Material thickness tolerance issues RE: Crowbox v2 assembly

61 views

Skip to first unread message

Scott Goff

Oct 12, 2022, 2:25:45 PM10/12/22

to Crow Box Kit

Hi all!

My name is Scott, and I work at Ponoko, an online laser cutting service. We've made many, many Crowboxes for folks over the years, with generally stellar results and no negative feedback regarding difficulty assembling, etc.

Unfortunately, in the last few months, we've had a couple (that I'm aware of) Crowbox customers complaining of difficulty in slotting parts together due to material thickness tolerance issues. It's a real bummer. We publish the thickness tolerance range for all of our materials on our site, and the parts these folks are having trouble with are within our stated tolerance range.

Our suggestion for people who run into this kind of issue is to revise their designs with thickness tolerance as a key design constraint, but as many of the folks making Crowboxes are not savvy in vector design software, they have no real recourse. And, because we are a manufacturing service, and not a design service, we can't really help them much to revise the designs to take thickness tolerance into account, aside from pointing them at Inkscape tutorials. It's a bit of a catch 22.

So, I wanted to contact the community here, and see if anyone has any ideas for alleviating this issue. I attempted to contact the original designer of the project via email, but didn't receive a response, so getting them to revise the design to take material thickness ranges into account, and republish (maybe as Crowbox v2.1?) does not seem to be an option.

So, if any of the wonderful bunch of folks in this group can help with this, even if it's just to point me in the right direction of a good place to contact the original designer of the project, I would be super grateful, and it'd help out some Crowbox folks who have found themselves, sadly, with unusable parts.

Thanks so much, y'all!

Cheers,

Scott | Ponoko

PS, feel free to hit me here with any Ponoko-specific questions, or even laser cutting questions in general! I've been in the biz for about 8 years now, so I know just enough to get myself into trouble ;-P

Michael Kapp

Oct 12, 2022, 3:41:45 PM10/12/22

to Crow Box Kit

Scott,

One could infer that if you had "stellar results" over the years, but are only recently getting customers complaining about the tolerance issue, the problem is not with the files.

Has the Maximum thickness of the acrylic sheets increased recently? Has your source for acrylic sheets changed?

With my recent order:

Clear & Medium Transparent Blue Acrylic sheets were just slightly over 3mm

The Opal Acrylic sheet is closer to 3.5 mm (Maximum Thickness).

This has forced me to sand some of my edges/slots.

I would think the original designer was Josh Klein (9/2/2018) ??? Maybe Theodor Ullrich (2/4/2013)

Does anyone know if a 2.1 version fix even worth it? Meaning, is there a 3.0 version being developed?

Thank you for posting in this group thread and trying to resolve this issue!!!!

Thanks,

MK

Josh Klein

Oct 12, 2022, 4:35:00 PM10/12/22

to CrowB...@googlegroups.com

Hey Scott, thanks for writing!! I'm part of the team that put together the original design and would love to connect around the tolerance ranges and what can be done to accommodate - it's only been within the last six months that we've seen such a range and we'd love to find a way to solve the issue. Can you contact me directly so we can compare notes?

- J

ᐧ

--

You received this message because you are subscribed to the Google Groups "Crow Box Kit" group.

To unsubscribe from this group and stop receiving emails from it, send an email to CrowBoxKit+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/CrowBoxKit/11b18566-93b6-4c54-bfc3-2b2b46382711n%40googlegroups.com.

Mandy Voss

Oct 12, 2022, 6:26:20 PM10/12/22

to CrowB...@googlegroups.com

I was able to put upload the designs but then it wanted me to puck out all of these materials and I had no clue what I was supposed to pick out. It seemed that with the various pricing for each upload it was going to be a lot more money than I had intended to spend.

To view this discussion on the web visit https://groups.google.com/d/msgid/CrowBoxKit/CACNgykONFiGFxQC%3DzKUkChQDBb3Z24Wf-ed%3DRCgwx51iwzUpkA%40mail.gmail.com.

