Taps and drills by the pound.

64 views

Skip to first unread message

tookys3

Jun 18, 2015, 5:07:01 PM6/18/15

to sa-hack...@googlegroups.com

For anybody who doesnt know i work for Cox Manufacturing Co.

We work in small parts for industry and specialize in metal cutting on CNC lathes.

Long story short we have done a number of company acquisitions in the last year and aquired their tools.

Issue being is we already have more than enough and are looking at getting rid of hundreds of pounds of drills and taps

My Co-workers have mentioned the option of donating it to the space, issue being is that we would need to have the drill dispensers to store them in.

The dispensers for drills include, fraction, letter, wire, and millimeter sizes.

The dispensors for taps include fraction, bumber, and millimeter sizes.

If you want to look at the ones i have in mind you can go to

Item numbers

-01691146

-89099535

-01512219

-97550115

---------______------______

End of story is that we will need about $775 to pay for the proper storage equipment to store these tools in. And volunteers to help put them away.

In exchange we get close to $2000 worth of tools (if purchased individually)

I will put $125 towards it and volunteer to help sort through them if we can pool enough money to get the storage units.

Sent via the Samsung GALAXY S®4, an AT&T 4G LTE smartphone

Chris Hardee

Jun 18, 2015, 5:53:52 PM6/18/15

to 10BitWorks on behalf of tookys3

I'd be willing to put in 100$ or so, where would be put them?

--

You received this message because you are subscribed to the Google Groups "10BitWorks" group.

To unsubscribe from this group and stop receiving emails from it, send an email to sa-hackerspac...@googlegroups.com.

To post to this group, send email to sa-hack...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/vwyarikjue1w129lxaxy1tlu.1434661612120%40email.android.com.

tookys3

Jun 18, 2015, 6:04:58 PM6/18/15

to 10BitWorks on behalf of Christopher Hardee

I was thinking on the middle shelf of the work bench in the shop area.

Sent via the Samsung GALAXY S®4, an AT&T 4G LTE smartphone

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/CAKeDzS8E3DhMcz%3D64bZwoAkaHVzYDZpyC52F0TB28YY1x%2B89jA%40mail.gmail.com.

Chris Hardee

Jun 18, 2015, 6:08:02 PM6/18/15

to 10BitWorks on behalf of tookys3

If we do this, then we really ought to totally reorganize the work shop. I don't want to go off-topic but we should discuss reorganizing it and have a spot ready to go. Willing to help out this weekend for it.

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/urj2ajypttcrflyiryk6et7w.1434665088621%40email.android.com.

tookys3

Jun 18, 2015, 6:11:18 PM6/18/15

to 10BitWorks on behalf of Christopher Hardee

I agree on a shop area over-haul.

Keep in mind this drill and tap deal is likely 1-2 weeks out.

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/CAKeDzS_37h0cnHWa%2BmukrY0BrE8DeHyTEo1SX7LjzPKf1tx2uw%40mail.gmail.com.

Chris Hardee

Jun 18, 2015, 6:12:40 PM6/18/15

to 10BitWorks on behalf of tookys3

I think it'll take that time to get it organized :)

Anyone else interested in joining in?

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/h1c2q7hm9odaplvrick91umu.1434665468655%40email.android.com.

kevin....@gmail.com

Jun 18, 2015, 9:42:51 PM6/18/15

to 10BitWorks on behalf of Christopher Hardee

I'm all for organizing the shop area and will match your $100 pledge.

Sent from my iPhone

Sent from my iPhone

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/CAKeDzS9%2B6PH0VThP7Ah-eDsuEiMN4cRVON8aS%2BWKi_7%3D4616fw%40mail.gmail.com.

Matt Grooms

Jun 19, 2015, 6:11:49 AM6/19/15

to 10BitWorks Hackerspace

Drill/tap donation, good.

$700 for a few shoeboxes worth of storage; seems expensive, but I can see it’s a specialty item. I’ll contribute.

Party this weekend; great time to set out a plastic pickle bucket with a picture on it requesting donations targeted for this particular acquisition.

Shop reorganization; always a good topic. What can we do with what we’ve got? How can we maximize the space we have? Is time for a fundraiser to "Jeremy-shelf” the north & east walls of the shop, resulting in lighted workbenches + storage above?

Grimey

$700 for a few shoeboxes worth of storage; seems expensive, but I can see it’s a specialty item. I’ll contribute.

Party this weekend; great time to set out a plastic pickle bucket with a picture on it requesting donations targeted for this particular acquisition.

Shop reorganization; always a good topic. What can we do with what we’ve got? How can we maximize the space we have? Is time for a fundraiser to "Jeremy-shelf” the north & east walls of the shop, resulting in lighted workbenches + storage above?

Grimey

Les Hall

Jun 19, 2015, 7:14:14 AM6/19/15

to 10BitWorks on behalf of Matt Grooms

When I saw James propose this gift-purchase I said to myself "no way". Yet here we are with over half of the funds raised. People are giving and in big chunks of ~$100+ each to get what is perhaps a bit of an esoteric toolset or perhaps something that is more enabling from a CNC perspective than I realize (how many taps do we really need for example). This just screams out the spirit of 10bit - the fact that we so strongly yearn for increased capability that we're willing to put our money (or in my case and many cases our time (or both) ) where our mouth is. All I can say is:

BRAVO 10BITWORKS !!!

