Saturday at 10BitWorks

39 views

Skip to first unread message

Don Smeller

Mar 12, 2017, 10:59:11 AM3/12/17

to 10BitWorks

We got slammed yesterday, Saturday at 10BitWorks: 30 people. They came early, the doorbell went off at 8:45AM, and stayed late.

David told us about anteing up to buy into the crowd funding of a Glowforge 3D laser printer. It has built-in cameras that take children’s artwork, zeroes the laser, finds the edges, and laser cuts a workpiece. No skill required. Or so goes the hype.

The Art in the AM MeetUp.com invitations have begun to bring in the early risers. In addition to the regulars, painters Don and Peggy and Militza, there were newcomers: Alice, Robert Hodge, Victor and David. These folks brought other artistic leanings.

Robert Hodge is an “Artist in Residence”, here from Houston, working on deadline to get ready for an event at ArtPace starting this coming Thursday. http://www.artpace.org/home/exhibits/international-artist-in-residence His art form, his media, is torn paper, old album covers, glued thickly together and laser cut with large font text carrying inspirational messages.

Victor is a commercial artist who gets clients from afar, not just San Antonio. He was working on a logo while immersed in the vibe at 10Bit.

George Hernandez brought to the space his five-year-old son, self confessed future engineer, Aaron. Their mission: to laser cut a clear acrylic face panel for a back lighted “merchandiser”. It’s for yet another Lancer drink dispenser.

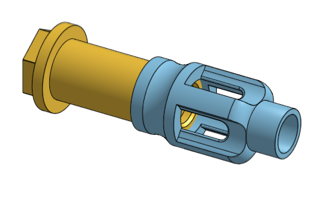

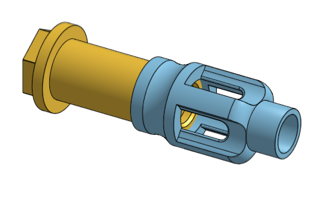

Joey, a cotton farmer from Lubbock, came in carrying a two part brass assembly. It’s a pump plunger from an ancient wind mill that once used leather seals. He wanted to scan it but instead Don helped Joey mic it and model it up in OnShape. Then James kicked off a scaled down 3D print. It was going to take 8 hours to print, but, no problem, Joey is living out of his truck and he can come back.

Gabby was in and out and up and down the ladder twice. She has taken her Mini Art Museum on the road and set it up and torn it down at half-a-dozen venues this past two months. She’s ready for a break.

Adam got his August App working. He now has 24hr access.

John 3D-Printed a case to hold a micro Arduino inside a carbon fiber tube. He’s up to something. Stay tuned.

We haven’t seen Debanita for a year. But she showed up Saturday with Jasmine, a fellow Texas A&M electrical engineering graduate. They took the tour, laser cut a keychain fob, ate some Whataburger, hung out. She talked about wanting to get involved with E-Nable whose slogan is: A Global Network of Passionate Volunteers Using 3D Printing to Give The World a “Helping Hand.” ” http://enablingthefuture.org This is a worthy organization. Les Hall volunteers. They have what they call “E-Nable Communities”. The local one meets at the San Antonio Central Library. Maybe Debanita will lure the community down to 10Bit. We’ve got the 3D Printers and we know how to use them.

Four other sets of first-time visitors came. Peggy and James and Kevin and John pitched in to welcome the visitors and show them around.

Jordan and Sunny

Benjamin and his middle school aged Son and Daughter

James and Andrew

Darin and Josh

We held our 2nd Saturday Board Meeting. Ken, Don, Chris, Ray, James, Kevin, Sue, Adam attended. Of note was the successful fund raiser and installation of a SawStop. We also discussed the heavier use of the laser cutter. The donations for laser use will continue to be done on the honor system. Online electronic transfer donations are now possible, incidentally.

Coming up:

Mini-Maker Faire at Central Library: Saturday March 25, 11AM to 4PM

Siclovia is coming past our door again this year: Sunday March 26, 11AM to 4PM

We need volunteers for both events.

Don S

Les Hall

Mar 12, 2017, 11:08:15 AM3/12/17

to 10BitWorks on behalf of Don Smeller

Hi Everyone,

It was fun to read about e-NABLE's presence at 10bit! Yes I volunteer as an R&D participant. I kinda do my own thing which right now is building a robotic arm. See the attached animation. I have begun to 3D print it and I keep revising the design as I go. Iteration is a blessing eh?

The idea is that while prosthetics are the mainstay of e-NABLE, there may be other ways in which we can serve the disabled population with our 3D printing expertise. So this robotic arm (named Ivan) is my idea for helping to branch out in this area. More later if anyone is interested. Been working on the design for a month while in hospital.

Les

--

You received this message because you are subscribed to the Google Groups "10BitWorks" group.

To unsubscribe from this group and stop receiving emails from it, send an email to sa-hackerspace+unsubscribe@googlegroups.com.

To post to this group, send email to sa-hackerspace@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/sa-hackerspace/BDAE0C3C-25A4-42EB-92E8-5D639AF011C6%40earthlink.net.

Professor X Prime

Mar 14, 2017, 10:12:49 PM3/14/17

to 10BitWorks

I really need to get down there soon. Who built the CNC mill?

Randy Ohman

Mar 15, 2017, 12:42:28 AM3/15/17

to 10BitWorks

For the most part, I think the controls rebuild was done by Ken Runner and Ray Good. I believe it's ready for your projects. Some fun stuff has been done on it...search the older posts for a Don Smeller project for some Houston researchers.