Scott Goff

Oct 12, 2022, 7:40:15 PM10/12/22

to CrowB...@googlegroups.com

Hey Mandy,

Yeah, pricing on laser cut parts can get pretty serious these days. We've been hit by supply chain issues (like everyone else in manufacturing) and endless increases on material pricing from our suppliers, then the recent inflation which raised the cost of labor for us significantly. On top of that, not too long ago we added a hefty carbon/HEPA filtration system for our exhaust from the lasers, necessary to keep us in line with California's strict air quality/emissions enforcement (and to keep our residential neighbors happy and healthy), which increased our overhead (but which we all still feel was very much the Right Thing to Do). In the face of all that, earlier this year we had to increase pricing for the first time in something like four years! We were all bummed about it, as we really do want to try to keep laser cutting accessible to as many folks as possible. But, it was a necessity to stay in business :-(

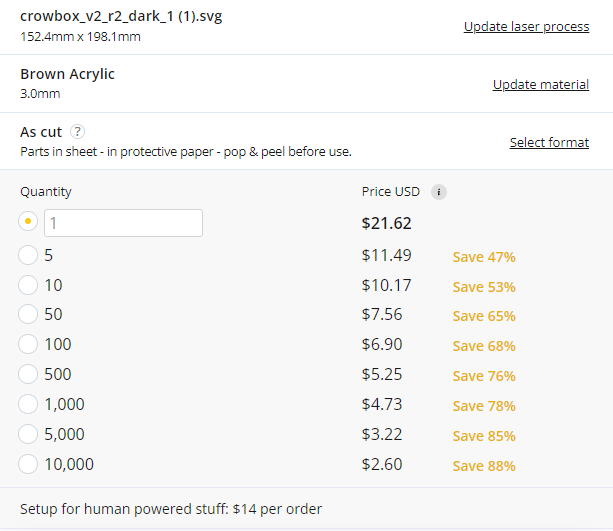

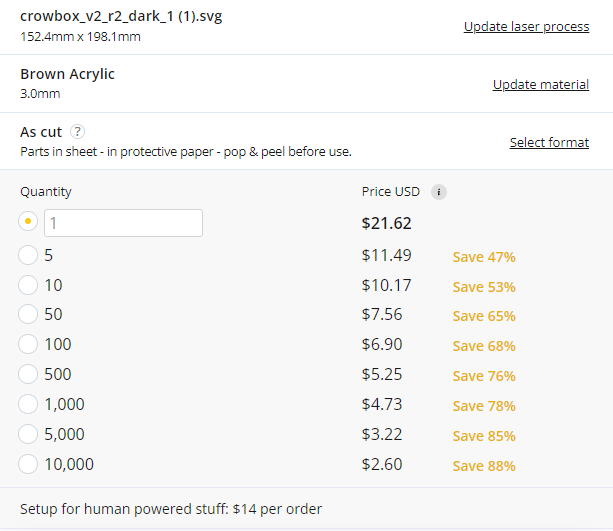

We do still have a very hefty discount pricing model, where the cost of laser time goes down significantly the more laser minutes are in any given order, though! It might be worth getting a few people together for group buys; either a big big one, or even ganging together smaller, but still "bulk", orders of like 5 to 10 sets of Crowbox parts. The different breakpoints on quantity pricing can have pretty steep drop offs vs. ordering parts for only one or two Crowboxes:

And, this is just an example of the pricing break points for a single one of the nested designs that make up a Crowbox order; a full complement of all the nested designs for 5 complete Crowboxes will likely have an even higher percentage discount applied. It's worth playing around with our quote generator to see!

As for choosing materials, maybe this is a tweak that could be applied to the filenames for all of the design files. Might could make sense to include material thicknesses and colors in the filenames to make it easier for people to quickly choose materials from wherever they're ordering them (for Ponoko, with a catalog of something like 300 unique materials, it's easy to see how frustrating it might be to have to go through and pick "the right ones"). In terms of which colors are the most economical, that's almost always going to be clear, black, and white, though. These are the colors we use the most, so these are the colors we'll be able to give the lowest pricing on.

