DFX File Sizing Mismatch

47 views

Skip to first unread message

Megan Bowen

Mar 16, 2022, 9:28:03 AM3/16/22

to Crow Box Kit

Hi all!

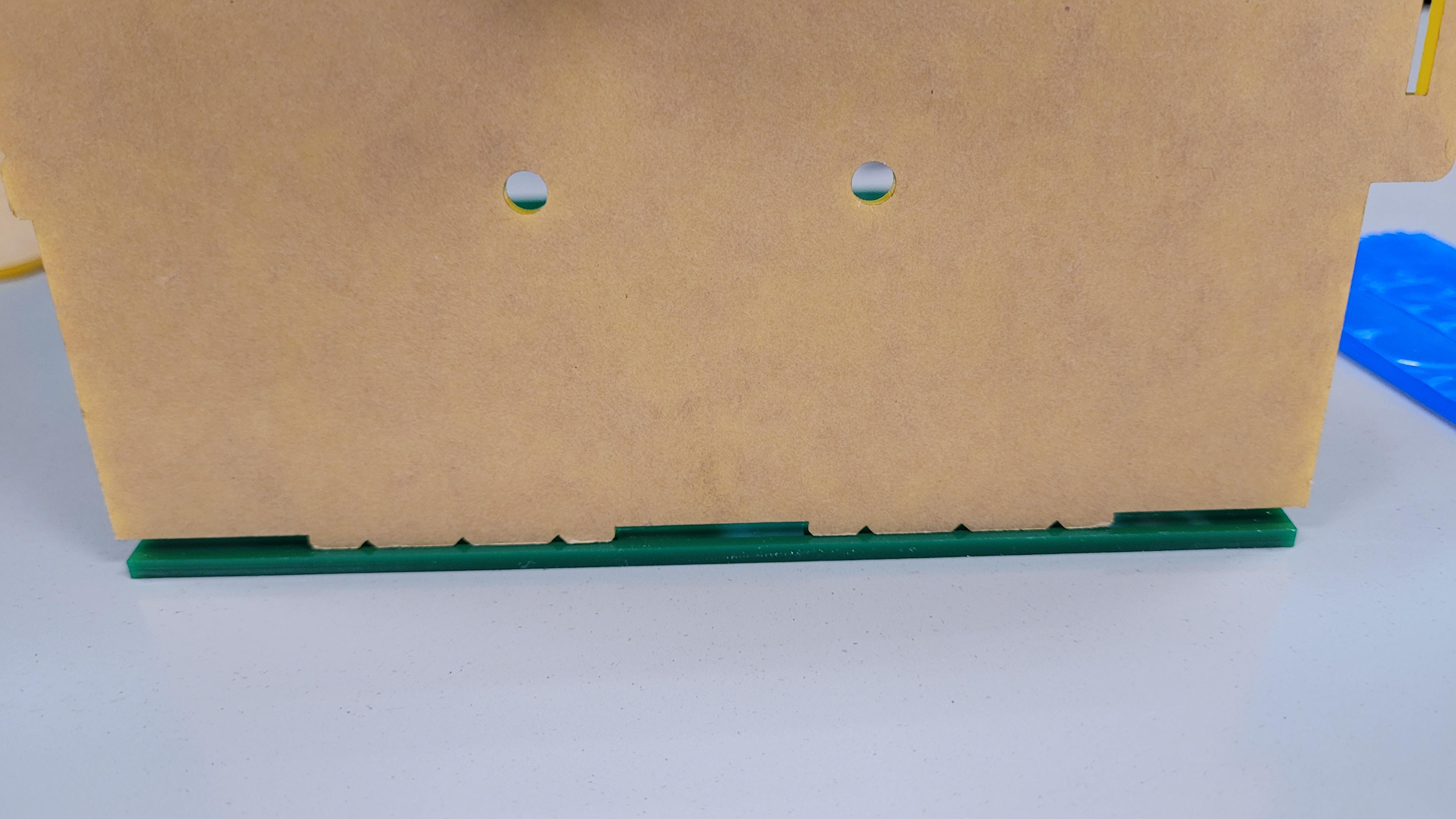

