extruder motor tuning

74 views

Skip to first unread message

bkaufm...@gmail.com

Jun 5, 2022, 8:02:09 PM6/5/22

to 3D Printing Tips and Tricks

During the discussion of Orbiters, Andy mentioned tuning the extruder motor current to eliminate artifacts. I am not sure that I have seen/heard that discussed in detail. This is not motor skipping vs overheating, but more artifact tuning. Can I get more information on the theory and optimization practice please?

Thanks,

Brett

TobyCWood

Jun 6, 2022, 1:31:40 PM6/6/22

to 3D Printing Tips and Tricks

Are you seeing patterns? Show us a pic.

the artifact I was getting on that Orbitor 2 was due to a damaged motor. However I do believe the patterns seen is some machines which use smaller steppers can be due to non optimal current.

Actually ime if the motors (most mid sized steppers) are running hot as in too hot to touch, you turn down the current. You do that in the fw. Conversely if the motors are slipping as in missing steps… after making sure that everything else is moving freely and smooth…. I up the current.

Artifacts can be caused by a lot of things besides a nonoptimal motor current, but for smaller steppers such as the round kind used in the Orbitor I’m finding that one may need to try different settings.

bkaufm...@gmail.com

Jun 7, 2022, 10:08:17 AM6/7/22

to 3D Printing Tips and Tricks

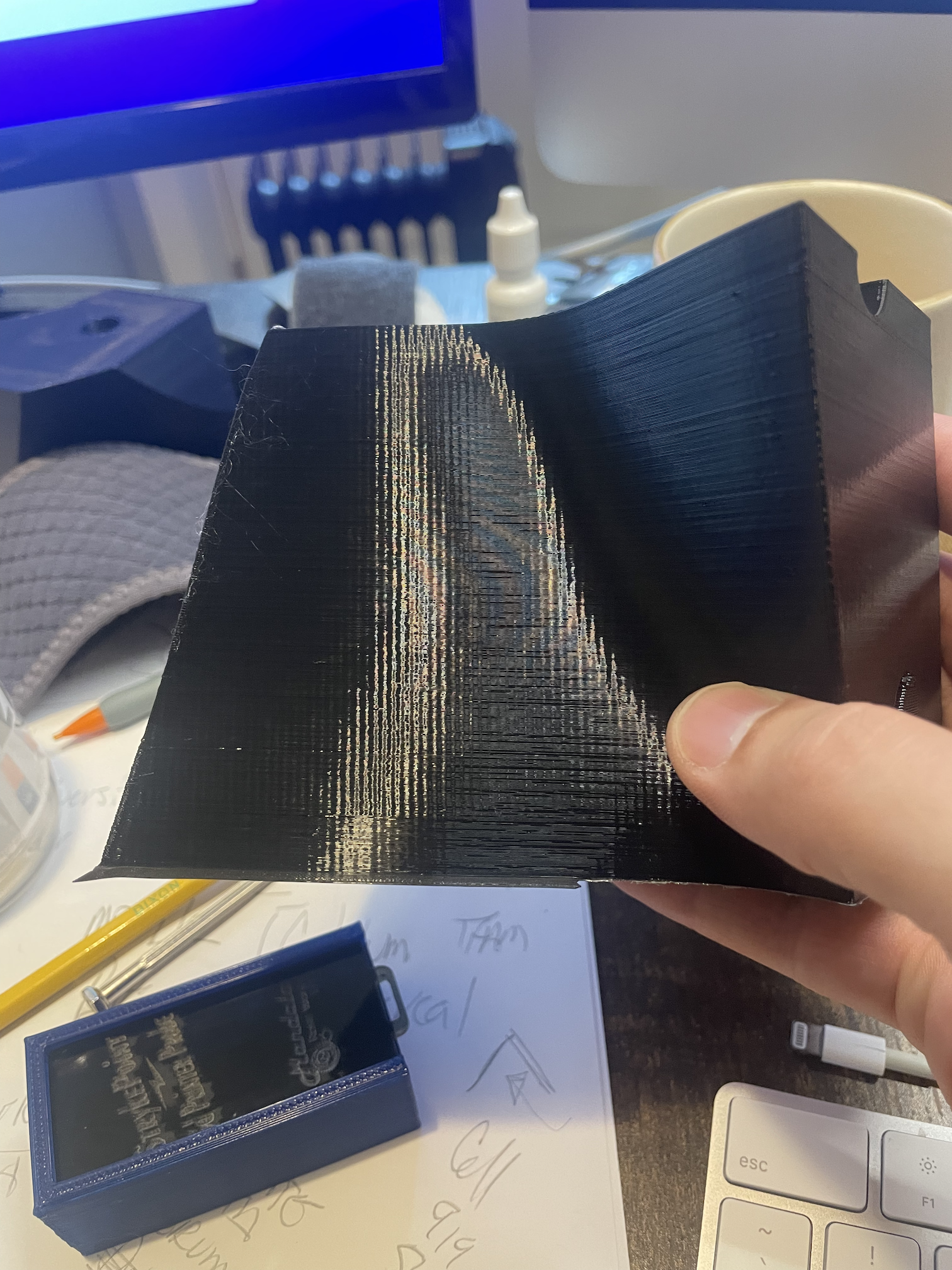

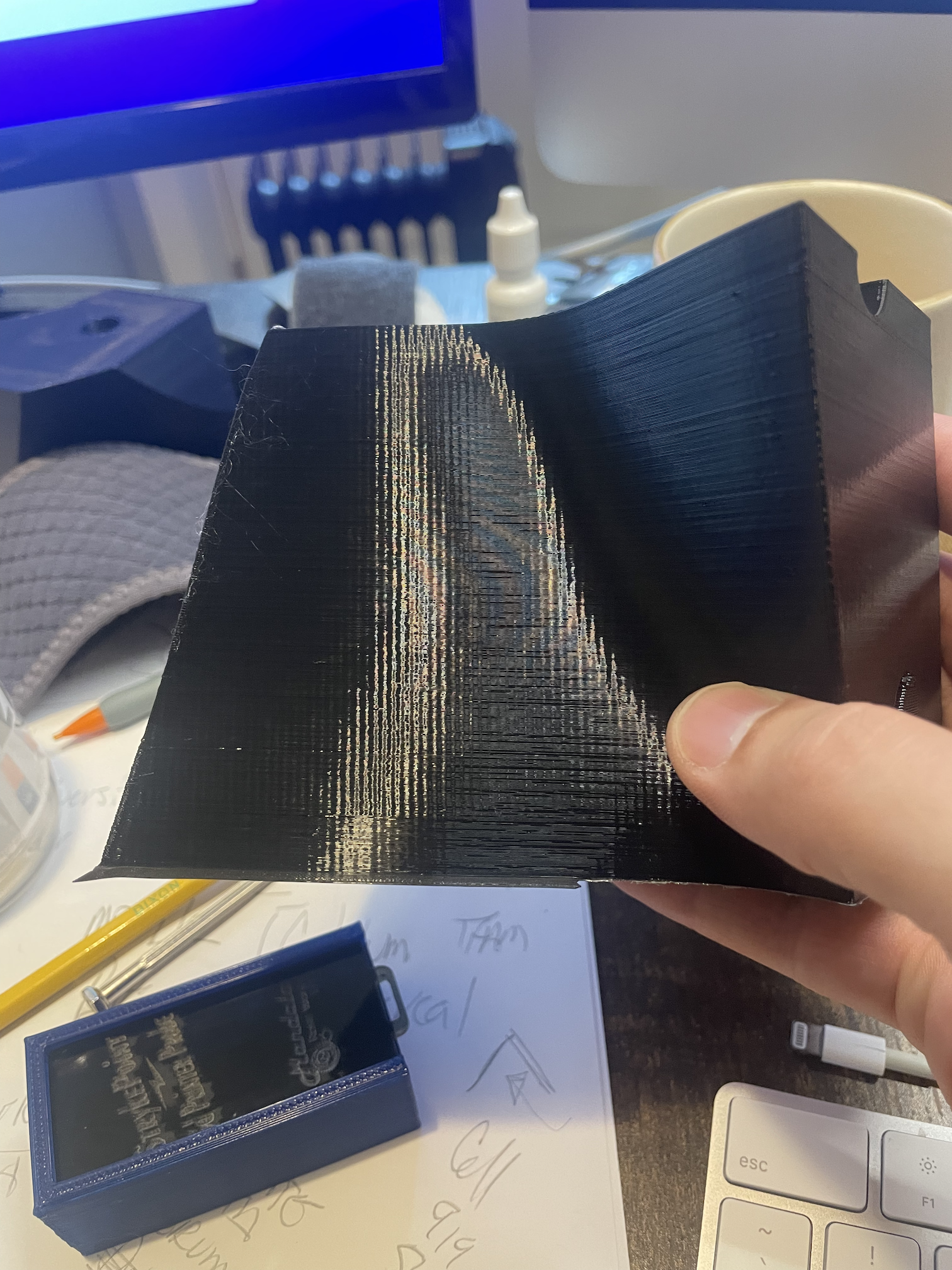

Something like this:

just looking at the verticals in this part.

just looking at the verticals in this part.

TobyCWood

Jun 7, 2022, 11:50:55 AM6/7/22

to 3D Printing Tips and Tricks