Les

--

You received this message because you are subscribed to the Google Groups "10BitWorks" group.

To unsubscribe from this group and stop receiving emails from it, send an email to sa-hackerspac...@googlegroups.com.

To post to this group, send email to sa-hack...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/6BDDB790-C48D-4759-9212-EC40C62E694D%40gmail.com.

tookys3

Jun 19, 2015, 8:17:53 AM6/19/15

to 10BitWorks on behalf of Les Hall

This storage set is essentially every single standard drill size between 0 and 1/2".

This is rather specefic to mill or latge working but the drills can be used for anything from fixing up something from home, to modifying a 3D print that needs a specific sized hole.

If we ever expanded our mill and lathe this would be a must have. But its still good to have just in general for many wood working or other projects have you scrambling to find the 1 drill you dont have.

Yes the storage boxes are expensive, but unless somebody wants to colunteer to design, plan, and build a 207 drawer storage box in the next 2 weeks, its easier to just buy it lol.

Also something to keep in mind that we will likely have certain sizes we just have to many of, and we can sell off a number of them on ebay (or other options)

Sent via the Samsung GALAXY S®4, an AT&T 4G LTE smartphone

-------- Original message --------

From: 10BitWorks on behalf of Les Hall <sa-hack...@googlegroups.com>

Date: 06/19/2015 06:14 (GMT-06:00)

To: 10BitWorks on behalf of Matt Grooms <sa-hack...@googlegroups.com>

Subject: Re: [10BitWorks] Taps and drills by the pound.

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/CABEAN--0ogWws26cfdT5%3DRa6q3tgHHMCZpN_YghK3pp%3DpbfLWA%40mail.gmail.com.

Randy Ohman

Jun 19, 2015, 6:16:03 PM6/19/15

to sa-hack...@googlegroups.com

Or....just sell them and save needing all the new drawers.

Randy Ohman

Jun 20, 2015, 1:36:27 AM6/20/15

to sa-hack...@googlegroups.com

Let me follow that lead balloon with the notion to shop them a bit. The savings can put a dent in a nice drill sharpener.*

A look at the first item, ~$131 + tax and shipping from MSC

or

But the following gets around all this: $80 (w/coupon) + tax: http://www.harborfreight.com/115-pc-cobalt-drill-bit-set-61886.html

Same applies to taps/dies and milling cutters at Grizzly or eBay. The issue really isn't so much about bits etc, but rather how much of what kind of storage you think the space needs. Many are chipping in so you might be on to something.

tookys3

Jun 20, 2015, 7:10:55 AM6/20/15

to 10BitWorks on behalf of Randy Ohman

The reason i advise against an index (like the one your gave a link to)

1)Is that an index only keeps 1 of each drill. And people tend to not put them back.

My work used to keep 3 to get around this problem, but it just turned to where all three were missing the same drill that were used the most often.

2) when you run out of a given size and do have to buy more you can buy a small pack and have room to store them all

An index would hold only 1 and the rest would have to find another home

3)periodicly you may want to buy a series of drills as the set includes a few your missing and a few your not.

The ones your not missing then have to find a new home as the index already has one.

----

Essentially i do like drill index units (like the one you showed) and in theory they would work great. But in practice they are a real pain as they are always missing the 1 you need, and only keep 1 of each.

Sent via the Samsung GALAXY S®4, an AT&T 4G LTE smartphone

-------- Original message --------

From: Randy Ohman via 10BitWorks <sa-hackerspace+APn2wQdqPUlJoE3XM...@googlegroups.com>

Date: 06/20/2015 00:36 (GMT-06:00)

To: sa-hack...@googlegroups.com

Subject: Re: [10BitWorks] Taps and drills by the pound.

--

You received this message because you are subscribed to the Google Groups "10BitWorks" group.

To unsubscribe from this group and stop receiving emails from it, send an email to sa-hackerspac...@googlegroups.com.

To post to this group, send email to sa-hack...@googlegroups.com.

You received this message because you are subscribed to the Google Groups "10BitWorks" group.

To unsubscribe from this group and stop receiving emails from it, send an email to sa-hackerspac...@googlegroups.com.

To post to this group, send email to sa-hack...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/b5191ef2-d6d5-4640-ab95-e9749753a1ce%40googlegroups.com.

Les Hall

Jun 20, 2015, 9:57:46 AM6/20/15

to 10BitWorks on behalf of tookys3

Now that it's being questioned, it finally dawns on me that $750 is an awful lot for storage containers. I mean, for that much money 10bit could literally build a robotic arm that would store the bits and serve up the one you want right into your hand! Just sayin....

Les

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/ixdjesp2hi0ix3awhgvbumk2.1434798645047%40email.android.com.

Les Hall

Jun 20, 2015, 10:04:36 AM6/20/15

to 10BitWorks on behalf of tookys3

Here you go James, just use that finely tuned 3D printer of yours to print up about ten of these! OK, I'm really only about half joking - wouldn't it be cool?

