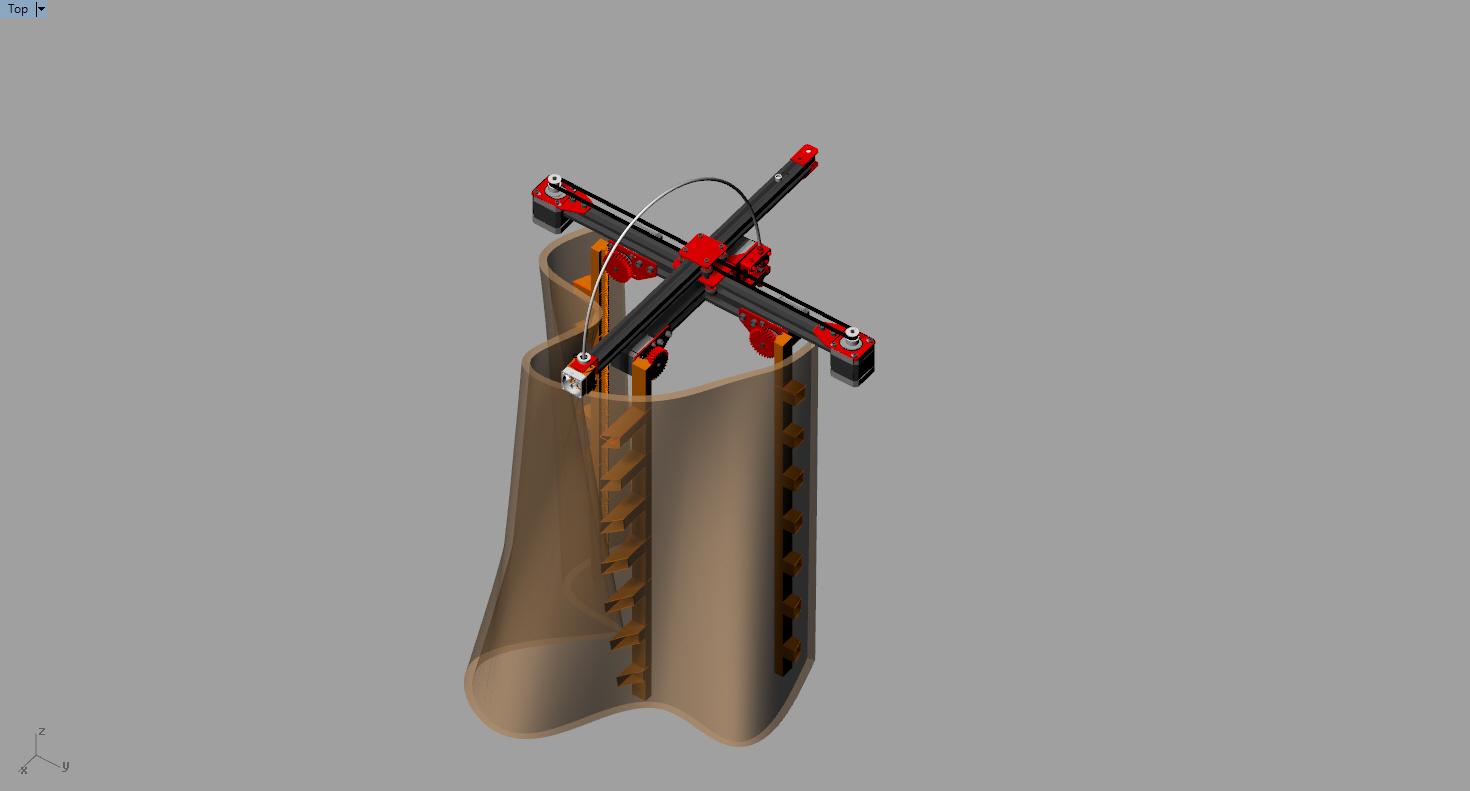

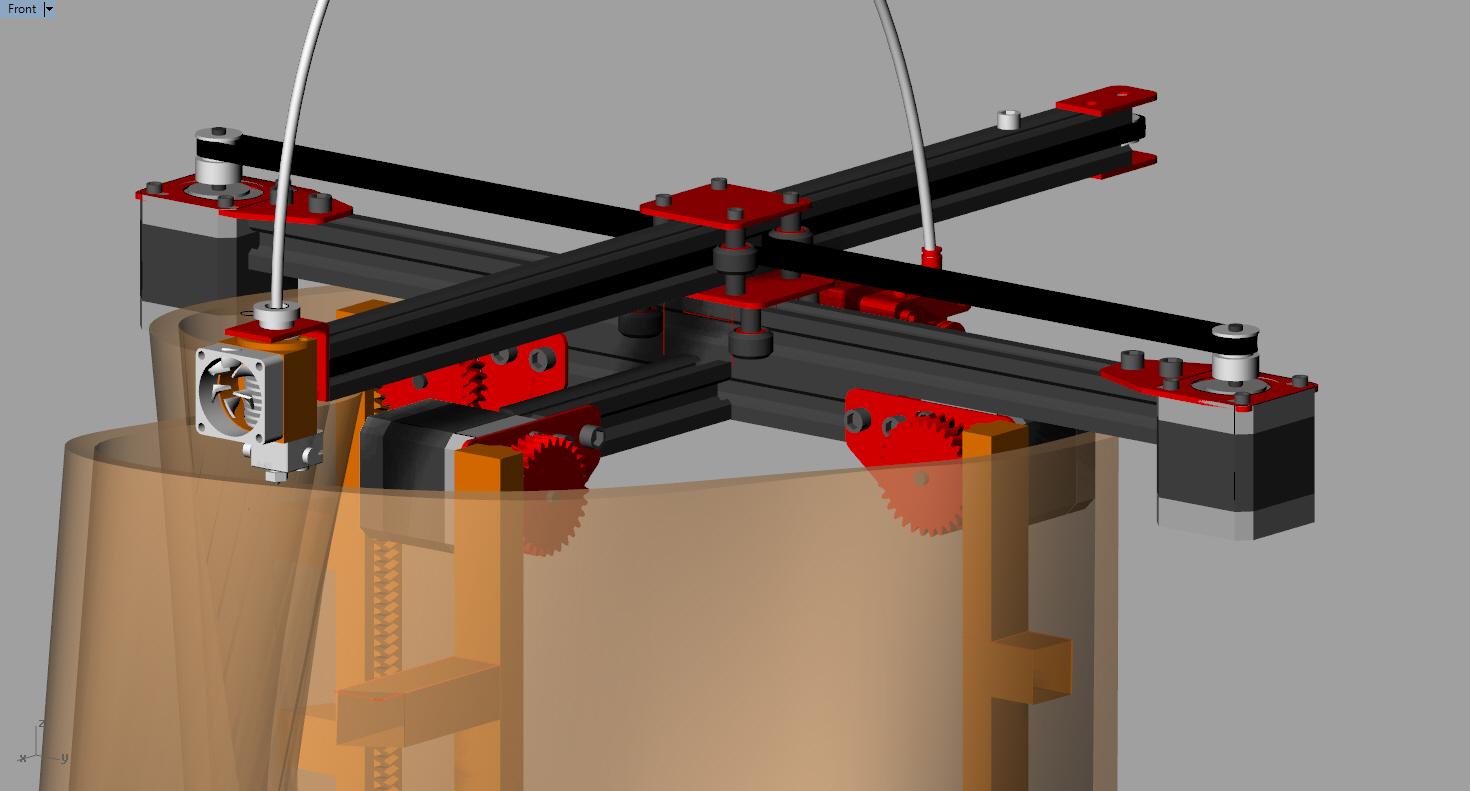

infinity z axis

77 views

Skip to first unread message

ekaggrat singh kalsi

Aug 30, 2019, 2:57:28 AM8/30/19

to 3DP Ideas

some thoughts on a possible z axis. One way of doing it . but it would need a printed base to start with and can only print on one side to simplify things. I am looking at building this for a art installation. But i am not sure how sound it will be in reality. The z travels on a set of 3 racks which are printed as a sacrificial structure along with the actual print ( dark orange ).