I’d check the gantry for x and y axes first. The pattern i was talking about is way more subtle and hard to see then that.

What’s the printer? How fast are you printing? What’s acceleration set to? Do you get weird noise or vibration that you can hear when it goes through that area?

What’s the printer? How fast are you printing? What’s acceleration set to? Do you get weird noise or vibration that you can hear when it goes through that area?

I note that the pattern is consistent. No variation. As such it’s not likely due to the filament flow. Looks systematic. First thing I’d do is grab the extruder carriage and move it around with my hands feeling for play. Next I’d inspect the gantry to make sure all the ways are secure. Check that the hot end is seated securely. Is the build plate secure? Is it on springs that have play?

TobyCWood

Jun 7, 2022, 11:52:28 AM6/7/22

to 3D Printing Tips and Tricks

Check the locking screws on every pulley.

TobyCWood

Jun 7, 2022, 11:58:50 AM6/7/22

to 3D Printing Tips and Tricks

Check your belts.

Hayden Pulley

Jun 23, 2022, 3:05:08 PM6/23/22

to 3D Printing Tips and Tricks

I've been having issues with my extruder and have been wondering if it simply needs to be better tuned. Regardless of whether or not it needs to be tuned, I'd love answers to some questions I have.

If I'm correct the current setting in the firmware is simply the maximum allowed current. If it ran at full current constantly the motor would get hot very fast. Some stepper motor drivers can help reduce heat by changing the way the stepper motor is driven, so shouldn't the stepper motor driver's be tuned and then the current? I know that the stepper motor drivers can be tuned in reprap firmware, but does anyone know how they are tuned?