Lest I risk this post turning into an advertorial, I should probably pump the brakes, now, but feel free to contact me directly at this email (which I usually check a couple, two-three times a week), or through our site's support chat (or email) if you have more pricing/etc. questions ;-)

Cheers,

Scott | Ponoko

You received this message because you are subscribed to a topic in the Google Groups "Crow Box Kit" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/CrowBoxKit/gBop_pNDOrY/unsubscribe.

To unsubscribe from this group and all its topics, send an email to CrowBoxKit+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/CrowBoxKit/CACbkK545%3DE%3DoZ21iHxGQsnAGWc4PX4Ju7s%3DFTSpVDWpxN2XZoQ%40mail.gmail.com.

Scott Goff

Oct 12, 2022, 7:42:53 PM10/12/22

to CrowB...@googlegroups.com

Sure thing, Josh! Wanna hit me at sc...@ponoko.com, and we can pick up the conversation there?

Cheers,

Scott | Ponoko

You received this message because you are subscribed to a topic in the Google Groups "Crow Box Kit" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/CrowBoxKit/gBop_pNDOrY/unsubscribe.

To unsubscribe from this group and all its topics, send an email to CrowBoxKit+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/CrowBoxKit/CACNgykONFiGFxQC%3DzKUkChQDBb3Z24Wf-ed%3DRCgwx51iwzUpkA%40mail.gmail.com.

Scott Goff

Nov 23, 2022, 7:17:17 PM11/23/22

to CrowB...@googlegroups.com

Hi Michael,

Sorry for the delay; I just discovered some (but not all?) of the emails from this list were getting plopped into my spam folder. 😩

The thickness tolerance ranges we publish on our site are straight from the manufacturers, and are pretty industry standard for cast acrylics of the grade we use. They are independent of the specific supplier we are purchasing from at any given moment, and all of our suppliers have pretty much the same brands of acrylic available, on a rolling basis, dependent on their supply chain and the deals they are doing. Unfortunately, we have little control over where the thickness of a particular sheet we've purchased sits inside of the stated tolerance range, and the thickness does vary from 4' x 8' supplier sheet to 4' x 8' supplier sheet, even from the same manufacturer/brand. In fact, cast acrylic can vary in thickness significantly across a single 31.5" x 15.75" panel (which is the panel size we use in the lasers). I've seen variations of as much as 0.8mm, comparing thickness at all four corners of a panel (and that's just from memory).

In terms of our suppliers, just a little inside baseball for you: acrylic sheets are basically a commoditized item, and we maintain relationships with several different suppliers to make sure that we are always getting the best possible pricing on the material we purchase. Anecdotally, I can say that we have probably stocked about 5 or 6 different manufacturer brands of acrylic over the years, but part of getting the best pricing in the moment is that you don't often get to choose which specific brand of acrylic you are getting. But, we purchase all of our acrylic with the explicit requirement that it meets the specs and tolerance ranges we list on our site.

It *is* possible to purchase acrylic sheets with tighter thickness tolerance range than 2.2mm to 3.5mm, but the more specific requirements one has when purchasing acrylic, the higher the price. And, while we can do custom material purchases for specific orders, it usually isn't economically feasible to go that route unless the quantity of parts for the order is sufficiently high.

As to the utility of a "Crowbox 2.1" in the face of a possible "Crowbox 3.0", that's a tough one. The "2.1" solution could be as simple as enlarging the slots and adding nodes inside each enlarged slot, so that they can accommodate material thicknesses spanning the full range of possibilities. That would still likely require some prototyping/testing, though, so it's really a question for the original developers. Of course, anyone with a copy of Inkscape could work independently and make a "fork" of the design (depending on the license it is released under; I must admit I haven't checked, which would be an important first step before going forward with a published modification to the design)...

Cheers,

Scott

--

You received this message because you are subscribed to a topic in the Google Groups "Crow Box Kit" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/CrowBoxKit/gBop_pNDOrY/unsubscribe.

To unsubscribe from this group and all its topics, send an email to CrowBoxKit+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/CrowBoxKit/7c1930d9-93de-4bec-a6ee-1c4af6d122b6n%40googlegroups.com.

Reply all

Reply to author

Forward

0 new messages