Ryan Carlyle

Sep 2, 2019, 5:59:23 PM9/2/19

to 3DP Ideas

Makes sense to me at a glance. I really like the idea of climbing a printed rack, but I think you'll run into column stability issues when the Z height gets taller than the XY span.

For ultimate victory: make the climbing racks a purge tower for multi-material printing.

Whosawhatsis

Sep 2, 2019, 6:20:24 PM9/2/19

to Ryan Carlyle, 3DP Ideas

There's a parallel thread on the Maker Forums where I posted some more thoughts. As for column stability, I don't see that being much of an issue, since you're interfacing with the columns a set distance below the nozzle. Yes, the whole structure might sway, but it shouldn't have a big impact on the print as long as the relative positions of the columns remains constant. One of my suggestions on the other thread was to add flanges to the racks with bearings to wrap around them to keep the pinions tensioned against them, which would also allow the pinions to act as braces for the racks to keep them in the same (relative) positions at the interface height.

--

You received this message because you are subscribed to the Google Groups "3DP Ideas" group.

To unsubscribe from this group and stop receiving emails from it, send an email to 3dp-ideas+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/3dp-ideas/f42d7d03-7536-4071-b20c-2a2c4e4c5b21%40googlegroups.com.

ekaggrat singh kalsi

Sep 4, 2019, 1:14:48 AM9/4/19

to 3DP Ideas

yes i will added the flanges and then build a smaller version of it to see stability issues. It is not meant to print it all that is possible and just smooth wavy surfaces. So maybe if the curves are stiff enough i can get away with wobble. Multimaterial tower is a great idea and maybe using 2 nozzles a fine one for the racks and a course one for the surfaces would be practical or it would be way too slow.

Ryan Carlyle

Sep 6, 2019, 11:56:34 AM9/6/19

to 3DP Ideas

Wing Wong

Sep 6, 2019, 3:27:40 PM9/6/19

to Ryan Carlyle, 3DP Ideas

Wow, that rig is pretty amazing.

Could waste plastic be heat/press formed into the jack up components?

Like the idea of an infinite z build. How would defects be countered to prevent accumulating drift/deviantions?

W

--

You received this message because you are subscribed to the Google Groups "3DP Ideas" group.

To unsubscribe from this group and stop receiving emails from it, send an email to 3dp-ideas+...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/3dp-ideas/8fd0f654-2d23-4c5b-b95a-e111aaf5befd%40googlegroups.com.

Ryan Carlyle

Sep 6, 2019, 3:49:31 PM9/6/19

to 3DP Ideas

Waste plastic... ehhh... seems like that would add a ton of complexity? Not sure I'd want to try to tackle that.

I don't think this would be a RepRapping machine, but you could do some tricks with elastic averaging to minimize tower defect problems. Like put two pinions on each tower with some horizontal compliance in the mount. That would cut in half the error at that tower.

On Friday, September 6, 2019 at 2:27:40 PM UTC-5, Wing Wong wrote:

Wow, that rig is pretty amazing.Could waste plastic be heat/press formed into the jack up components?Like the idea of an infinite z build. How would defects be countered to prevent accumulating drift/deviantions?W

On Fri, Sep 6, 2019 at 8:56 AM Ryan Carlyle <temp...@gmail.com> wrote:

What I would probably do is build a "jackup" Z stage first (pre-made rack legs for the gantry to climb up) before getting into self-printing. That way you can decouple the rack-leg climbing printer design from the self-printing aspect.--

This is how we do jackup oil rigs

You received this message because you are subscribed to the Google Groups "3DP Ideas" group.

To unsubscribe from this group and stop receiving emails from it, send an email to 3dp-ideas+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/3dp-ideas/8fd0f654-2d23-4c5b-b95a-e111aaf5befd%40googlegroups.com.

ekaggrat singh kalsi

Sep 6, 2019, 6:38:31 PM9/6/19

to 3DP Ideas

great idea. I will look into it after i get it working.. one complexity at a time. Another way of starting would be to have a servo which turns the z motors out of the way and slowly moves them back in place while printing the initial layers till it finally engages the rack.. BUt these are all far fetched thoughts. first the baby steps of making it climb a printed rack consistently :)

Reply all

Reply to author

Forward

0 new messages