LukeH

Jun 25, 2022, 5:07:57 PM6/25/22

to 3D Printing Tips and Tricks

Extruders are capable of relatively high acceleration (like 10,000mm/s/s). Problem is, that their acceleration has to be proportionally matched in the firmware to the X and Y movement (which accelerates slower because of the mass of the carriages), otherwise it will overextrude at the start of a movement, then underextrude when the carriage got up to speed. It would also depend on the density of the plastic you are printing, since the mass flow of filament would affect the acceleration of extruder stepper.

The accepted method of tuning an extruder is to set the acceleration at whatever rate is recommended by the extruder manufacturer (usually in the region of 10,000mm/s/s) and then use pressure/linear advance to match it to the movement characteristics of the individual printer and filament brand/type, which tunes extruder speed and acceleration profiles.

LukeH

Jun 25, 2022, 5:36:35 PM6/25/22

to 3D Printing Tips and Tricks

Even tuning acceleration and jerk in X and Y is becoming a bit old hat.

Junction deviation, introduced into Marlin 2.0 (and other open source firmwares after) actively adjusts jerk on the fly, so you didn’t have to settle for an average best setting, but instead had the calculated optimal setting for every movement.

These days input shaping adjusts acceleration and jerk on the fly to minimise resonance.

Soon we’ll be using full closed-loop systems (full time accelerometer feedback), and manually tinkering with acceleration and jerk will totally be a thing of the past.

Reply all

Reply to author

Forward

0 new messages