Les

Chris Hardee

Jun 20, 2015, 10:13:39 AM6/20/15

to 10BitWorks on behalf of Les Hall

I trust James to pick out the right storage solution on this, I think it'll work out great

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/CABEAN-8GQu6ohM1YZ3R60hnn3KZGGW6W2MSs2DRfkpWkqi%2BPew%40mail.gmail.com.

Don Smeller

Jun 20, 2015, 10:38:38 AM6/20/15

to 10BitWorks

Ditto, James’ solution will be a long step in the direction of making us into a real machine shop. I’ll take Taps and Drills for $50, Alex.

Don S

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/CAKeDzS9z3Cx4P4GLjj%3DPSC3UnesWVF-YnuAPQ4jfqw7iAEoc-g%40mail.gmail.com.

Les Hall

Jun 20, 2015, 10:44:17 AM6/20/15

to 10BitWorks on behalf of Don Smeller

Yeah but... but.. the robots would be so cool! Awww, alright, I yield my silliness to the reigning spirit of common sense! Funny though, you could actually do it for about the same cost or lower. But then you'd have maintenance and time invested and all that jazz.

I guess it's because I have three servos and I want to build a robotic arm with them that my mind goes in such strange directions. Plus I'm just kidding James. But you guys know better so...

Back to plan A!!!

Les

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/7C2ABBF4-0A96-47F7-B54A-EC6C3225024F%40earthlink.net.

Sdfhg Sgh

Jun 21, 2015, 11:46:57 PM6/21/15

to 10BitWorks on behalf of Les Hall

ok we are half way (375) to the 775 we need for the storage set.

If we don't get the money together, i cant really facilitate getting the tools donation.

If there is anybody else wanting to pitch in for the storage boxes please let us know soon. As I need to pitch it to my supervisor before he decides what to do with the tools in the next couple days.

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/CABEAN-_VurJ6yL5Q5SkrXQMa%2BQ_P58rB21rQF-TcGByLf9pbaQ%40mail.gmail.com.

M. Good

Jun 22, 2015, 2:26:20 AM6/22/15

to 10BitWorks on behalf of tookys3

I'm in for $50.

Ray

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/1412878482.2940410.1434944687918.JavaMail.yahoo%40mail.yahoo.com.

Mike Garis

Jun 22, 2015, 9:55:45 AM6/22/15

to sa-hack...@googlegroups.com

We can also bring this up on Wednesday when most of the Officers are around and see if this is something we could help with general funds from 10Bit as well. Is there anyway to get an actual quote from a seller for what we would need for the storage solution?

- Mike G.

Ken Runner

Jun 22, 2015, 4:35:26 PM6/22/15

to sa-hack...@googlegroups.com

I can donate $50 as well.

...

joseph

Jun 22, 2015, 4:39:36 PM6/22/15

to sa-hack...@googlegroups.com

Is there a possibility we could 3D print laser cut and build something similar? I'm not sure if this has been brought up yet.

tookys3

Jun 22, 2015, 5:41:09 PM6/22/15

to 10BitWorks on behalf of joseph

It is completly possible to build our own index boxes yes.

The issue being is having somebody volunteer to design, fab, and assemble 220 drawers of varying sizes.

Sent via the Samsung GALAXY S®4, an AT&T 4G LTE smartphone

-------- Original message --------

From: joseph via 10BitWorks <sa-hackerspace+APn2wQf208EjG1Z0v...@googlegroups.com>

Date: 06/22/2015 15:39 (GMT-06:00)

To: sa-hack...@googlegroups.com

--

You received this message because you are subscribed to the Google Groups "10BitWorks" group.

To unsubscribe from this group and stop receiving emails from it, send an email to sa-hackerspac...@googlegroups.com.

To post to this group, send email to sa-hack...@googlegroups.com.

You received this message because you are subscribed to the Google Groups "10BitWorks" group.

To unsubscribe from this group and stop receiving emails from it, send an email to sa-hackerspac...@googlegroups.com.

To post to this group, send email to sa-hack...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/64ec9b9d-0be8-4e71-99b3-6383fb3daeab%40googlegroups.com.