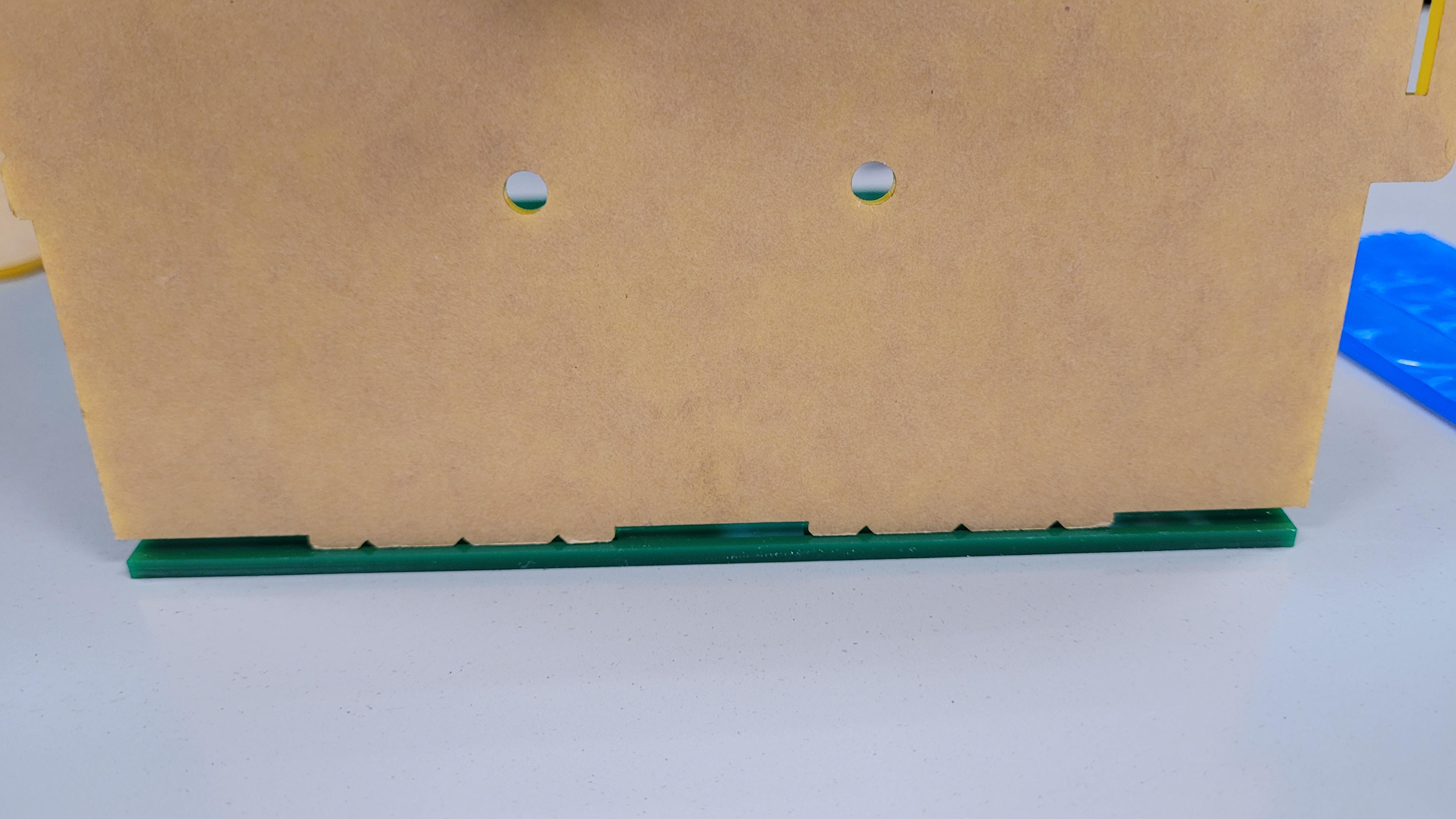

For anyone who has laser cut their own parts, have you found that there is a mismatch in sizing?