Don Smeller

Mar 19, 2017, 1:01:23 PM3/19/17

to 10BitWorks, barbara fuchs

This week there were only 15 at 10Bit on Saturday; last week it was 30. What caused the difference? Probably Spring Break.

We got the little Full Spectrum laser back up and cutting. It needed more adjustment (more tilt of the mirrors) than was built into the adjusting mechanisms. So I hacked a yoga mat and made thicker rubber elements for the mirror-tilt-platforms. Alas, it has developed a new idiosyncrasy. You know that honeycomb metal mesh that forms the floor for the work sheet? It got warped, bent, abused, taped down and yanked up, whatever. It doesn’t lay flat, anymore, and hence neither does your sheet of plastic. It’s subtle but it’s bad enough to effect the focus of the laser and therefor the cutting efficiency. I used a weight to force both the work sheet and the metal mesh to be flat, and got a good result, but . . . we probably need to replace the mesh.

Does anyone remember the occasion, maybe 3 years ago, when Josef Prusa looked at Gramps and declared, in his gruff Czech accent, “It has a Y-Wobble.” That’s when Roo and Nancy first came to 10Bit. They were back Saturday. In the meantime, they started a maker space just north of Houston. Now, they are shutting it down and looking for a temporary home for their equipment. Would 10Bit be interested in being foster home for wayward laser cutters?

looked at Gramps and declared, in his gruff Czech accent, “It has a Y-Wobble.” That’s when Roo and Nancy first came to 10Bit. They were back Saturday. In the meantime, they started a maker space just north of Houston. Now, they are shutting it down and looking for a temporary home for their equipment. Would 10Bit be interested in being foster home for wayward laser cutters?

looked at Gramps and declared, in his gruff Czech accent, “It has a Y-Wobble.” That’s when Roo and Nancy first came to 10Bit. They were back Saturday. In the meantime, they started a maker space just north of Houston. Now, they are shutting it down and looking for a temporary home for their equipment. Would 10Bit be interested in being foster home for wayward laser cutters?

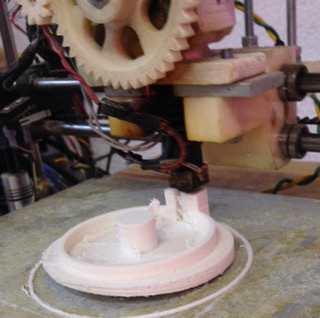

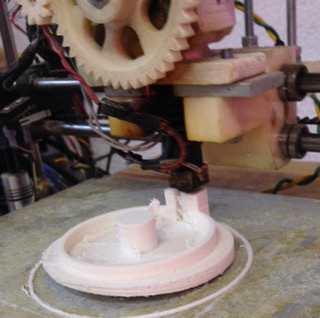

looked at Gramps and declared, in his gruff Czech accent, “It has a Y-Wobble.” That’s when Roo and Nancy first came to 10Bit. They were back Saturday. In the meantime, they started a maker space just north of Houston. Now, they are shutting it down and looking for a temporary home for their equipment. Would 10Bit be interested in being foster home for wayward laser cutters?Manuel and Christian (father, son) worked on two projects, Saturday. We got the bugs out of Christian’s OnShape model of the thingamabob shown. So it printed and got past the 10th layer where it crashed before. Now you can see the next problem. It has warped up from the bed but not catastrophically. Duh, we ran out of ABS goo. We made more goo but only after the print had started. Then there was the persistence of vision project. Christian learned enough tricks in OnShape to draw up the meridian strip that holds the LED’s. He exported a dxf and laser cut it from really thin acrylic. There will be a lot of soldering and programming before the world turns blinkingly. https://www.youtube.com/watch?v=m9tNHbk_BqY Click the link for a video.

Christine is a baker. Morgan is chasing a nursing degree. They took the first-time-visitor tour.

Andre and Andres are boss and worker bee. They build short run circuitry among other things. Andre thinks 10Bit could occupy a piece of the building that he leases. Ken intends to check it out.

Randy and Adam did their welding-class-on-the-sidewalk. Now there’s a plan afoot for an actual project. Stay tuned.

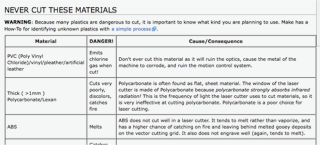

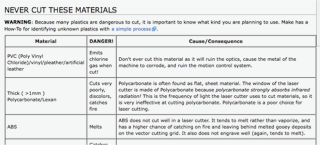

Oscar came back after a year with thoughts of laser cutting his domino-esque game board from ABS. I directed him to a website that tells him which materials are safe to cut and which ones are dangerous and why http://atxhackerspace.org/wiki/Laser_Cutter_Materials

ABS is on the Never Cut These Materials list.

James is making 100 masonite toy cars of his own finger-joint design to be assembled at the Maker Faire next week. He’ll have a few left over, methinks, for the Siclovia event next day.

Dates:

Maker Faire Central Library 11: to 4: Saturday 3/25

Siclovia comes past our door 11: to 4: Sunday 3/26

Don S

Randy Ohman

Mar 21, 2017, 6:38:19 PM3/21/17

to 10BitWorks

Yes, certainly I think...and per our discussion I have space at the school for one to camp out and exercise. Our school website: http://school.judsonisd.org/JSTEM.cfm

Reply all

Reply to author

Forward

0 new messages