tookys3

Jun 22, 2015, 7:05:16 PM6/22/15

to 10BitWorks on behalf of tookys3

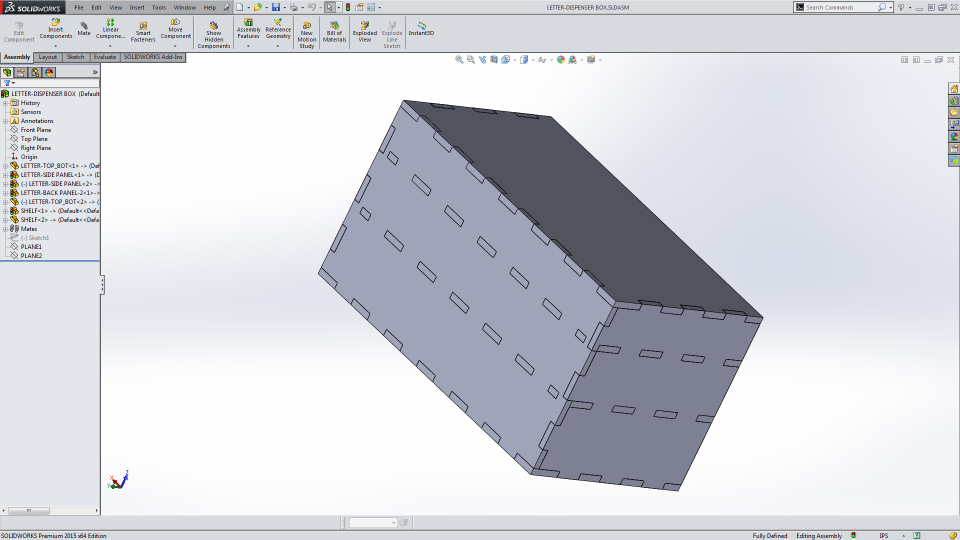

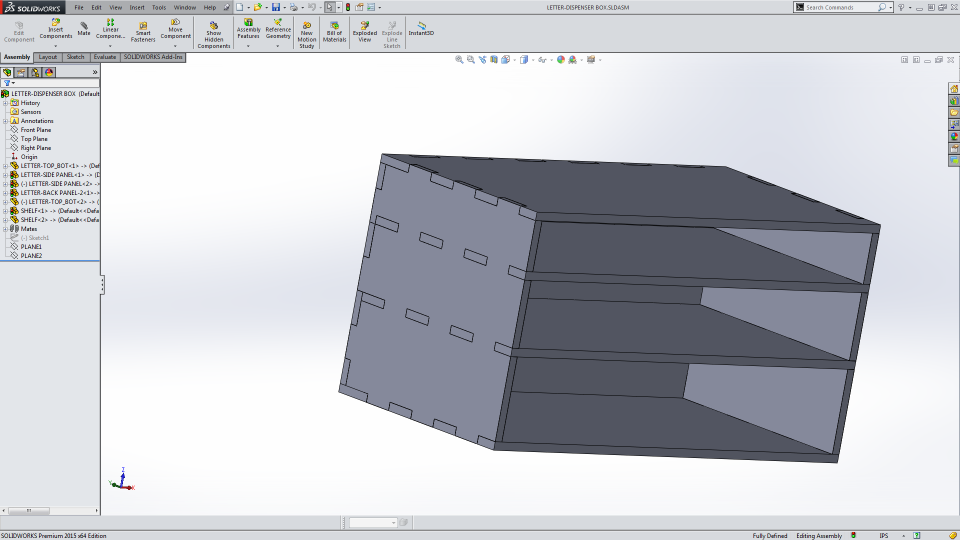

Now that i think about it, it wouldnt be to difficult to go ahead and make it ourselves.

I could help do the designs if we had somebody else laser cut and assemble them.

All we would need is the wood, free laser time, and volunteerism.

joseph

Jun 23, 2015, 2:48:54 PM6/23/15

to sa-hack...@googlegroups.com

I think this might be my niavete talking but, how herculean in this type of effort? Could we use 3D printing? I know Customizer on thingiverse allows you to custom size screw compartments with labels. Would that be useful in this situation? Up until a week ago I have never heard of a "drill case". I think additionally we would need ball bearing drawer slides. When you say 220 drawers did you mean compartments? Because 220 drawers sounds like a lot of work.

Sdfhg Sgh

Jun 23, 2015, 4:53:43 PM6/23/15

to 10BitWorks on behalf of joseph

I do mean compartments, depending how big you make the compartments, and how many you make in the drawer, you can set them up without rollers.

I think laser cutting would be faster, easier, and more cost effective than 3D printing.

tookys3

Jun 24, 2015, 9:54:19 AM6/24/15

to 10BitWorks on behalf of tookys3

UPDATE UPDATE UPDATE!!!!!

my boss has agreed to donate the bulk of drills,mills and, taps.

I will try and bring it by this weekend.

Atached is a pic of the donation. We cant keep the boxes but everything inside is ours.

tookys3

Jun 24, 2015, 10:59:13 AM6/24/15

to 10BitWorks on behalf of tookys3

Btw for anybody interested in the idea of making our own dispensers attached is a excel spreadsheet, of the expected drawers and their approximate sizes (for what i had for reference)

I do plan to make them all on the laser cutter using plywood. But some had mentioned wanting to do it with other methods, so here is your reference info.

xmrg

Jun 24, 2015, 11:58:43 AM6/24/15

to 10BitWorks on behalf of tookys3

Fantastic. Give your boss a big thank you from me.

I prefer the idea of building DIY drawers/compartments for the tools since we are a maker space and it should save a lot of money. I will model something for consideration.

Ray.

Sent by Sprint from my Samsung Galaxy Note® II

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/nunas3nhl4s8u0ketsy5dmg5.1435154003491%40email.android.com.

tookys3

Jun 24, 2015, 12:26:08 PM6/24/15

to 10BitWorks on behalf of Ray Good

Btw the fact that we are a 501(c)3 did play a role in his decision.

He didn't ask for any donation recipt as the donation doesnt have a monetary value.

Les Hall

Jun 24, 2015, 1:14:31 PM6/24/15

to 10BitWorks on behalf of tookys3

Are you all SURE you don't want to make a robot array for this? Each robot can store 64 bits on a chessboard! Just kidding, relax!

