123.64 -1.0 -0.02

5 20 110 139.0 138.99 -1.0 0.20

6 20 121 153.0 154.51 -1.0 0.42

7 23 66 65.0 64.92 -0.7 -0.68

8 23 77 77.0 76.46 -0.7 -0.46

9 23 88 90.5 88.48 -0.7 -0.24

10 23 99 103.0 100.85 -0.7 -0.02

11 23 110 115.0 113.43 -0.7 0.20

12 23 121 128.0 126.08 -0.7 0.42

13 23 132 140.0 138.68 -0.7 0.64

14 23 143 152.0 151.07 -0.7 0.86

15 25 66 55.0 56.76 -0.5 -0.68

16 25 77 65.0 66.93 -0.5 -0.46

17 25 88 77.0 77.50 -0.5 -0.24

18 25 99 87.0 88.35 -0.5 -0.02

19 25 110 98.0 99.35 -0.5 0.20

20 25 121 109.0 110.37 -0.5 0.42

21 25 132 120.0 121.28 -0.5 0.64

22 25 143 130.0 131.97 -0.5 0.86

23 25 154 140.0 142.33 -0.5 1.08

24 28 66 48.0 46.93 -0.2 -0.68

25 28 77 57.0 55.36 -0.2 -0.46

26 28 88 65.0 64.08 -0.2 -0.24

27 28 99 72.5 72.98 -0.2 -0.02

28 28 110 82.0 81.96 -0.2 0.20

29 28 121 90.5 90.88 -0.2 0.42

30 28 132 99.0 99.65 -0.2 0.64

31 28 143 108.0 108.15 -0.2 0.86

32 28 154 117.0 116.29 -0.2 1.08

33 32 66 37.5 37.46 0.2 -0.68

34 32 77 43.0 44.06 0.2 -0.46

35 32 88 51.0 50.84 0.2 -0.24

36 32 99 58.0 57.68 0.2 -0.02

37 32 110 65.0 64.50 0.2 0.20

38 32 121 71.0 71.19 0.2 0.42

39 32 132 78.0 77.67 0.2 0.64

40 32 143 85.0 83.85 0.2 0.86

41 32 154 91.0 89.64 0.2 1.08

42 37 66 30.0 30.07 0.7 -0.68

43 37 77 36.0 35.01 0.7 -0.46

44 37 88 40.0 39.99 0.7 -0.24

45 37 99 45.0 44.94 0.7 -0.02

46 37 110 49.0 49.76 0.7 0.20

47 37 121 53.0 54.38 0.7 0.42

48 37 132 58.0 58.73 0.7 0.64

49 37 143 62.0 62.74 0.7 0.86

50 37 154 68.0 66.34 0.7 1.08

Nick Bull

Jul 13, 2012, 7:51:05 PM7/13/12

to bq...@googlegroups.com

Thanks, Joe,

The original data were just my best effort to capture some x,y pairs from the graph that is taken from Berto's findings--though it would be interesting to see what that graph truly looks like when it is the original data complete with measurement error. So ... given the amount of uncertainty there, it seemed like once I had a regression that kind of worked, it was time to stop. It's just for figuring out what to pump my tires up to! Step one in the process is knowing how much I and my bike and equipment weigh, plus the weight distribution between wheels, all of which is usually somewhat uncertain, as is the actual size of my tires. And when I pump my tires, I'm using an analog gauge, so it's just approximate, and when I take the hose off the valve stem some unknown quantity of air escapes, adding to the uncertainty. And it seems like a wide range of pressures all feels not too wildly different when I'm on the bike. Though the other day, riding to work it felt like I was working extremely hard and my legs were really hurting but just not getting the expected speed. Turns out my tires were about 30 pounds low!

Anyway, I think your regression probably looks like it's doing a better job!

Nick

The original data were just my best effort to capture some x,y pairs from the graph that is taken from Berto's findings--though it would be interesting to see what that graph truly looks like when it is the original data complete with measurement error. So ... given the amount of uncertainty there, it seemed like once I had a regression that kind of worked, it was time to stop. It's just for figuring out what to pump my tires up to! Step one in the process is knowing how much I and my bike and equipment weigh, plus the weight distribution between wheels, all of which is usually somewhat uncertain, as is the actual size of my tires. And when I pump my tires, I'm using an analog gauge, so it's just approximate, and when I take the hose off the valve stem some unknown quantity of air escapes, adding to the uncertainty. And it seems like a wide range of pressures all feels not too wildly different when I'm on the bike. Though the other day, riding to work it felt like I was working extremely hard and my legs were really hurting but just not getting the expected speed. Turns out my tires were about 30 pounds low!

Anyway, I think your regression probably looks like it's doing a better job!

Nick

Allan in Portland

Jul 13, 2012, 8:46:22 PM7/13/12

to bq...@googlegroups.com

Um, wow. That's some strong medicine. So you're saying the equation is:

PSI = [ 1.159610 * ((load - 100)/50) +

-0.186693 * ((load - 100)/50)^2 +

-1.256772 * ((width - 30)/10) +

0.319017 * ((width - 30)/10)^2 +

-0.370594 * ((load - 100)/50) * ((width - 30)/10) ]^0.4

How did you get (load-50)/100 & (width-30)/10? That seems almost totally random.

I take it multiplying the load & width there at the end is a normal statistical regression thing to do?

Oh, and width is mm and load is kg?

Thanks,

-Allan

Joe V

Jul 17, 2012, 12:01:47 AM7/17/12

to bq...@googlegroups.com

Allan,

What you said is correct, except that weight is in pounds (I just used the data that Nick supplied).

I took, for example, load - 100 because the average load was about 100. I divided by 50 because the range of loads was in that ballpark. You are correct that those numbers are arbitrary. I did that to make the coefficients have a reasonable size--here they turned out to be in range of 0.2 to 1.3 aside from their signs.

If I used other constants, or just used load instead of (load - 100)/50, the coefficients would change but the the PSI answers would be the same. (This is because I used a polynomial of degree 2, if that means anything to you. That polynomial includes that weight*size feature--yes, that is a standard thing to do, and helps the model fit better--at least this one.)

If I had used load and weight directly, here are what the coefficients would be:

Estimate

(Intercept) 6.675e+00

weight 6.036e-02

size -2.430e-01

weight^2 -7.468e-05

size^2 3.190e-03

weight:size -7.412e-04

so the weight coefficient would be -0.00007468. Ugly, and with only 4 digits (at least for the default o/p here) instead of the 6 you see below.

Joe

Reply all

Reply to author

Forward

0 new messages