I am super frustrated because we do not have extra acrylic since we are doing this as a school project. and I downloaded/printed the files exactly as provided on the correct sized acrylic but the slots do not line up. The pictures aren't super clear but the slots are way too small and the pieces don't slip together. Does anyone have files with the righ sizing?

Josh Klein

Mar 16, 2022, 1:01:59 PM3/16/22

to crowb...@googlegroups.com

When I've seen this before it's because the acrylic wasn't actually the right thickness. Is there any way you can double check?

So sorry this happened - agreed, that's super frustrating!!

- J

ᐧ

--

You received this message because you are subscribed to the Google Groups "Crow Box Kit" group.

To unsubscribe from this group and stop receiving emails from it, send an email to CrowBoxKit+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/CrowBoxKit/073629cf-ade0-4d71-8028-bb1af267c1e3n%40googlegroups.com.

Michael Berna

Mar 17, 2022, 1:53:34 AM3/17/22

to Crow Box Kit

That is unfortunate. As a possible solution, perhaps try needle files to file the slot larger as needed.

Example:

(only $5)

Marko

Apr 19, 2022, 2:39:14 PM4/19/22

to Crow Box Kit

Hi

So sorry for what happened.

I downloaded the files from the site and forwarded to my cutter. In my case everything went perfect.

I don't think the files are wrong.

Hope you will find a solution.

Annette S.

May 6, 2022, 4:02:01 AM5/6/22

to Crow Box Kit

Hi Megan,

Acrylic manufacturers tend to specify a tolerance for sheet thickness, which can vary by a fraction of a mm. That can be problematic when you are slotting material in at right angles, because it will sit proud or below the surface of the other sheet if there is a difference, but that's not what you are showing here.

Additionally, the laser's 'kerf' needs to be accounted for by the laser cutter. The kerf is the width of the cut that the laser makes in the material. Ideally, your laser cutter should have done a test cut and measured the item cut using digital calipers, in order to calculate the kerf, and then entered a kerf offset in the laser software, in order to account for that kerf. For example, if I cut a 40mm square, it might come out at 3.88mm - normally such a small difference may not be significant, but when it comes to slots, it definitely will. So that 0.12 needs to be factored in to the cut...how this is done depends on the laser software being used.

Kerf may not be the issue here, but it's worth knowing about...

Acrylic manufacturers tend to specify a tolerance for sheet thickness, which can vary by a fraction of a mm. That can be problematic when you are slotting material in at right angles, because it will sit proud or below the surface of the other sheet if there is a difference, but that's not what you are showing here.

Additionally, the laser's 'kerf' needs to be accounted for by the laser cutter. The kerf is the width of the cut that the laser makes in the material. Ideally, your laser cutter should have done a test cut and measured the item cut using digital calipers, in order to calculate the kerf, and then entered a kerf offset in the laser software, in order to account for that kerf. For example, if I cut a 40mm square, it might come out at 3.88mm - normally such a small difference may not be significant, but when it comes to slots, it definitely will. So that 0.12 needs to be factored in to the cut...how this is done depends on the laser software being used.

Kerf may not be the issue here, but it's worth knowing about...

Josh Klein

May 6, 2022, 7:24:18 AM5/6/22

to CrowB...@googlegroups.com

Thanks, Annette - you’re right that tolerance (and kerf!) can be issues. We tried to build the design such that these problems were minimized, but good to be aware of!

- J

--

You received this message because you are subscribed to the Google Groups "Crow Box Kit" group.

To unsubscribe from this group and stop receiving emails from it, send an email to CrowBoxKit+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/CrowBoxKit/2b0640e9-99b9-4c84-be45-b29d868b9626n%40googlegroups.com.

Reply all

Reply to author

Forward

0 new messages