Les

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/p5yh6rf4a533cjte6u70dxrw.1435163155316%40email.android.com.

joseph

Jun 24, 2015, 2:25:39 PM6/24/15

to sa-hack...@googlegroups.com

Where is the voting button to vote for this awesome idea!? What if we used an XY gantry bot with a electromagnet on the end? People come up and check out the taps they need and when they return them the bot puts them back.

Les Hall

Jun 24, 2015, 2:33:26 PM6/24/15

to 10BitWorks on behalf of joseph

We should take the robot concept to another thread....

Les

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/6f3481bf-9e77-4561-a391-aa098dfd0b15%40googlegroups.com.

tookys3

Jun 24, 2015, 5:34:31 PM6/24/15

to 10BitWorks on behalf of tookys3

Forgot pipe thread sizes.

1/16-27npt

1/8-27npt

1/4-18npt

3/8-18npt

1/2-14npt

3/4-14npt

Also i went ahead and dropped off the buckets of bits.

Sent via the Samsung GALAXY S®4, an AT&T 4G LTE smartphone

-------- Original message --------

From: 10BitWorks on behalf of tookys3 <sa-hack...@googlegroups.com>

Date: 06/24/2015 09:59 (GMT-06:00)

To: 10BitWorks on behalf of tookys3 <sa-hack...@googlegroups.com>

Subject: Re: [10BitWorks] Taps and drills by the pound.

Btw for anybody interested in the idea of making our own dispensers attached is a excel spreadsheet, of the expected drawers and their approximate sizes (for what i had for reference)

I do plan to make them all on the laser cutter using plywood. But some had mentioned wanting to do it with other methods, so here is your reference info.

tookys3

Jun 25, 2015, 9:45:39 PM6/25/15

to 10BitWorks on behalf of tookys3

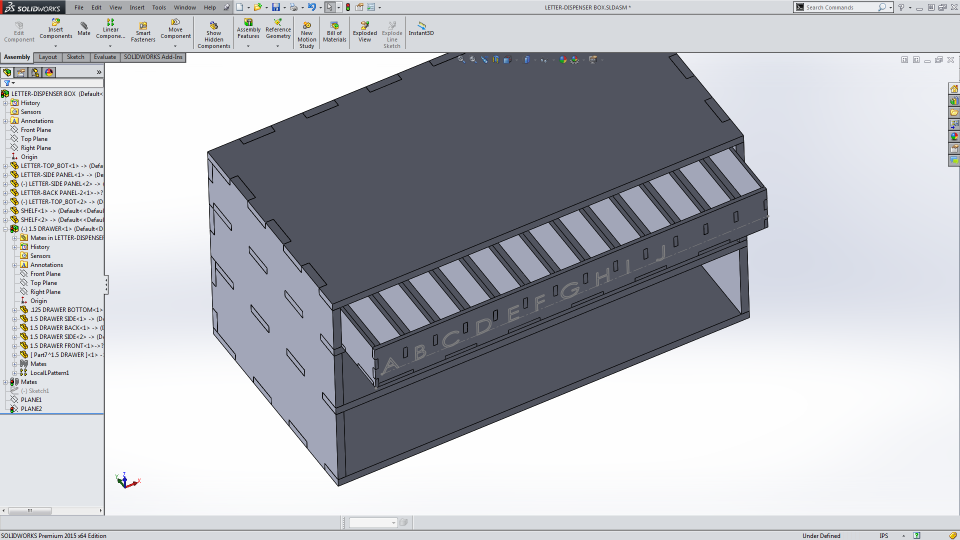

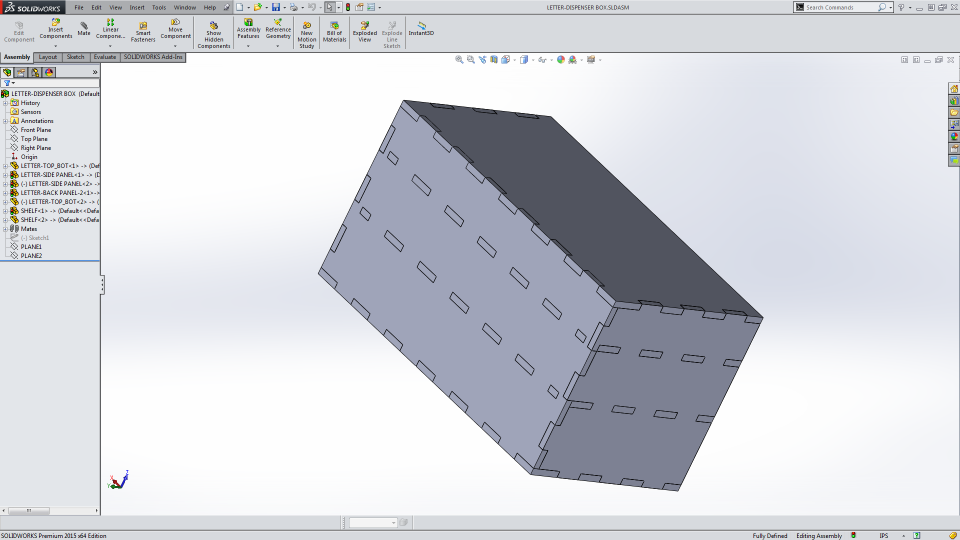

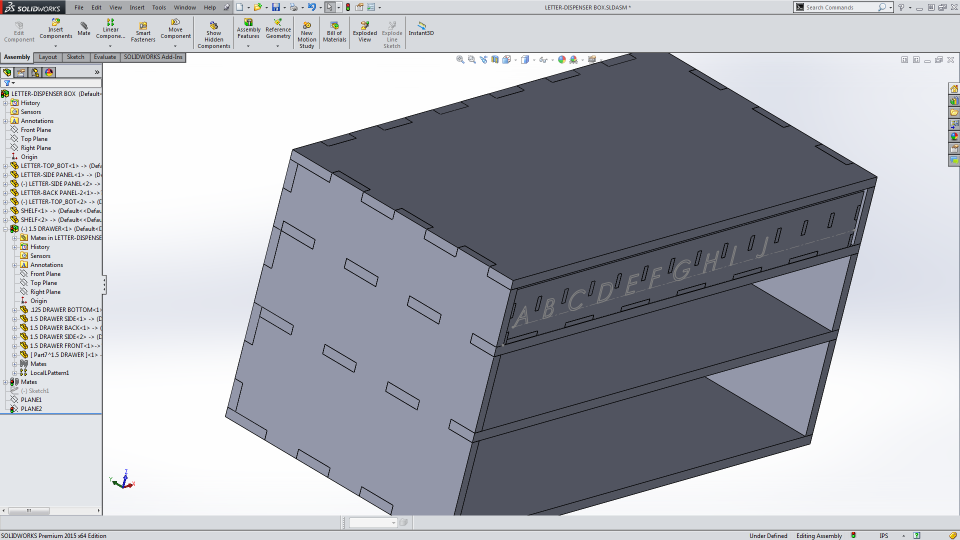

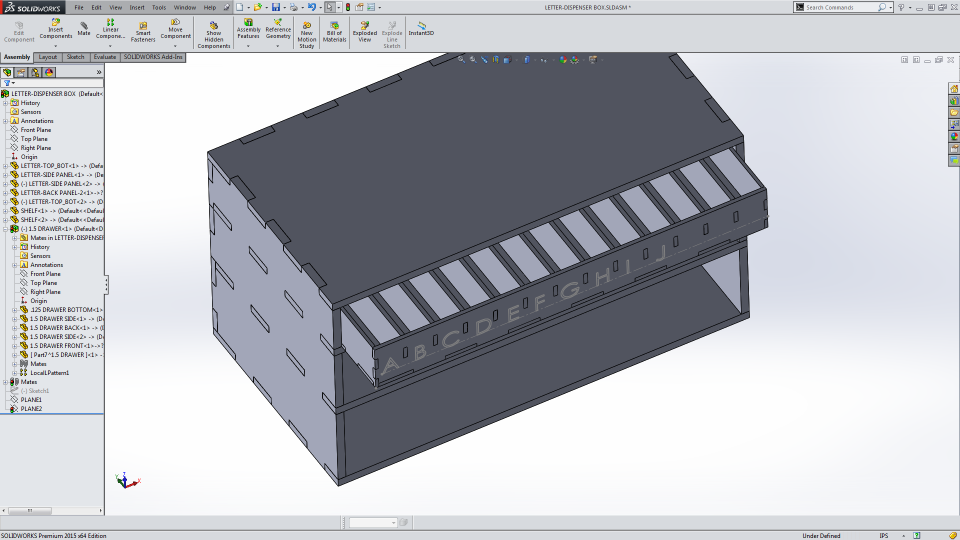

Anybody following the developements of this i have revised a few numbers and arrangements so that i only have to do 2 designs to make the 6 dispenser cases we need.

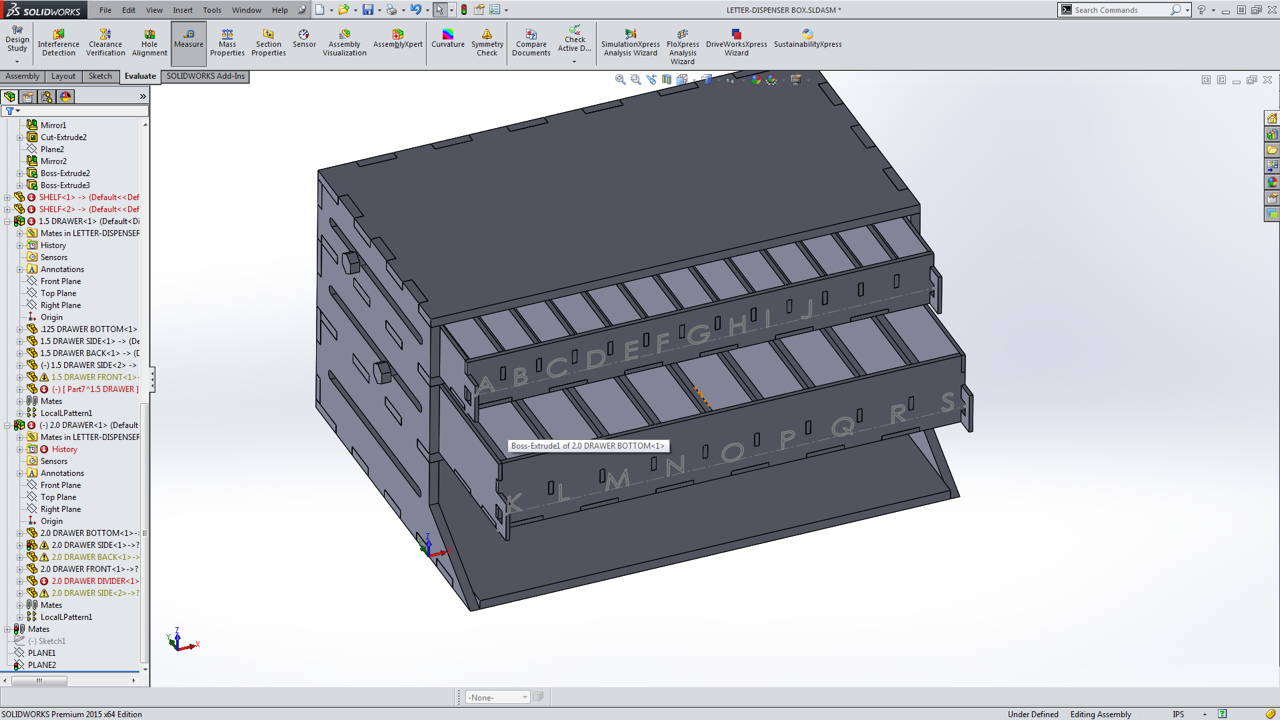

Attached is a few pics of the first one, i plan to have it ready this saturday. (We will need 4 of this style, and 2 of the other)

It will require alot of laser time, but luckily once we get the first one made we only gotta repeat the process 3 more times lol.

Les Hall

Jun 25, 2015, 10:12:56 PM6/25/15

to 10BitWorks on behalf of tookys3

Looks great! Also I saw the video linked on the SXSW page featuring James, Don, and the aluminum metals - I had no Idea James was such an excellent showman! And he's got the mettle to make metal things too! I'm even a bit ashamed that I teased him with the robot comments - but it did get me thinking about my next non-work project! Good work on the drawers too James!

Les

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/qwa2togqb5j7g1xjhmayvp3n.1435283061856%40email.android.com.

Don Smeller

Jun 26, 2015, 8:49:46 AM6/26/15

to 10BitWorks

James,

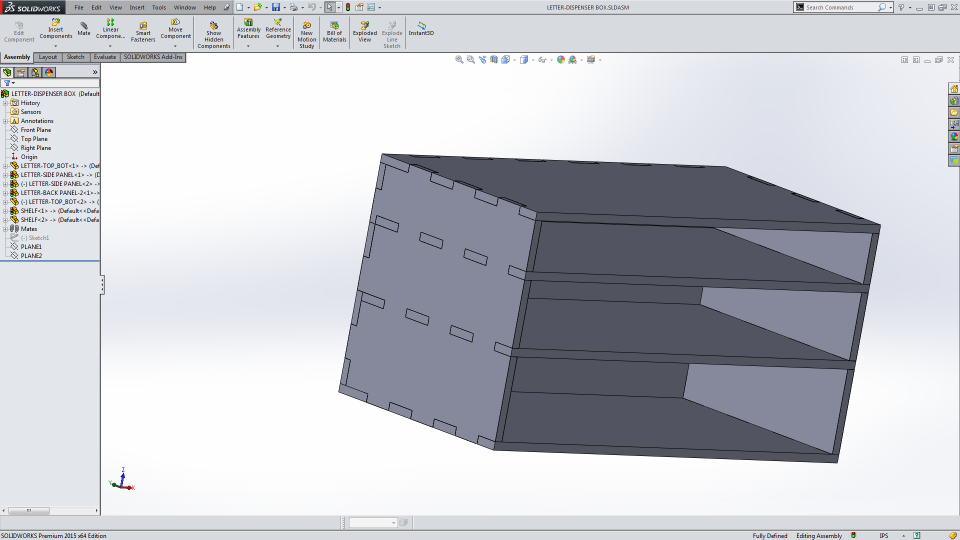

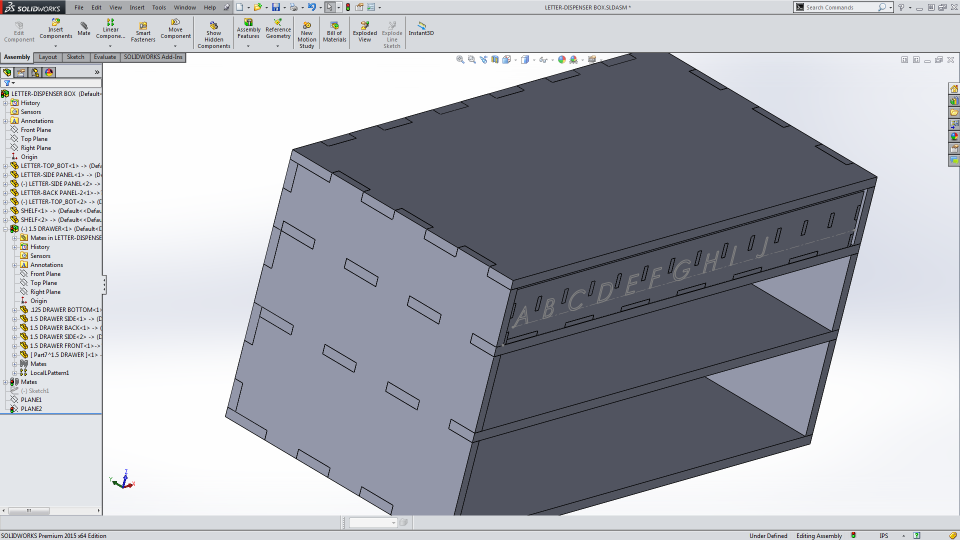

Where we (Ray, DonS, Bob) work, when a design is proposed, we go through a failure modes and effects analysis. FMEA. Don’t take this personally.

I anticipate problems with bending & sagging of the front middle of the shelves, especially when a drawer or two is/are pulled out.

Plywood will keep bending over time (creep) under a constant gravity load of steel.

I suggest you halve (x 0.5) the left-to-right width dimension of the shelves, make a unit, and test it with a bucket of taps, before you go whole hog.

And/Or, design a system of center support partitions to carry the load to the floor.

In the immortal words of Peggy Lee, “he’s got to be straight . . . don’t want to a bent one”

Secondly, I don’t see a provision for positively stopping the skinny drawers from coming all the way out and landing on my toe. Am I missing something??? Obviously I can learn the hard way to use two hands, but we’re talking about a perpetual parade of untrained rookies looking through these drawers. Surprise! A warning sign isn’t going to help 10Bit’s legal defense when the visiting maker (whose slime-ball husband is a lawyer) sues us for loss of income from her tragically truncated professional ballet career.

Thirdly, another classic failure mode of these kinds of boxes is the whole damn thing tips forward into your arms when too many drawers are pulled out. I found myself juggling a 150 pound case of pin gages once upon a time. I suggest a scheme be designed in for securing the whole box to whatever it sits on.

Fourthly, the joining of the front of each drawer to its sides is dubious. The integrity depends on glue, I suppose. If the contents are heavy, in time the fronts will become dislodged from their drawers as they are pulled out against friction. A greater glue area can be achieved with triangular vertical strips in the front corners.

Fifthly, the aspect ratio of the drawers is suspect. It’s not a failure mode, but it might be a valid cause for questioning the ancestry of the designer. A tiny drill bit lurking at the bottom of a deep narrow drawer will require good light and chop sticks to find and pluck out. Or is this only for the mega bits? and you have a shallower scheme for the little bitty bits?

Don S

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/qwa2togqb5j7g1xjhmayvp3n.1435283061856%40email.android.com.

tookys3

Jun 26, 2015, 10:26:28 AM6/26/15

to 10BitWorks on behalf of Don Smeller

I can see about adding a larger foot-print to the base to prevent toppling over.

I was thinking about adding a stopping mechanism to the drawers but hadnt gotten around to it.

(My plan was to add some slits to the sides that bolts on the drawer would ride in)

The full frame is planning to be made from 1/4 plywood.

The drawers from 1/8, except for the bottom ones that would be 1/4 (as they would be the heaviest)(thats also why they are kept on the bottom)

The depth of the drawers do vary with size.

The top drawers are small, and the bottom drawers are big (correlating with the size of the drills in them)

As far as the creep and fastening goes i dont have a basis for comparison. Glue is often considered to be stronger than nails for wood.

tookys3

Jun 26, 2015, 5:41:41 PM6/26/15

to 10BitWorks on behalf of tookys3

Here are some updates based on the input provided earlier.

1) bigger base

2) drawer stops

You can see that the compartments get wider and deeper as the drills do in the box.

I.E. the smaller drill have smaller compartments, the bigger drills have bigger compartments.

Ive also added small handles to the ends of the drawers for pulling them out.

I would want to test on a full scale design (so i dont have to go through all the extra effort of redoing it on a small scale)

See picture attached for updated design details.

Don Smeller

Jun 27, 2015, 12:49:18 AM6/27/15

to 10BitWorks

James, I didn’t mean to for you to make a half scale model, I was suggesting that you cut the spans in half. It’s too wide to be made out of wood and to be carrying 400 pounds of steel forever. One way to cut the span in half is to put in a central load bearing partition.

Other improvements look to be good solutions.

If the fronts of the drawers come off, they can be reinforced later.

Don S

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/cheuu21cxtf6yux2qedrvmb2.1435354758253%40email.android.com.

tookys3

Jun 27, 2015, 7:08:15 AM6/27/15

to 10BitWorks on behalf of Don Smeller

Well i would have to disagree on the issue of the sag for 2 reasons.

1) each individual drawer shouldnt exceed 5-7 pounds of drills.

2) the drawer itself is reinforced with a array of partitions. The drawere redistributes the load more evenly on the boxes shelf partition.

I.E itd be the same if i left a 1/2 ridge along the edges for the drawer to slide onto.

Drawer-1/8 plywood with partition

+Support-1/4 plywood

=3/8 plywood with partitions.

Reply all

Reply to author

Forward

0 new messages